Professional Documents

Culture Documents

Inspecting Screw and Bolt Straightness: by Larry Borowski President

Uploaded by

Mian Muhammad Jazib0 ratings0% found this document useful (0 votes)

32 views2 pagesArticle about usage

Original Title

Straightness Article 131202

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentArticle about usage

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views2 pagesInspecting Screw and Bolt Straightness: by Larry Borowski President

Uploaded by

Mian Muhammad JazibArticle about usage

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

0 THE DISTRIBUTOR’S LINK

Greenslade & Company Inc.

2234 Wenneca Avenue, Fort Worth, TX 76102

Tel: 817-870-8888

Fax: 817-870-9199

Email: sales1@greensladeandcompany.com

www.greensladeandcompany.com

INSPECTING SCREW AND BOLT

STRAIGHTNESS by Larry Borowski President

When a screw or bolt’s length exceeds eight times its You would then rotate the fastener 360º in between the

body diameter (example: 1/2-13 X 4”) straightness jaws. If the part binds, you have exceeded your maximum

becomes a concern for many end users. If a long screw or bow or camber. If it rotates freely, you are within your

bolt is not sufficiently straight it can create significant allowable bow or camber.

assembly problems for the end user, which can then result The camber gage illustrated in the ASME standards

in customer complaints or rejects for the fastener supplier. and shown in this article is an attribute gage. It will only

When measuring bolt straightness, any area indicate to the user whether or not the part being inspected

containing swell under the head should be avoided. ASME is within the specified limits for straightness, but will not

B18.5 states; The length of any permissible swell on the indicate the exact magnitude of the camber or bow in the

body under the head or neck of bolts should be excluded part.

from checks for shank straightness. A good rule of thumb

is to hang about 1 times the shank diameter outside of the

jaws when performing this check.

Straightness gages in ASME standards

Several of the American Society of Mechanical

Engineers (ASME) B18 standards appendices contain an

attribute type of gage for determining part straightness.

The pictured gage consists of a base plate with one

stationary side rail and one adjustable side rail. The gap

between the rails is set with a pair of micrometer heads.

This style of gage is quite versatile and cost effective, as it

will accommodate a range of diameters and lengths. Indicating gage for measuring the amount of

Most of the ASME standards are consistent in their screw or bolt camber

straightness specifications. Screws and bolts up to and To determine the extent of the bow in a part used for

including 12 inches in length can be bowed .006 inches either gathering statistical process control (SPC) data or for

per inch of length. Parts exceeding 12 inches can be final inspection documentation, an indicating, variable type

bowed .008 inches per inch of length. If a user’s of gage such as the CamberChek® is needed.

application requires a part straighter than these limits, they The CamberChek® gage is similar to the rail-type gage

must specify their required straightness limits on their print illustrated in the ASME standards except the non-stationary

and/or purchase order. side rail slides on two precision bearings instead of a fixed

In the case of our 1/2-13 x 4” long example, the position. The gage is designed so that gravity provides a

maximum allowable bow would be .024” (4” length x .006” constant closing pressure against the sliding rail. A digital

per linear inch). When using this attribute type gage, you indicator contacts the outside of the sliding rail for

would add the allowable bow (.024”) to the basic diameter indicating the exact amount of bow in the parts being

(.500”) of the bolt, and set the gap in the jaws at .524”. inspected by the gage.

please turn to page 000

0 THE DISTRIBUTOR’S LINK

INSPECTING SCREW AND BOLT STRAIGHTNESS continued from page 000

To determine the exact gage and our 1/2-13 x 4”

amount of camber or bow, fastener, you cannot exceed

the part is placed between the .024” max allowable bow

the rails so that the sliding in screw or bolt to determine

rail is at its closet position to if it is within the acceptable

the stationary rail. To find straightness limits of the

this spot, the bolt would be standard

rotated 360º to determine

the lowest indicator reading. Inspect straightness to

The indicator is then “zeroed avoid complaints

out”. Bent screws and

The part is then rotated until the maximum indicator bolts can cause their users major assembly problems.

reading is achieved. The reading on the indicator is the When supplying screws and bolts that have lengths

exact amount of camber or bow in the measured part. greater than eight times their body diameter, suppliers

Unlike the fixed jaw style of gage, you do not add the should inspect them for straightness to avoid potential

screw diameter to the allowable bow. Using this style of customer complaints and/or rejects.

You might also like

- DsgazDocument5 pagesDsgazAayxee ReactionsNo ratings yet

- QuestionnaireDocument2 pagesQuestionnaireMian Muhammad JazibNo ratings yet

- QuestionnaireDocument2 pagesQuestionnaireMian Muhammad JazibNo ratings yet

- M Haris CVDocument1 pageM Haris CVMian Muhammad JazibNo ratings yet

- Seerat (S) 1 CV (1) - 231027 - 145943Document2 pagesSeerat (S) 1 CV (1) - 231027 - 145943Mian Muhammad JazibNo ratings yet

- Growth Chart and Measurment Chapter # 6Document26 pagesGrowth Chart and Measurment Chapter # 6Mian Muhammad JazibNo ratings yet

- IME 3020 Module 1 Model ScenarioDocument4 pagesIME 3020 Module 1 Model ScenarioMian Muhammad JazibNo ratings yet

- IME 3020 Module 1 Model ScenarioDocument4 pagesIME 3020 Module 1 Model ScenarioMian Muhammad JazibNo ratings yet

- Post Mid AssignmentDocument2 pagesPost Mid AssignmentMian Muhammad JazibNo ratings yet

- Iycf Practical NotebookDocument8 pagesIycf Practical NotebookMian Muhammad JazibNo ratings yet

- Growth Chart and Measurment Chapter # 6Document26 pagesGrowth Chart and Measurment Chapter # 6Mian Muhammad JazibNo ratings yet

- Iycf Practical NotebookDocument8 pagesIycf Practical NotebookMian Muhammad JazibNo ratings yet

- Artcile Review Summary Application of Attribute Control Charts inDocument2 pagesArtcile Review Summary Application of Attribute Control Charts inMian Muhammad JazibNo ratings yet

- Artcile Review Summary Application of Attribute Control Charts inDocument2 pagesArtcile Review Summary Application of Attribute Control Charts inMian Muhammad JazibNo ratings yet

- Post Mid AssignmentDocument2 pagesPost Mid AssignmentMian Muhammad JazibNo ratings yet

- Standard Incercari MecaniceDocument35 pagesStandard Incercari Mecanicenicolicescu_claudiu5152No ratings yet

- Standard Incercari MecaniceDocument35 pagesStandard Incercari Mecanicenicolicescu_claudiu5152No ratings yet

- A Barrel Straightness Measurement System For Medium CaliberDocument18 pagesA Barrel Straightness Measurement System For Medium CaliberMian Muhammad JazibNo ratings yet

- Main Report Plot#1494, Street#50, Sector-M, Phase-VIII, Bahria Town RWPDocument11 pagesMain Report Plot#1494, Street#50, Sector-M, Phase-VIII, Bahria Town RWPMian Muhammad Jazib100% (1)

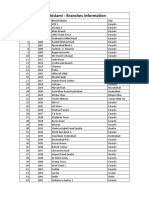

- Bankislami - Branches Information: S.No Branch Code Branch Name CityDocument8 pagesBankislami - Branches Information: S.No Branch Code Branch Name CityMian Muhammad JazibNo ratings yet

- Armalite 2015 PDFDocument44 pagesArmalite 2015 PDFAdrian Kozel100% (1)

- Inspecting Screw and Bolt Straightness: by Larry Borowski PresidentDocument2 pagesInspecting Screw and Bolt Straightness: by Larry Borowski PresidentMian Muhammad JazibNo ratings yet

- Mil STD 3046 (Ar) DraftDocument90 pagesMil STD 3046 (Ar) DraftMian Muhammad JazibNo ratings yet

- Greounds of Appeal To The Commissioner Appeal Against 122Document3 pagesGreounds of Appeal To The Commissioner Appeal Against 122Mian Muhammad Jazib100% (1)

- Mil STD 3046 (Ar) DraftDocument90 pagesMil STD 3046 (Ar) DraftMian Muhammad JazibNo ratings yet

- Mil DTL 71135aDocument57 pagesMil DTL 71135aMian Muhammad JazibNo ratings yet

- Test ScribdDocument1 pageTest ScribdMian Muhammad JazibNo ratings yet

- Test ScribdDocument1 pageTest ScribdMian Muhammad JazibNo ratings yet

- Test ScribdDocument1 pageTest ScribdMian Muhammad JazibNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Final DemoDocument14 pagesFinal DemoangieNo ratings yet

- G.R. No. 201354 September 21, 2016Document11 pagesG.R. No. 201354 September 21, 2016Winston YutaNo ratings yet

- Sarah Observation 4Document2 pagesSarah Observation 4api-249483736No ratings yet

- The Absurdity of The Official DoctrineDocument5 pagesThe Absurdity of The Official DoctrinemarpeqNo ratings yet

- A Guide To Conducting A Systematic Literature Review ofDocument51 pagesA Guide To Conducting A Systematic Literature Review ofDarryl WallaceNo ratings yet

- مذكرة التأسيس الرائعة لغة انجليزية للمبتدئين?Document21 pagesمذكرة التأسيس الرائعة لغة انجليزية للمبتدئين?Manar SwaidanNo ratings yet

- Florida Firearm Bill of SaleDocument4 pagesFlorida Firearm Bill of SaleGeemoNo ratings yet

- PHNCDocument6 pagesPHNCAmit MangaonkarNo ratings yet

- Molina Vs de La Riva 6 Phil 12 INOKDocument2 pagesMolina Vs de La Riva 6 Phil 12 INOKErick Jay InokNo ratings yet

- Worksheet For Mathematics For ManagementDocument3 pagesWorksheet For Mathematics For Managementabel shimeles100% (1)

- How To Manage Asthma: A GuideDocument44 pagesHow To Manage Asthma: A GuideSrinivas YerriboinaNo ratings yet

- Operations Research Letters: Meichun Lin, Woonghee Tim Huh, Guohua WanDocument8 pagesOperations Research Letters: Meichun Lin, Woonghee Tim Huh, Guohua WanQuỳnh NguyễnNo ratings yet

- Sample DCCM, DLHTM and DCLRDocument38 pagesSample DCCM, DLHTM and DCLREagle100% (5)

- Universal Declaration of Human Rights - United NationsDocument12 pagesUniversal Declaration of Human Rights - United NationsSafdar HussainNo ratings yet

- Analgesic ActivityDocument4 pagesAnalgesic ActivitypranaliankitNo ratings yet

- แนวข้อสอบเข้าม.1 อังกฤษ ชุดที่1Document8 pagesแนวข้อสอบเข้าม.1 อังกฤษ ชุดที่1ณิชคุณ สอนคุ้มNo ratings yet

- Theater - The View ArticleDocument2 pagesTheater - The View ArticleRishi BhagatNo ratings yet

- Urban Design ToolsDocument24 pagesUrban Design Toolstanie75% (8)

- Aswini Expert SystemsDocument37 pagesAswini Expert SystemsKarishma Satheesh KumarNo ratings yet

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesReno TadashiNo ratings yet

- Phrygian Gates and China Gates RecordingsDocument1 pagePhrygian Gates and China Gates RecordingsCloudwalkNo ratings yet

- Beginner Levels of EnglishDocument4 pagesBeginner Levels of EnglishEduardoDiazNo ratings yet

- Gallirei Weekend 2018Document7 pagesGallirei Weekend 2018Reiner Albert BraunNo ratings yet

- M40 Mix DesignDocument2 pagesM40 Mix DesignHajarath Prasad Abburu100% (1)

- Ponty Maurice (1942,1968) Structure of BehaviorDocument131 pagesPonty Maurice (1942,1968) Structure of BehaviorSnorkel7No ratings yet

- Why I Want To Be An Army OfficerDocument1 pageWhy I Want To Be An Army OfficercmphalanNo ratings yet

- DR LukeDocument126 pagesDR Lukegabryelbarretto7No ratings yet

- Luzande, Mary Christine B - Motivating and Managing Individuals - Moral LeadershipDocument15 pagesLuzande, Mary Christine B - Motivating and Managing Individuals - Moral LeadershipMAry Christine BatongbakalNo ratings yet

- FS 1 Activity 3.3Document6 pagesFS 1 Activity 3.3HYACINTH GALLENERONo ratings yet

- Spelling Menu Days and MonthsDocument1 pageSpelling Menu Days and MonthsLisl WindhamNo ratings yet