Professional Documents

Culture Documents

Planificacion Indices

Uploaded by

LOBOCRISPCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Planificacion Indices

Uploaded by

LOBOCRISPCopyright:

Available Formats

Planning

for

Maintenance

Excellence

By

Ralph W. “Pete” Peters

President, The Maintenance Excellence Institute

The Greater Charlotte Plant Engineering and Maintenance Show

November 6-7, 2002

Charlotte Merchandise Mart-Freedom Hall

Charlotte, NC

The Maintenance Excellence Institute

A Division of Ralph W. Peters and PEOPLE Inc.

6809 Foxfire Place, Raleigh, NC 27615

Office: 919-270-1173 or Fax: 919-846-9804

www. PRIDE-in-Maintenance. com

Session Objectives

Presentation Based Upon Extracts From

“Maximizing Maintenance for Profit-Optimization”

is Free and Available in EBook Format

from EBOOKOMATIC.COM:

http://www.buymyebook.com/buy/authorinfo.asp?id=646X838Y1

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 2

Session Objectives

1.To show how Craft Productivity in every type of

maintenance operation can be significantly enhanced

with effective maintenance planning and scheduling.

2. Participants will learn how to develop and implement a

Maintenance Excellence Index (MEI) to validate results

of a new planning process

3.Participants will be able to determine and select the right

type of metrics for their overall maintenance operation.

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 3

Today’s Maintenance Challenges

Challenge One: Maintain existing facilities and equipment in safe and

sound conditions.

Challenge Two: Improve, enhance and then maintain existing physical

assets to achieve environmental, regulatory life safety/security

standards and energy best practices.

Challenge Three: Enhance, renovate and add to existing physical

assets using capital funds and then maintain the additions.

Challenge Four: Commission new physical assets and assume

increased scope of work to maintain plus be prepared to assume

more work from Challenges One, Two and Three above as assets

get older and older.

Most maintenance organizations must assume growth with

little or no additions in maintenance staff

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 4

Facing Today’s Maintenance Challenges

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 5

Continuous Reliability

Improvement

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 6

Continuous Reliability Improvement

CONTINUOUS RELIABILITY IMPROVEMENT

GOES BEYOND RCM AND TPM

Physical Asset

and Equipment

Resources

Craft Labor

Synergistic Team Resources

Based Resources

Continuous

Reliability

Improvement

Craft Knowledge

Spare Parts

and Technical

and Material

Skill Resources

Resources

Information

Resources and

CMMS

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 7

Continuous Reliability Improvement

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 8

Continuous Reliability Improvement

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 9

Continuous Reliability Improvement

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 10

Continuous Reliability Improvement

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 11

Continuous Reliability Improvement

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 12

Continuous Reliability Improvement

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 13

Improving Craft Productivity

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 14

Understanding the Elements of Craft Productivity

Three Key Elements

1. Craft Utilization (CU) (Actual Wrench Time)

2. Craft Performance (CP)

3. Craft Service Quality (CSQ)

Overall Craft Effectiveness (OCE)

OCE = %CU x %CP x %CSQ

as Compared to

Overall Equipment Effectiveness (OEE)

OEE = %Asset Availability x % Performance x % Quality

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 15

What is Your Wrench Time?

1. Surveys consistently show that wrench time (craft

utilization) within a reactive, fire fighting maintenance

environment is within the range of 30 to 40 percent.

2. This means that for a ten hour day there is only four hours

of actual hands-on, wrench time.

3. Typically, low craft utilization is due to no fault of the craft

work force.

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 16

Improving Craft Productivity

Most of the lost craft wrench time can be attributed to the

following reasons:

1. Running from emergency to emergency; a reactive, fire fighting operation

2. Waiting on parts and finding parts or part information

3. Waiting on other information, drawings, instructions, etc.

4. Waiting for the equipment to be shut down

5. Waiting on rental equipment to arrive

6. Waiting on other crafts to finish their part of the job

7. Travel to/from job site

8. Make-ready, put away, clean up, meetings, troubleshooting, etc.

Bottom Line: Lack of Effective Planning and Scheduling

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 17

The Value of Increased Craft Productivity

Wrench Time and Actual Costs Per Hour at Various Levels of Craft Utilization

Example: Total Craft Hours Available and Annual Craft Labor Costs

• 20Crafts x 40 hrs/week x 52 wks/yr = 41,600 Craft Hours Available

• 41,600 Total Craft Hours @ $18/hr. = $748,800 Craft Labor Cost/Year

Level of Total Wrench Actual Hands On Average Wrench

Craft Utilization Time (Hours) Cost Per Hour Time Hours

Per Craft Position

30% 12,480 $60.00 624

40% 16,640 $45.00 832

50% 20,800 $36.00 1040

60% 24,960 $30.00 1248

70% 29,120 $25.71 1456

*80% 49,920 $22.50 1664

*85% 35,360 $21.18 1768

90% 37,440 $20.00 1872

100% 41,600 $18.00 2080

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 18

The Value of Increased Craft Productivity

Example: With effective planning and scheduling we can achieve at least a

minimum a 10 point improvement in craft utilization. From a baseline of 40

percent up to a level of 50 percent we in effect get a 25 percent increase in craft

capacity for actual work.

Total Hours Gained in Wrench Time: 4,160 hours gained

20,800 hours @ 50% - 16,640 hours @40% = 4,160 hours gained

Total Gain in Equivalent Number of Craft Positions: 5

4,160 Hours Gained ÷ 832 Average Wrench Time Hours @ 40%

= 5 Equivalent Craft Positions

Total Gained Value of 5 Equivalent Positions: $187,200

5 Equivalent Crafts x 40 Hr/wk x 52 wks/yr. x $18/hr.= $187,200 Gained Value

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 19

Effective Planning and

Scheduling

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 20

Effective Planning and Scheduling

What size operation can justify formal planning and

scheduling?

Large Operations

Small Operations

Invest in a Planner Position

Pick a qualified internal candidate whenever possible

Some key traits of an effective planner

Provide formal and OJT training

Measure Results

Overall Results with Your Maintenance Excellence Index

Results of Your Planning and Scheduling Investment

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 21

Selecting the Right Metrics for

Your Maintenance Operation

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 22

Profit-Centered Maintenance

Five Important Tools From The Maintenance Excellence Institute

Provides overall total maintenance operations assessment guide

The

TheScoreboard

Scoreboardfor

for Ensures consistency with today’s best practices

Maintenance

Maintenance Provides baseline and opportunities for Strategic, Tactical and Operational Plans

Excellence

Excellence Serves as external benchmarking tool for today’s maintenance best practices

Provided as a client-specific tool for measurement of overall best practice progress

Ensures application predictive maintenance technologies

Reliability

ReliabilityTechnology

Technology Provides direction to condition-based monitoring

Application

ApplicationGuide

Guide Ensures that client knowledge base exists for Continuous Reliability Improvement

Supports focus on critical assets and successful implementation occurs

Ensures best use of overall energy resources

Energy

Energyand

and Provide assistance in defining opportunities

Regulatory

Regulatory Leverages internal knowledge with expert service support

Management

ManagementGuide

Guide Identifies specific energy savings and regulatory issues for resolution

Provides an important internal benchmarking tool for IT investments

Develops specific metrics to maximize CMMS

The

TheCMMS

CMMS Ensures that best practices are enhanced by CMMS

Benchmarking Identifies implementation issues/gaps and helps resolve them

BenchmarkingSystem

System Provided as a client-specific tool for continuous measurement of CMMS (or

new system) utilization progress

Provides an essential internal benchmarking tool for shop level results

The Defines key performance goals and support ROI from best practice investments

TheMaintenance

Maintenance Validates Strategic, Tactical and Operational Plan execution and progress

Excellence

ExcellenceIndex

Index Validates actual ROI from maintenance investments and projected savings

Provided as a client-specific tool for continuous measurement of maintenance

excellence impact on the total operation

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 23

The Scoreboard for Maintenance Excellence

Today’s More Comprehensive and Effective Assessment Tool:

• Provides baseline for comprehensive assessment of the current state of maintenance

• Defines specifically where you are

• Recommends where you should go with mission-essential maintenance

• Includes 27 evaluation categories, 300 unique evaluation criteria for today’s best

practices for maintenance, MRO materials and facilities management excellence

• Results become the standard for future best practices at single or multiple sites

• Results can be applied to multiple parts of a large operation and future expansions

• Provides recommended best practices for Continuous Reliability Improvement that

improves;

• Asset uptime, reliability and total operations productivity

• Planning, scheduling, craft productivity and service to the customer

• Overall costs, material inventory accuracy, tracking

• Profits, improved service levels and many other key performance factors

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 24

The Scoreboard for Maintenance Excellence

For Plant Maintenance Operations

CATEGORY

The Scoreboard for Maintenance Excellence Evaluation

Items

Total Points

in Category

Category Descriptions (Part I)

A. The Organizational Culture and P.R.I.D.E. in Maintenance 6 60

B. Maintenance Organization, Administration and Human Resources 12 120

C. Craft Skills Development and P.R.I.D.E. in Maintenance 12 120

D. Operator Based Maintenance and PRIDE in Ownership 6 60

E. Maintenance Supervision/Leadership 9 90

F. Maintenance Business Operations, Budget and Cost Control 12 120

G. Work Management and Control: Maintenance and Repair (M/R) 12 120

H. Work Management and Control: Shutdowns and Major Overhauls 6 60

I. Shop Level Planning and Scheduling 18 180

J. Shutdown and Major Planning/Scheduling and Project Management 9 90

K. Manufacturing Facilities Planning and Property Management 9 90

L. Production Asset and Facilities Condition Evaluation Program 6 60

M. Storeroom Operations and Internal MRO Customer Service 12 120

N. MRO Materials Management and Procurement 12 120

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 25

The Scoreboard for Maintenance Excellence

For Plant Maintenance Operations

CATEGORY

The Scoreboard for Maintenance Excellence Evaluation

Items

Total

Points in

Category Descriptions (Part 2 Continued) Category

O. Preventive Maintenance and Lubrication 18 180

P. Predictive Maintenance and Condition Monitoring Technology Applications 15 150

Q. Process Control, Building Automation and Instrumentation Systems 9 90

Technology

R. Energy Management and Control 12 120

S. Maintenance Engineering Support 9 90

T. Safety and Regulatory Compliance 12 120

U. Maintenance and Quality Control 9 90

V. Maintenance Performance Measurement 12 120

W. Computerized Maintenance Management System (CMMS) and Business 18 180

System

X. Shop Facilities, Equipment, and Tools 9 90

Y. Continuous Reliability Improvement 15 150

Z. Asset Facilitation and Overall Equipment Effectiveness (OEE) 15 150

ZZ. Overall Craft Effectiveness (OCE) 6 60

Total Evaluation Items and Points 300 3000

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 26

The Scoreboard for Facilities Management Excellence

For Facilities Maintenance Operations

CATEGORY The Scoreboard for Facilities Management Excellence Evaluation

Total Points

in Category

Category Descriptions (Part 1) Items

A. The Organizational Culture and PRIDE in Maintenance 5 50

B. Facilities Organization, Administration and Human Resources 10 100

C. Craft Skills Development 10 100

D. Facilities Management Supervision/Leadership 10 100

E. Business Operations, Budget and Cost Control 15 150

F. Work Management and Control: Maintenance and Repair (M/R) 10 100

G. Work Management and Control: Construction and Renovation (C/R) 5 50

H. Facilities Maintenance and Repair Planning and Scheduling 15 150

I. Facilities Construction and Renovation Planning /Scheduling and 10 100

Project Management

J. Facilities Planning and Property Management 10 100

K. Facilities Condition Evaluation Program 5 50

L. Facilities Storeroom Operations and Internal MRO Customer Service 15 150

M. MRO Materials Management and Procurement 10 100

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 27

The Scoreboard for Facilities Management Excellence

For Facilities Maintenance Operations

CATEGORY

The Scoreboard for Facilities Management Excellence Evaluation Total Points

Category Descriptions (Part 2 Continued) Items in Category

N. Preventive Maintenance and Lubrication 20 200

O. Predictive Maintenance and Conditioning Monitoring Technologies 10 100

P. Building Automation and Control Technology 5 50

Q. Utilities Systems Management 10 100

R. Energy Management and Control 10 100

S. Facilities Engineering Support 10 100

T. Safety and Regulatory Compliance 15 150

U. Security Systems and Access Control 10 90

V. Facilities Management Performance Measurement 15 150

W. Facilities Maintenance Management System (FMMS) and Business 15 150

System

X. Shop Facilities, Equipment, and Tools 10 100

Y. Continuous Reliability Improvement 10 100

Z. Grounds and Landscape Maintenance 15 150

ZZ. Housekeeping Service Operations 15 150

Total Evaluation Items and Points 300 3000

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 28

The CMMS Benchmarking System

Purpose: The CMMS Benchmarking System was developed to support:

• Gaining maximum value from an investment in CMMS or FMMS

• To evaluate how well existing CMMS/FMMS functionality is being used

• To provide a method for developing an overall benchmark of your CMMS installation

• To provide a baseline for determining how well CMMS is supporting best practices

• For use as the baseline to measure the success of a future CMMS installation.

Benchmarking Your CMMS Installation: The CMMS Benchmarking System provides a

means to evaluate and classify your current installation as either “Class A, B, C or D”.

• A total of 9 major categories are included along with 50 specific evaluation items

• Each evaluation item that is rated as being accomplished satisfactorily receives a

maximum score of 4 points.

• If an area is currently being “worked on” a score of 1, 2 or 3 points can be assigned

based on the level of progress achieved. For example, if spare parts inventory accuracy

is at 92 % compared to the target of 95 %, a score of 3 point is given.

• A maximum of 200 points is possible. A benchmark rating of “Class A” is within the 180

to 200 point range.

• The CMMS Benchmarking System evaluation categories are provided on the next page.

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 29

The CMMS Benchmarking System

The CMMS Benchmarking System EVALUATION

EVALUATION CATEGORIES ITEMS

1. CMMS Data Integrity 6

2. CMMS Education and Training 4

3. Work Control/Work Management 5

4. Budget and Cost Control 5

5. Planning and Scheduling 7

6. MRO Materials Management 7

7. Preventive and Predictive Maintenance 6

8. Maintenance Performance Measurement 4

9. CMMS for Continuous Reliability Improvement 6

TOTAL CMMS EVALUATION ITEMS 50

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 30

Developing Your Maintenance

Excellence Index

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 31

The Maintenance Excellence Index

Developing a Maintenance Excellence Index: Our approach has been to help clients create a

Maintenance Excellence Index (MEI) that includes 12 to 15 key performance indicators with agreed

upon importance and weighted values. Key elements of developing your Maintenance Excellence

Index;

• The metrics selected are specific to the organization and validate total operations success

• The MEI measures how all key resources that contribute to profit optimization,

greater customer service and more effective facilities management;

• People resources; internal craft labor and outside contractors

• Dollar resources and overall budget dollars of maintenance and the customer

• MRO parts and material resources

• Planning resources and customer service

• Critical assets; uptime, availability or OEE and reliability for intended function

• Information resources; how data becomes true information via effective CMMS

Summary: The MEI provides a very powerful, one page Excel spreadsheet that brings

12-15 key metrics together for a composite Total MEI Performance Value and a very

“balanced scorecard” for the total facilities and maintenance process. The Maintenance

Excellence Index is ideal for Continuous Reliability Improvement across multiple site

operations where standard best practices are needed

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 32

Developing Your Maintenance Excellence Index

MAINTENANCE EXCELLENCE INDEX:

Example with 14 Performance Measurement Categories

Performance Level Scores

Completed as Scheduled

Completed as Scheduled

4. % Other Planned WO's

(PM and Planned Work)

8. % Craft Performance

9. % Work Orders with

5. Overall Equipment

13. % Value of MRO

3. % Estimated Jobs

7. % Craft Utilization

1. Direct Purchasing

Inventory Reduction

Effectiveness (OEE)

2. % Overall Budget

Compliance Overall

11. Gained Value of

Capacity Increases

14. # of Stock Outs

6. % Craft Time to

("Wrench Time")

12. % Inventory

Planned Time

Cost Savings

Work Orders

Compliance

10. % PM

Accuracy

A. Performance

Metrics

B. Current Month Perf.

200 94 94 91 60 36 56 85 56 74 300 91 2 19

Performance Levels

C. Performance

F. PERFORMANCE LEVEL SCORES

500 98 98 95 85 40 60 95 60 90 1700 98 10 10 10

Goal

450 96 96 93 80 38 58 90 58 88 1500 97 9 11 9

400 94 94 91 75 36 56 85 56 86 1300 96 8 12 8

350 92 92 89 70 34 54 80 54 84 1100 95 7 13 7

300 90 90 87 65 32 52 75 52 82 900 94 6 14 6

250 88 88 85 60 30 50 70 50 80 700 93 5 15 5

200 86 86 83 55 28 48 65 48 78 500 92 4 16 4

D. Baseline 150 81 26 46 60 46 76 300 91 3 17 3

Performance 84 84 50

100 82 82 79 45 24 44 55 44 74 100 90 2 18 2

50 80 80 77 40 22 42 50 42 72 50 89 1 19 1

0 78 78 75 35 20 40 45 40 70 0 88 0 20 0

E. Performance

Level Scores 4 8 8 8 5 8 8 8 8 2 3 3 2 1 SCORES

X

G. Weighted Value

WEIGHT

of Metric 11 8 6 8 13 6 10 5 7 2 9 5 5 5

H. Performance

Level Score (F) x

Weight (G) 44 64 48 64 65 48 80 40 56 4 27 15 10 5

= 565

J. Total MEI Values

Over Time I. TOTAL MAINTENANCE

2/02 3/02 4/02 5/02 6/02 7/02 8/02 9/02 10/02 11/02 12/02 1/03 2/03 4/03

EXCELLENCE INDEX

VALUE

565

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 33

Developing Your Maintenance Excellence Index

Step Description Comments

A Performance From 10 to 15 metrics are selected and agreed upon by the organization.

Metrics

B Current This is the actual performance level for the metric for the reporting month. This value

Month will also be noted in one of the incremental values blocks below the performance goal.

Performance This value will correspond to a value for F, the performance level scores which go

from 10 down to 1

C Performance This is the pre-established performance goal for each of the MEI metrics. For example,

Goal if the Current Month’s Performance is at the Performance Goal level, the performance

level score for that goal will be a 10, the maximum score.

D Baseline The baseline performance level prior to start of MEI performance measurement

Performance

E Current Depending on the current month’s performance, a performance level score (F) will be

Performance obtained. This value then goes to the Current Performance Score row and serves as

Score the multiplier for the (G) the Weighted Value of the Performance Metric

F Performance Values from 10 down to one, which denotes the level of current performance,

Level Score compared to the goal. If current performance achieves the predetermined goal, a

performance value of 10 is given. Each metric is broken down into incremental value

from the baseline to the goal. Each incremental value in the column corresponds to a

performance level value. This value becomes the Current Performance Score.

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 34

Developing Your Maintenance Excellence Index

Step Description Comments

G Weighted The values along this row are the weighted value or relative importance of each of

Value of the the metrics. These values are obtained via a team process and a consensus on the

Performance relative importance of each metric that is selected for the MEI. All of the weighted

Metric values sum to 100.

H Performance The Weighted Values (G) are multiplied by (E) the Current Performance Scores to

Value Score get the Performance Value Score (H).

I Total MEI The sum of the Performance Value Scores for each of the metrics and the

Performance composite value of monthly maintenance performance on all MEI metrics

Value

J Total MEI Location for tracking Total MEI Performance Values over a number of months

Performance

Values Over

Time

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 35

Maintenance Performance

Metrics

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 36

Maintenance Performance Metrics

No Performance Metric, Purpose and Data Goal How to Calculate Metric

. Source

1. % Overall Maintenance Budget Compliance: 98% Traditional Budget Variance +/- % Variance to

To evaluate management of $ assets; Obtained Actual Planned Budget

from monthly financials

2. Actual Maintenance Cost per Unit of TBD Total Maintenance Materials and Labor per

Production: To evaluate/benchmark actual reporting period ÷ Total Units produced

costs against stated goals/baselines or against Note: Production units could also be expressed in

industry standards; Obtained from asset records and equivalent standard hours if traditional

monthly CMMS WO file of completed WOs for the standard cost system is being used

month. Obtained from production results and financial

report. Provides ideal support to ABC Costing practices

3. % Customer or Capital Funded Jobs Completed as 98% Total # of Customer or Capital Funded Jobs

Scheduled and within +/- 5% of Cost Estimate: Completed as Scheduled within Budget

To measure customer service & $ assets plus Variance Goal ÷ Total # of Customer or

planning effectiveness; Obtained from funded WO capital Funded Jobs Completed

types from the CMMS WO files, comparing date

promised to date completed and estimated cost to

actual cost

4. % Other Planned Work Orders Completed as 95% Total # of Planned Jobs Completed as Scheduled

Scheduled: To measure customer service and within Time Variance Goal ÷ Total # of

planning effectiveness; Obtained from a query of all Planned Jobs completed (Typically higher

planned WO types in CMMS WO files and comparing priority jobs where customer was given a

date promised to date completed. Could be expressed promised completed date, not PM work

in % based on craft hours. which is planned)

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 37

Maintenance Performance Metrics

5. Schedule Compliance: To evaluate how 95% Total Scheduled Jobs Completed as Per the

effectiveness scheduling was in regards to executing to Schedule ÷Total Jobs Scheduled

meet scheduled dates/time; Obtained from query of CMMS

completed WO file where all scheduled jobs coded and their

actual completion compared to actual planned completion

date/time

6. % Planned Work Orders versus % True 80% to Total Emergency Type WOs Completed ÷

85% Total WOs Completed Per Reporting

Emergency Work Orders: To evaluate positive Planned

impact of PM, planning processes and other proactive Period (could be expressed as % also using

improvement initiatives (CRI,/RCM/etc); Obtained from a craft hours)

query of all true emergency WO types in CMMS WO files and

comparing to total WOs completed. Could be expressed in %

based on craft hours.

7. % Craft Time to Work Order for Customer 85% Total Craft Hours for All Work Charged

Charge Back: To monitor craft resource Back to Customer ÷ Total Craft Hours Paid

Accountability for Internal Revenue Generation (or for Reporting Period

External); Obtained from a query of all WO types in CMMS WO

files that are charged back comparing these craft hours to total

craft hours paid

8. % Craft Time to Work Orders: To monitor 100% Total Craft Hours Charged to All Work

overall craft resource accountability and to support Order Types (Including Standing WOs) ÷

internal revenue generation ; Obtained from a query of all Total Craft Hours Paid for Reporting Period

WO types in CMMS WO files and summation of actual craft hours

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 38

Maintenance Performance Metrics

9. % Craft Utilization (Actual Wrench 60% to- Total Craft Hours of Pure Wrench Time Charged

70% to All Work Order Types minus Total Time to

Time): To maximize craft resources for

Non Wrench Time Standing WO Types) ÷ Total

productive, value-adding work and to evaluate

effectiveness of planning process; Obtained from a query Craft Hours Paid for Reporting Period

of all craft hours reported to non craft work from CMMS

time keeping WO files and summation of actual craft

hours

10. % Craft Performance (Against 95% Total Actual Craft Hours Charged to Completed

Reliable Estimates for PM and WOs With Planned Times ÷ The Total Planned

Time from the WOs Having Planned Times

planned work): To maximize craft resources,

to evaluate planning effectiveness and also to

determine training ROI; Obtained from completed WO

file in CMMS

11. Craft Quality and Service Level: To 95% 100% - Total # Call Backs/Etc ÷ Total Number

evaluate quality and service level of repair work as of WOs Completed Per Reporting Period

defined by customer; Obtained from WO file in CMMS

where all call backs are tracked and monitored via work

control and planning processes

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 39

Maintenance Performance Metrics

12. Overall Craft Effectiveness (OCE): To 65% OCE = % CU x % CP x % CSQ

evaluate cumulative positive impact of overall Where: CU = 70%....a Realistic Maximum

improvements to Craft Utilization (CU), Craft CP = 95%....plus is Achievable

Performance (CP) and Craft Quality and Service CSQ = 95%....plus is Achievable

Excellence (CQSE) in combination; Obtained from Therefore:

using results of measuring all three OCE Factors: a) Craft OCE = .70 x .95 x .95 = .632 ≅ 65%

Utilization, b) Craft Performance and c) Craft Service

Quality

13. % Work Orders with Reliable Planned 60 % # Work Orders with Reliable Planned Times ÷

Total Number of WOs Completed Per Reporting

Times: To measure planner’s effectiveness at Period

developing reliable planning times; Obtained from

completed WO file in CMMS where panning times are

being established for as many jobs as possible by

planner/supervisor

14. % Overall Preventive Maintenance 100% Total # PM WOs Completed as Scheduled ÷

Compliance (Could be by type asset, Total Number of PM WOs Due and Scheduled

production department/location or by supervisory Per Reporting Period (Note: PMs to be

area): To evaluate compliance to actual PM completed within reasonable window of time

requirements as established for assets under scope from date they are generated for scheduling)

of responsibilities; Obtained from completed WO file in

CMMS

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 40

Maintenance Performance Metrics

15 Gained $Value from Craft Utilization TBD [Total Current Craft Hours of Wrench Time

. minus Baseline Average Wrench Time Hours] x

and Performance: To determine actual gained

$ value of craft productivity gains as compared to Baseline Cost / Wrench Time Hour (or Actual

original estimate and/or the initial baseline; Cost Per Hour)

Obtained only from using results of measuring two of the

OCE Factors: a) Craft Utilization, b) Craft Performance

16 % Inventory Accuracy: To evaluate one 98% A: Item Count Variance: Total Stock Items

. element of MRO material management and Cycle Counted as Correct ÷ Total Stock Items

inventory control policies; Obtained from cycle count Cycle Counted

results and could be based on item count variances or on B: Cost Variance: Actual Inventory Cost of

cost variance Total Stock Items Counted as Correct ÷ Total

Actual Inventory Cost of Stock Items Counted

17 % or $ Value of Actual MRO Inventory 10% Actual $ Value of Inventory Reduction ÷

. Baseline Inventory Value

Reduction: To evaluate another element of MRO

material management against original estimates

and the initial baseline MRO inventory value;

Obtained from inventory valuation summation at end of

each reporting period

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 41

Maintenance Performance Metrics

18. Number of Stock Outs of Inventoried Stock ???? Actual Stock Outs Recorded/Tallied as

They Occur

Items: To monitor actual stock item availability per

demand plus to monitor any negative impact of MRO

inventory reduction goals; Obtained from tracking stock item

demand and recording stock outs manually or by coding

requisition/purchase orders for the items not available per demand

19. $ Value of Direct Purchasing Cost Savings: To TBD Tracked via best method per a standard

track direct cost savings from progressive procurement procedure that defines how direct

practices as another element of MRO materials purchasing savings to be accounted for

management. Could apply to contracted services, valid the organization

benefits received from performance contracting, contracted

storerooms, vendor managed inventory; Obtained via best

method per a standard procedure that defines how direct

purchasing savings are to be accounted for

20 Overall Equipment Effectiveness (OEE): World 85% Where OEE = % Availability x %

–class metric to evaluate cumulative positive impact of overall Performance x % Quality

reliability improvements to Asset Availability A), Asset Performance An OEE Factor of 85% is recognized as

(P) and Quality (Q) of output all in combination. (Similar to OCE world-class, which therefore is:

above but for the most critical production assets); Obtained via OEE = A x P x Q

downtime reporting process, operations performance on critical

assets and the resulting quality of output OEE = .95 x .95 x 95 ≅ 85%

21. % Asset Availability/Uptime: To evaluate trends in Total Hours Asset Performs Its Primary

downtime due to maintenance and the positive impact of actions to Function ÷ Total Hours Asset Scheduled

increase uptime; Obtained via downtime reporting process to Perform Its Primary Function

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 42

Conclusion

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 43

Planning for Maintenance Excellence

We must Remember that:

• Maintenance is Forever!

• We can Plan for Maintenance Excellence!

• We can lead maintenance forward with profit-centered practices and

attitudes.

• We can achieve PRIDE in Maintenance with

People Really Interested in Developing Excellence in Maintenance

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 44

About The Maintenance

Excellence Institute

The Maintenance Excellence Institute

A Division of Ralph W. Peters and PEOPLE Inc.

6809 Foxfire Place, Raleigh, NC 27615

Office: 919-270-1173 or Fax: 919-846-9804

www. PRIDE-in-Maintenance. com

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 45

Maintenance: Our Primary Focus

• One Primary Focus: Our single focus is on improving maintenance

processes, maintenance management and leadership. The Maintenance

Excellence Institute has provided a broad range of services for

Continuous Reliability Improvement of total maintenance and MRO

materials management operations.

• The Maintenance Excellence Institute has provided these services for:

– Facilities management operations in public and private sectors:

¾ Healthcare facilities and large hospital complexes

¾ Educational system facilities at all levels

¾ Property management operations

– Manufacturing plant operations

– Continuous processing operations

– Power generation and power distribution

– Fleet maintenance operations in public and private sectors

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 46

Links to Free Publications

PRIDE-in-Maintenance.com WEB SITE Links

1. Maintenance Excellence Services Brochure:

http://www.pride-in-

maintenance.com/Alliances/Maintenance_Excellence_Services.pdf

2. Operational Service Brochure:

http://www.pride-in-maintenance.com/Alliances/Operational_Services.pdf

3. Training for Maintenance Excellence Brochure:

http://www.pride-in-

maintenance.com/Alliances/Training_for_Maintenance_Excellence.pdf

4. Training for Maintenance Excellence 2002 Catalog:

http://www.pride-in-

maintenance.com/Alliances/2002_Training_for_Maintenance_Excellence_Catelog.pdf

5. Maintenance is Forever! Article: http://www.pride-in-

maintenance.com/Alliances/Maintenance_is_Forever.pdf

EBOOKS AVAILABLE from EBOOKOMATIC.COM:

Maximizing Maintenance for Profit-Optimization (Free)

http://www.buymyebook.com/buy/authorinfo.asp?id=646X838Y1

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 47

The Maintenance Excellence Institute

Maintenance Excellence Services:

We highly recommend what SBBC is pursuing with RFP 23-113N. Our very first step with every client begins

with a Maintenance Excellence Assessment to “determine where you are” with opportunities for improvement.

Results from our Scoreboard for Facilities Management Excellence evaluation provides today’s most

comprehensive assessment process by looking at 27 essential categories and 300 specific criteria. All areas

are very specific to facilities management operations. We then help clients like SBBC and many others apply

today’s best practices for maintenance excellence to:

– Implement Preventive and Predictive Maintenance Technology

– Achieve Effective Planning and Scheduling

– Improve Maintenance Storeroom Operations

– Develop Improved MRO Materials Management

– Go Beyond RCM and TPM with Continuous Reliability Improvement (CRI)

– Maximize Asset Uptime and Overall Equipment Effectiveness (OEE)

– Increase Craft Wrench Time and Overall Craft Effectiveness (OCE) SM

– Achieve Benefits from Effective Craft Skills Development

– Develop Operator-Based Maintenance for PRIDE in Ownership

– Select and Implement Effective CMMS/EAM/FMMS

– Implement Profit-Centered Maintenance Performance Measurement

– Provide Critical Asset Performance Facilitation

– Evaluate Contracted Maintenance Services

– Conduct Facility and Critical Asset Condition Assessments

– Perform Energy Management, Security and Regulatory Compliance Audits

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 48

The Maintenance Excellence Institute

Operational Services

We also provide highly qualified, temporary resources to manage and lead plant maintenance (or facilities

management) operations over a short duration, transitional period of time. They also provide effective

leadership to implement your strategic, tactical or operational improvement plans while in a temporary services

role. Operational Services provide grass roots support to successful implementation of today’s best

maintenance practices and achieve the results we define during a Maintenance Excellence Services

engagement. Our capabilities for Operational Services include:

– Managing and Leading Your Total Maintenance Operation as manager or supervisor

– Serving as Your Chief Maintenance Officer (CMO) or CFMO for a larger multiple site

operation like SBBC

– Providing Planning For Maintenance Excellence as interim staff planners at all levels;

day to day, construction/renovation and project management

– Managing Storeroom Operations and Providing Support for Storeroom Modernization

– Developing and Leading Your Craft Skills Development Program for Technical

Training Needs

– Performing Critical Asset Performance Facilitation or Facility Condition Assessments

– Performing Turn Key Preventive and/or Predictive Maintenance Program Development

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 49

The Maintenance Excellence Institute

Training for Maintenance Excellence

• Our Training for Maintenance Excellence Service is our third area and a very essential element of our

approach to providing both Maintenance Excellence Services and Operational Services. Our suite of

over 29 course offerings focus upon creating organizational awareness and an internal understanding that

maintenance must be managed and led as a profit center. Successful implementation of today’s best

practices requires changes in philosophies, attitudes and the application of technical knowledge.

• Training for Maintenance Excellence can provide a measurable return on investment to justify your

training dollars. The most beneficial part is that Training for Maintenance Excellence “is not over when

it’s over”. Following completion of each session, whether as an in-house presentation or a public session,

there is a personalized follow-up scheduled for each participant. Personal follow-up and one on one

coaching is to help you apply what you have learned.

• The PRIDE in Maintenance presentation process is typically scheduled for presentation during the on site

time for a Maintenance Excellence Assessment. Scheduling is flexible to coordinate with shift start ups,

shift overlaps and ideally is presented to every member of the craft work force, storeroom and support

staff. It provides very important communications feature to support cooperation and ideas from the craft

work within the SBBC operation. All sessions are developed scheduled and presented by Ralph “Pete”

Peters, President of MEI. An overview is included on Page 34.

• A summary of course offerings from The Maintenance Excellence Institute is included in the Appendix B.

Course abstracts and objectives are available in our 2003 Catalog available for download at our Web Site

at www.PRIDE-in-Maintenance.com

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 50

Our Maintenance Experience

• Atomic Energy Canada Limited (2 sites) • Rockwell International

• Boeing Commercial Airplane Group (55 sites) • Rohm & Haas

• Braun Medical • Siderar SAIC (8 sites in Argentina)

• Bucyrus International • University of North Carolina Facilities Services

• Carolinas Medical Center Division (6 work units)

• Consolidated Stores/BigLots (4 sites) • University of NC-CH Building Services

• Consolidated Thermoplastics (3 sites) Department, Facilities Services Division

• Dominion Terminal Associates (Ongoing)

• DIMON International (4 sites) • University of NC-CH Energy Services Department,

• Eli Lilly (Puerto Rico) Facilities Services Division (Future)

• Ford Motor (Canada) • Victor Insulator

• General Foods • VIOX Facilities Services (Contract Services Firm)

• GlaxoSmithKline • The Werner Company (3 sites)

• Great River Energy • Wyeth-Ayerst (3 sites in U.S.)

• Heinz USA • Wyeth Medica (Ireland)

• Lucent Technologies (2 sites) • Weyerhaeuser

• Marathon Ashland Petroleum (4 sites) • NC Department of Transportation (15 sites)

• The Marmaxx Group • National Gypsum (3 sites)

• National Defense • NYCOMED (Puerto Rico)

• Purolator • Polaroid Corporation

• Rocketdyne Propulsion (Div of Boeing) • Pratt & Whitney (Canada)

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 51

Approach for Assessment of the

Total Maintenance Operation

The Maintenance Excellence Institute

A Division of Ralph W. Peters and PEOPLE Inc.

6809 Foxfire Place, Raleigh, NC 27615

Office: 919-270-1173 or Fax: 919-846-9804

www. PRIDE-in-Maintenance. com

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 52

Phase I: Project Deliverables to Achieve Results

1. A Maintenance Excellence Strategy Team chartered to facilitate world-class maintenance

2. A World-class maintenance strategy defined by the Scoreboard for Maintenance Excellence with a

recommended Plan of Action for Implementation

3. An in-depth assessment of current maintenance practices during Phase I

4. Recommendations in 27 maintenance excellence evaluation categories

5. Recognition of current successes

6. Develop and present PRIDE in Maintenance sessions to crafts work force and other staff

7. Recommendations for improvement to the current installation of CMMS

8. A CMMS Benchmarking System to measure CMMS improvement success or define functionality gaps and

support replacement

9. Recommended Implementation Plan with Tactical/Operations action plans and timelines

10. Definition of all improvement opportunities with definition of all savings/benefits and timeline for achieving

11. Performance measurement process documented via a written standard operations procedure

12. A Maintenance Excellence Index to validate results and value of MEI services ready to implement after

Phase I assessment

13. Plan of action for best practice support from The Maintenance Excellence Institute

14. Preliminary review of results by the client

15. Written and oral presentation of results to client leaders at end Phase I and all defined milestones

16. Implementation beginning from Day One with methods in place to validate results

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 53

Phase I: Achieving Maintenance Excellence

Methodology

The Maintenance Excellence Institute envisions a seven-step approach to perform

the required assessments, analyses, plan for implementations, and to measure

results. Step 2

a. Establish Client

a. Establish Client

Specific Scoreboard

Specific Scoreboard

for Maintenance

for Maintenance

Excellence

Step 1 Excellence Step 3 Step 4 Step 5

b. Conduct

b. Conduct

Establish Maintenance Assessment of Total Develop Performance

Establish Maintenance Assessment of Total Evaluate CMMS, Define Recommended Develop Performance

Excellence Strategy Maintenance Evaluate CMMS, Define Recommended Measurement Process

Excellence Strategy Maintenance Develop Recommended Path Forward and Measurement Process

Team; Confirm Operation and Develop Recommended Path Forward and and a Client Specific

Team; Confirm Operation and Strategy and Redefine Estimated and a Client Specific

Objectives, Priorities Present PRIDE in Strategy and Redefine Estimated Maintenance

Objectives, Priorities Present PRIDE in Improvement Savings Maintenance

and Metrics Maintenance Sessions Improvement Savings Excellence Index

and Metrics Maintenance Sessions Opportunities Excellence Index

Opportunities

c. Develop Best

c. Develop Best

Practice

Practice

Recommendations

Recommendations

NOTE: Concurrent Support for Step 2 will be to present PRIDE in Maintenance sessions for

NOTE: Concurrent Support for Step 2 will be to present PRIDE in Maintenance sessions for

craft work force and other staff as a communications session. Objectives are to set the stage for

craft work force and other staff as a communications session. Objectives are to set the stage for

the MEI Action Plan and for promoting profit-centered maintenance attitudes and practices. An

the MEI Action Plan and for promoting profit-centered maintenance attitudes and practices. An

overview of this session that is provided within Step 2 is provided.

overview of this session that is provided within Step 2 is provided.

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 54

Phase I: Achieving Maintenance Excellence

Methodology (continued)

The Maintenance Excellence Institute Team envisions results from Step 1 through Step

7 being implemented and becoming the performance measurement foundation for Best

Practices Implementation during Phase II.

Step 6 Step 7

Step 5

(Continued) Refine Client

Written and Oral Refine Client

Written and Oral Scoreboard for

Presentation of Scoreboard for

Presentation of Maintenance

Assessment Results Maintenance

Step 5 The Client’s Assessment Results Excellence

Step 5 The Client’s Excellence

Maintenance

Maintenance

Excellence Index

Excellence Index

Provides a Key

Provides a Key

Deliverable and Plan for staffing and

Deliverable and Define Action Plan, Plan for staffing and

Methodology in Place Define Action Plan, execution of Action

Methodology in Place define specific target execution of Action

to Validate Results define specific target Plan to Continue

to Validate Results dates with firm Plan to Continue

dates with firm Improvement Process

schedule of Support Improvement Process

schedule of Support

Steps1 through 7 are defined in more detail on the pages that follow.

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 55

Phase I: PRIDE in Maintenance Presentation

Step 2b of our Maintenance Excellence Assessment process includes a very important communications

feature to support PRIDE in Maintenance and Teamwork within each client’s operation. All sessions are

developed scheduled and presented by Ralph “Pete” Peters, President of MEI. An overview is included below:

PRIDE in Maintenance

Session Length: Approx 1 Hour

• Session Overview: Without support from the craft work force and real shop level PRIDE in Maintenance,

achieving maintenance excellence can be extremely difficult. This session was developed specifically for

presentation to the crafts work force and other Client staff. It serves as a means to gain support, understanding

and greater cooperation for maintenance excellence initiatives within all types/sizes of plant, fleet, facilities and

healthcare maintenance operations. It provides a brief overview of the Maintenance Excellence Assessment and

expected results. It also provides positive reinforcement to the crafts worker that their job is important and their

ideas will be welcomed. Since they perform a mission essential role in the success of their respective

organizations, it emphasizes the need for positive input from them during times when they might be interviewed

during the assessment.

• This session is tailored to help explain current improvement initiatives (MEI/Client Action Plan) being considered or

that are currently being implemented by the Client. PRIDE in Maintenance strives to instill a philosophy of profit-

centered maintenance into the thinking and attitudes of each craft person. It supports teamwork, eliminates fear of

changing the status quo and enhances the importance of our most valuable (and often a very scarce maintenance

resource)- the craft person. This presentation is also typically scheduled for presentation during the on site time for

a Maintenance Excellence Assessment. Scheduling is flexible to coordinate with shift start ups, shift overlaps and

ideally is presented to every member of the craft work force, storeroom and support staff.

• Clients are able to review and approve all materials prior to presentation. Materials developed are client-specific,

handouts are provided to each attendee and the session is video taped. Client receives rights for future use of

their PRIDE in Maintenance video and internal future use of all custom materials prepared for their session.

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 56

Phase I Assessment: Typical Timeline

Phase I – Achieving Maintenance Excellence

Number of Months Prior to 1 Weeks 2 3

Start

1. Establish team, objectives, and priorities Step 1

2a Define Client Scoreboard for Maintenance Step 2a

Excellence

2b. Conduct Phase I Assessment and Step 2b

Present PRIDE in Maintenance sessions

PRIDE in Maintenance Step 2b

2c. Develop best practice recommendations

Step 2c

3a. Evaluate current CMMS installation and

Step 3a

Develop CMMS Benchmarking System

4. Define path forward and savings Step 4

5. Develop methodology for implementation Step 5

of Client Specific Maintenance Excellence

Index

6a Client preliminary review of results Step 6a

6b Finalize written report and oral

presentation of results during Week 3 Step 6b

7. Refine Client Scoreboard and Define

Implementation Action Plan with timelines Step 7

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 57

Next Steps

PLANNING FOR MAINTENANCE EXCELLENCE The Maintenance Excellence Institute 58

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Critical Reading, Using Reading Prompts To Promote Active Engagement With Text Final PDFDocument6 pagesCritical Reading, Using Reading Prompts To Promote Active Engagement With Text Final PDFemysamehNo ratings yet

- Scientific MethodDocument2 pagesScientific MethodEmerson Nunez100% (2)

- The Best HR KPIs Aligned With Company StrategyDocument6 pagesThe Best HR KPIs Aligned With Company StrategyLOBOCRISPNo ratings yet

- Read Aloud Lesson PlanDocument5 pagesRead Aloud Lesson Planapi-300877581No ratings yet

- SIMDocument15 pagesSIMViemel Glico GecozoNo ratings yet

- NN Bhargava Basic Electronics and Linear Circuits PDFDocument169 pagesNN Bhargava Basic Electronics and Linear Circuits PDFJovin Pallickal Thomas67% (3)

- Ista 7eDocument6 pagesIsta 7eduygu9merve100% (1)

- 04 BCSetDocument49 pages04 BCSetLOBOCRISPNo ratings yet

- Configuration & Development ConventionDocument11 pagesConfiguration & Development ConventionLOBOCRISPNo ratings yet

- Making IT Strategic To The Business: SAP All-in-One - How To Develop IDocument33 pagesMaking IT Strategic To The Business: SAP All-in-One - How To Develop ILOBOCRISPNo ratings yet

- Oil Gas PDFDocument16 pagesOil Gas PDFLOBOCRISPNo ratings yet

- 20 Phrases For Closing An EmailDocument2 pages20 Phrases For Closing An EmailThùy Linh PhạmNo ratings yet

- Labview Exercises With Annotations PDFDocument131 pagesLabview Exercises With Annotations PDFuser2014523No ratings yet

- Exp4-Add, Sub, Mul, Div of 8 Bit & 16 BitDocument6 pagesExp4-Add, Sub, Mul, Div of 8 Bit & 16 Bitjinto0007No ratings yet

- Analisa Pengaruh Fasilitas Dan Kepuasan Pelanggan Terhadap Loyalitas Pelanggan Menginap Di Mikie Holiday Resort Dan Hotel BerastagiDocument13 pagesAnalisa Pengaruh Fasilitas Dan Kepuasan Pelanggan Terhadap Loyalitas Pelanggan Menginap Di Mikie Holiday Resort Dan Hotel BerastagiAisa WaNo ratings yet

- Quiz - IELTS NINJA 4 - 5 PDFDocument3 pagesQuiz - IELTS NINJA 4 - 5 PDFBhushan Yadav100% (1)

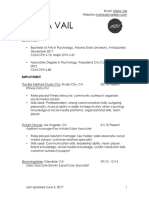

- Maria Vail ResumeDocument2 pagesMaria Vail Resumeapi-360258460No ratings yet

- GauriDocument78 pagesGauriSatyabodh RaichurkarNo ratings yet

- RRLDocument3 pagesRRLTyrone BautistaNo ratings yet

- NIRALADocument29 pagesNIRALAzee100% (4)

- Introduction To Embedded Systems Design On FPGAsDocument20 pagesIntroduction To Embedded Systems Design On FPGAsemumanuNo ratings yet

- Dna Extraction of Strawberries Lab Sheets Spring 2016 No RubricDocument6 pagesDna Extraction of Strawberries Lab Sheets Spring 2016 No Rubricapi-298247873No ratings yet

- Review Effective Marketing Strategy For Umkm Coffee Shop in The Face of PandemiDocument10 pagesReview Effective Marketing Strategy For Umkm Coffee Shop in The Face of PandemiAn Nissa Ar RauufiNo ratings yet

- Revision For The Midterm TestDocument3 pagesRevision For The Midterm TestLinh Tran KhanhNo ratings yet

- Ltvs-Pro-Hd User Manual v3-25 R110728engDocument45 pagesLtvs-Pro-Hd User Manual v3-25 R110728englivetvsystemsNo ratings yet

- Benefits: All The Benefits of A Production Logging Tool in A Compact Modular Designed PackageDocument3 pagesBenefits: All The Benefits of A Production Logging Tool in A Compact Modular Designed PackageDaniel ChiriacNo ratings yet

- English Grammar Class XDocument15 pagesEnglish Grammar Class XTinkercad SifatNo ratings yet

- AYUSHDocument8 pagesAYUSHDikshantNo ratings yet

- Fronteira Infosys: Venue: Dates: Course FacilitiesDocument2 pagesFronteira Infosys: Venue: Dates: Course Facilitiesapi-26281459No ratings yet

- CRM in Organizational Structure Design: Hamid Tohidi, Mohammad Mehdi JabbariDocument4 pagesCRM in Organizational Structure Design: Hamid Tohidi, Mohammad Mehdi JabbariHum92reNo ratings yet

- Thickness of Paper and Paperboard: Standard Test Method ForDocument3 pagesThickness of Paper and Paperboard: Standard Test Method ForAnil PandeyNo ratings yet

- Kerala Syllabus 8th Standard Maths Solutions ChapDocument2 pagesKerala Syllabus 8th Standard Maths Solutions ChapShamshitha IrshadNo ratings yet

- Synopsis On Employee Satisfaction Bhel NewDocument6 pagesSynopsis On Employee Satisfaction Bhel NewArchi guptaNo ratings yet

- Basic UNIX CommandsDocument6 pagesBasic UNIX CommandsRahul JaiswalNo ratings yet

- A Study of Educational Facilities Available in District Institute of Education and Training in AssamDocument5 pagesA Study of Educational Facilities Available in District Institute of Education and Training in AssamresearchinventyNo ratings yet