Professional Documents

Culture Documents

GLM TPL Ugc 01 GC Ol T 601

GLM TPL Ugc 01 GC Ol T 601

Uploaded by

Md Arif0 ratings0% found this document useful (0 votes)

53 views39 pagesRDGDJGFVOHLO

Original Title

GLM-TPL-UGC-01-GC-OL-T-601

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRDGDJGFVOHLO

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

53 views39 pagesGLM TPL Ugc 01 GC Ol T 601

GLM TPL Ugc 01 GC Ol T 601

Uploaded by

Md ArifRDGDJGFVOHLO

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 39

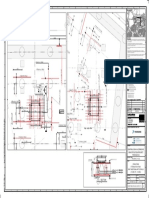

Pune Phase - | Underground Section

(Agriculture College to Northem End of Budhwar Peth Station)

Transmittal Form

CONTRACTOR EIMPLOYER’S REPRESENTATIVE

NAME: Gulermak—TPL | TRANSMITTAL REF N

Pune Metro Joint GLV-TPL-UGC-01-6C-O1-

Venture 7601 rs

CONTRACT Nor DATE OF SUBMISSION: ‘Mr, Suresh Kumar

PLUGC-OL 24.04.2021 Project Director

SIGNATURE

Alper Vahit Vildz

Project Manager

‘We Submit

a Cspecifications _Ciseparately Via Design

iWon plsb aid Mettiodoldey, POS Littems to Specify Clexecution

Report Crests

(design Criteria Studies a cia bape

Ucaleulations Eien rs (to specify

BDrawing anne

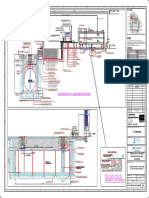

‘SUBJECT: CRD Submission of Tower Crane Foundation GA & RC details for Civil Court Station.(A2 Size)

REF:

Date of Document | _No. of Copies Document Reference Revision

24.04.2021 06 PABOI-GUT-Cv-BAS-CVC-00-00-ESD-0025 BOL

24.08.2021, 06 PABOL-GUT-CV-BAS-CVC-00-00-ESD-8292 BOL

‘These are transmitted as checked below:

For your Information

BaFirst Submission for Notice of No

Objection

REMARKS,

COPY TO:

Additional CPM/UG/Maha Metro

CRE/UG/GC ai

resubmission with corrections for Notice of No Objection

others (to specify)

ISSUING ENTITY:

The document (s) hereby submitted have been

properly reviewed according to our QA system,

to confirm its completeness, accuracy,

adequacy & validity.

Signature:

Name: Sumit Wagh

(Chief Design Coordinator) | 24.04.2021

‘ACKNOWLEDGEMENT OF RECEIPT:

Sg? GOLERMAK TATA PROJECTS

GULERMAK - TPL

PUNE METRO JOINT VENTURE

GULERMAK- TPL JV

Pune Metro Rail Project

CONTRACT: UGC-01

Project: Design and Construction of Underground stations viz. Shivajinagar and Civil Court

and tunnels between Agriculture College and Northern End of Budhwar Peth Station on the

North-South Corridor of Pune Metro Rail Project

DESIGN OF TOWER CRANE FOUNDATION

DETAIL AT CIVIL COURT STATION

| ae

Client a MAHARASHTRA METRO RAIL CORPORATION

LTD

PUNE METRO

SW? GOLERMAK TATA PROJECTS

GULERMAK - TPL Gulermak- TPL JV

Contractor | py ye METRO JOINT VENTURE

cS

Consultant tf; TCPL- GC JV

Document No: P4B01-GUT-CV-C' 'VC-00-00-ESD-0025

Bol

DOCUMENT STATUS

Proliminary Design

B DESIGN OF TOWER CRANE

c FOUNDATION DETAIL AT CIVIL.

Definitive Design G COURT STATION

Construction Reference a P4B01-GUT-CV-CVC-00-00-ESD-

Design 0025

Sa? cousmane TATA PROJECTS

Office of Origin SOMERMAK, 5 f)20 GULERMAK-TPL IV

Originator Sumit Wagh (S.W)

Checker Sumit Wagh (S.W)

Approver :Alper Vahit Yyldyz (AY)

&p 1 | .

CHETAN TIERE

imi AShokraq*Wagh | Sumit Ashokrao Wagh | Alper Vahit Yyldyz

Design Engineer Chief Design Co-Ordinator | Contractor Representative

REVISION BLOCK

BOL | 24/04/2021 (S.W) (B.S) (AY)

| Rev. ‘No. Date Description Originated | Checked | Approved

Projet. «METRO UGC-OT y TNIAPHORCS

Location ‘vit COURT STATION cicerman —_ Sohlae

[Gacsaton For Tower Gane Feundaton coor [er | ome | 424021

cnaay | SW _| Site

onerat

this design note represents analysis and design for Tower Crane Foundation at Civil Court Station

Location & Geometry.

Project: METRO UGC-01 y ne

[sean | _ eMC GOURT STATON catnine

[Calculation For Tower Crane Foundation cat.ey [oT | Date a

onaey | _SW_| Sh.Ne.

[Analysis and Design of Foundation Block

rhe aralyas of foundation block has been done in STAAD software for Maximum Force from Tower Crane,

1 5. CALCULATION OF THE CONCRETE BLOCKS e

[STAD Model

line STAAD medel i presented bow along wth the loads

rotten

phistette

bb be eb be ee

pee be bet

bot ee

Pere ter

oe ttt

PHT eee

se he teres

Tobe bt eet

act — beer

°

‘Staad Loading

sa1oNwONDAY NO NOLO,

Project \ METRO UGC-O1 y THTAMOLECTS

Location ‘civil COURT STATION cocraax ible

[Calculation For Tower Crane Foundation cae8y | oT | Date 2472021

Se

lBase Pressure Check

subgrade Modulus = #821908 = 18000 Kt/m2/m

Ls

wore | Ue

fiexre| 1 [yeonpexs|

fun | 11 coo cas

[Nex ey| rs _—_[rvoocas|

fey [1 [reoaocas|

fasxe=| 1] Lona cas

[anes | 1 —_|reoaneas|

Maximum Base Pressure is 87.734 Kpa sles than 180 Kpe, Hence OK

Project METRO UGC-01

y THINA

ROLES

Location: CIVIL COURT STATION stir 3

[Calculation For Tower Crane Foundation cacey | CT | Date 472472021

cna. [| sw sh.te

[Design for Flexure

Project: \ METRO UGC-01

TATAMOECS

Location CIVIL COURT STATION coienuax ‘ible

[Galcdaton For Tower Crane Founsaton cae by | oT | ome aaa

cuay_| SW] Sine

fizer| —ee— [sano]

fer] — sr — [araeioao

{pra

[inser —[oraeeoen

fest ve — [parva]

ayer ibar dia [a

Specne 00}

Specs Da 23fnm |

[tyr bara sol

Feary oor

sce 25lnm

ayer 3 bar di no

Soci Baan

ser [nm

ayer daca am

Scio 3.09)

em Aw 27nd

i ne

isk asfmm

n Sealine

b rool

ql Tam

our 3olnm

eee Tatsfam

ei in m7

Eesmesee seman —T srayaag

ia coer

Project METRO UGC-O1 y TATAPROLECTS

Location CIVIL COURT STATION sting

Calculation For Tomer Crane Foundation cacy | cr | bate | sizsizont

caer | sw | sme |

[Shear Ckock

a

Maximum shearstess | (| ~—0.684]mpa

Sade ofoain see Sool a

Grade ofshen see asia

Grade ofconerete imp

th of section 000mm

Depth ofsection nm

efecive depth 346mm

lcover | -30[mm

seacngattar mm

bar da nm

otal A S8z7imn

kore 025%

eta ad

Perle Shan esses neonate csp

ia of inl [in

[bis of teal ink nm

No of eps! Mater

Spcing of ups in

shear capacty of tk oss|oa

ott permis shea se ops oc]

Project: s METRO UGC-01

y me

Locator Cv. COURT STATION aati

Gatsaton Fer Tower Gane Foundation coor [ct | me ee

arse [sw] Sue

lOVERTURNING CHECK

(Overtuening Moment 2685p

[axial Laod S35|e0

size of foudnation

lenth 70m

Jwicth 7.00

[deoth 1.40)

self wt of concrete block 715.00)

[Restoring moment

From self wtof foundation | 6002.5 xm

From self tof crane 1276|kun.

Ferashinm

Fos 2,93]0«

ae a

n

SUBSTRUCTURE ON FIXING ANGLES ..

4. INSTALLATION ON FIXING ANGLES

4. GENERAL NOTES ..

101, FITTING THE FIXING ANGLES

4.2 EXECUTION OF THE CONCRETE BLOCKS.

FITTING THE NOT REUSABLE FIXING ANGLES .

1. DIMENSIONS OF THE FIXING ANGLES .....

> SETTING INTO CONCRETE OF THE FIKING ANGLES . 3

FITTING THE REUSABLE FIXING ANGLES .

1. DIMENSIONAL CHARACTERISTICS OF THE FIXING ANGLES

2. FITTING THE FIXING ANGLES

2.1, FITTING THE RODS

2.2 DETERMINATION OF A FIXING.

2.8.FITTING THE FIXING ANGLES. 0

2

2

2.

3.

3

3

3

a

3

4, PREPARING THE CONCRETE BLOCKS

4.

4

4,

4

45,

4

4,

4.

1

1

t

T EABRICATION RULES FOR REINFORCED CONCRETE i 1"

2. EXPLANATION AND SYMBOLS 5 do ine 12

3, CONCRETE BLOCK (MS2N) ‘i 13

4, CONCRETE BLOGK (M64N) é ne 4

5, CONCRETE BLOCK (M74N) : Fgiisiness 15

6. CONCRETE BLOCK (MBIN) ....- es Sicaapeaes 7 16

7, CONCRETE BLOCK (M101N) 2 ; 7

8, CONCRETE BLOCK (M126N) & owt ue 18

ee

18A-0000-064-0-G8 28.

ere MC125-491016

a sues TCTURE Ganrtowec

SUBSTRUCTURE ON FIXING ANGLES

4. INSTALLATION ON FIXING ANGLES

1.1, GENERAL NOTES

“There are two types of fixing angles:

[Not reusable fixing angles; they are set into the concrete block.

D) Rausable fixing angles; they are fixed onto the concrete block by means ofthe fixing rods:

“The choice of the concrete block and the loads and reactions applied on the fixing angles are given in

the brachure 178,

4.4.1, FITTING THE FIXING ANGLES

‘Abad mounting ofthe fixing angles may cause serious troubles when using the crane (perpencicularty

not observed, warpage of the fiting surfaces of the mast).

‘An operating method is given as indication in paragraph 184-0420 for not reusable fixing engles and in

paragraph 184-0420 for reusable fixing angles, The fiting elements (frame, standard mast section)

pecemmended in the operating method can be supplied at the same time as the fixing angles and before

the crane,

NOTE: The frame is only used for fting the fixing angles.

4.1.2. EXECUTION OF THE CONCRETE BLOCKS

“The plans desorbed on the following pages are in compliance with the maximum loads given for each

case,

IMPORTANT: The reinforcementis given on the following pages as an indi-

cation and can be carried out differently, if necessary, under

the responsibility of a competent specialist.

TEA-0000-064-0 | 1BA-0400-007-0 2286-08-15

MC125-491016

Gontewre, suestmucrune

2. FITTING THE NOT REUSABLE FIXING ANGLES

2. 1, DIMENSIONS OF THE FIXING ANGLES:

Shafts 050

1600 _,.|

i! == ae.

Conorate level ‘See operating instructions

1600

+1

REFERENCE EDGE

2

9 fo

ees

@*§

ie

Qh

[194) 296 |_,

490 +

gigeatins eiees

a.

MC125-491016

cs

8 sisieciek ed

2. 2, SETTING INTO CONCRETE OF THE FIXING ANGLES

In order to set perfectly into concrete the fixing angles, following components are necessary:

4 fixing angles and 8 shatts.

O 1 template

1 sighting device

‘The fixing angles and the template can be supplied before the delivery of the crane.

‘The fixing angles must be symmetrically set into concrete with regard tothe axes of the concrete blook

‘and form a square according to the dimension of the masts to be fited.

“Tolerance of surface eveness: 1/400 of the mast cross-section

Near the fixing angle, NEVER GUT REINFORCING STEELS NOR REDUCE THEIR NUMBER GIVEN

“Take care that the fixing angles are correctly earthed (see Operating Instructions)

“The template is only used for fiting the fixing angles.

IMPORTANT: When assembling the fixing angles and the template, make sure that the bearing

surfaces of borings and shafts are clean and free from any smecr.

TEA-0000-064-0 ] 16A-0400-047-0 4 28-08-18

coe MC125-491016

Contre Sect a

‘Ganecare

{2 Outside or inside the atch, arrange the fixing anges (1 byobserving thelr distance (DetalA~ Figure

4)

Pin-connect the template (2) to the fixing angles (1) by means of x2 shafts (3). Lock the shafts (3)

Using the pins (4); fx the pins with split pins (Detail B, C - Figure 1).

Figure 1

STR

TERT O | TORO OT-O «S28 OTS

MC125-491016

a auesraverune Conrowoe

Position the assembly comprising the fixing angles and the template in the reinforcement strange

fring ditch and carry out an adjustable wedging (1) under the plates ofthe fixing angles (Detail A

Figure 2).

IT IS ESSENTIAL TO OBSERVE THE DIMENSION OF 150 mm (Detail B - Figure 2).

[Cd Check the perpendicularity ofthe assembly by means of the sighting device

{Gy Pourthe concreteblack and watthattis completly dry befor dismantling the template andthe starr

dard mast section.

Conerete level

Figure 2.

TER-0000- 068-0 [| 1BA-0420-047-0 6 28-08-18

MC125-491016

Goareirgs ‘SUBSTRUCTURE

3. FITTING THE REUSABLE FIXING ANGLES

2. 1. DIMENSIONAL CHARACTERISTICS OF THE FIXING ANGLES

1600

Tal

Dimensions in mm,

TBA-OOOD-U6E-0 [ TOA-0AGO-020-0,

MC125-491016

a suesTnuoTURE Gontowor

CraneCare

3. 2. FITTING THE FIXING ANGLES

“The dimension, number andfiting ofthe fixing rods ofthe fixing angles onto the concrote block (oy Any

aoe oye.) are on the user's responsibilty, The loads and reactions are given in chapter 174.

itispossible to use the constuctr’s standard of eoncrete blocks forthe informations ofmass, denser

SP aound pressure, The concrete blocks are defined forthe plate-type thing angles, vetoes te

ar a SGnY to adept them to the reusable fixing angles and to the connecting mathed between ie

con ples andthe coneete block Theadopaton ofthe reusable fixing angle to these concrete books

see i user’s responsibility (tne reinforcement type is to be adapted tothe fixing rods used).

Near the fixing angle, NEVER CUT REINFORCING STEELS NOR REDUCE THEIR NUMBER GIVEN.

“The fing angles can be supplied before the delivery of the crane in order to use then as positioning jig

tenths trang rods ofthe fixing angles. The template can also be supplied before the delivery ofthe crane

‘The template is only used for fing the fixing angles.

Fiting tis equipment increases the hookheight by 290 mmin comparison with the standard fixing angles

to be sel in concrete.

“Take care that the fixing angles are correctly earthed (see Operating Instructions)

3. 2.1, FITTING THE RODS

Fitting the rods varies depending on the number of rods used:

DD 4 rods - use the holes 1, 3, 4, 6 (Figure 1)

( Grods - use the holes 1,2, 3, 4,5, 6 Figure 1)

ST

Reference edge

Figure 4

TeA-0000-064-0 1

MC125-491016

Ga

rn ee a

3. 2. 2, DETERMINATION OF A FIXING

‘The tensile loads, compression and shearing forces applied on te fixing angles fr the various working

heights are given in another file:

FIXING ANGLE - LOADS AND.

‘This information allows carrying out the calculation of the fting of the fixing angles adapted to your ease

of use, knowing that the shearing force is always taken up by two fixing angles:

tn general, can be indicated that, in case offing by screw connections or by high-strength He ro. 8

correct assembling will be obtained by observing the following data, that is to say:

[DF (unit: dat) ~ maximum static load under tensile strength on 1 fixing angle,

Fe (unit da) — the capacity coresponding tothe elastic init of tha tie rod: Fe = S x Re with:

3S (unit: mm) = cross-section of the tie rod

Re (unit: daN/mm®) = elastic iit ofthe tie ad (lass 10.9 Re = 90 kgm: cass 6.8 Re =

64 kglmm; class 6.6 Re = 96 kgimm?),

Definition of the number of rods (N) to be used per fixing angle

Gare = Niobe reunded

“The number ofthe rods is always even: 4 or 6, and symmetrical with respect to the upright.

Ej Considering a permissible load per rod, equal to 0,3 ofthe elastic limit, taking up the moment

2) given by the shearing force and the various dynamic coefficients are integrated.

2 Prestress Fp to be applied on the high-strength rod (Fp = 0. Fe)

rmanlike the fixings are entirely on the user's responsibilty

i Bosides this information conceming the number andthe quality ofthe rods, choosing and iting work:

Example: Calculation ofthe number oftiorods (40 mm diameter, cass 8.8) which are necessary for xing

a crane with a max. tensile load of 650 KN at the fixing angle:

F =650 kN = 65.000 daly

1D Fo= Sx Re = 1 256 x 64 = 60.984 daN with:

@ S= nx 402/ 4 = 1 256 mm? (tod diameter 40 mm)

Re = 640 MPa = 64 daNfmm? (class of the rod 8:8)

Therefore N =F / (03 x Fe) = 65 000 (0,3 x 80 384) = 2:

By rounding up to tho nearest even number, 4 fixing rods are necessary per fixing ani

] Prestross Fp tobe applies on the high-stenath rot: Fp = 0.5 Fe = 0.5 x 80.984 = 40 192 daN

ai 5500-0590 TTR 0450-020-0 3 26-08-15

MC125-491016

a sues TRUCTURE Ganvrowoe

3.2.3, FITTING THE FIXING ANGLES

Ly Arrange the fixing angles (1) by observing their distance (Detall A - Figure 2),

[G Pin-connet the template (2} othe fing anges (1) by means of 4x2 shafts (3). Lack he shatts@)

using the pins (4); fix the pins with split pins (Detall B, C - Figure 2).

[Cl Tighton the nuts ofthe fixing rods according to the supplier's instructions,

1G Check the surtace eveness ofthe fing angles by moans of the sighting device, The sighting r=

rence is to be taken at the top (@) of the template uprights (2) (etal C - Figure 2)

A Tolerance of surface eveness: 1/400 of the mast cross-section

PORTANT : When assembling the fling angles and the template, make sure that the bearing sur-

faces of borings and shafts are clean and free from any smear.

_1,6m__

Figure 2

ee

1

TGA-0000-06-0 ] 18A-0490-020. 102.

MC125-491016

4, PREPARING THE CONCRETE BLOCKS

4, 1. FABRICATION RULES FOR REINFORCED CONCRETE

Concrete and reinforcement determined accordingtotheB.A.E.L. (reinforced concre-

te boundary condition) Rules, 1989.

4.1.1. CONCRETE

of

[Dy te] = characteristic compressive strength of the j days old concrete

NOTE 1 - Inany case, the compressive strength is maasured by axial pressure ofthe oylinder having @

prphery of 200 cm cross section and aheight which s the double ofits ciameter (16 om), Thess dere

Here cose an aggregate size ofa east equal to 40 mm, a condition general filed for reinforced

concrete,

jaracteristic tensile strength of the | days old concrete

NOTE2 ~The dimensions and characteristics ofthe reinforcements and of the concrete for the execu

ae mate works indicated in this manual, are defined by a compressive strength value at 28 days old

G= 29)

Reinforced concrete mixing of 350 kglm® - CPAAS

‘that means, for 1 m° of sand with gravel:

350 kg PORTLAND cement 45.

For a vibrated concrete correctly prepared, we obtain:

fe28 = 20MPa

128 0,6+0,061028 = 1.6MPa

Pp Weight of reinforced concrete in daN

D = Average density of reinforced concrete equal to about 2,35

4.1.2. STEEL (except other indications)

Es: Longitudinal modulus of elasticity of steel: 200000 Nimm?

i.e. 200000 MPa

‘Type 4; Reinforcement with high adherence obtained by het-roling of natural high-carbon sleek

Quality: Fe E 50 ie, fe=500MPa

SHOULD THE ABOVE RULES NOT APPLY, REFER TO THE RULES APPLIED IN THE USER

‘COUNTRY.

EDO ROOT TS

MC125-491016 yes

SUBSTRUCTURE

4. 2, EXPLANATION AND SYMBOLS

Designation of a concrete block (M54).

(QM: Conorete biock

54: Weight ofthe conorete block in tons.

Ny Intemal coding

“The reinforcement of a conerete block is composed of an upper and a lower reinforcing cage connected

by pins. Each cage comprises two crossed layers

(Example)

Upper layer 6 Number of bars

= HA Round steel with high adherenc

Sars SS

6 HA 16x 450 2: 15 46 Diameter of iron in mm

|

450: Unit length of iron in em

Lower ayer Lg: space inem

ep: pin

D: density

VV: volume in

1 length in om

I: width in em.

Hi height in om

41LH : First upper layer

4LB : First lower layer

2LH : Second upper layer

2LB: Second lower layer

T: Rod

eee 0 both ccections

TBA-0000-064-0 ] 1BA-0440-007=0 72 28-08-18

MC125-491016

Gonirowoc suBsTRUCTURE

‘Crane Care

4. 3. CONCRETE BLOCK (M52N)

2LH 24HA20x435 e=17 2062.20

L:4001: 400 h: 135 V:22m3

TEA-OOOO-06E-0 | 1OA-0445-007-0 1528-08-15,

MC125-491016

suBSTRUCTURE Gentowoc

4,4, CONCRETE BLOCK (M64N)

PLM 24HAzox480 e=19 206 920

1LH 24H1A20x490 0-19 206920

_——___ sf,

~ wi

228

45

22s

|

4h t+

|

g—i-

ea

|

wt

—t++4H ee

D:24

l

1: 4451: 445

T

h:135 V:27 m9

TeA-0000-064-0 | 1GA-OMS-002-0 Ta 25-06-15,

= MC125-491016

itowoc

Convenes suesmucrune a

4.5. CONCRETE BLOCK (M74N)

a7

| 4B caHa2oxsao o=17 20¢~edz0 ‘|

475, ”

PLB 26 HA20x540 0 = 17 2c y20

8x8 HA14x155 0 =57

240

D:24

L:4901:480 h: 135 V:31 m3

TEA-O00-06T-O | T6A-0445-005-0 TE 25-08-15,

MC125-491016

utowoc

fisraerube Gontowec

4, 6. CONCRETE BLOCK (M81N)

4LB 30 HA 20x 560 @=17 20498 20 |

ane r g

2LB S0HA20x 560 e=17 Ss 20 = |

10x10 HA14x155 0-51

a —_—+

[ose __p_ ______.

eer eres

flow

L;5001:500 hi 195 V:34m3

TGA-0000-064-0 ] 16A-0445-004-0 1626-06-13

MC125-491016

G@anitowoc

4,7. CONCRETE BLOCK (M101N)

“2LH 93 HA25 x 620 @ = 17

(TH 39 HA 25 620,

TT PoRERPE FEES

4

reek

iS

bette tht

L:5601:560 h:135 V:42m3

TERT [EROS UST 17-08-18

MC125-491016

‘GraneCare

a sueemmdciune @onrowoc

4. 8. CONCRETE BLOCK (M126N)

2LH 52HA25x680 e=12 __

[1B 52HA25x690 6=12 20 6820904

|_2Le s2HiA2s x690 @=12 _

130

Rett ttt th

9125

RO

| |

acy a a Kae ala

: ot

Ket ttt tie ttt t

L:6251:625 h: 135 V:53m3

TEA-DOI0-O64-0 | 16A-0445- 008-0 Te _ 26-08-15,

MC125-491016

ERECTION ON FIXING ANGLES

janitowoc

Crane Care

LOADS, REACTIONS AND MOMENTS ON FIXING ANGLES

4A.

42

13,

14,

18,

16

INSTALLATION ON FIXING ANGLES.

EXPLANATION AND LEGENDS OF THE REACTION TABLES.

EXPLANATION AND LEGENDS OF THE TABLES CONCRETE

BLOCK CALCULATION.

EXPLANATION AND LEGENDS OF THE TABLES PRESSURE

UNDER CONCRETE BLOCKS.

REACTIONS ON THE FIXING ANGLES.

M125 ~ P16A ~ FEM.

CALCULATION OF THE CONCRETE BLOCKS.

PRESSURE UNDER THE CONCRETE BLOCKS.

“1

T7A-0000-362.0

MC125-491016

0-01-2070

anifowoc

ERECTION ON FIXING ANGLES a

Crane Care q

LOADS, REACTIONS AND MOMENTS ON FIXING ANGLES

4. INSTALLATION ON FIXING ANGLES

The following tables define:

1 theloads and the reactions applied on the fixing angles according to the conditions in service and

out of service.

the elements for the calculation of the concrete blocks.

1 the concrete blocks and the pressure under the recommended concrete blocks:

“The direction of dimensions L, | and h with respect to the mark concems the main parts only.

“The dimensions of the fixing angles, the setting ofthe fixing angles in the concrete blocks as well as

the execution plans are shown in chapter 18A.

Ground as well as the minimum mass which are equal to those of the smallest permissible

Forthe crane stabilty requirements, compulsorily observe the minimum dimensions on the

A Soncrete block, which is compatible with the ground pressure at the erection site.

FIXING ANGLE - PREPARATION OF THE.

CONCRETE BLOCK

Pressure under the concrete blocks ~ during erection

Pressure under the concrete blocks ~ in service - out

A ror any ther dnensons which donot observe these recommendations please consul us

[7A-0000-352-07 17A-0200-004-0 3 (05-04-2070

MC125-491016

j ERECTION ON FIXING ANGLES

5) Q@anrrowoc

Crane Care

4.1, EXPLANATION AND LEGENDS OF THE REACTION TABLES

The Indicated reactions do not include coefficients for dead weights nor a dynamic

coefficient for the lifting load.

itis appropriate to take into consideration the usual or standardized safety

coefficients valid for the indicated loads and reactions.

‘he usual, a negative (-) reaction corresponds to a pressure on a bearing and a

positive (+) reaction toa traction.

max: 100% kN

one | ofc o-c | ofc | oof!

| tone | ISL | LAL | pombe | 181 | LA |

LRoe | age | #e | ASe | age) woe ||

vse | RO Fao Re TRO RO tax any) ROROT RD ROT RO RO | Toa a

peas eat (betes alee ate ent

wm | ay fam | cay | ey! oooh cy | Tet)

1 “q T ttt T t—~|

A |

4

HSC (m)

ERR

=== Direction ofthe jib

With a crane “in service” » and “out of service” w , the column (Rmax) indicates the maximum

reaction between tho 3 jib position shown,

Tivindicated shearing force (Tmax) as well as the torsional moment (Cmax) are tranmitted as

Horaontal forces onto the bearings. The maximum horizontal force onto a bearing amounts to:

FHimax = Tmax, Cmax

2 d

NOTE:

the moment (Cmax) is only present “In service”

(the vertical force corresponding to the crane weight can be obtained by summing up the

reactions onto the 4 bearings.

T7A-0000-562-0 1 17A-0220-012-0 a 05-01-2010

MC125-491016

ERECTION ON FIXING ANGLES j

Q@anitowoc |

Crane Care

4.2.EXPLANATION AND LEGENDS OF THE TABLES

CONCRETE BLOCK CALCULATION.

the indicated reactions do not include coetfitents for dead weights nor a dynamic

oefcint or the iting ond

coefficient ofa take Into consideration the usual or standardized safety

4] rtelente al fr the indeated toads and reactors.

Sonfcent va ee) reaction corresponds fo a pressure on a bearing and a

postive (i) veaction oa traction.

MV = Wind moment

MR = Moment resulting from dead weight + load + centrifugal force moment (MFC)

ET = Shearing force except the mast torsional moment

Mmax = Maximum moment

‘max = 000% kN 1 \

| e | u | During erection

pip yy yp i ft fy yt dt tt

j HC | var jm a | ET | MY | MR) Mae DD | Er | tay A | ET

| ton Loaml aay wain cay |g gal anal nnt en Lay | a | ca

Sa ee ee

b

4

‘SC (m)

be

ET >

Case of rear wind |The maximum moment depends on

Maximum moment = MV + MR he values of the dead weight moment

Or (MR) and the wind moment (MV): |

Case of perpendicular wind Maximumif MV <2 x MR then max. moment =)

moment =\/ (MVM) MR

Tas is the most unfavourable case which!t MV > 2 xMIR then max moment = |

appears in the table MV" MR

Maxirurt sheng ocean Tingangle Wek

ET Cmax | |

20d 2 H

Cmax = Max. torsion moment on the Jou of senanconlon te ran is \

masts in weathervaning position. Cmax=0

d= mast width \

hearing forse of fing angie ~~

T7A-0000-362-0 7 17A-0220-012-0 5 05-07-2070

‘porno,

MC125-491016

Q@anitowoc

a ERECTION ON FIXING ANGLES

Crane Care

4.3. EXPLANATION AND LEGENDS OF THE TABLES

PRESSURE UNDER CONCRETE BLOCKS

CONCRETE BLOCK (T)

oy

| 30.90

| @ rove under the conrte locks (aN

ea (m)

TTR 3 SORE

MC125-491016

5

ERECTION ON FIXING ANGLES

Crane Care

G@anitowoc

zet~ vs

o6L- 2zT-

oz

> 02e

199- 0zT-

ert- Hoe

ops- ert~

SUt- Ut

Lz9~ SIT

ert o8e-

#ST ett-

ort cue-

ust ott

eot- see~

6st a0t-

so

1

£0

29)

t= tLe

os

T= OLE

Tt e0T-

QLOL6y-SZLOW

tes- 982

res~ 382

epe- 602

sye- 602 1 s0L~

eLe- Bet

ELE eet | 199-

pL y0e-

sL WoE- 1 LTS~

se toe-

9L Toe- I pas~

1 66z~

1 6Bz~ | 9Ss~

8 Le

tes-

8 62-

1

i

ee p62- |

| a0s~

i

1

Ler

tse-

set-

80L-

ect

139-

oer

una

ect

p3s-

sete

oss~

ezt-

Tes-

ozt-

209-

ert

1

zee | uie~ soy

wet | t2e~ 2

i

tee | Bez~ ete

Ser- | ce9- ze~

1

gee | toz~ ace

EEt- 1 99-19

i

use | vot~ 9¥e

det- | 903- 96-

i

eze | szt- ste

eet- | ous- 9zt~

soe | s6- vez

Set- | $es- 9st~

sez | cs- sz

€cI- | Tos- Pet~

1

uz | oe- Lez

ozt- | 9e- Ttz~

i

os | t toe

ett | cep Lez~

i

e WIN ZOU 2xXELD,

WA - V9Ld - SZLOW

SATONV ONIXId SHL NO SNOILOWSY “Yb

05-07-2010

T7A-0000-362-0 7 17A-0230-398-0

Crane Care

@antowoc

ERECTION ON FIXING ANGLES

QLOL6GY-SZLOW

1 | ver eet | pps ops | tte PEO I i | set

roet-1 ett | TOPt-FET- | Tté- Cte | Tr6- pr9 | ase- | Gy | B6~

i ‘

Tel €16 | 99s 90S | B0B- 915 i oot

sezt-I ett | S€Zt-TET~ | B08- so8- | B0B- 915 lee | 9z6~

i

azt- te | esp bse | ItL~ oSy i 1 eve

aeor-I 901 | scot-ezt~ | Tte~ Tte~ | TTL~ Ps¥ Lew | age

1 i

1 set 619 | | opt

6z6- | ot | 6z6- szt- | (te 1 rte

i i i Hl

eee fanaa ewannn nnn [nna a

me | Se mt

1 i la wie wigs (wl ae

| xomg | ceuz | od gu | od Ge | 8 a | meu | xem | OF

069 96s

6et- | 968- BT

veo | cop- uss

9¥t- | 6p8- OTT

1

Tes | ege- 61s

eet~ | o8- ex

oes | ete~ za¥

opt- | e91- 6

i

a ie

mL

wi) ge

aa | 38

aut 966

6a 959-

ort uss

6Pe- 209-

ce ots

S08- 6se-

ue 2P

e9u- Bte-

os

a

a

! gow

| Roe

WNA ZOE XeWD

05-07-2010

T7A-0000-362-0 / 17A-0230-398-0

D

Ww

a

o

Zz

=

9

=

x

z

z

3°

Zz

So

ie

°

wu

iva

w

Crane Care

aMirowoc

G@

ge tyes 17P9LT

Iesz 7zae 969

52 we ([°Te9T

lee

se 69st

ere (*TIST

eee I t8seT

aze 1 "809T

[est ate 19Et

ser It60e TET

let 667

let 602

[rat r08z

“et uz 1T8ETT

om) to) (uN)

a | GO | cw

NOILOawa ONIENG

QLOL6r-SZLOW

ual

ag

BE

3 ca

Hieert—I-3e8 row rest ow LE

TT rpzs ir699 I*se6T. el [S| .

es oe

“oot I-t0s Hiss eer fi ovse |

Sse 1088 gop roret. fi ovee

— = 093 o-ez |

we (or 03 ose

Soe 29 ovee | {oy

139

099)

989

9

999

ovoz,

overt |

over |

i

sou

8s

3

15

ts

ze

zee

21

ott

oe

(ur) (wn) wn) E(w)

Godt) WN (un) Cuan)

13 QP | uw | ww AN 4a G | cw | ow AW OSH

"F7A-0000-962-0 1 17A-0230-398-0

WN ZO} XEUD

$9078 JLFYONOD FHL 40 NOLLWINDTV9 ‘St

QLOL6P-SZLOW

ge

g

8

gs e

gu S|

© i

8 a gic ueensnavee enews £0777 3

re oe renee C05

Qo 1 ¢ 7 2

: soe a

zg eo eT oe A

z S|

2 ee z

Zz so 60 et rt eorut SI

3

5 a0 60 z ot E0°HT =|

ow Lo “0 at wr ert SI

& ; Ey

co we eS) Hi

S|

& $0078 SLYONOD SHL YANN SUNSSsUd ‘91

COMMENTS ON RCC FOUNDATION FOR TOWER CRANE AT CIVIL COURT LOCATION.

Date: - 22.04.2021,

We have gone through design document & following drawings furnished by you on mail dated

21.04.2021 for RCC Foundation for Tower Crane at Civil Court location.

a) File Name- Tower Crane Foundation (1 to 1 sheet)- showing details of tower crane RCC

Foundation.

We have gone through the above design & drawings. It's generally in order. However, following

‘observations are listed below for information & necessary corrections in the drawing & design.

21) Provide nominal reinforcement on side face of foundation as depth more than 1000mm 25 per 18456,

1345,

JV Response: Addition T16@250 C/C Reinforcement Is Provided On Side Face.

2) For foundation provide minimum clear cover SOmm as per 15456, c126.4.2.2. correct in drawing.

JV Response: 50 mm clear cover is provided as per comment.

3) For load combination load factor is considered as 1.3. it should be 1.5 as per IS code, Please check.

JV Response: Load Factor 1.30 Is Considered as Per tender document.

4) Load reaction given as vertical downward is $36 KN and moment 2685 kN-m only, There iso

horizontal reaction and upward/uplift forces. Please confirm.

JV Response: Maximum design Load is taken from data provided by the tower crane vendor

5) Other remarks ifany will be informed after getting & studying all above data.

JV Response: Noted

Regards,

Dr. JM.Mulay

1 3 4 5 6 = 1 8 9 1 10. 4 1 42 1 43 1 44 15, 16

i i 1 2500(rnin) TOWER CRANE

| I GROUND LEVEL FOUNDATION

Aen \ y Pol

1 | A fs ch

\ I :

i I LEVEL- 1 >

1 1

| 1

| 1

aie 1

1 1

|

| | 1

ah ul !

Tg OW cme FONOAHON \

is cera

Ga |

\ @- = i oom THK

| H i SHOTCRETE "|

a ! |

fat g i |

| ELEVATED STATION ‘ !

q | | |

re | '

i 1 y

| |

le / _ SSS ae

\

I \

fC hae oe i

a TOWER CRANE

. 5 (40) 1) a I ! GROUND_LEVEL Sa FOUNDATION

: A t—] 4 388.500 y

iat ai E ap weeeeeea eae sie He aS aa

aT a al ee

i a z tee | ee | ae

ae f , t ‘ | 100MM THK,

== Soeiese Sopa lbs ee ee | | GQBAOE

! | [UGsTATION} + 1 \ 2 is

eM le ao Pole Soy ee ae po orem Pd a | Boe al ALS BN [eee

CIVIL COURT STATION TOWER CRANE LOCATION AT UG & ELEVATED STATION

d (SEA 1300)

250125 C/C

4

: =

2 “| |2

' is =

TA OMSK ABE mon AND LEVELS ARE, UNLESS OTEBWSE

a SHEAR Links| | 2. CLE«® COVER 10 REINFORCEHE\T=0mer

vi2e2s0 c/é © Gece OF RENOREEUENT = Fe £00/ 5000

¥250125 C/¢ steers

: 53 choowo LEVEL 70 BE VERPIED AT STE RD AY DISCREPANCY SHOULD BE

‘TOWER CRANE FOUNDATION RINFORCEMENT DETAIL FOUNDATION DESIGN APPLICABLE FOR TOWER CRANE (POTAIN MC*25 6. Te, ORANG SL EE READ WY CONRICTEN WIN SERMCES MO OTHER

ATION RI Sasa Seams For So-osbnaion OF haEwa: SawceS ee

7, S04 SBC 10 Ee ASHEVED taTOn/ua Ton rouomTe

elie cared pa are Daemon 2 Sthoc'se Muse 15'be uted ro nas Gestne onouN cove.

| rin at rrr te pes meas por otnarton 41 Mn oti oF Founwaren FROM CAUND Lev TO 2 Ge

= SeeRATA Scars ona mime misenrecerernecaamens" | pSrmaente ieee mee [0 merase comma (MORSE 2% PUNE METRO RAIL PROJECT

haves neste vt be ake ConsuLrr Beaten Deon Contant seanTtosroR.|TMEPISenntn eos Ako Ts RESOINENRES PCH SEE NO | gan cpa ccten sineaer ‘The on Biting, tt lar, Opposia Don Boao es

4 eee epee besetconae my teanicion [Rea ee ies, © someon TR oe

CONTRACTOR ‘PROOF CONSULTANT ‘Teeued As Good For Cansiucton, vmem Park, Pune- 411001, MH, India

See SION rors [see in Zp S168 stow [stene (=) et

za iar ei Eee of ee ET DARE = ~ ace 1 cue MAHARASHTRA METRO RAIL CORPORATION LTD. x

EE [NATSU W— [NRE SHAR SE BET) — RE PE = ae = wwe [= a ___[teention Giviout 5

oramvay | —sesrvey | —crecrenay | ssrmoveDBy meceereny TEES RUST ENG} OROVED HY TEAVIRSSER) | REMEDY ‘eros, BY-FOO | TOWER CRANE FOUNDATION GA&RODETALS ———SC=S 9

, z

4 SW? couenan TATAPRONECTS /A=COM eee a gon = STE

Ce ce GOLERMAK - TPL AECOM INDIA PVT.LTD. METRO RAIL PROJECT) Hon DRG No:

REVO ATE DESCRIPTION ro ere af eee Tee Beene P4B01-GUT-CV-BAS-CVC-00-00-ESD-8292 B01

7 = T 3 a T 5 T 6 v e B T 9 10 T cr) ay T 13 T 4 7 5 T 16

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design Calculation of Thrustblock: Central Doha & Corniche Beautification Package 2ADocument1 pageDesign Calculation of Thrustblock: Central Doha & Corniche Beautification Package 2AMd ArifNo ratings yet

- CDCBP P086 Cp02a Jec SD Me 0002Document1 pageCDCBP P086 Cp02a Jec SD Me 0002Md ArifNo ratings yet

- CDCBP P086 Cp02a Jec SD Me 0003Document1 pageCDCBP P086 Cp02a Jec SD Me 0003Md ArifNo ratings yet

- Section - 5 Section - 9 Section - 4: Key PlanDocument1 pageSection - 5 Section - 9 Section - 4: Key PlanMd ArifNo ratings yet

- SD 8-4-106 Rev 3 Structural NotesDocument1 pageSD 8-4-106 Rev 3 Structural NotesMd ArifNo ratings yet

- Central Doha & Corniche Beautification Project Package 2ADocument1 pageCentral Doha & Corniche Beautification Project Package 2AMd ArifNo ratings yet

- CDCBP P086 Cp02a Jec SD STR 1119 1Document1 pageCDCBP P086 Cp02a Jec SD STR 1119 1Md ArifNo ratings yet

- Design Calculation Structural Design Calculation For Lifting Beam (Heb400-S275) - 480KN LOADDocument4 pagesDesign Calculation Structural Design Calculation For Lifting Beam (Heb400-S275) - 480KN LOADMd ArifNo ratings yet

- Central Doha & Corniche Beautification - Package 2A Page 4 of 96 Microtunneling Shaft MT-3 Design Report CGD - Form.Tr - Rev02Document1 pageCentral Doha & Corniche Beautification - Package 2A Page 4 of 96 Microtunneling Shaft MT-3 Design Report CGD - Form.Tr - Rev02Md ArifNo ratings yet

- Central Doha & Corniche Beautification - Package 2A Page 4 of 96 Microtunneling Shaft MT-3 Design Report CGD - Form.Tr - Rev02Document1 pageCentral Doha & Corniche Beautification - Package 2A Page 4 of 96 Microtunneling Shaft MT-3 Design Report CGD - Form.Tr - Rev02Md ArifNo ratings yet

- Address PDFDocument1 pageAddress PDFMd ArifNo ratings yet

- Tour ExpencesDocument1 pageTour ExpencesMd ArifNo ratings yet