Professional Documents

Culture Documents

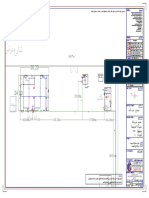

CDCBP P086 Cp02a Jec SD Me 0003

Uploaded by

Md ArifOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CDCBP P086 Cp02a Jec SD Me 0003

Uploaded by

Md ArifCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12

KEY PLAN

.

.

.

.

.

.

ALL H/L VENT PIPE WILL COVER WITH FLAME ARRESTOR WITH PRESSURE VACUUM VENT PIPE SUPPORT

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

H:+5m AFFL

SAT

50mmØ VENT VALVE

.

A A

.

.

G.I CONDUITS WITH CONTROL CABLES FEEDING FROM

A.T.G & PUMP CONTROL PANEL

POWER WILL FEED BY MAIN CONTRACTORS

LV ISOLATOR PROVIDE BY MAIN CONTRACTORS 50mmØ SUPPLY LINE

120

POWER WILL FEED BY MAIN CONTRACTORS

50mmØ VENT VALVE

150

120

50

LV ISOLATOR PROVIDE BY MAIN CONTRACTORS 350 350

50

ATG PANEL

PUMP CONTROL PANEL

500

G.I CONDUITS WITH CONTROL CABLES FEEDING FROM

A.T.G & PUMP CONTROL PANEL

1400

Franklin Fueling Systems

200

NOTES:

50

E.P.B

25mmØ RETURN LINE

500

300

80Ømm CS SCH40 FUEL 100X100mm G.I TRUNKING WILL PROVIDE BY MAIN CONTRACTORS 200 7000 LTR. 1) ALL LEVELS, DIMENSIONS ARE IN MM UNLESS OTHERWISE SPECIFIED.

FILLING PIPE DROP DOWN 25mmØ BALL VALVE 200

B 2) DRAWINGS TO BE READ IN CONJUNCTION WITH OTHER DISCIPLINES DRAWINGS. B

950Ømm OPENING (BOTTOM SIDE)

80Ømm GATE VALVE 3) THE ALL EARTH PIT & EARTHING CONNECTION FOR THE FUEL SYTEM SHALL BE

50

1100Ø OPENING FRP (TOP SIDE)

250 250

DONE BY MEP CONTRACTOR

700

120

650

OF TANK SLAB FRP ACCESS (TYP.)

600

600

50

500

4) APPROVED MAS REF # CDCBP-P086-CP02A-JEC-MS-0089

SUBMERSIBLE TURBINE PUMP

WITH ASSEMBLY (1 WORKING, LEGENDS:

1 STAND BY) 2460 2460 300

40mmØ DUMP LINE

40mmØ BALL VALVE 1000

DAILY FUEL TANK LOW/ HIGH FLOAT SWITCHES

700

LEGEND-FUEL SYSTEM STAINLESS STEEL FLEXIBLE HOSE (F.H)

500

ACCESS COVER (TYP.) FIRE SAFE VALVE 25mmØ SUPPLY LINE

400

SYMBOLS DESCRIPTION INCEREASE IN PIPE SIZE (R)

25mmØ SUPPLY LINE BUND WALL SENSOR WITH DUMP PIT DECREASE IN PIPE SIZE (R)

50mmØ BALL VALVE TO GENERATOR 110Ø DIESEL FUEL FILLING POINT SPILL CONTAINER

HIGH LEVEL AUDIBLE ALARM

FFP 110Ømm HDPE U/G DIESEL FUEL FILLING PIPE

50mmØ UNION 25mmØ RETURN LINE 75/63Ømm UPP/PE DOUBLE CONTAINMENT U/G PUMP CONTROL PANEL WITH IN-BUILT PUSH BUTTON

625 FSP

DIESEL FUEL SUPPLY PIPE

50mmØ SOLENOID VALVE TO GENERATORS

FSP 25/50Ømm CS SCH40 DIESEL FUEL SUPPLY PIPE AUTOMATIC TANK GAUGE MONITORING & CONTROL PANEL

75/63Ømm UPP/PE DOUBLE CONTAINMENT U/G

FRP

DIESEL FUEL RETURN PIPE MWS-XX MONITOIRNG WELL SENSOR

50mmØ BALL VALVE @ BY PASS LINE FRP 25/50Ømm CS SCH40 DIESEL FUEL RETURN PIPE

WASHED FINE SAND FVP 63Ømm UPP/PE U/G DIESEL FUEL SUPPLY PIPE

ENTRY BOOT

WILL FILL UPTO NECK ALL CS PIPES COVERED WITH Ø90 FVP 50Ømm CS SCH40 DIESEL FUEL VENTILATION PIPE

16AMP.1PH/240VAC/50Hz SINGLE PHASE LV ISOLATOR

(PROVIDE BY MEP CONTRACTORS)

50mmØ Y-STRAINER 4CX18AWG BELDON CONTROL CABLES

OF SUMP (TYP.) HDPE SLEEVE FROM TANK ACCESS 3X4mm² Cu/MICA/LSHF FIRE GUARD POWER CABLES

(WILL PROVIDE BY MEP CONTRACTORS)

100x100mm G.I TRUNKING (PROVIDE BY MEP CONTRACTORS)

CHAMBER UNTIL BUILDING FUEL 50mmØ UNION @ BY PASS LINE 1CX16mm² Cu/PVC Y/G EARTHING CABLES

F/A

12KG DRY POWDER FIRE EXTINGUISHER (PROVIDE BY JTC/ MEP CONTRACTORS)

FROM ABOVE

(WILL PROVIDE BY MEP CONTRACTORS)

C 50Ømm CS SCH40 SERVICE ACCESS CHAMBER F/B FROM BELOW C

FUEL SUPPLY PIPE 50mmØ UNION 1CX120mm² Cu/PVC Y/G EARTHING CABLES

(WILL PROVIDE BY MEP CONTRACTORS) T/A TO ABOVE

(BY CIVIL CONTRACTOR) DEDICATED EARTH BAR FOR FUEL SYSTEM

(4 WAY WILL PROVIDE BY MEP CONTRACTORS)

T/B TO BELOW

H/L HIGH LEVEL

BUND WALL SUMP SENSOR (BWS)

150Ømm uPVC SLEEVE BALL VALVE (BV)

NORMALLY OPEN (N.O.) / NORMALLY CLOSED (N.C)

L/L

UP

LOW LEVEL

RISING UP

2 NO,S (BY CIVIL CONTRACTOR) TRANSITION SUMP FIRE SAFETY VALVE / DUMP VALVE (FSV)

DN DROP DOWN

UNION (TYP.) 1200(L)x900(W)x1300(H)mm VENTILATION CAP WITH FLAME ARRESTOR

BALL VALVE TRANSITION SUMP TRANSITION FITTING (HDPE TO CS TYP.)

4365

UNION (UN)

(N.O) (TYP.) 700(L)x700(W)x600(H)mm PIPE FLANGE

FIREMATIC VALVE (FMV)

50mmØ VENT LINE SOLENOID VALVE (SOV)

Y-STRAINER

50mmØ C.S. RETURN LINE SUBMERSIBLE TURBINE PUMP (1 DUTY, 1 STAND BY)

G.I CHANNEL SUPPORT (75X40mm)

ATG ATG LEVEL PROBE WITH LOW/HIGH LEVEL FLOAT SWITCHES

ALL CS PIPES COVERED WITH Ø90 ISS INTERSTITIAL LEAK SENSOR

HDPE SLEEVE FROM TANK ACCESS

CHAMBER UNTIL BUILDING FUEL REFERENCE DETAILS DRAWINGS

SERVICE ACCESS CHAMBER DRAWING NUMBER DRAWING TITLE REV. NO.

(BY CIVIL CONTRACTOR) MECHANICAL ATTENUATION

TANK GROUND FLOOR PLAN CB

D CDCBP-P2A-PIL-ME-1013

FUEL SYSTEM LAYOUT

D

HOLD DOWN STRAPS AS PER

TANK MANUFACTURER'S

400 300

J HOOK (TYP.) FRONT ELEVATION OF INSIDE GENRTOR BUILDING

3555 16mm² REINFRPCEMENT BAR ATTACHED

IN CONCRETE BASE (TYP.) (BY JEC CIVIL TEAM) C0

BITUMINOUS LIQUID PRIMER 4355

400mm THICK. REINFRPCEMENT BELOW SLAB (BY JEC CIVIL TEAM)

300mm THICK. COMPACTED WASHED FINE SAND

APPLY BEFRPE INSTALL THE UNDERGROUND TANK

00 01-06-2022 ISSUED FOR APPROVAL SA

E REV. E

500Ø

DATE DESCRIPTION APPR.

NO.

Access to

WOQOD VEHICLES

Only

690

Switch Off Engine

Public Works Authority

No Smoking P.O.Box 22188

1200

Tel. : (0974) 44950000

The Use of Mobile Phone is

Strictly Prohibited

Fax. : (0974) 44950999

3000

DANGER www.ashghal.gov.qa Qatar Deserves The Best

Highly Flammable

100

PROJECT AFFAIRS

Emergency Contact No. In Case of Fire

2515

contact No.

Police, Fire and Ambulance

999

665

Highly Flammable

GENERAL ENGINEERING CONSULTANT

400

DIESEL

FINE SAND UNIT THE NECK OF SUMP No Smoking

No Naked Light

590

100

1215

TANK INSIDE COMPLETETLY WILL BE COVER BY F

720

700

F FINE SAND UNIT THE NECK OF SUMP 3" PAINTED GI PIPE

325

325

400 1055

395

CONTRACTOR

500

SUBMERSIBLE

1270

300

1255

1310

TURBINE PUMP

1560

1560

TANK SUMP

SUB-CONTRACTOR

OVER FILL PREVENTION VALVE

50mm THICK. STEEL TRENCH PROJECT

TANK INSIDE COVERED BY

10mm LEAK PROOF MATERIAL

CENTRAL DOHA & CORNICHE

25Ømm CS SCH40 GENERATOR

G

FUEL RETURN PIPE (TYP.) FFL BEAUTIFICATION PROJECT

G

2650+5

PACKAGE 2A

Ø2505 2+5

50000

25Ømm CS SCH40 GENERATOR

400mm THICK.

700000

FUEL SUPPLY PIPE (TYP.) 162501

600000

CONC. RETAINING WALL (TYP.) 125000

PROJECT CODE

75000

125000 125000 162499

75X40mm G.I C CHANNEL BAR

& PIPES ARE ATTACHED THE BAR GROUND FLOOR FUEL SYSTEM

WITH THE PIPE U CLAMP

LAYOUT SECTION DETAILS-01

400mm THICK. CONC.TRENCH

RATCHET NYLON TANK

HOLDING STRAP (TYP.)

400 300

H

300mm THICK. COMPACTED WASHED FINE SAND

APPLY BEFRPE INSTALL THE UNDERGROUND TANK

SECTION VIEW OF DESIGNED

CHECKED

SA

STATUS

APPROVAL

SHOP DRAWING

H

SA SA

10mm LEAK PROOF MATERIAL

J HOOK (TYP.)

16mm² REINFORCEMENT BAR ATTACHED

IN CONCRETE BASE (TYP.)

GENERATOR TRENCH DATE 01-06-2022 SCALE

1:100

11882+5 DWG. NO. REV. NO.

CDCBP-P086-CP02A-JEC-SD-ME-0003 00

1 2 3 4 5 6 7 8 9 10 11 12

You might also like

- Solt Equity Agreement For Westend Theatreartists 200819 Formerly 15018Document55 pagesSolt Equity Agreement For Westend Theatreartists 200819 Formerly 15018Adam Moore-WhiteNo ratings yet

- This Is MySong - GuitarDocument2 pagesThis Is MySong - GuitarFelipe OliveiraNo ratings yet

- Portfolio Final FileDocument93 pagesPortfolio Final FileUrvashi SughaNo ratings yet

- UntitledDocument155 pagesUntitledZed MindsetNo ratings yet

- Slavin Volume 4 - Book 4 - PUZZLES TO SOLVEDocument45 pagesSlavin Volume 4 - Book 4 - PUZZLES TO SOLVEEduardo AP0% (1)

- CBSE Class 12 Economics 2011 Question PaperDocument11 pagesCBSE Class 12 Economics 2011 Question PaperananyaNo ratings yet

- 4mezrab-E - ShoorDocument2 pages4mezrab-E - Shoorahmad.moradianNo ratings yet

- ME17 Wiring DiagramDocument1 pageME17 Wiring DiagramdavidNo ratings yet

- Borough: Ordinance To Install Business District Passes Parking JtletersDocument6 pagesBorough: Ordinance To Install Business District Passes Parking JtletersnarberthcivicNo ratings yet

- WWII 1944 UAV Tow Target ReportDocument18 pagesWWII 1944 UAV Tow Target ReportCAP History LibraryNo ratings yet

- FP PlanDocument5 pagesFP PlanMahmoud Abd ElhamidNo ratings yet

- CDCBP P086 Cp02a Jec SD Me 0002Document1 pageCDCBP P086 Cp02a Jec SD Me 0002Md ArifNo ratings yet

- PDF of SITE PLANDocument1 pagePDF of SITE PLANAR TitoNo ratings yet

- RudderDocument1 pageRudderyosua perdanaNo ratings yet

- Acero 2Document2 pagesAcero 2Emily MartinezNo ratings yet

- Condominio SAN DIEGO ALCALADocument3 pagesCondominio SAN DIEGO ALCALApapelera zarateNo ratings yet

- Our Town December 1, 1942Document4 pagesOur Town December 1, 1942narberthcivicNo ratings yet

- Icl F100Document1 pageIcl F100nicamarcosNo ratings yet

- Pdu Motorola MXv3Document2 pagesPdu Motorola MXv3Петров ДмитрийNo ratings yet

- Spe 113673 MsDocument7 pagesSpe 113673 MsБатырхан ИзбасарNo ratings yet

- NamastheDocument16 pagesNamastheP.SRIDHAR REDDYNo ratings yet

- Current Affairs 220517Document1 pageCurrent Affairs 220517Ravi VarmaNo ratings yet

- Manual Rk0232Document2 pagesManual Rk0232J AbrahanNo ratings yet

- Longman Living English Structure SearcablepdfDocument175 pagesLongman Living English Structure Searcablepdfrizkyansyah100% (2)

- 15Document2 pages15antzNo ratings yet

- Lamp CatDocument28 pagesLamp CatBagus GunataliantoNo ratings yet

- Our Town October 10, 1946Document12 pagesOur Town October 10, 1946narberthcivicNo ratings yet

- Contactos Auxiliares NSX100FDocument4 pagesContactos Auxiliares NSX100FLeonardoNo ratings yet

- Google Privacy Policy MRDocument9 pagesGoogle Privacy Policy MRlucasNo ratings yet

- 17658251723Document3 pages17658251723Mayur DeokarNo ratings yet

- Black & Decker Complete Home Improvement With 300 Projects and 2,000 Photos PDFDocument602 pagesBlack & Decker Complete Home Improvement With 300 Projects and 2,000 Photos PDFTab101 Woking100% (2)

- Hig An Av E: Egr and Rive Rav EDocument2 pagesHig An Av E: Egr and Rive Rav EPaul MarinescuNo ratings yet

- Comet User ManualDocument72 pagesComet User ManualAndy LNo ratings yet

- 11kV VCB Penal - PDF - Relay - Fuse (Electrical)Document17 pages11kV VCB Penal - PDF - Relay - Fuse (Electrical)vishwabaranNo ratings yet

- 29 General Problems RemediesDocument145 pages29 General Problems RemediesMahesh KumarNo ratings yet

- Sources Morale During Inf (15617958)Document3 pagesSources Morale During Inf (15617958)Emmanuel El GrecoNo ratings yet

- Aesop Kathakal (PDFDrive)Document556 pagesAesop Kathakal (PDFDrive)Lemon GundersonNo ratings yet

- Epistolae Et Evangelia Totius AnniDocument342 pagesEpistolae Et Evangelia Totius AnniPaddy PollockNo ratings yet

- Project Oxygas (15687530)Document2 pagesProject Oxygas (15687530)Mario Alberto Pineda CastilloNo ratings yet

- Flow Chart Project LogisticsDocument2 pagesFlow Chart Project LogisticsQadir MohideenNo ratings yet

- NT 2023 09 01 NID 5 - 03 7ccd4d 01092023100916 UxzDocument1 pageNT 2023 09 01 NID 5 - 03 7ccd4d 01092023100916 UxzRaja SNo ratings yet

- Published From: OnlineDocument16 pagesPublished From: Onlinerajesh1924No ratings yet

- Visithra JothiDocument569 pagesVisithra Jothimbhuvana jhojhoNo ratings yet

- Serra Geral Formation - São Paulo State, Brazil: A Source For Natural Pozzolanic MaterialsDocument6 pagesSerra Geral Formation - São Paulo State, Brazil: A Source For Natural Pozzolanic MaterialsFrancisco GulisanoNo ratings yet

- Eelvation-D 1: Al Maktoum International AirportDocument1 pageEelvation-D 1: Al Maktoum International AirportRicky KhannaNo ratings yet

- Feeding An Urban Population - Healthtech2Document51 pagesFeeding An Urban Population - Healthtech2DIANA MARIA DUEÑAS QUINTERONo ratings yet

- 19 Swipe Files Do John CaplesDocument20 pages19 Swipe Files Do John CaplesEvandro VianaNo ratings yet

- PDF Psicologia en El Futbol Videos Motivacionales CompressDocument21 pagesPDF Psicologia en El Futbol Videos Motivacionales CompressEduardo RojasNo ratings yet

- PDF Psicologia en El Futbol Videos Motivacionales - CompressDocument21 pagesPDF Psicologia en El Futbol Videos Motivacionales - CompressEduardo RojasNo ratings yet

- Plan Stands v1Document1 pagePlan Stands v1Anne de MalliardNo ratings yet

- Udrb PlansDocument52 pagesUdrb PlansNone None None100% (2)

- DTEC009257 1576371 D-PrintDocument60 pagesDTEC009257 1576371 D-PrintYoan Hoyos MartinezNo ratings yet

- Use & Care Guide Guide D'Utilisation Et D'Entretien Manual de Uso Y CuidadoDocument23 pagesUse & Care Guide Guide D'Utilisation Et D'Entretien Manual de Uso Y CuidadoRoshNo ratings yet

- Use & Care Guide Guide D'Utilisation Et D'Entretien Manual de Uso Y CuidadoDocument72 pagesUse & Care Guide Guide D'Utilisation Et D'Entretien Manual de Uso Y CuidadoFeligNo ratings yet

- Eurovision: Standard TuningDocument1 pageEurovision: Standard Tuningjilali mohcinNo ratings yet

- 9 - Bhattiacademy - Com - Chemistry - 5. Scholar Series (Obj)Document13 pages9 - Bhattiacademy - Com - Chemistry - 5. Scholar Series (Obj)Amir FarooqNo ratings yet

- West Godavari District MapDocument1 pageWest Godavari District MapCVS RAJUNo ratings yet

- West Godavari District Map PDFDocument1 pageWest Godavari District Map PDFCVS RAJUNo ratings yet

- CDCBP P086 Cp02a Jec SD Me 0002Document1 pageCDCBP P086 Cp02a Jec SD Me 0002Md ArifNo ratings yet

- Option 5Document1 pageOption 5Md ArifNo ratings yet

- EJ EJ EJ EJ: Central Doha & Corniche Beautification Project Package 2ADocument1 pageEJ EJ EJ EJ: Central Doha & Corniche Beautification Project Package 2AMd ArifNo ratings yet

- Key Plan: Project AffairsDocument1 pageKey Plan: Project AffairsMd ArifNo ratings yet

- SD 8-4-106 Rev 3 Structural NotesDocument1 pageSD 8-4-106 Rev 3 Structural NotesMd ArifNo ratings yet

- Section 3Document39 pagesSection 3Md ArifNo ratings yet

- Cust. Ref:: BAR Mark BAR Shape BAR LGTH NO. MEM BER Total No - of Bars No - of Member Each Each KG/M Weight SH CodeDocument2 pagesCust. Ref:: BAR Mark BAR Shape BAR LGTH NO. MEM BER Total No - of Bars No - of Member Each Each KG/M Weight SH CodeMd ArifNo ratings yet

- Section - 5 Section - 9 Section - 4: Key PlanDocument1 pageSection - 5 Section - 9 Section - 4: Key PlanMd ArifNo ratings yet

- Attachment B Site Plan: Proposed Pedestrian UnderpassDocument2 pagesAttachment B Site Plan: Proposed Pedestrian UnderpassMd ArifNo ratings yet

- UNIVERSAL BEAMS: Dimensions and Properties: Second Moment of Area Radius of Gyration Elastic Modulus Plastic ModulusDocument1 pageUNIVERSAL BEAMS: Dimensions and Properties: Second Moment of Area Radius of Gyration Elastic Modulus Plastic ModulusSri KayNo ratings yet

- SectionDocument1 pageSectionMd ArifNo ratings yet

- Central Doha & Corniche Beautification Project Package 2ADocument1 pageCentral Doha & Corniche Beautification Project Package 2AMd ArifNo ratings yet

- CDCBP P086 Cp02a Jec SD STR 1119 1Document1 pageCDCBP P086 Cp02a Jec SD STR 1119 1Md ArifNo ratings yet

- Design Calculation Structural Design Calculation For Lifting Beam (Heb400-S275) - 480KN LOADDocument4 pagesDesign Calculation Structural Design Calculation For Lifting Beam (Heb400-S275) - 480KN LOADMd ArifNo ratings yet

- Central Doha & Corniche Beautification - Package 2A Page 4 of 96 Microtunneling Shaft MT-3 Design Report CGD - Form.Tr - Rev02Document1 pageCentral Doha & Corniche Beautification - Package 2A Page 4 of 96 Microtunneling Shaft MT-3 Design Report CGD - Form.Tr - Rev02Md ArifNo ratings yet

- Address PDFDocument1 pageAddress PDFMd ArifNo ratings yet

- Design Calculation of Thrustblock: Central Doha & Corniche Beautification Package 2ADocument1 pageDesign Calculation of Thrustblock: Central Doha & Corniche Beautification Package 2AMd ArifNo ratings yet

- Comments Marked (p4b01 Gut GT Bas CVC 00 00 Dsu 1331)Document1 pageComments Marked (p4b01 Gut GT Bas CVC 00 00 Dsu 1331)Md ArifNo ratings yet

- Central Doha & Corniche Beautification - Package 2A Page 4 of 96 Microtunneling Shaft MT-3 Design Report CGD - Form.Tr - Rev02Document1 pageCentral Doha & Corniche Beautification - Package 2A Page 4 of 96 Microtunneling Shaft MT-3 Design Report CGD - Form.Tr - Rev02Md ArifNo ratings yet

- Design Calculation of Thrustblock: Central Doha & Corniche Beautification Package 2ADocument1 pageDesign Calculation of Thrustblock: Central Doha & Corniche Beautification Package 2AMd ArifNo ratings yet

- Tour Expences PDFDocument1 pageTour Expences PDFMd ArifNo ratings yet

- Tour ExpencesDocument1 pageTour ExpencesMd ArifNo ratings yet

- Seismic Design and Analysis of Underground StructuresDocument47 pagesSeismic Design and Analysis of Underground Structuresfoush basha100% (2)

- Honeywell RTH7500 InstallationDocument64 pagesHoneywell RTH7500 Installationtennis5luvNo ratings yet

- Revised Boq For Office & Linlk Building R01 12.05.2021Document5 pagesRevised Boq For Office & Linlk Building R01 12.05.2021SajeshKumarNo ratings yet

- Types of Pipes and Their UsesDocument8 pagesTypes of Pipes and Their UsesMENDOZA Marie GenielleNo ratings yet

- 12/31/20 DESIGN NO. - SECTION 15985 Sequence of Operation Part 1 - General 1.1. Description of WorkDocument367 pages12/31/20 DESIGN NO. - SECTION 15985 Sequence of Operation Part 1 - General 1.1. Description of WorkJhoNo ratings yet

- Handgun Safety Reference Owner'S Manual: International, IncDocument34 pagesHandgun Safety Reference Owner'S Manual: International, IncpreceptiveinquirerNo ratings yet

- Flow Line Fill Up Line: The Layout Scheme of The Cellar and The Wellhead For BK Rig On The 190melykhivka SiteDocument3 pagesFlow Line Fill Up Line: The Layout Scheme of The Cellar and The Wellhead For BK Rig On The 190melykhivka SiteЕвгений МусиенкоNo ratings yet

- Tightening Torques Lubricants Tools: AB 0100 EN Servicing SAMSON ProductsDocument184 pagesTightening Torques Lubricants Tools: AB 0100 EN Servicing SAMSON ProductsROSNo ratings yet

- Reece S2 Instruction ManualDocument80 pagesReece S2 Instruction ManualJuan pablo ChavezNo ratings yet

- KNIPEX EN Product-Data-Sheets 1252195 2020 V01 A4 RZ20200221Document2 pagesKNIPEX EN Product-Data-Sheets 1252195 2020 V01 A4 RZ20200221Abdullah AzzamNo ratings yet

- MCQ in Machine Design and Shop Practice Part 8 ME Board ExamDocument12 pagesMCQ in Machine Design and Shop Practice Part 8 ME Board Examtagne simo rodrigue100% (1)

- At 300Document11 pagesAt 300mne79054No ratings yet

- CNC TrainingDocument19 pagesCNC TrainingMahipal Singh RanawatNo ratings yet

- Promoções BETA WWW - Perfectool.ptDocument64 pagesPromoções BETA WWW - Perfectool.ptPerfectoolNo ratings yet

- Nautilus Crane - GA Drawing - OCRDocument12 pagesNautilus Crane - GA Drawing - OCREpuAmerNo ratings yet

- Erma Manual I. JhonsonDocument8 pagesErma Manual I. Jhonsonp317No ratings yet

- Model: Lever Action RifleDocument19 pagesModel: Lever Action RifleMauro AndradeNo ratings yet

- List of Indian Standards For Fire Fighting: Revision)Document2 pagesList of Indian Standards For Fire Fighting: Revision)Nanu PatelNo ratings yet

- Parts Manual: Cornelius - Viper 4 FlavorDocument16 pagesParts Manual: Cornelius - Viper 4 FlavorAndrewNo ratings yet

- New Holland Fr9060 Forage Harvester Parts CatalogDocument20 pagesNew Holland Fr9060 Forage Harvester Parts Catalogbrandon100% (42)

- Drill Chuck Key EZtipDocument1 pageDrill Chuck Key EZtipsivakumarNo ratings yet

- S08 Diesel Power PackDocument94 pagesS08 Diesel Power PackAlvaro GuerreroNo ratings yet

- Ultra - Temp Installation and Maintenance Manual IOM 101.2Document16 pagesUltra - Temp Installation and Maintenance Manual IOM 101.2Abdiel Kadir Martinez MendozaNo ratings yet

- TX Catalogue EnglishDocument12 pagesTX Catalogue EnglishDjuraTheHarpYNo ratings yet

- Kings Coppice - Flakt Woods - BACnet PointsDocument1 pageKings Coppice - Flakt Woods - BACnet Pointstonyhogg72No ratings yet

- Torrent G.I Job CardDocument5 pagesTorrent G.I Job Cardshanivi vrindavanNo ratings yet

- CAA Tactical Catalog 2012Document72 pagesCAA Tactical Catalog 2012PredatorBDU.comNo ratings yet

- ZF 5HP30 Transmission Repair ManualDocument104 pagesZF 5HP30 Transmission Repair ManualHaji RashidNo ratings yet

- HZL-F PartsList EngDocument34 pagesHZL-F PartsList EngSalman MajeedNo ratings yet

- Hydraulic Bolt TensioningDocument19 pagesHydraulic Bolt Tensioningadarsh100% (1)

- Yanbu: Export Refinery ProjectDocument8 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet