Professional Documents

Culture Documents

Abrasive Blasting and Coating

Abrasive Blasting and Coating

Uploaded by

rishibarathiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abrasive Blasting and Coating

Abrasive Blasting and Coating

Uploaded by

rishibarathiCopyright:

Available Formats

Abrasive Blasting and Coating

The following precautions shall be followed during abrasive blasting and coating operations:

Only qualified and certified individuals shall operate Abrasive blasting and coating

equipment.

All personnel in the area affected by abrasive blasting and coating shall wear proper

PPE and respiratory protection (e.g., ventilated hoods).

Supplied air for hoods or respirators shall be of the proper type (grade D) and the

delivery system per the manufacturer’s specifications.

Operators shall inspect compressors and the air delivery system on a regular basis.

Operators shall perform mechanical integrity testing (i.e., wall thickness

measurement) on equipment that will undergo abrasive blasting.

Only approved abrasive blasting materials shall be used. Silica sand is prohibited as

an abrasive blasting material.

Abrasive blasting and coating equipment shall be properly grounded/ bonded.

A deadman’s switch (automatic shut-off) is required on the abrasive blasting nozzle.

Proper safety pins and connecting lines shall be in place at all potential disconnect

points.

Fall protection is required for heights above 1.8 m (6 ft) (e.g., proper scaffolding,

work platforms, and harnesses).

Abrasive blasting and coating areas shall be properly contained.

Proper barricades and warning signs shall be in place.

Air compressors used to supply breathing air shall be third party certified.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Request Letter Format For Dormant Account ActivationDocument2 pagesRequest Letter Format For Dormant Account ActivationrishibarathiNo ratings yet

- CriteriaDocument1 pageCriteriarishibarathiNo ratings yet

- Cn2nl Doc List TourismDocument6 pagesCn2nl Doc List TourismrishibarathiNo ratings yet

- KWT - Tenders Dated 19.09.21Document20 pagesKWT - Tenders Dated 19.09.21rishibarathiNo ratings yet

- ADCO CV FormatDocument8 pagesADCO CV FormatrishibarathiNo ratings yet

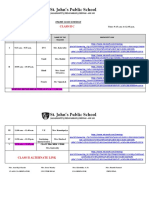

- St. John's Public School: Class Ii CDocument2 pagesSt. John's Public School: Class Ii CrishibarathiNo ratings yet

- Machinery Inspection ChecklistDocument3 pagesMachinery Inspection ChecklistrishibarathiNo ratings yet

- BSC Diploma CertificateDocument2 pagesBSC Diploma CertificaterishibarathiNo ratings yet

- Training MatrixDocument2 pagesTraining Matrixrishibarathi100% (2)

- Drilling Engineer AbubakerDocument20 pagesDrilling Engineer AbubakerrishibarathiNo ratings yet

- Environmental Challenges During DrillingDocument46 pagesEnvironmental Challenges During Drillingrishibarathi100% (1)

- Site Safety Plan: Project: Coal Handling TerminalDocument29 pagesSite Safety Plan: Project: Coal Handling Terminalrishibarathi100% (2)

- JSA Master 2021 HIRE MANPOWER REQUIRMENTS FOR SPLP-IIDocument25 pagesJSA Master 2021 HIRE MANPOWER REQUIRMENTS FOR SPLP-IIrishibarathiNo ratings yet

- Confined Space SOPDocument15 pagesConfined Space SOPrishibarathiNo ratings yet

- Careful Driving Prevents AccidentsDocument2 pagesCareful Driving Prevents AccidentsrishibarathiNo ratings yet

- Ectpl Hse Report DailyDocument2 pagesEctpl Hse Report DailyrishibarathiNo ratings yet

- Mock Drill PlanDocument1 pageMock Drill PlanrishibarathiNo ratings yet

- Compressed Gas Cylinder SafetyDocument3 pagesCompressed Gas Cylinder SafetyrishibarathiNo ratings yet

- IGD For Diesel Tank Inspection and CleaningDocument1 pageIGD For Diesel Tank Inspection and CleaningrishibarathiNo ratings yet