Professional Documents

Culture Documents

JSA Master 2021 HIRE MANPOWER REQUIRMENTS FOR SPLP-II

Uploaded by

rishibarathiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA Master 2021 HIRE MANPOWER REQUIRMENTS FOR SPLP-II

Uploaded by

rishibarathiCopyright:

Available Formats

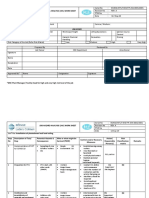

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

This procedure is to review work steps and their associated hazards to put in place correct solutions to eliminate or minimize the risk.

MANPOWER REQUIRMENTS

Job Type Client: SABIC (HADEED) Area: SPLP II

FOR SPLP-II TA

Estimated

PO # 4801909235 1 WEEK

Duration:

Scope of Works PROVIDING MANPOWER FOR TA WORKS

Document

Mahammad Haneef Date Prepared: 30 May 2021

Prepared By:

Height

Manual Electrical/ Confined Hazardous Forklift Truck/ Mechanical

Work/ Cranes Lay down Area

Handling Instrument Space Substances Mobile Plant Work

Scaffold

Job

Yes No Yes No Yes No Yes No Yes No Yes No Yes No Yes No Yes No

Elements:

ICMS HSE Plan and safety procedures are always to be followed:

Minimum PPE to be worn at all times.

General This JHA to be available at all points of work – operatives must be informed of this JHA and understand the risks involved in the works.

safety condition

requirements Toolbox talk / pre-job brief to be given at the start of each work shift and before starting a new task or activity.

Summer and Ramadan working hours changes are to be observed and details posted at worksite.

Paramedical or ambulance facilities to be available.

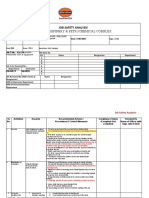

Activity / Task Mechanical Technician New Revised

Job Steps (Sub-Task) 1. Mechanical Works

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

2. Site preparation and mobilization of personnel,

materials, and equipment’s.

3. Working Under Extreme Heat Environment, Heat Stress.

4. COVID-19 prevention and protection.

5. Working with hand and power tools, Power & Drill

Machine.

6. Conduct of Housekeeping

Job Step SN Initial Risk Residual Responsibility

Hazard’s Control Measures Risk

Probability Severity Risk Probability Severity Risk Responsible

Person

• Unauthorized commencement of L3 C4 4 • Authorized Work permit holder shall L3 C5 3

works. ensure to obtain and maintain valid

1. • Unavailability of Work permit Work permit (and other required and

required attached certificates for approved documents)

the job. • The supervisor responsible for this

activity must check all required

certificates, photography permit and

other documents are attached and

placed on worksites.

• To comply with all necessary

documentations and permit

requirements prior to commencement

of activities.

• Poor Communication. L3 C4 4 • Discussion of work steps/sequences to L3 C5 3

all work members (with translation-if

possible) before the actual Activity

• Maintain and establish good

coordination and communication

between team members

• Shall have proper approval and

communication from Roots PMT,

Hadeed Focal Point and Station Permit

Authority/Controller for the activity

ICMS (International construction & manufacturing services)

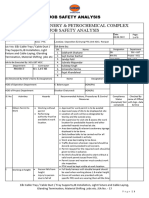

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

• Exposure to H2S L3 C4 4 • Ensure that no unauthorized personnel L3 C5 3

• Emergency in the working area.

• Personal H2S/Toxic Clip shall always be

worn.

• Ensure that all personnel should have a

valid H2S training ID Card.

• Ensure that gas testing done before

starting the activities.

• Ensure that all personnel fully

understand to raise alarm in event of an

emergency and all personnel are fully

aware the action to be taken in case of

emergency, the nearest muster point,

emergency number and the safe escape

route.

• Emergency response L3 C4 4 • Stop the work L3 C5 3

• Check wind direction

• Locate nearest Assembly point and

emergency exit

• Evacuate upside.

• Use H2S clip

• Inform Hadeed control room

• Use of emergency Hadeed number.

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

2. • Heat stroke/Stress • To follow State Law for summer

L3 C4 4 L3 C5 3

• Cramps/ Heat Exhaust working hours, outdoor activities during

• Dehydration summer shall have break down as pe

• Poor ventilation procedure.

• Follow Hadeed HSE Heat Stress

Management Guidelines & OH(D) Heat

Stress Management Plan.

• Rest shelters to be provided.

• Welfare facilities to be provided.

• Cool drinking water igloos to be

provided.

• Toolbox talk to be conducted and

ensure all workers aware to response in

heat stress risks, If any worker feel

dizzy, has a headache, moist, pale skin

or weak.

• Schedule work/rest/drink water as per

heat index

• requirements/ regulations.

• Warning flags to be displayed at

frequent locations.

• Avoid dehydration: rest and drink water

frequently.

• Personal water flask to be provided.

• No plastic (fizzy drink) bottles to be

used, disposable plastic cups for

drinking water to be provided.

• No water no work rule to be

implemented shall implement and

follow up the Heat Stress Prevention

Check List, any failure can lead to

stop/suspend the work activity.

• Heat index to be monitored hourly and

recorded with a calibrated Anemometer

and documented.

• Follow the work ratio as per heat stress

prevention measures.

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

3 • Biological Hazards L3 C4 4 • Ensure Temperature Screening for all L3 C4 3

• Cold & Flu Virus personnel involved of the activities.

• Ensure to check flu symptoms, fever,

cough, and shortness of breath

reported to immediate supervisor and

project management team.

• Ensure COVID-19 Mandatory PPE (mask,

disposable gloves, etc.) shall always be

worn.

• Keep working surfaces sanitized

• Avoid touching your face, your eyes and

mouth.

• Catch coughs and sneezes in a tissue.

Disposed of the tissue responsibly in

trash bin.

• Good Hygiene and clean environment

should be maintained. Wash your hands

frequently with soap and water and or

use hand sanitizers-alcohol.

• Maintain Social Distancing, minimum of

1.5 meter apart.

• Avoid direct contacts, no shaking hands

• Avoid spitting and direct contacts with

installation.

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

4 • Finger injuries (pinch, nip points) L3 C4 4 • Only experienced and competent L3 C5 3

• Hand and body injuries personnel to do the installation and

witness by Hadeed representative and

to be done in accordance with stated

procedure on approved method

statement.

• Ensure no deviation on procedure

stated on approved method statement.

• Proper manual handling technique

should be observed.

• Ensure that all hand tools used are in

good condition

• Wear appropriate gloves while

installation.

• Inspection of hand tools for damages

before use

• Ensure that all hand tools used are in

good condition

• Defective tools shall be removed from

service

• Dropped objects leading to feet L3 C4 4 • Close supervision while doing the L3 C5 3

injuries installation.

• Ensure that tools are secured, use tools

belt while doing the activity.

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

• Improper manual handling L3 C4 4 Use correct manual handling techniques L3 C5 3

Maintain good coordination and

communication between team

members

Access routes is clear from all potential

obstacles

Do not place hands and fingers in trap

points

Ensure adequate manpower for the job

• Slips/trips/falls L3 C4 4 Conduct walkways and access routes, L3 C5 3

access routes should be clear from all

potential obstacles

Use appropriate means of accessing

areas which is difficult to reach

Ensure hand and fingers away from

pinch points, sharp and protruding

objects.

Good command from the Supervisor

Ensure that all personnel will avoid

overreaching.

• Hand and finger injury.

L3 C4 4 Ensure De-termination, Removal of L3 C5 3

cables and cable glanding to be

Supervised by Site Supervisor and Site

Engineer

Keep hand and finger away from trap

points, sharp and protruding objects.

Wear appropriate type of gloves for the

activity.

• Hand and finger injury. Inspect hand and power tools prior to

5 • Rotating tools parts – entanglement L3 C4 4 each use L3 C5 3

• Cuts, rush, bruises, electrocution, All hand power tools shall be physically

• Flying debris/dust inspected and tested by competent

• Hand and eye injuries personnel

• Sharp edges If using battery drills, ensure to remove

the battery before replacing or

installing new drill bits

Ensure that only trained and

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

experienced personnel will operate the

drill

Continuous training/awareness sessions

be conducted to all users and

Supervisors

Install visual tags/labels for power

toolsas reminders on safe its safe use

Never remove safety guard from

powers tools

Do not rush is replacement of drill bits.

Do not take shortcuts

Do not operate in wet or damp

environments

User to be familiar with the safety

switch of each power tools

Before servicing any power tools, such

as changing drill bits, saw blades, or

grinding wheels, you must unplug the

tools

Damage tools or equipment’s shall be

removed from service and tagged”

Damage”

Only appropriate tools shall be used for

the job. Do not use makeshift tools

Ensure hands, feet and loose clothing

are kept clear from moving parts of the

drill.

Ensure Drill bit is tightened, drill

checked properly

Always maintain good housekeeping.

Appropriate PPE for the task must be

used, such as eyeglasses, gloves, face

shields and earplug (as applicabel) shall

be available when using hand and

power tools

6 • Trips and falls/Sharp Objects L3 C4 4 All waste generated shall be contained L3 C5 4

and disposed off in designated waste

areas

All materials shall be removed from the

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

site to a safe storage location

immediately after the work

Activity / Task Electrician New Revised

Job Steps (Sub-Task) 1. Electrician Works site preparation and mobilization of

personnel, materials, and equipment’s.

2. Working Under Extreme Heat Environment, Heat

Stress.

3. COVID-19 prevention and protection.

4. Installation of barricades around working area.

5. Working with Electrical Equipment’s Using Hand

tools, Testing equipment’s.

6. Conduct of Housekeeping

Job Step SN Initial Risk Residual Responsibility

Hazard’s Control Measures Risk

Probability Severity Risk Probability Severity Risk Responsible

Person

• Unauthorized commencement of L3 C4 4 • Authorized Work permit holder shall L3 C5 3

works. ensure to obtain and maintain valid

1. • Unavailability of Work permit Work permit (and other required and

required attached certificates for approved documents)

the job. • The supervisor responsible for this

activity must check all required

certificates, photography permit and

other documents are attached and

placed on worksites.

• To comply with all necessary

documentations and permit

requirements prior to commencement

of activities.

• Poor Communication. L3 C4 4 • Discussion of work steps/sequences to L3 C5 3

all work members (with translation-if

possible) before the actual Activity

• Maintain and establish good

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

coordination and communication

between team members

• Shall have proper approval and

communication from Roots PMT,

Hadeed Focal Point and Station Permit

Authority/Controller for the activity

• Exposure to H2S L3 C4 4 • Ensure that no unauthorized personnel L3 C5 3

• Emergency in the working area.

• Personal H2S/Toxic Clip shall always be

worn.

• Ensure that all personnel should have a

valid H2S training ID Card.

• Ensure that gas testing done before

starting the activities.

• Ensure that all personnel fully

understand to raise alarm in event of an

emergency and all personnel are fully

aware the action to be taken in case of

emergency, the nearest muster point,

emergency number and the safe escape

route.

• Emergency response L3 C4 4 • Stop the work L3 C5 3

• Check wind direction

• Locate nearest Assembly point and

emergency exit

• Evacuate upside.

• Use H2S clip

• Inform Hadeed control room

• Use of emergency Hadeed number.

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

2. • Heat stroke/Stress • To follow State Law for summer

L3 C4 4 L3 C5 3

• Cramps/ Heat Exhaust working hours, outdoor activities during

• Dehydration summer shall have break down as pe

• Poor ventilation procedure.

• Follow Hadeed HSE Heat Stress

Management Guidelines & OH(D) Heat

Stress Management Plan.

• Rest shelters to be provided.

• Welfare facilities to be provided.

• Cool drinking water igloos to be

provided.

• Toolbox talk to be conducted and

ensure all workers aware to response in

heat stress risks, If any worker feel

dizzy, has a headache, moist, pale skin

or weak.

• Schedule work/rest/drink water as per

heat index

• requirements/ regulations.

• Warning flags to be displayed at

frequent locations.

• Avoid dehydration: rest and drink water

frequently.

• Personal water flask to be provided.

• No plastic (fizzy drink) bottles to be

used, disposable plastic cups for

drinking water to be provided.

• No water no work rule to be

implemented shall implement and

follow up the Heat Stress Prevention

Check List, any failure can lead to

stop/suspend the work activity.

• Heat index to be monitored hourly and

recorded with a calibrated Anemometer

and documented.

• Follow the work ratio as per heat stress

prevention measures.

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

3 • Biological Hazards L3 C4 4 • Ensure Temperature Screening for all L3 C4 3

• Cold & Flu Virus personnel involved of the activities.

• Ensure to check flu symptoms, fever,

cough, and shortness of breath

reported to immediate supervisor and

project management team.

• Ensure COVID-19 Mandatory PPE (mask,

disposable gloves, etc.) shall always be

worn.

• Keep working surfaces sanitized

• Avoid touching your face, your eyes and

mouth.

• Catch coughs and sneezes in a tissue.

Disposed of the tissue responsibly in

trash bin.

• Good Hygiene and clean environment

should be maintained. Wash your hands

frequently with soap and water and or

use hand sanitizers-alcohol.

• Maintain Social Distancing, minimum of

1.5 meter apart.

• Avoid direct contacts, no shaking hands

• Avoid spitting and direct contacts with

installation.

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

4 • Hand and body injuries L3 C4 4 • Maintain proper distances when L3 C5 3

installing barricade using safety cones.

• Close supervision by the Site Supervisor

• Keep hand and fingers away from trap

points. Ensure activity to be Supervised

by Site Supervisor and Site Engineer

• Keep hand and finger away from trap

points, sharp and protruding objects.

• Wear appropriate type of gloves for the

activity.

• Electric Shock – (Possible contact Give emphasis on precautions with

5 with energized system) L3 C4 4 respect to inherent hazards nearby at L3 C5 3

the energized installation, panels and

equipment’s particularly on high

voltage hazards

Never allow any team member to touch

or get near any energized, live/running

equipment and all personnel involved in

Verification & Energization and should

be aware of nearby running system.

Close supervision from the Site

Supervisor and Site Engineers at all

times.

Establish close communication to all

members.

• Working without PTW To comply with all necessary

L3 C4 4 documentations and permit L3 C5 3

requirements prior to commencement

of activities

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

• Failure or Accidental System Ensure that activities should be done by

Shutdown L3 C4 4 competent trained personnel with L3 C5 3

appropriate authorization involved in

the task and to the Batteries testing and

Verification & Engergization activities.

Ensure that no unauthorized personnel

in the working area.

Ensure that Equipment calibrated and

in good condition

Ensure to use correct tools for the task.

Verification & Engergization activities

on Batteries should be done as per

stated on approved method statement.

Shall have proper approval by Permit

Authority/Controller for the Verification

& Engergization activities

Follow battery manufacturer’s

recommended Verification &

Engergization procedure.

Measure and record the voltage of each

battery cells before charging (also total

voltage and ambient & battery cell

temperature)

Measure and record the voltage of each

battery cells during charging, as well as

total dc, current, AC ripple, ambient

temperature and battery temperature.

Perform battery discharge test

according to battery manufacturer’s

discharge data.

• Electric shock Check insulation of all electrical cords.

L3 C4 4 No exposed wires. L3 C5 3

Remove any body accessories which

can be a conductor of electricity

Only competent and authorized

Electricians to do the job under

supervision of Electrical

Supervisor/Engineer and in accordance

with approved method statement.

Shall have proper approval by Permit

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

Authority/Controller for the testing and

Verification & Engergization activities

and Ensure that all electrical cabling

works are completed and inspected by

authorized QP personnel and QA/QC

Engineers

• Fire Explosion. Suitable fire extinguisher (co2/dry

L3 C4 4 powder) & blanket should be available L3 C5 3

prior to carrying out testing works.

6 • Trips and falls/Sharp Objects L3 C4 4 All waste generated shall be contained L3 C5 3

and disposed off in designated waste

areas

All materials shall be removed from the

site to a safe storage location

immediately after the work

Activity / Task Hydraulic Fitter New Revised

Job Steps (Sub-Task) 1. Hydraulic Works site preparation and mobilization of

personnel, materials, and equipment’s.

2. Working Under Extreme Heat Environment, Heat

Stress.

3. COVID-19 prevention and protection.

4. Working with hand and power tools, Power & Drill

Machine.

5. Conduct of Housekeeping

Job Step SN Initial Risk Residual Responsibility

Hazard’s Control Measures Risk

Probability Severity Risk Probability Severity Risk Responsible

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

Person

• Unauthorized commencement of L3 C4 4 • Authorized Work permit holder shall L3 C5 3

works. ensure to obtain and maintain valid

1. • Unavailability of Work permit Work permit (and other required and

required attached certificates for approved documents)

the job. • The supervisor responsible for this

activity must check all required

certificates, photography permit and

other documents are attached and

placed on worksites.

• To comply with all necessary

documentations and permit

requirements prior to commencement

of activities.

• Poor Communication. L3 C4 4 • Discussion of work steps/sequences to L3 C5 3

all work members (with translation-if

possible) before the actual Activity

• Maintain and establish good

coordination and communication

between team members

• Shall have proper approval and

communication from Roots PMT,

Hadeed Focal Point and Station Permit

Authority/Controller for the activity

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

• Exposure to H2S L3 C4 4 • Ensure that no unauthorized personnel L3 C5 3

• Emergency in the working area.

• Personal H2S/Toxic Clip shall always be

worn.

• Ensure that all personnel should have a

valid H2S training ID Card.

• Ensure that gas testing done before

starting the activities.

• Ensure that all personnel fully

understand to raise alarm in event of an

emergency and all personnel are fully

aware the action to be taken in case of

emergency, the nearest muster point,

emergency number and the safe escape

route.

• Emergency response L3 C4 4 • Stop the work L3 C5 3

• Check wind direction

• Locate nearest Assembly point and

emergency exit

• Evacuate upside.

• Use H2S clip

• Inform Hadeed control room

• Use of emergency Hadeed number.

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

2. • Heat stroke/Stress • To follow State Law for summer

L3 C4 4 L3 C5 3

• Cramps/ Heat Exhaust working hours, outdoor activities during

• Dehydration summer shall have break down as pe

• Poor ventilation procedure.

• Follow Hadeed HSE Heat Stress

Management Guidelines & OH(D) Heat

Stress Management Plan.

• Rest shelters to be provided.

• Welfare facilities to be provided.

• Cool drinking water igloos to be

provided.

• Toolbox talk to be conducted and

ensure all workers aware to response in

heat stress risks, If any worker feel

dizzy, has a headache, moist, pale skin

or weak.

• Schedule work/rest/drink water as per

heat index

• requirements/ regulations.

• Warning flags to be displayed at

frequent locations.

• Avoid dehydration: rest and drink water

frequently.

• Personal water flask to be provided.

• No plastic (fizzy drink) bottles to be

used, disposable plastic cups for

drinking water to be provided.

• No water no work rule to be

implemented shall implement and

follow up the Heat Stress Prevention

Check List, any failure can lead to

stop/suspend the work activity.

• Heat index to be monitored hourly and

recorded with a calibrated Anemometer

and documented.

• Follow the work ratio as per heat stress

prevention measures.

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

3 • Biological Hazards L3 C4 4 • Ensure Temperature Screening for all L3 C4 3

• Cold & Flu Virus personnel involved of the activities.

• Ensure to check flu symptoms, fever,

cough, and shortness of breath

reported to immediate supervisor and

project management team.

• Ensure COVID-19 Mandatory PPE (mask,

disposable gloves, etc.) shall always be

worn.

• Keep working surfaces sanitized

• Avoid touching your face, your eyes and

mouth.

• Catch coughs and sneezes in a tissue.

Disposed of the tissue responsibly in

trash bin.

• Good Hygiene and clean environment

should be maintained. Wash your hands

frequently with soap and water and or

use hand sanitizers-alcohol.

• Maintain Social Distancing, minimum of

1.5 meter apart.

• Avoid direct contacts, no shaking hands

• Avoid spitting and direct contacts with

installation.

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

4 • Finger injuries (pinch, nip points) L3 C4 4 • Only experienced and competent L3 C5 3

• Hand and body injuries personnel to do the installation and

witness by Hadeed representative and

to be done in accordance with stated

procedure on approved method

statement.

• Perform preoperational inspection

• Connect the wrench to the hydraulic

pump

• Plug in the hydraulic pump

• Start the pump

• Test the function of the wrench and

pump

• Setting the Reaction Arm

• Setting Torque

• Setting the appropriate pressure on the

Pump

• Ensure no deviation on procedure

stated on approved method statement.

• Proper manual handling technique

should be observed.

• Ensure that all hand tools used are in

good condition

• Wear appropriate gloves while

installation.

• Inspection of hand tools for damages

before use

• Ensure that all hand tools used are in

good condition

• Defective tools shall be removed from

service

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

• Dropped objects leading to feet L3 C4 4 • Close supervision while doing the L3 C5 3

injuries installation.

• Ensure that tools are secured, use tools

belt while doing the activity.

• Improper manual handling L3 C4 4 Use correct manual handling techniques L3 C5 3

Maintain good coordination and

communication between team

members

Access routes is clear from all potential

obstacles

Do not place hands and fingers in trap

points

Ensure adequate manpower for the job

• Slips/trips/falls L3 C4 4 Conduct walkways and access routes, L3 C5 3

access routes should be clear from all

potential obstacles

Use appropriate means of accessing

areas which is difficult to reach

Ensure hand and fingers away from

pinch points, sharp and protruding

objects.

Good command from the Supervisor

Ensure that all personnel will avoid

overreaching.

• Hand and finger injury. Inspect hand and power tools prior to

5 • Rotating tools parts – entanglement L3 C4 4 each use L3 C5 3

• Cuts, rush, bruises, electrocution, All hand power tools shall be physically

• Flying debris/dust inspected and tested by competent

• Hand and eye injuries personnel

• Sharp edges If using battery drills, ensure to remove

the battery before replacing or

installing new drill bits

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

Ensure that only trained and

experienced personnel will operate the

drill

Continuous training/awareness sessions

be conducted to all users and

Supervisors

Install visual tags/labels for power

toolsas reminders on safe its safe use

Never remove safety guard from

powers tools

Do not rush is replacement of drill bits.

Do not take shortcuts

Do not operate in wet or damp

environments

User to be familiar with the safety

switch of each power tools

Before servicing any power tools, such

as changing drill bits, saw blades, or

grinding wheels, you must unplug the

tools

Damage tools or equipment’s shall be

removed from service and tagged”

Damage”

Only appropriate tools shall be used for

the job. Do not use makeshift tools

Ensure hands, feet and loose clothing

are kept clear from moving parts of the

drill.

Ensure Drill bit is tightened, drill

checked properly

Always maintain good housekeeping.

Appropriate PPE for the task must be

used, such as eyeglasses, gloves, face

shields and earplug (as applicabel) shall

be available when using hand and

power tools

6 • Trips and falls/Sharp Objects L3 C4 4 All waste generated shall be contained L3 C5 4

and disposed off in designated waste

areas

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

All materials shall be removed from the

site to a safe storage location

immediately after the work

Prepared by: HSE Engineer Acknowledged by Section Manager:

Name:__________________ _________________________Signature:__________________________ Badge:__________

JSA Team Members

Team members include area owner, maintenance, EHSS, Technical supervisor or engineer. if needed, contractor (if job is to be done through

the contractor)

Name: ________________ Signature: _________________ Badge: ______

Name ID Department Signature Date

Note: For risks cannot be reduced or mitigate after formal JSA study,

then approval shall be obtained as per SHEM-02 SAFER requirement.

Approved by Department / Operation Manager:

Name:____________________________________ Signature:______________________________ Badge: ___________

Approved By

SN HOD Department Signature Date

01

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

Note: If Residual Risk is, Significant and above SAFER Approval Required.

ENDORSEMENT SECTION (This section shall be filled incase this document use for same scope of work in future)

Date Section Manager (Signature) Area Manager (Signature) Validity Date

SFM-08.10-SHEM-0

Emergency Procedures

In an emergency, or if a “stop work alarm” sounds.

Stop work

Shutdown the equipment

Evacuate personnel to assembly points

Account for every man. (Head Count)

Re-enter work area only with permission from HSE & Security representative after hearing the all clear alarm.

Emergency Response

If Plant emergency should arise, the Emergency Action Plan, approved by ……………………. shall be followed.

Note: The Project In –charge, Safety Officer, Supervisor, or employee shall stop all works in the event of emergency evacuation.

In case of emergency Call: .......................................

Pre-work instruction to all personnel exposed to hazards. Outline precautions. Attendees to sign form which is attached to work permit documents.

ICMS (International construction & manufacturing services)

JOB SAFETY ANALYSIS (JSA) AND HAZARDIDENTIFICATION PLAN (HIP):

ICMS (International construction & manufacturing services)

You might also like

- Hornbill Property DevelopersDocument20 pagesHornbill Property DevelopersSmiley Suresh89% (9)

- Jha For Batching Plant OprationDocument7 pagesJha For Batching Plant Oprationpoovazhagan80% (5)

- Jsa-0002 - CCTV Pipe Inspection RapidDocument8 pagesJsa-0002 - CCTV Pipe Inspection RapidMohamad AfifNo ratings yet

- Lesson Plan - Sight Word ObservationDocument2 pagesLesson Plan - Sight Word Observationapi-253277023No ratings yet

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- Method Statement WeldingDocument9 pagesMethod Statement Weldingkiki270977No ratings yet

- Risk Assessment For Trial Pit Excavation-RevDocument15 pagesRisk Assessment For Trial Pit Excavation-RevRawoofuddin ChandNo ratings yet

- IGC 2 - Installation of Automatic Fare Gate System - SubmissionDocument18 pagesIGC 2 - Installation of Automatic Fare Gate System - SubmissionVivek Vj67% (3)

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius DsouzaNo ratings yet

- JSA Installation of PumpsDocument6 pagesJSA Installation of Pumpsyc safety100% (2)

- To Tell The TruthDocument5 pagesTo Tell The TruthNabeel Ahmed KhanNo ratings yet

- Sketch NotesDocument32 pagesSketch NotesFilipe Rovarotto100% (8)

- JSA GI Earthstrip at PTAO&M Building 05Document5 pagesJSA GI Earthstrip at PTAO&M Building 05Saiyad RiyazaliNo ratings yet

- 5-6. Overhauling of TGS & CGS JSA HADEED MODULE A-BDocument8 pages5-6. Overhauling of TGS & CGS JSA HADEED MODULE A-Bammar mughalNo ratings yet

- 26.RG Cooler Overhauling, Pipe Work and Seal Leg Replacement JSA HADEED MODULE A-BDocument8 pages26.RG Cooler Overhauling, Pipe Work and Seal Leg Replacement JSA HADEED MODULE A-Bammar mughalNo ratings yet

- Jsa-0001 - Excavation Cipp RapidDocument11 pagesJsa-0001 - Excavation Cipp RapidMohamad Afif100% (1)

- Day 3 Job Hazard Analysis (Handout)Document6 pagesDay 3 Job Hazard Analysis (Handout)mike camsNo ratings yet

- StockYard Conveyor System Overhauling JSA HADEED MODULE A-BDocument8 pagesStockYard Conveyor System Overhauling JSA HADEED MODULE A-Bammar mughalNo ratings yet

- 01 Method Statement For Electrical Cable TerminationDocument4 pages01 Method Statement For Electrical Cable TerminationHimanshu NiveriyaNo ratings yet

- JSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaDocument4 pagesJSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaMohammed Minhaj100% (1)

- Jsa Steel ErectionDocument9 pagesJsa Steel Erection01095902062ahmedNo ratings yet

- ICS SMNCI RA 007 Cable Wire TerminationDocument7 pagesICS SMNCI RA 007 Cable Wire TerminationJayson EscamillanNo ratings yet

- Jsa For TIE INS in Accommodation BlockDocument4 pagesJsa For TIE INS in Accommodation BlockAliNo ratings yet

- JSA Tie in ActivitiesDocument15 pagesJSA Tie in ActivitiesQADEER SHANNo ratings yet

- ACMV Hirac - Tipping RoomDocument19 pagesACMV Hirac - Tipping RoomNethiyaaRajendranNo ratings yet

- DEL - 062 Punch List Killing of Switch RoomDocument7 pagesDEL - 062 Punch List Killing of Switch RoomCaminBonNo ratings yet

- Job Safety Analysis / Permit To WorkDocument3 pagesJob Safety Analysis / Permit To WorkSEDAM 9656100% (1)

- Safety Campaign - Awareness On Permit To Work SystemDocument36 pagesSafety Campaign - Awareness On Permit To Work SystemsivaNo ratings yet

- C164 JSA Forr Tie On Fire Water Line On South Side of Train 1Document3 pagesC164 JSA Forr Tie On Fire Water Line On South Side of Train 1CaminBonNo ratings yet

- MS Excavation WorksDocument5 pagesMS Excavation WorksLethal IllusionNo ratings yet

- ACMV Hirac - Mcintyre Boiler AreaDocument14 pagesACMV Hirac - Mcintyre Boiler AreaNethiyaaRajendranNo ratings yet

- PipingDocument9 pagesPipingshamierrul shahliNo ratings yet

- Hydro TestDocument8 pagesHydro Testmozzammil saqibNo ratings yet

- Ir Power Plant - Left Padlock Key and No Id TagDocument21 pagesIr Power Plant - Left Padlock Key and No Id Tagsafetyassistant23No ratings yet

- Work Inspection Checklist: Project DetailsDocument1 pageWork Inspection Checklist: Project Detailsmark lester caluzaNo ratings yet

- Job Safety SiteDocument11 pagesJob Safety SiteMohd Arfeen RezaNo ratings yet

- E&I - 13, JSA For Separation & Drying AreaDocument8 pagesE&I - 13, JSA For Separation & Drying AreaNikunja mohantyNo ratings yet

- SWMS (Cable Glanding and Termination )Document6 pagesSWMS (Cable Glanding and Termination )PRIYESH . K. PRIYANNo ratings yet

- DEL - 064 Jsa For Load Test of Davit ArmsDocument4 pagesDEL - 064 Jsa For Load Test of Davit ArmsMohammed Minhaj100% (1)

- ACMV Hirac - Mcintyre Prep Room 2Document13 pagesACMV Hirac - Mcintyre Prep Room 2NethiyaaRajendranNo ratings yet

- Paint Work Using Mobile Crane PSO FSD.Document5 pagesPaint Work Using Mobile Crane PSO FSD.fiazhussaindbxNo ratings yet

- WSWP For Hamisa Installation of Lift FramesDocument6 pagesWSWP For Hamisa Installation of Lift FramesVictor Thembinkosi MakhubeleNo ratings yet

- ETV-IBMS-SWMS For Perforated GI Cable Tray With Cover InstallationDocument6 pagesETV-IBMS-SWMS For Perforated GI Cable Tray With Cover InstallationPRIYESH . K. PRIYANNo ratings yet

- Unit IG2: Risk AssessmentDocument23 pagesUnit IG2: Risk AssessmentGoutham Jkumar100% (1)

- JSA-control Panel Final Reviwed AVCDocument5 pagesJSA-control Panel Final Reviwed AVCSubhash Chekka SEC 115KV ProjectNo ratings yet

- PTW in Working at HeightDocument1 pagePTW in Working at Heightbach.pham0932719192No ratings yet

- MS FSK Demolition 071119Document2 pagesMS FSK Demolition 071119DilxazNo ratings yet

- Chandu Raveendran 00643493Document13 pagesChandu Raveendran 00643493rah uaeNo ratings yet

- MS FSK PSK Fiber Optic 031120Document3 pagesMS FSK PSK Fiber Optic 031120DilxazNo ratings yet

- Contractor Permitting PolicyDocument5 pagesContractor Permitting PolicyMark RusianaNo ratings yet

- Jsa For Installation of Bracket in Phase 1Document4 pagesJsa For Installation of Bracket in Phase 1Mohammed Minhaj100% (1)

- JSA Contruction of Pipe Rack (3m) Footing Including Welding JobDocument10 pagesJSA Contruction of Pipe Rack (3m) Footing Including Welding Jobnoahlungu96No ratings yet

- Job Safety Analysis Work SheetDocument5 pagesJob Safety Analysis Work SheetMuhammad UsmanNo ratings yet

- Overhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Document5 pagesOverhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Javid AaqibNo ratings yet

- Door Window and Roller ShutterDocument7 pagesDoor Window and Roller Shuttershamierrul shahliNo ratings yet

- Block Work MSDocument19 pagesBlock Work MSjonesNo ratings yet

- Asad 2Document17 pagesAsad 2mysticmirza1No ratings yet

- 5.3-Safe Work PermittingDocument12 pages5.3-Safe Work PermittingBsvk Dupana100% (1)

- Nebosh International Technical Certificate in Oil and Gas Operational SafetyDocument27 pagesNebosh International Technical Certificate in Oil and Gas Operational SafetyHtoo Htoo KyawNo ratings yet

- 5.19 JSP Self Levelling Epoxy Painting ActivityDocument8 pages5.19 JSP Self Levelling Epoxy Painting Activitymuhammad.younisNo ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- Scope On Field Instrument Calibration - 2023Document3 pagesScope On Field Instrument Calibration - 2023ISAACNo ratings yet

- Request Letter Format For Dormant Account ActivationDocument2 pagesRequest Letter Format For Dormant Account ActivationrishibarathiNo ratings yet

- Cn2nl Doc List TourismDocument6 pagesCn2nl Doc List TourismrishibarathiNo ratings yet

- KWT - Tenders Dated 19.09.21Document20 pagesKWT - Tenders Dated 19.09.21rishibarathiNo ratings yet

- CriteriaDocument1 pageCriteriarishibarathiNo ratings yet

- ADCO CV FormatDocument8 pagesADCO CV FormatrishibarathiNo ratings yet

- BSC Diploma CertificateDocument2 pagesBSC Diploma CertificaterishibarathiNo ratings yet

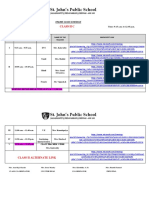

- St. John's Public School: Class Ii CDocument2 pagesSt. John's Public School: Class Ii CrishibarathiNo ratings yet

- Drilling Engineer AbubakerDocument20 pagesDrilling Engineer AbubakerrishibarathiNo ratings yet

- Environmental Challenges During DrillingDocument46 pagesEnvironmental Challenges During Drillingrishibarathi100% (1)

- Machinery Inspection ChecklistDocument3 pagesMachinery Inspection ChecklistrishibarathiNo ratings yet

- Ectpl Hse Report DailyDocument2 pagesEctpl Hse Report DailyrishibarathiNo ratings yet

- Training MatrixDocument2 pagesTraining Matrixrishibarathi100% (2)

- Mock Drill PlanDocument1 pageMock Drill PlanrishibarathiNo ratings yet

- Confined Space SOPDocument15 pagesConfined Space SOPrishibarathiNo ratings yet

- Site Safety Plan: Project: Coal Handling TerminalDocument29 pagesSite Safety Plan: Project: Coal Handling Terminalrishibarathi100% (2)

- Careful Driving Prevents AccidentsDocument2 pagesCareful Driving Prevents AccidentsrishibarathiNo ratings yet

- Compressed Gas Cylinder SafetyDocument3 pagesCompressed Gas Cylinder SafetyrishibarathiNo ratings yet

- IGD For Diesel Tank Inspection and CleaningDocument1 pageIGD For Diesel Tank Inspection and CleaningrishibarathiNo ratings yet

- Ddec VDocument30 pagesDdec Vllama100% (1)

- HLA HART Concept of LawDocument19 pagesHLA HART Concept of LawHarneet KaurNo ratings yet

- Pemisah ZirconDocument10 pagesPemisah ZirconLorie Banka100% (1)

- T HR El 20003 ST PDFDocument20 pagesT HR El 20003 ST PDFAngling Dharma100% (1)

- Adolescents and Career DevelopmentDocument10 pagesAdolescents and Career DevelopmentMasrijah MasirNo ratings yet

- Technology For Duck - Fish Integrated Farming System in GoaDocument4 pagesTechnology For Duck - Fish Integrated Farming System in GoagavinilaaNo ratings yet

- Malnutrition Case StudyDocument3 pagesMalnutrition Case Studyapi-622273373No ratings yet

- Month Puzzle Two VariableDocument6 pagesMonth Puzzle Two VariableNayan KaithwasNo ratings yet

- Management Accounting/Series-4-2011 (Code3024)Document18 pagesManagement Accounting/Series-4-2011 (Code3024)Hein Linn Kyaw100% (2)

- Rotex GS Zero-Backlash Shaft CouplingDocument19 pagesRotex GS Zero-Backlash Shaft CouplingIrina DimitrovaNo ratings yet

- Decs vs. San DiegoDocument7 pagesDecs vs. San Diegochini17100% (2)

- Simulation of 1,3-Butadiene Extractive Distillation Process Using N-Methyl-2-Pyrrolidone SolventDocument7 pagesSimulation of 1,3-Butadiene Extractive Distillation Process Using N-Methyl-2-Pyrrolidone SolventAA0809No ratings yet

- Periodicity Review SL KeyDocument4 pagesPeriodicity Review SL KeyYeyoung ParkNo ratings yet

- Pipetite: Pipetite Forms A Flexible, Sanitary Seal That Allows For Pipeline MovementDocument4 pagesPipetite: Pipetite Forms A Flexible, Sanitary Seal That Allows For Pipeline MovementAngela SeyerNo ratings yet

- Transformational Leadership in The UmcDocument17 pagesTransformational Leadership in The Umcapi-202352366No ratings yet

- Text Descriptive Tentang HewanDocument15 pagesText Descriptive Tentang HewanHAPPY ARIFIANTONo ratings yet

- THE PERFECT DAY Compressed 1 PDFDocument218 pagesTHE PERFECT DAY Compressed 1 PDFMariaNo ratings yet

- Root End Filling MaterialsDocument9 pagesRoot End Filling MaterialsRuchi ShahNo ratings yet

- Algorithm Design: Figure 1. Architecture Diagram For Greykite Library's Main Forecasting Algorithm, SilverkiteDocument3 pagesAlgorithm Design: Figure 1. Architecture Diagram For Greykite Library's Main Forecasting Algorithm, Silverkitesiper34606No ratings yet

- Roles of Community Health NursingDocument2 pagesRoles of Community Health Nursingdy kimNo ratings yet

- Bachelors of Engineering: Action Research Project - 1Document18 pagesBachelors of Engineering: Action Research Project - 1manasi rathiNo ratings yet

- VectorCAST QA Factsheet ENDocument2 pagesVectorCAST QA Factsheet ENChaos XiaNo ratings yet

- TuberkulosisDocument285 pagesTuberkulosisTeuku M. FebriansyahNo ratings yet

- Charging Station For E-Vehicle Using Solar With IOTDocument6 pagesCharging Station For E-Vehicle Using Solar With IOTjakeNo ratings yet

- PICUDocument107 pagesPICUsarikaNo ratings yet

- (Official) AVTC5 - Unit 1 - Before ClassDocument11 pages(Official) AVTC5 - Unit 1 - Before ClassNhân NguyễnNo ratings yet

- Module 2 - Part III - UpdatedDocument38 pagesModule 2 - Part III - UpdatedDhriti NayyarNo ratings yet