Professional Documents

Culture Documents

ICS SMNCI RA 007 Cable Wire Termination

Uploaded by

Jayson EscamillanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ICS SMNCI RA 007 Cable Wire Termination

Uploaded by

Jayson EscamillanCopyright:

Available Formats

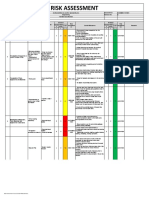

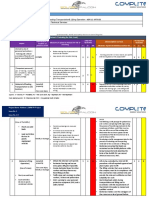

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-007

Department/s Engineering Revision No 0

Job Description Termination Works

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• Coordinate the activity to the Project End-user

and Project Owner before commencing.

• Follow Schedule and arrange the required

document to avoid any cause of delay.

• Miscommunication

• Delay to schedule

with the Project End- • Refer to gant chart as the reference for

and work activity.

user and Project

• May result in preparing PTW.

Preparation of documents or Owner MEDIUM • Supervisor and Safety Officer shall ensure

1 exposing workers and 3 2 6 2 1 2 LOW RISK

Permit To Work (PTW) • Unauthorized RISK obtaining and maintaining valid work permit and

or potential to harm

commencement of

and danger. all mandatory associated permits.

works

• Inform all workers regarding permit condition

before work starts.

• Supervisor shall conduct toolbox talks about

•nature of works

Provide and associated

an awareness training potential

regarding line of

hazards

fire and their

and hand essential

finger safety. precautionary

measure.

Preparation of Tools, • Cuts, wound/hand • Know the hazards and dangers in the job to be

2 • Pinch point 4 3 12 HIGH RISK 2 2 4 LOW RISK

Equipments and Materials injury done.

• Be aware of potential pinch points

• Check

Remove andany

inspect

itemsthethattools

maythat they are

obstruct the in

work

good condition

activity. Keep theand safe toarea,

working use. platform clear of

• Wearor

debris safety

liquidgloves

spills.

• Cordon the area and keep sign to warn others

of the potential hazard.

• Ensure close monitoring and supervision.

• Materials to be stored in a safe and secure

manner.

• Sprain / strain /

• Physical injury to • Wear suitable Safety Shoes.

fracture MEDIUM

workers due to Slip / 3 2 6 • (Practice Good Housekeeping) Remove 3 1 3 LOW RISK

RISK

trip hazard unnecessary materials that may cause trip, slip.

• Make sure the work area is left clean and tidy.

• Check all the potential cause of trip and slip

and remove it in the work area.

• Provision of Safe pedestrian access.

• Ensure all workers abide to the traffic rules

• Hit by moving and regulations in the plant.

Mobilization of Manpower,

machinery • Physical injury/ EXTREME

3 Tools, Materials and 5 3 15 2 2 4 LOW RISK

fatality RISK

Equipments to work area

• Ensure workers use the pedestrian walkway

provided during travelling.

• Check Vehicle of its road worthiness.

• Physical injury/ • Comply with plant road speed limits and driving

• Be extra careful when crossing the road

• Hit against Fatality EXTREME regulations.

5 3 15 • Banksman or spotter shall be provided during 2 2 4 LOW RISK

personnel or property • Property damage RISK

loading, unloading, moving operation.

• Keep access and egress routes clear and

segregate the work area from others and

vehicles in access areas.

• Remove any items that may obstruct the work

activity; and

• Check for any items that may cause slips, trips

• Sprain / strain /

• Slip and Trip 4 3 12 HIGH RISK and falls and remove or secure them as 2 1 2 LOW RISK

Fracture required.

• Review prospective route of access prior to

carrying materials to work area with

consideration given to any obstacles / trip or slip

hazards

• Prior to the commencing of activities all

personnel

• Involved has attended the safety induction re

covid-19.

• Compliance to 100% PPE. Including face mask

and hand gloves medical and cotton.

• Social distancing of 1 meter is mandatory

instructed.

• Proper hygiene by means of washing the hand

by soap and alcohol.

• Continue monitoring of Body temperature will

• Transmission of EXTREME be conducted by our First Aider using therma MEDIUM

• Spreading of virus 5 3 15 gun scanner. 3 2 6

Covid-19 disease RISK RISK

• In case if there will be a suspected infected

worker he will be removed from the site and

proper medical administration will apply.

• A quarantine area will be provided to the

affected Worker

• Proper tracing will be conducted by our

management

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

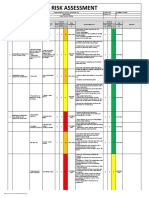

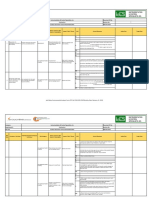

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-007

Department/s Engineering Revision No 0

Job Description Termination Works

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• Assess lift, lift within capabilities, use correct

lifting procedure,

• Ensure correct manual handling techniques,

warm up & stretch to avoid strains / sprains.

• Do not carry long or awkward materials on your

own.

• Designing and organizing tasks to avoid

manual handling completely or at least restrict it.

• Neck and Back • Organizing manual/lifting task in a safe way,

injuries with loads split into smaller ones, and proper

• Strains and Sprains rest period provided.

• Slip and fall crush • Providing information and training to workers

incidents on tasks, and the use of equipment and correct

• Crush, bruises and handling/lifting technique.

Loading and unloading of • Manual Lifting / broken bones • Using automation and lifting equipment.

4 4 3 12 HIGH RISK • Move your feet rather than twist your back. 4 1 4 LOW RISK

materials to work area manual handling • Hand and foot

injuries • Keep the load in front and close to your body

• Hernias and straighten your legs to lift.

• Occupational • Never lift a heavy object above shoulder level.

Overuse Syndrome • During long shifts, change tasks around to give

(OOS) muscle a break.

• Wear appropriate PPE’s for the tasks

• Never walk away from a machine that is turn

on or coasting.

• Discuss and point out pinch point hazards as

part of your risk assessment and toolbox

meeting.

• Pay attention to where your hands are around

any moving parts that have the potential to

move.

• Bruising • Do not place your hands where you cannot see

• Cuts and Laceration them.

• Pinch point (Hand • Sprains

4 3 12 HIGH RISK • Wear the proper gloves and PPE for the jobs 4 1 4 LOW RISK

hazards) • Fractures where you can get injured.

• Crushing • Communicate with your co-workers when

• Punctures working with materials that could cause a

hazard.

• Provide an awareness training regarding line of

fire and hand finger safety.

• Ensure workers use all necessary PPE.

• Strive to maintain a safe distance outside of

the swing radius of lifting materials.

• Proper communication and coordination before

lifting tubular and long objects.

• Struck by/against • Workers should always wear proper PPE such

• Physical injury 4 3 12 HIGH RISK as hard hats, safety glasses, goggles and safety 4 1 4 LOW RISK

lifting materials

shoes to help protect workers from flying, falling,

hitting, swinging, and rolling objects.

• Ensure equipment is placed firmly on floorings,

and load is evenly distributed.

• Loads projecting beyond vehicle must be

flagged

• Damage / injury due • Park vehicle in a stable position, in gear with

• Serious injury

to crane or boom

• Property damage EXTREME handbrake on MEDIUM

truck / forklift failure 5 3 15 • Operators / helpers must be competent and 3 2 6

• Fatality RISK RISK

or incompetent qualified.

operator • Plant and lifting equipment must be in

serviceable condition and have documented

maintenance records

• Access/egress points are checked regularly

including condition of tiles, steps, handrails,

doors and handles.

• Actions are in place to deal with hazardous

weather conditions which could affect

access/egress.

• Adequate lighting at entrance /exit (inside and

outside).

• Fire exit are clearly marked.

• Door regularly checked and kept clear from

• Poor access and obstruction.

egress (Poor lighting, • No trip hazards on entrance/exit routes and

obstructed door) • Delayed escape in walkways.

• Slip, trip and fall the event of fire or • Stair and steps identified and particular

hazards including other emergency precautions in place to prevent slips, trips and

5 Preparation of work area mats, broken tiles, • Sprain / strain / 4 3 12 HIGH RISK falls including operational controls, 4 1 4 LOW RISK

holes in floor, trailing Fracture environmental controls, hazardous steps and

cables • Physical injury handrails.

• Poor or bad weather • Make sure all access and egress, access

condition ladders, steps and ramps are safe and secure.

• Immediately cease work in hazardous weather

condition such as:

Strong winds that may cause loss of balance.

Rain is causing a slippery work surface.

Thunder storm and lightning.

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-007

Department/s Engineering Revision No 0

Job Description Termination Works

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• Implement the lock out procedure when

required.

• Refer to list of cables and circuit breaker to be

isolated.

• Test cables with approved test equipment to

ensure that cables are electrically “dead”

• Implement the lock out procedure when

required

• Lock out procedure to be implemented only by

authorized persons and signed off in the sub-

station permit book

• Hazard awareness training by means of

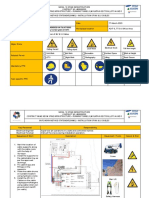

Prepare cables for termination • Serious injury EXTREME MEDIUM

6 • Electrocution 5 3 15 toolbox talks 3 2 6

works • Fatality RISK RISK

• Only competent and authorized personnel to

perform the activity.

• Educate and train personnel in basic electrical

safety.

• Educate personnel in lock out tag out

procedure.

• Lock out tag out procedure to be implemented

only by authorized person

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-007

Department/s Engineering Revision No 0

Job Description Termination Works

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• Hazard awareness training by means of

toolbox talks

• Supervision by site supervisor

• Inspections by safety officer.

• Worn or blunt knife and saw blades must be

replaced before use

• Only knives with which the blade can be

reversed into the knife casing will be permitted to

be used

• Defective hand tools

• Hand injuries 4 3 12 HIGH RISK • Only competent persons are permitted to use 2 2 4 LOW RISK

causing cuts hacksaws and knives for the purpose of

stripping cable

• Use the correct technique, always cut away

from the body

• Keep hands behind the cutting edges

• Use an assistant at all times

• Ensure that the persons are away from the

Cable terminals while Meggering.

• Ensure that the Cable terminals at the farther

end and are safe and isolated from human

• Shock Hazard dues approach/caution boards are put.

Taking Insulation Resistance to test voltage and EXTREME • Discharge of Earth Cable before work.

7 • Electrocution 5 3 15 • Ensure that the cable ends are properly 2 2 4 LOW RISK

test (IR) wrong cable RISK

identification identified before start of work.

• Check the presence of Voltage line tester.

• Test for the presence of voltage by remote

voltage indicator

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-007

Department/s Engineering Revision No 0

Job Description Termination Works

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• Electric drill shall be in good running condition

• Electric drill must be provided with guide

stopper, properly positioned and grip.

• Only competent and authorized personnel to

perform the activity.

• Provide adequate monitoring and supervision

at the workplace.

• Incorrect use of

electrical power tools • Use right tools for the right job.

Cable Glanding (drilling holes

8 • Twisting of electric • Hand injury 4 3 12 HIGH RISK 2 2 4 LOW RISK

on panels for cable wire entry) • Educate and train personnel for proper use and

drill

handling of power tools.

• Only use appropriate power tools that are in

good condition and use them in a correct

manner.

• Power tools should be inspected and has

inspection tag and color coded.

• Only competent and authorized personnel to

perform the activity.

• Provide adequate monitoring and supervision

at the workplace.

• Ensure that no open wires and splicing joints

on extension

• Use cords.

right tools for the right job.

• Educate and train personnel for proper use and

• Fatality •handling

Equipment shall be

of power inspected and color coded.

tools.

EXTREME

• Electrical shock • Serious injury 5 3 15 2 2 4 LOW RISK

RISK

• Sockets

Only useoutlets shall be

appropriate weather

power toolsproof

that are in

industrial type and

good condition andapproved

use themasin per project

a correct

requirement

manner. provided with grounding terminals.

• Wear suitable safety gloves.

•• Only

Power tools should

competent and be inspectedpersonnel

authorized and has to

inspection

perform thetag and color coded.

activity.

• Provide adequate monitoring and supervision

• Flying debris at the workplace.

MEDIUM

created during drilling • Eye injury 3 3 9 2 1 2 LOW RISK

RISK

works

• Use right tools for the right job.

• Hazard awareness training by means of

toolbox talk.

• Supervision by foreman/leadman.

• Ensure that your hands do not slip when

tightening the cable

• Supervision glands.

by safety officer

• Wear safety glasses/goggles.

• Use the correct size spanner on the smaller

size glands.

• Hand injury • Use dedicated gland spanners on the larger

• Sharp edges and MEDIUM

• Cuts, laceration 3 3 9 size cable gland. 2 1 2 LOW RISK

burrs on gland holes RISK

• Do not use stilson wrenches or adjustable

spanner.

• Hazard awareness training by means of

toolbox talk.

• Supervision by foreman/leadman.

• Supervision by Safety officer.

• Ensure that that the power supply is shutting

off before will proceed to terminating the

wires/cables.

• Refer to list of cables and Circuit breaker to be

isolate (LOTOTO)

• Test cables with approved test equipment to

ensure that cables are electrically dead.

• Only competent and authorized personnel to

perform the activity.

• Electrocution

• Short circuit during EXTREME • Use insulated terminal screw while terminating MEDIUM

9 Wire cable Termination • Fatality 5 3 15 the cables/wires. 3 2 6

termination works RISK RISK

• Provide adequate monitoring and supervision

at the workplace.

• Educate and train personnel in basic electrical

safety.

• Implement the lock out procedure when

required

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-007

Department/s Engineering Revision No 0

Job Description Termination Works

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• Use appropriate tools stripper for stripping the

steel wired armored cable.

• Only used appropriate tools that are in good

condition and use them in correct manner.

• Only competent personnel to carry out the

task.

• Injury from hand • Only Knives with which the blade can be

• Cuts, Laceration 4 3 12 HIGH RISK reversed into the knife casing will be permitted to 2 2 4 LOW RISK

tools

be used.

• Use the correct technique, always cut away

from the body

• Keep hands behind the cutting edges

• Ensure that all workers issued with adequate

hand gloves to avoid cuts and wounds.

• Ensure the conductor when stripping

insulation and always pare when using the

blade.

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

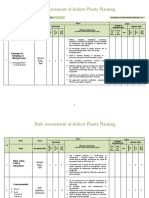

RISK ASSESSMENT Document ID

Company Name Instrumentation & Control Specialists, Inc ICS-SMNCI-RA-007

Department/s Engineering Revision No 0

Job Description Termination Works

Plant/Location

Inherent Residual

Aspect / Hazard / Risk Risk

Risk Impact / Risk / Impac Likeli Impac Likeli

Procedure / Job Steps Risk Source / Total Classificati Control Measures Total Classificat Remarks

Item Threat t hood t hood

Vulnerability on ion

I L I x L I L I x L

• Provide adequate ventilation.

• Educate workers on symptoms and precaution

of heat stress.

• Provide adequate rest periods and rest

shelters at the area.

• Provide cold & safe drinking water.

• Hot working • Heat stress and

4 3 12 HIGH RISK • Monitor humidity & temperature frequently. 2 1 2 LOW RISK

environment dehydration • Provision of Oral rehydration solution when

necessary.

• Provide adequate ventilation at the area

• Advise to increase water intake.

• Working area should be clear of unnecessary

material and waste

• Walkway should be maintained without tripping

caused material

• When work finishes, housekeeping shall be

implemented

• Supervisors need to inspect the area before

dismissal of work

• Isolate or remove all tripping hazards in the

workplace and passage area.

• Remove any items that may obstruct the work

activity; and

material • Check for any items that may cause slip, trip

• Slip and trip • Physical Injury and falls and remove or secured them as

MEDIUM

10 House keeping • Obstruction to other • Fracture 3 3 9 required. 2 1 2 LOW RISK

RISK

trade contractor • Ensure all material off cuts and rubbish are

removed as they are generated and disposed of

in appropriate receptacles.

• Ensure all materials/tools and equipment is

removed from the work area when departing.

• Cleanup work area and dispose of all rubbish

in bins.

• Maintain good housekeeping practices before,

during and after the activity.

Prepared by / Date: Checked by / Date: Approved by / Date:

Risk Assessment Form ICS-ESD-PMS-RA-Rev1

You might also like

- The Peat WhispererDocument85 pagesThe Peat Whispererzarrin77100% (6)

- Risk Assessment For Concrete Coring, Chipping and DrillingDocument17 pagesRisk Assessment For Concrete Coring, Chipping and DrillingJayson Escamillan80% (5)

- JOB HAZARD ANALYSIS - Cable PullingDocument7 pagesJOB HAZARD ANALYSIS - Cable PullingJayson Escamillan100% (2)

- Risk Assessment For BorescopeDocument14 pagesRisk Assessment For BorescopeJayson Escamillan100% (1)

- Smith Slides CH 4Document26 pagesSmith Slides CH 4USHA RANI SONOWALNo ratings yet

- Risk Assessment Template For Film and Video ProductionDocument3 pagesRisk Assessment Template For Film and Video Productionapi-646836603No ratings yet

- LFI CSE Fatal Incident at Qatar GasDocument1 pageLFI CSE Fatal Incident at Qatar Gasmalek sammoudiNo ratings yet

- Contractor Ehs Risk Assessment For NDT TestingDocument6 pagesContractor Ehs Risk Assessment For NDT TestingBernard PenuliarNo ratings yet

- ICS SMNCI RA 001 Temfacil ConstructionDocument7 pagesICS SMNCI RA 001 Temfacil ConstructionJayson Escamillan100% (1)

- ICS SMNCI RA 001 Temfacil ConstructionDocument7 pagesICS SMNCI RA 001 Temfacil ConstructionJayson Escamillan100% (1)

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson Escamillan100% (1)

- Risk Assessment of Scaffolding Works - Rev. 1Document20 pagesRisk Assessment of Scaffolding Works - Rev. 1Jayson Escamillan67% (3)

- JSEA-ICS-004 Cable Laying and PullingDocument16 pagesJSEA-ICS-004 Cable Laying and PullingJayson EscamillanNo ratings yet

- Winter Safety Toolbox TalkDocument18 pagesWinter Safety Toolbox TalkKristina100% (1)

- ICS SMNCI RA 006 Cable Laying PullingDocument6 pagesICS SMNCI RA 006 Cable Laying PullingJayson EscamillanNo ratings yet

- ICS SMNCI RA 004 Cable Tray InstallationDocument8 pagesICS SMNCI RA 004 Cable Tray InstallationJayson EscamillanNo ratings yet

- RA 1 CocacolaDocument5 pagesRA 1 CocacolaIbrahim EsmatNo ratings yet

- Risk Assessment - Working in or Near WaterDocument5 pagesRisk Assessment - Working in or Near WaterabogadieNo ratings yet

- RISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023Document6 pagesRISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023arabiangulfdoorest2008No ratings yet

- Risk Assessment - ExcavationDocument6 pagesRisk Assessment - Excavationganesh gbNo ratings yet

- Core Cutting JHA For Cooling Tower.Document11 pagesCore Cutting JHA For Cooling Tower.Omkar Mishra100% (1)

- 0000000working in Live AreasDocument1 page0000000working in Live Areasgueettaf faresNo ratings yet

- NDT RaDocument8 pagesNDT RaHassanNo ratings yet

- Copy Risk Assessment KFA - IWPTDocument19 pagesCopy Risk Assessment KFA - IWPTAnandha BharathiNo ratings yet

- Swms For LV, MV Cable Laying 17.12.22Document5 pagesSwms For LV, MV Cable Laying 17.12.22Md Shahbaz AlamNo ratings yet

- AB8-ELE-05-HMO - PM On EM GeratorDocument2 pagesAB8-ELE-05-HMO - PM On EM Geratorvikrant911No ratings yet

- Risk Assessment - Rev01 8 4 2020-2Document14 pagesRisk Assessment - Rev01 8 4 2020-2shaibaz chafekar100% (1)

- JSA E&I 3..electrical Equipment Installation (Lighting)Document6 pagesJSA E&I 3..electrical Equipment Installation (Lighting)AmyNo ratings yet

- Task Risk Assessment Enter Company Name: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Enter Company Name: Risk Evaluation (Refer To Evaluation Form)Aftab QadirNo ratings yet

- Jsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.Document67 pagesJsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.jafar mohdNo ratings yet

- Working On or Near Water (River) Safety PlanDocument16 pagesWorking On or Near Water (River) Safety PlanzaimNo ratings yet

- RISK Assement AGE - Maintenance of SOD Sapin Uae-18-8-2023Document7 pagesRISK Assement AGE - Maintenance of SOD Sapin Uae-18-8-2023arabiangulfdoorest2008No ratings yet

- DDC Construction Safety and Health ProgramDocument17 pagesDDC Construction Safety and Health ProgramRino BonhocNo ratings yet

- Sep-Ope-Xxx-Xxxx - Project Hse Plan DraftDocument40 pagesSep-Ope-Xxx-Xxxx - Project Hse Plan DraftEmmanuel Akporuvie AkemuNo ratings yet

- Bolt Testing MethodBolt Testing MethodDocument8 pagesBolt Testing MethodBolt Testing Methodazmatkhan30No ratings yet

- Ji 2027 Jsa 050 Grouting Work PDF FreeDocument2 pagesJi 2027 Jsa 050 Grouting Work PDF FreeBinayNo ratings yet

- 8) SWP-08 Working at HeightsDocument3 pages8) SWP-08 Working at HeightsRachel NoraNo ratings yet

- PAINTING Risk AssessmentDocument5 pagesPAINTING Risk AssessmentrajNo ratings yet

- HSE Inspection Report 148 AttendDocument11 pagesHSE Inspection Report 148 Attendtuan mai vanNo ratings yet

- 6 RA Installation Testing Commissioning of Fire Fighting PumpsDocument7 pages6 RA Installation Testing Commissioning of Fire Fighting PumpsAdel MorsyNo ratings yet

- IUMI Webinar Flat RacksDocument35 pagesIUMI Webinar Flat RacksJackNo ratings yet

- Occupational Exposure To DustDocument11 pagesOccupational Exposure To DustTony GuoNo ratings yet

- Planned Job Observation: ChecklistDocument2 pagesPlanned Job Observation: ChecklistMOHAMMED RIYAN TNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- Method Statement For Cable Terminaton (CP3)Document20 pagesMethod Statement For Cable Terminaton (CP3)Jacky TamNo ratings yet

- Data Logger Discovery Risk Assessment 1Document1 pageData Logger Discovery Risk Assessment 1Coin DozerNo ratings yet

- Risk Management and AssessmentDocument50 pagesRisk Management and Assessmentfaik395No ratings yet

- HEMP-006 Operation of Wood Cutting & Grooving Machine Rev.1 PDFDocument7 pagesHEMP-006 Operation of Wood Cutting & Grooving Machine Rev.1 PDFsaravana.bNo ratings yet

- #011 Hotwork-Welding Machinery Spaces - 01-03-10Document4 pages#011 Hotwork-Welding Machinery Spaces - 01-03-10Tolias EgwNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument30 pagesJSA For Scaffolding Erection Dismantling and Modification Workkmohamedkeita906No ratings yet

- DevicorebbtDocument1 pageDevicorebbtDaviss Pauca Morón100% (1)

- Bidaa Tower Risk Assessment From CALISTO UpdatedDocument5 pagesBidaa Tower Risk Assessment From CALISTO Updatedirshad gNo ratings yet

- 10SF.11 - MOG-HSEQ-SF-P-081 Rev A1 Electrical SafetyDocument21 pages10SF.11 - MOG-HSEQ-SF-P-081 Rev A1 Electrical SafetySamerNo ratings yet

- PJHA Form - Compi (Coco Shell)Document2 pagesPJHA Form - Compi (Coco Shell)Paul TamayoNo ratings yet

- DAIS I1912 HSE CRA AIPL 08 (Installation of Pelmet)Document2 pagesDAIS I1912 HSE CRA AIPL 08 (Installation of Pelmet)Aiplshubh ChavanNo ratings yet

- Risk Assessments - Materials Offloading-Transportation& Lifting Opereation - ADFI-GFTS-CESDocument7 pagesRisk Assessments - Materials Offloading-Transportation& Lifting Opereation - ADFI-GFTS-CESIbrahim Esmat0% (1)

- Larsen & Toubro Limited Buildings and Factories Independent CompanyDocument5 pagesLarsen & Toubro Limited Buildings and Factories Independent CompanyabbasNo ratings yet

- Hazard Identification, Risk Assessment and Risk Control (Hirarc)Document2 pagesHazard Identification, Risk Assessment and Risk Control (Hirarc)Khaty JahNo ratings yet

- Risk Assessment For FlushingDocument9 pagesRisk Assessment For FlushingABDUL BASITHNo ratings yet

- Baseline Risk Assessment: Phindile Kula (Project Coordinator)Document9 pagesBaseline Risk Assessment: Phindile Kula (Project Coordinator)EmilNo ratings yet

- JSA 01 (Mechanical Excavation and Soil Loading Unloading, Night Shift)Document1 pageJSA 01 (Mechanical Excavation and Soil Loading Unloading, Night Shift)abdulthahseen007No ratings yet

- Safe Driving - Defensive DrivingDocument20 pagesSafe Driving - Defensive Drivingfaik395No ratings yet

- AE-SWM - 12B-LG-Marine-Rev-02Document61 pagesAE-SWM - 12B-LG-Marine-Rev-02Planning C7100% (1)

- FR - HSE - 061 - en Permit To Work Audit ChecklistDocument2 pagesFR - HSE - 061 - en Permit To Work Audit ChecklistNibu P ShajiNo ratings yet

- Risk AssessmentDocument9 pagesRisk Assessmentاahmed Amer100% (1)

- Binder Spine Indexing SlipsDocument4 pagesBinder Spine Indexing Slipspundir_vineetNo ratings yet

- Risk Assessment (INTERCOM)Document9 pagesRisk Assessment (INTERCOM)rocknNo ratings yet

- Task Risk Assessment For Lifting & Installation of Ladder and PlatformDocument3 pagesTask Risk Assessment For Lifting & Installation of Ladder and PlatformAftab QadirNo ratings yet

- Risk Assessment On Demolition Work - CompressDocument8 pagesRisk Assessment On Demolition Work - CompressAbegail Manuel GatusNo ratings yet

- ICS SMNCI RA 005 Electrical Conduit InstallationDocument8 pagesICS SMNCI RA 005 Electrical Conduit InstallationJayson EscamillanNo ratings yet

- JOB HAZARD ANALYSIS - Electrical WorksDocument9 pagesJOB HAZARD ANALYSIS - Electrical WorksJayson Escamillan100% (1)

- Job Hazard Analysis - TubingsDocument9 pagesJob Hazard Analysis - TubingsJayson Escamillan100% (1)

- JOB HAZARD ANALYSIS - ConduitDocument9 pagesJOB HAZARD ANALYSIS - ConduitJayson Escamillan100% (1)

- ICS SMNCI RA 005 Electrical Conduit InstallationDocument8 pagesICS SMNCI RA 005 Electrical Conduit InstallationJayson EscamillanNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document3 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document4 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- JOB HAZARD ANALYSIS - Cable TrayDocument10 pagesJOB HAZARD ANALYSIS - Cable TrayJayson Escamillan100% (1)

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document8 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- TG Panel Relocation - JSEA FormDocument13 pagesTG Panel Relocation - JSEA FormJayson EscamillanNo ratings yet

- Job Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Document7 pagesJob Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Jayson EscamillanNo ratings yet

- EL S EC: Job Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Document8 pagesEL S EC: Job Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Jayson EscamillanNo ratings yet

- Risk Assessment of Conduit Pipe InstallationDocument17 pagesRisk Assessment of Conduit Pipe InstallationJayson Escamillan75% (4)

- Risk Assessment of Manual Excavation and TrenchingDocument14 pagesRisk Assessment of Manual Excavation and TrenchingJayson Escamillan100% (1)

- Safety Walkthrough Report - 2-11-16 PDFDocument2 pagesSafety Walkthrough Report - 2-11-16 PDFJayson EscamillanNo ratings yet

- Job Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Document7 pagesJob Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Jayson EscamillanNo ratings yet

- Safety Walkthrough Report - 2-11-16Document2 pagesSafety Walkthrough Report - 2-11-16Jayson EscamillanNo ratings yet

- Company Instrumentation & Control Specialists, Inc Document ID No. Department/s Contractor Revision No Job Title Coring Works Effective DateDocument11 pagesCompany Instrumentation & Control Specialists, Inc Document ID No. Department/s Contractor Revision No Job Title Coring Works Effective DateJayson EscamillanNo ratings yet

- Jsea PipingDocument13 pagesJsea PipingJayson EscamillanNo ratings yet

- Job Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Document7 pagesJob Safety Environmental Analysis Form CPC-SAF-PRO-029-F01Effectivity Date February 11, 2019Jayson EscamillanNo ratings yet

- Hematology EMQDocument7 pagesHematology EMQfrabzi100% (1)

- Whitesboro Isd - 1995 TEXAS SCHOOL SURVEY OF DRUG AND ALCOHOL USEDocument6 pagesWhitesboro Isd - 1995 TEXAS SCHOOL SURVEY OF DRUG AND ALCOHOL USETexas School Survey of Drug and Alcohol UseNo ratings yet

- Presentations Day 1 - Session 1 - Presentation 06 - Sri LankaDocument29 pagesPresentations Day 1 - Session 1 - Presentation 06 - Sri LankaAnkur MishraNo ratings yet

- Window Cleaning Safety GuidelineDocument4 pagesWindow Cleaning Safety Guidelinejhunvalencia1203No ratings yet

- Konsolidasi WelmiDocument72 pagesKonsolidasi WelmiWelmi Sulfatri IshakNo ratings yet

- (OSHPD 1, 2, 3 & 4) See Sections 404.0 Through 418.0. (SFM) Air Filters Shall Comply With All Requirements ofDocument0 pages(OSHPD 1, 2, 3 & 4) See Sections 404.0 Through 418.0. (SFM) Air Filters Shall Comply With All Requirements ofOanh NguyenNo ratings yet

- SITHKOP005 - Written AssessmentDocument7 pagesSITHKOP005 - Written AssessmentTephieNo ratings yet

- Indian Research Funding AgenciesDocument6 pagesIndian Research Funding AgencieskcchtphdNo ratings yet

- Intrebari Interviu Asistent MedicalDocument3 pagesIntrebari Interviu Asistent MedicalanaNo ratings yet

- Spring Term Core A Formative AssessmentDocument9 pagesSpring Term Core A Formative Assessmentdiscord.tazzNo ratings yet

- General Deductions (Under Section 80) : Basic Rules Governing Deductions Under Sections 80C To 80UDocument67 pagesGeneral Deductions (Under Section 80) : Basic Rules Governing Deductions Under Sections 80C To 80UVENKATESAN DNo ratings yet

- Internship PresentationDocument23 pagesInternship Presentationapi-556937362No ratings yet

- Art Comparison Essay ExampleDocument5 pagesArt Comparison Essay Exampleflrzcpaeg100% (2)

- Inspection ReportDocument5 pagesInspection ReportVimal SinghNo ratings yet

- Abnormal Illness BehaviorDocument7 pagesAbnormal Illness Behavioransha2011p0% (1)

- MSPE Noteworthy Characteristics Worksheet: Complete This Worksheet and Bring It To Your Mandatory Career Advising SessionDocument2 pagesMSPE Noteworthy Characteristics Worksheet: Complete This Worksheet and Bring It To Your Mandatory Career Advising SessionHải Dương NguyễnNo ratings yet

- Ergonomic Factors in Construction Industry: A Literature ReviewDocument14 pagesErgonomic Factors in Construction Industry: A Literature ReviewdhanarajNo ratings yet

- HSC 430 - Lesson Plan Underage DrinkingDocument11 pagesHSC 430 - Lesson Plan Underage Drinkingapi-487139726No ratings yet

- The Legal Bases of Special EducationDocument14 pagesThe Legal Bases of Special EducationMaria Dulcinea Basbas86% (7)

- Hizon Interview Group 2Document3 pagesHizon Interview Group 2Dan HizonNo ratings yet

- Surat Permintaan Obat Dinkes BaruDocument21 pagesSurat Permintaan Obat Dinkes BaruHafizh JhunkoNo ratings yet

- Common Skin Diseases in Africa: An Illustrated GuideDocument85 pagesCommon Skin Diseases in Africa: An Illustrated GuideJohn EnioladeNo ratings yet

- Zinc in Wound Healing Theoretical, ExperimentalDocument15 pagesZinc in Wound Healing Theoretical, ExperimentalRifky Budi TriyatnoNo ratings yet

- Complete Guide To Communication Problems After StrokeDocument22 pagesComplete Guide To Communication Problems After Strokeapi-215453798100% (1)

- Risk Assessment of Indoor Plants PlantingDocument5 pagesRisk Assessment of Indoor Plants Plantingطارق رضوانNo ratings yet

- Jhs Learner DataDocument3 pagesJhs Learner Dataapi-377500541No ratings yet

- Complete Holistic Guide To Working Out in The GymDocument218 pagesComplete Holistic Guide To Working Out in The Gympsichi21No ratings yet