Professional Documents

Culture Documents

Hot Water Circulation Pump Calculation

Hot Water Circulation Pump Calculation

Uploaded by

victor.sCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Water Circulation Pump Calculation

Hot Water Circulation Pump Calculation

Uploaded by

victor.sCopyright:

Available Formats

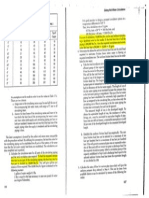

HOT WATER CIRCULATING PUMP (FLOW CALCULATION)

Length of hot water supply pipe work : 550 Mts.

Length of hot water return pipe work : 450 Mts.

Total Length of Piping : 1000 Mts.

Approximate Heat Loss from piping at 60 C Inlet, 20C Ambient =10 W/m

Multiply above value by total length of Hot water piping.

Total heat loss (q) 1000 x 10 10000 W

Pump capacity is calculated by following formula:

q

Q L/s

Cp t

where

Q pump capacity, L/s

q heat loss, W

density of water (0.99kg/L)

Cp specific heat of water (4180 J/Kg.K)

t allowable temperature drop, K

For a 10 K allowable temperature drop,

q

Q L/s

41400

Therefore Pump capacity will be

10000

Q L/s 0.24 L/s.

41400

Say 0.50 L/s.

Proposed pump is of 8.0gpm.

ulation pump calculation 1 9/24/2019

Pump Head calculation

o The formula below for calculate these losses over a given length of pipe.

o hL = 10.67 * L * Q1.852 / C1.852 / d4.87 (SI Units)

Where,

o hL represents friction head loss (meters of H2O),

o L represents length of pipe (meters),

o d represents internal pipe diameter (meters),

o Q represents flow rate through the pipe (cubic meters per second), and

o C represents the Hazen-Williams coefficient.

‐ The domestic booster pump set hydraulic loss calculation is done based on the most critical

path from the booster pump set which locate at the roof of the building until the last fixture at

the 4th basement-floor toilet With counting the pipe size length within the site, all valves and

fittings to determine the hydraulic pressure loss. (Contractor shall recalculate and verify the

required head as per site condition)

‐ The selected pipe dia at 1.0m/s = mm from the chart

‐ The selected pipe dia at 1.0m/s = 25mm from the chart

‐ The length of the pipe = 200m

‐ The equivalent length for fitting and valves =50% of total length of the pipe = 100

‐ The total pipe length = 300m

‐ The friction losses = 16.86m

The pump head is equal to = (vertical head + friction losses + residual pressure) 10%

Vertical head = -2.0 m

Friction losses = 16.083m

Residual pressure (max flow pressure required at lavatory) = 8 psi =5.6 m.

The pump head = (-2+16.86+5.6) x1.1=22.5 m

So, the Hot water circulated pump which located above the roof of the buildings will be duplex

variable speed with 8gpm flow and 25 m head (each) is designed to serve the building with the

domestic water needs and to cover the peak load. Variable frequency drive controller is selected

for proper pump operation and to cover the building demand curve within the day. Three pumps

will operate with one stand by pump.

Booster Pump Set: 8 GPM @ 25m – 1D+1S

You might also like

- Pressurization Unit Pressure Vessel CalculationDocument1 pagePressurization Unit Pressure Vessel Calculationsheetalnath100% (1)

- Mechanical Calculations - Plumbing PDFDocument43 pagesMechanical Calculations - Plumbing PDFRaoof0% (1)

- 02-Fire Pump Room CalculationsDocument1 page02-Fire Pump Room CalculationsHamdy AdelNo ratings yet

- Booster Pump Capacity CalculationDocument1 pageBooster Pump Capacity CalculationSHIBIN T100% (1)

- 1715-DD-M004 Water Booster Pump Demand CalculationDocument5 pages1715-DD-M004 Water Booster Pump Demand CalculationMUBASHIRNo ratings yet

- Drainage CalculationDocument2 pagesDrainage CalculationΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Fixture Units Sizing ChartDocument4 pagesFixture Units Sizing ChartAfrooz Momeni100% (1)

- Plumbing CalculationDocument2 pagesPlumbing CalculationAnonymous qOBFvINo ratings yet

- Hot Water Circulation Pump Capacity CalculationDocument2 pagesHot Water Circulation Pump Capacity CalculationKarthy GanesanNo ratings yet

- A. Load Values, in Water Supply Fixture Units (Wsfu) For All AreasDocument4 pagesA. Load Values, in Water Supply Fixture Units (Wsfu) For All AreasIbrahim A. HameedNo ratings yet

- Calculation ReportDocument29 pagesCalculation Reportvictor.sNo ratings yet

- 06 Hot Water Circulating Pump CalDocument11 pages06 Hot Water Circulating Pump CalZiaullah Biyabani100% (1)

- Head Loss Calculation Circulation PumpDocument1 pageHead Loss Calculation Circulation PumpKarthy Ganesan100% (1)

- ASPE-Domestic Water Heating Design Manual 2013 PDFDocument2 pagesASPE-Domestic Water Heating Design Manual 2013 PDFMohamedHany100% (1)

- ASHRAE Table9 Hot Water DemandDocument1 pageASHRAE Table9 Hot Water Demandbandithaguru633875% (4)

- Booster Pump CalculationDocument3 pagesBooster Pump CalculationYe Myat Thu93% (14)

- Section 3 - Summary of Key Water Plant Operator Math FormulasDocument18 pagesSection 3 - Summary of Key Water Plant Operator Math Formulasretawdog7111No ratings yet

- Fcu SizingDocument12 pagesFcu SizingLloydNo ratings yet

- Magnesium-Alloy Engine Cylinder BlockDocument8 pagesMagnesium-Alloy Engine Cylinder BlockIsmet ZülfikarNo ratings yet

- High-Rise Design - Hot Water Recirculations and General Pumping PracticesDocument156 pagesHigh-Rise Design - Hot Water Recirculations and General Pumping PracticesAnonymous PCsoNCt0mFNo ratings yet

- ASHRAE Hot Water CalculationsDocument1 pageASHRAE Hot Water CalculationsrazahNo ratings yet

- Tabreed RequirementsDocument2 pagesTabreed RequirementsWaseem SiddiqueNo ratings yet

- Hot and Cold Water Supply AMGDDocument26 pagesHot and Cold Water Supply AMGDJasleenNo ratings yet

- Zurn Roof Drain CatalogDocument22 pagesZurn Roof Drain CatalogperezismaelNo ratings yet

- Hot Water CalculationDocument2 pagesHot Water CalculationNghiaNo ratings yet

- HAP Head Load Calculations Inputs in UAEDocument1 pageHAP Head Load Calculations Inputs in UAEDesigner Forever100% (1)

- 1 - Introduction To Social Media AnalyticsDocument132 pages1 - Introduction To Social Media AnalyticsAnkit Srivastava100% (1)

- Water Flow and Pipe Size - As Per NBC 2016 - Flushing WaterDocument2 pagesWater Flow and Pipe Size - As Per NBC 2016 - Flushing Watertribhuvan ShankarNo ratings yet

- Design of Centralized Hot Water Supply SystemDocument43 pagesDesign of Centralized Hot Water Supply SystemAbhik Bhattacharjee100% (2)

- Hot Water Heat Pump DesignDocument3 pagesHot Water Heat Pump DesignAdhikar HariramNo ratings yet

- Solar Heaters DM FormatDocument1 pageSolar Heaters DM Formatanas shehabiNo ratings yet

- HVAC Beta Linear Slot Diffusers CatalogDocument14 pagesHVAC Beta Linear Slot Diffusers CatalogwissamnafoukhNo ratings yet

- BOQ From (HVAC)Document26 pagesBOQ From (HVAC)Neeta Samir Munj ParkarNo ratings yet

- Design of Centralized Hot Water Supply SystemDocument36 pagesDesign of Centralized Hot Water Supply SystemAbhik BhattacharjeeNo ratings yet

- Pipe Flow Problems-III: Example 1Document10 pagesPipe Flow Problems-III: Example 1Chaithanya Kumar DanduNo ratings yet

- Grease Interceptor Sizing WorksheetDocument16 pagesGrease Interceptor Sizing WorksheetsamehNo ratings yet

- Hot Water Circulation Pump Sizing1Document1 pageHot Water Circulation Pump Sizing1imtiyaz94No ratings yet

- Drainagesystemslecturei 091022013358 Phpapp02Document62 pagesDrainagesystemslecturei 091022013358 Phpapp02Abdul Raoof100% (1)

- Guide To The Water Supply Regulations Issue 3 (2017)Document87 pagesGuide To The Water Supply Regulations Issue 3 (2017)abdulkadhirNo ratings yet

- Swimming Pool Heater SizingDocument1 pageSwimming Pool Heater SizingAmeer AbbasNo ratings yet

- Xapp1082 Zynq Eth PDFDocument12 pagesXapp1082 Zynq Eth PDFAhmedAlazzawiNo ratings yet

- Water DemandDocument1 pageWater Demandnido77100% (1)

- ASHRAE Design CriteriaDocument4 pagesASHRAE Design CriteriaJin Fong KuehNo ratings yet

- Sizing of Water HeatersDocument40 pagesSizing of Water Heatersssgjmlim100% (2)

- Hot Water Circulating Pump Cal2Document2 pagesHot Water Circulating Pump Cal2Nghia100% (1)

- Plumbing CalculationDocument7 pagesPlumbing CalculationSenghouNo ratings yet

- Generator Room LouverDocument1 pageGenerator Room LouverKarthy Ganesan50% (2)

- Plumbing Design CourceDocument39 pagesPlumbing Design CourceAli Hossain100% (1)

- IPC Loading UnitsDocument3 pagesIPC Loading UnitsTaqui Mubeen67% (3)

- 19.5 Plumbing - Hot Water StorageDocument11 pages19.5 Plumbing - Hot Water StorageNadeesha BandaraNo ratings yet

- BS Standard - Drainage Fixture Units & Flow Rate Calculation PDFDocument2 pagesBS Standard - Drainage Fixture Units & Flow Rate Calculation PDFlijo john100% (2)

- Water Plumbing Lect 3 2015 EDUDocument80 pagesWater Plumbing Lect 3 2015 EDUMoudi Houri100% (3)

- PumpDocument3 pagesPumpfazila fauziNo ratings yet

- Water - Plumbing (Lect - 2a)Document74 pagesWater - Plumbing (Lect - 2a)k_bassyouni83% (6)

- NREL - Process DesignDocument147 pagesNREL - Process Designsum1else4No ratings yet

- Hot Water-Plumbing Lect - 2015 BAUDocument60 pagesHot Water-Plumbing Lect - 2015 BAUAbed BaayounNo ratings yet

- 004-National Building CodeDocument6 pages004-National Building Codercdprelude100% (2)

- 121 Chapter 5 - Cold-Water Systems: Factors Affecting SizingDocument1 page121 Chapter 5 - Cold-Water Systems: Factors Affecting SizingRaheem_kaNo ratings yet

- Sizing Your Grease Trap or InterceptorDocument3 pagesSizing Your Grease Trap or InterceptorMike Mor'zNo ratings yet

- Documents - Tips - Water Consumption Calculation Sheet DewaDocument1 pageDocuments - Tips - Water Consumption Calculation Sheet DewaSijo JoyNo ratings yet

- Fluid Mechanics-II AssignmentDocument7 pagesFluid Mechanics-II AssignmentMuntaha AnjumNo ratings yet

- Name of Project Sample 2. Location 2.1. RMC Sample 2.2. Ward No: 2,3 3. District Kaski 4. Total Demand 2345 5. Total Rvts 2Document15 pagesName of Project Sample 2. Location 2.1. RMC Sample 2.2. Ward No: 2,3 3. District Kaski 4. Total Demand 2345 5. Total Rvts 2Rajendra K KarkiNo ratings yet

- Pump DesignDocument38 pagesPump Designujjwal sapkota0% (1)

- Pump - Design BahirisenDocument14 pagesPump - Design Bahirisenujjwal sapkotaNo ratings yet

- Chapter 8 Internal Forced Convection: H H H H Z G G P H Z G G PDocument20 pagesChapter 8 Internal Forced Convection: H H H H Z G G P H Z G G PKerem GönceNo ratings yet

- FLM3B0S Tutorial 2a TurbomachinesDocument3 pagesFLM3B0S Tutorial 2a TurbomachinesFabrizio NEBESSENo ratings yet

- skmm2323 Turbomc Tutorial PDFDocument3 pagesskmm2323 Turbomc Tutorial PDFLove StrikeNo ratings yet

- Air System Sizing Summary For ITR 87-AHUDocument10 pagesAir System Sizing Summary For ITR 87-AHUvictor.s100% (1)

- Zone Sizing Summary For ITR 87-105 Prayer Room: Air System InformationDocument28 pagesZone Sizing Summary For ITR 87-105 Prayer Room: Air System Informationvictor.sNo ratings yet

- Annex A: Determination of The Water Level in The Well. When A VerticalDocument1 pageAnnex A: Determination of The Water Level in The Well. When A Verticalvictor.sNo ratings yet

- Classic Cool Brochure - tcm478-51423Document2 pagesClassic Cool Brochure - tcm478-51423victor.sNo ratings yet

- What Is Email Security?Document20 pagesWhat Is Email Security?victor.sNo ratings yet

- (ME - Rev.00 02) SD - E-Bus Charger (Kiosk) - Complied SheetDocument4 pages(ME - Rev.00 02) SD - E-Bus Charger (Kiosk) - Complied Sheetvictor.sNo ratings yet

- Pressure Loss Major LossDocument2 pagesPressure Loss Major Lossvictor.sNo ratings yet

- Hvac 01 Kichen HoodDocument1 pageHvac 01 Kichen Hoodvictor.sNo ratings yet

- CFD Fire (Smoke) Simulation Analysis of Development of Al Wukair Logistics Park-ParcelC Manateq, Qatar-Rev01Document42 pagesCFD Fire (Smoke) Simulation Analysis of Development of Al Wukair Logistics Park-ParcelC Manateq, Qatar-Rev01victor.sNo ratings yet

- Tr7 Installation InstructionsDocument8 pagesTr7 Installation InstructionsNairo Alfonzo Martinez MoralesNo ratings yet

- Example 1: Bar 035 - 0 at 2 Bar 42 at 1Document3 pagesExample 1: Bar 035 - 0 at 2 Bar 42 at 1CantalicioNo ratings yet

- Lendi Institute of Engineering and Technology: Part BDocument6 pagesLendi Institute of Engineering and Technology: Part BBaswamy CseNo ratings yet

- Anh 11 de HK2 2022 Mã Đê 002Document5 pagesAnh 11 de HK2 2022 Mã Đê 002Hoài ThươngNo ratings yet

- Language and The Cognitive Science - Noam ChomskyDocument20 pagesLanguage and The Cognitive Science - Noam ChomskySamar HamadyNo ratings yet

- Document No. T51-08-DOC-0002-A Date: 12/9/2009 Page 1 of 1Document4 pagesDocument No. T51-08-DOC-0002-A Date: 12/9/2009 Page 1 of 1Steven PentonNo ratings yet

- John Eddy ResumeDocument2 pagesJohn Eddy ResumeJ EddyNo ratings yet

- Liaqat AliDocument3 pagesLiaqat AliUzair Maqbool KhanNo ratings yet

- Niphade Tejas Prabhakar: Sahyadri Farms CorporateDocument2 pagesNiphade Tejas Prabhakar: Sahyadri Farms CorporateTejas NiphadeNo ratings yet

- Moisture Analyzer Ma30Document37 pagesMoisture Analyzer Ma30Navi MoralesNo ratings yet

- I 2 I F 2 F F I 2 5 5 I P 2 P P 4 P 5 P 6 P 7 P 8 P P U S I: Control Unit For Swing Gate Single or Double Leaf 230VDocument6 pagesI 2 I F 2 F F I 2 5 5 I P 2 P P 4 P 5 P 6 P 7 P 8 P P U S I: Control Unit For Swing Gate Single or Double Leaf 230VAndrei C.No ratings yet

- Assignment 1Document10 pagesAssignment 1Farrina Aziz100% (1)

- CoffeeMaker ExampleDocument3 pagesCoffeeMaker Examplefaisal3096No ratings yet

- Kerb 07Document2 pagesKerb 07Chris DunlopNo ratings yet

- Openshift CheatsheetDocument11 pagesOpenshift CheatsheetTân MaiNo ratings yet

- 4 TSM EngineDocument245 pages4 TSM EngineEvert Vargas TorrezNo ratings yet

- Canon IR-1020 - 1021 - 1024 - 1025 PMDocument82 pagesCanon IR-1020 - 1021 - 1024 - 1025 PMcustompcoutlet100% (1)

- Title: Boiler Operation: 1.0 PurposeDocument4 pagesTitle: Boiler Operation: 1.0 PurposeGafour ParadizNo ratings yet

- Skse ReadmeDocument3 pagesSkse ReadmeBen JamesNo ratings yet

- Bluetooth® Audio System: Operating Instructions Manual de InstruccionesDocument68 pagesBluetooth® Audio System: Operating Instructions Manual de InstruccionesRamsesNo ratings yet

- Incremental Ø80mm Hollow Shaft Type E80H SeriesDocument3 pagesIncremental Ø80mm Hollow Shaft Type E80H SeriesAndre SoaresNo ratings yet

- Libero 08Document52 pagesLibero 08Luis OrtegaNo ratings yet

- VIYELLATEXDocument4 pagesVIYELLATEXAmit BaruaNo ratings yet

- Mba Projects-Ipca Laboratories LTDDocument49 pagesMba Projects-Ipca Laboratories LTDMechanical Prasad100% (2)