Professional Documents

Culture Documents

Fluid Assignment 2

Uploaded by

Abdurezak Hayiru0 ratings0% found this document useful (0 votes)

47 views1 pageCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views1 pageFluid Assignment 2

Uploaded by

Abdurezak HayiruCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

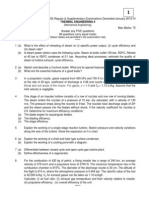

5. A stage of an axial flow compressor used to compress air at 101.

3 kPa and 20 0C has

an impeller rotating at 12000 rpm. The blade angle at the inlet, β1, is 250. The rotor

stage has a tip diameter of 42 cm, a hub diameter of 24.3 cm. The air enters the rotor

and leaves the stator in axial direction with no change in velocity or radius. The blade

angle at the discharge is 450 .Assuming constant specific heats with k=1.44. Assume a

hydraulic efficiency of 92%. There are no guide vanes at the inlet. Calculate the

volume flow rate and compression ratio for a vane congruent flow.

10. A centrifugal pump should operate at a head and flow rate of 140m and 115m 3/hr

respectively the available motor speed is 1450 rpm determine the number of stages if

the minimum allowable specific speed is 15 and the actual specific speed in the

number of stages you calculated.

12. If the above pump is used to move water with ρ=998kg/m3, using the specific speed

efficiency curve determine the annual saving of power cost if you use a multi-stage

impeller with your proposed number of stages instead of using a single stage. What if

the number of stages is 8? Use 2600 hr/annum operating hours, unit cost of 0.75

Birr/kw-hr and motor efficiency 0.97.

13. The dimensions of a radial flow impeller rotating at a speed of 2000rpm is given

below draw the theoretical head capacity curves and the power curve. Given:

D2=250mm b2=13mm β2=250, number of blades is 6.

You might also like

- Tutorial 4 Turbomachinery v2Document4 pagesTutorial 4 Turbomachinery v2Nik JaffNo ratings yet

- Mechanical Engineering Faculty Turbomachinery DocumentDocument3 pagesMechanical Engineering Faculty Turbomachinery DocumentLove StrikeNo ratings yet

- SET A With Answer Key Quiz 2 Fluid Machineries (Prof. Enh. 2)Document4 pagesSET A With Answer Key Quiz 2 Fluid Machineries (Prof. Enh. 2)Famela Gad100% (1)

- Assignments of Turbo MachineryDocument8 pagesAssignments of Turbo Machinerysohaib310% (1)

- SET B With Answer Key Quiz 2 Fluid Machineries (Prof. Enh. 2)Document4 pagesSET B With Answer Key Quiz 2 Fluid Machineries (Prof. Enh. 2)Famela GadNo ratings yet

- Assignment 6Document3 pagesAssignment 6Muhammad Jawad IsmaeelNo ratings yet

- HDM360S Tutorial 3 -2024 - TurbinesDocument6 pagesHDM360S Tutorial 3 -2024 - TurbinesSimphiweNo ratings yet

- Assignment - 2 TE-1-1Document1 pageAssignment - 2 TE-1-1Lalith SunkojuNo ratings yet

- Term End Exam - Nov 2014 TurbomachinesDocument4 pagesTerm End Exam - Nov 2014 TurbomachinesyashvantNo ratings yet

- ME401 Assignment 4 compressor calculationsDocument3 pagesME401 Assignment 4 compressor calculationsPrakhar GuptaNo ratings yet

- Module 3 - Pump Configuration Specific Speed and Affinity Laws - No AnsDocument17 pagesModule 3 - Pump Configuration Specific Speed and Affinity Laws - No AnsRoi Vincent AnitNo ratings yet

- Problem Set-Turbines and PumpsDocument3 pagesProblem Set-Turbines and PumpsBob MarleyNo ratings yet

- Muzeyin FocusDocument3 pagesMuzeyin FocuseyobNo ratings yet

- Assignment 04Document16 pagesAssignment 04Pritam SahNo ratings yet

- Fans and Blowers ProblemsDocument8 pagesFans and Blowers ProblemsJULIAN DOMINIC SOLEDADNo ratings yet

- Sample Fans and Blowers Problems #1Document8 pagesSample Fans and Blowers Problems #1DEKUU MidoriyaNo ratings yet

- Hydraulic Machines Question BankDocument11 pagesHydraulic Machines Question BankAdit Gaur100% (3)

- Qip JP ProblemsDocument9 pagesQip JP Problemsmurad_ashourNo ratings yet

- Jitorres - Ejercicios TH - VentiladoresDocument3 pagesJitorres - Ejercicios TH - VentiladoresJuanDiegoReyesSanchezNo ratings yet

- PSet03 TurboB2020Document2 pagesPSet03 TurboB2020Kyillos SaaidNo ratings yet

- Steam EnginesDocument6 pagesSteam Engineschat2adiNo ratings yet

- 2135 Tutorial 1Document4 pages2135 Tutorial 1Eezhar JumadiNo ratings yet

- TM 7me4a Question Bank Mid Term IDocument1 pageTM 7me4a Question Bank Mid Term IVijay SharmaNo ratings yet

- Propulsion Ii Question BankDocument13 pagesPropulsion Ii Question BankSathya NarayananNo ratings yet

- 210479820563440B840B297C6C79B23CDocument3 pages210479820563440B840B297C6C79B23CyashvantNo ratings yet

- Assignment 1 ATDDocument4 pagesAssignment 1 ATDPrashant Singh0% (1)

- Fluid Machinery Question Bank No.02Document7 pagesFluid Machinery Question Bank No.02Sunil KumarNo ratings yet

- Taller 5 FluidosDocument5 pagesTaller 5 FluidosManuel OlayaNo ratings yet

- VHP Phase 4Document142 pagesVHP Phase 4kristan7No ratings yet

- PipeDocument8 pagesPipeVon A. DamirezNo ratings yet

- Soal Pump PCRDocument2 pagesSoal Pump PCRRoma GunawanNo ratings yet

- Fluid Machinery Turbine Lecture 1Document22 pagesFluid Machinery Turbine Lecture 1Jarred TañedoNo ratings yet

- FMM Anna University Unit IV QuestionsDocument4 pagesFMM Anna University Unit IV QuestionsUma MaheshNo ratings yet

- IES CONV Mechanical Engineering 1989Document5 pagesIES CONV Mechanical Engineering 1989ChandanKumarSinghNo ratings yet

- Tutorial 4Document1 pageTutorial 4Krivai NagarNo ratings yet

- Turbo Assignment 1 - 2013Document2 pagesTurbo Assignment 1 - 2013Shreyash SinghNo ratings yet

- Fluid Mechanics-II AssignmentDocument7 pagesFluid Mechanics-II AssignmentMuntaha AnjumNo ratings yet

- 9A03501 Thermal Engineering IIDocument4 pages9A03501 Thermal Engineering IIsivabharathamurthyNo ratings yet

- c4 Tutorial TurbineDocument2 pagesc4 Tutorial TurbinehahahaNo ratings yet

- Channabasaveshwara Institute of Technology: (NAAC Accredited & An ISO 9001:2015 Certified Institution)Document2 pagesChannabasaveshwara Institute of Technology: (NAAC Accredited & An ISO 9001:2015 Certified Institution)cenu 1999No ratings yet

- TutorialDocument27 pagesTutorialbassemNo ratings yet

- 2 CalculationsDocument11 pages2 CalculationsThiện KhiêmNo ratings yet

- Turbo QuesDocument6 pagesTurbo QuesHariharanNo ratings yet

- TurbomachinesDocument2 pagesTurbomachinesThesinghNo ratings yet

- Variable Compression Ratio ExperimentDocument7 pagesVariable Compression Ratio ExperimentMuruganNo ratings yet

- Propulsion 1 Unit-V Question Bank (Compressors)Document4 pagesPropulsion 1 Unit-V Question Bank (Compressors)kevintsubasa0% (2)

- Page 1 of 3Document3 pagesPage 1 of 3yashvantNo ratings yet

- Diesel HydroDocument1 pageDiesel HydroVon A. DamirezNo ratings yet

- Air Compressor Cylinder Size and Centrifugal Compressor PerformanceDocument2 pagesAir Compressor Cylinder Size and Centrifugal Compressor PerformanceXheikhKaleemNo ratings yet

- Chapter 9 Pump SelectionDocument40 pagesChapter 9 Pump SelectionDuke ThibbotuwawaNo ratings yet

- CIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 4 (Water Turbine)Document1 pageCIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 4 (Water Turbine)AnkurTripathiNo ratings yet

- AE 303 Aerospace Propulsion Tutorial ProblemsDocument3 pagesAE 303 Aerospace Propulsion Tutorial ProblemsVinoth BillaNo ratings yet

- Mechanical Engineering Turbomachinery Assignment QuestionsDocument2 pagesMechanical Engineering Turbomachinery Assignment QuestionsAbebe AyingdaNo ratings yet

- MT 1Document1 pageMT 1JamesNo ratings yet

- AE 6404 PROPUSION-I QUESTION BANK AND UNIT GUIDEDocument9 pagesAE 6404 PROPUSION-I QUESTION BANK AND UNIT GUIDEVinod BalakrishnanNo ratings yet

- Assignment 4-1Document2 pagesAssignment 4-1ashutoshNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Corrosion Control in the Oil and Gas IndustryFrom EverandCorrosion Control in the Oil and Gas IndustryRating: 4 out of 5 stars4/5 (12)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet