Professional Documents

Culture Documents

ASTM D2158 Residuos en GLP

Uploaded by

FredyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM D2158 Residuos en GLP

Uploaded by

FredyCopyright:

Available Formats

An American National Standard

Designation: D 2158 – 05

Designation: 317/95

Standard Test Method for

Residues in Liquefied Petroleum (LP) Gases1

//^:^^#^~^^"^@"^"^#$:@#~"#:$@:#^~:$~^#~~#^~:^^*:""^~^\\

This standard is issued under the fixed designation D 2158; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2 Other Document:

1.1 This test method covers the determination of extraneous IP Appendix A4

--`,,```,,,,````-`-`,,`,,`,`,,`---

materials weathering above 38°C that are present in liquefied 3. Terminology

petroleum gases. The extraneous materials will generally be

dissolved in the LPG, but may have phase-separated in some 3.1 Definitions of Terms Specific to This Standard:

instances. 3.1.1 oil stain observation, n—the volume of solvent-

1.2 Liquefied petroleum gases that contain certain anti-icing residue mixture required to yield an oil stain or ring that

additives can give erroneous results by this test method. persists for 2 minutes under specified conditions on absorbent

1.3 Although this test method has been used to verify paper.

cleanliness and lack of heavy contaminants in propane for 3.1.2 residue, n—the volume, measured to the nearest 0.05

many years, it might not be sensitive enough to protect some mL, of the residual material boiling above 38°C resulting from

equipment from operational problems or increased mainte- the evaporation of 100 mL of sample under the specified

nance. A more sensitive test, able to detect lower levels of conditions of this test method.

dissolved contaminants, could be required for some applica- 3.1.3 solvent-residue mixture, n—a mixture (solution) of 10

tions. mL of solvent with any residue remaining in the centrifuge

1.4 This standard does not purport to address all of the tube at the conclusion of the first step in this test method.

safety concerns, if any, associated with its use. It is the 4. Summary of Test Method

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 4.1 A 100-mL sample of liquefied petroleum gas is weath-

bility of regulatory limitations prior to use. ered in a 100-mL centrifuge tube. The volume of residue

remaining after heating the tube to 38°C is measured and

2. Referenced Documents recorded.

2.1 ASTM Standards:2 4.2 To dissolve any residue, 10 mL of solvent is added to the

D 96 Test Methods for Water and Sediment in Crude Oil by centrifuge tube. Small, measured volumes of solvent-residue

Centrifuge Method (Field Procedure)3 mixture are deposited on an absorbent paper in a specified

D 1796 Test Method for Water and Sediment in Fuel Oils by manner. The appearance of the absorbent paper to which the

the Centrifuge Method (Laboratory Procedure) residue solution has been added in measured increments is

D 1835 Specification for Liquefied Petroleum (LP) Gases observed and recorded.

E 1 Specification for ASTM Liquid-in-Glass Thermometers 5. Significance and Use

5.1 Control over the residue content (required by Specifica-

1

This test method is under the jurisdiction of ASTM Committee D02 on tion D 1835) is of considerable importance in end-use appli-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee cations of LPG. In liquid feed systems residues can lead to

D02.H0 on Liquefied Petroleum Gas.

Current edition approved Nov. 1, 2005. Published November 2005. Originally

troublesome deposits and, in vapor withdrawal systems, resi-

approved in 1963. Last previous edition approved in 2004 as D 2158–04. dues that are carried over can foul regulating equipment. Those

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website. Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

3

Withdrawn. U.K. www.energyinstpubs.org.uk

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International

Provided by IHS under license with ASTM

1

No reproduction or networking permitted without license from IHS Not for Resale

D 2158 – 05

that remain will accumulate, can be corrosive, and will is especially important. The taper shall be uniform and the

contaminate following product. Water, particularly if alkaline, bottom shall be rounded as shown in Fig. 1. Tubes shall be

can cause failure of regulating equipment and corrosion of made of thoroughly annealed heat-resistant glass. Volumetric

metals. graduation tolerances, based on air-free water at 20°C, are

given in Table 1. Detailed requirements for centrifuge tubes

6. Interferences appear in Test Methods D 96 and D 1796.

6.1 Solid contaminants such as rust, scale or dirt can 7.2 Cooling Coil and Cooling Bath, a minimum length of 6

interfere with this test method, which is not intended for m of 5 to 7-mm outside diameter copper tubing wound to a

representative measurement of solid, undissolved contami- diameter of 63.5 6 1.5-mm outside diameter, and assembled in

nants. a suitable cooling bath. (See Fig. 2 as an example.)

7.2.1 Mechanical refrigeration is permitted provided that

7. Apparatus the coolant temperature is below −43ºC. If dry ice is used, a

//^:^^#^~^^"^@"^"^#$:@#~"#:$@:#^~:$~^#~~#^~:^^*:""^~^\\

7.1 Centrifuge Tube, 100-mL graduated, conforming to non-glass dewar or vessel is recommended.

dimensions given in Fig. 1. The first 0.5 mL shall be graduated 7.3 Syringe, 2-mL graduated in 0.1 mL and equipped with a

in 0.05-mL increments. The shape of the lower tip of the tube needle 200 6 5 mm long. The needle may be either a sharp

FIG. 1 Cone-Shaped Centrifuge Tube, 203 mm

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

2

No reproduction or networking permitted without license from IHS Not for Resale

D 2158 – 05

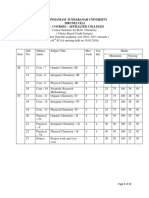

TABLE 1 Centrifuge Tube Graduation Tolerances 7.4.1 For routine testing, a general purpose thermometer

Range, mL

Scale, Division, Limit of Error, with 0.5°C subdivisions and a maximum scale error of 0.5°C

mL mL may be used.

0.0 to 0.1 0.05 0.02 7.5 Absorbent Paper, white, 125-mm diameter. Medium

0.1 to 0.3 0.05 0.03

0.3 to 0.5 0.05 0.05

grade, rapid filter paper has been found to be satisfactory. In

0.5 to 1.0 0.1 0.05 this test method, the paper will be referred to as “filter paper.”

1.0 to 3.0 0.1 0.1 7.6 Solvent Wash Bottle, typically polyethylene.

3.0 to 5.0 0.5 0.2

5.0 to 25.0 1.0 0.5

7.7 Water Bath, controlled at 38 6 2°C.

25.0 to 100.0 1.0 1.0 7.8 Copper Wire, 1.6 6 0.1-mm diameter, 300 6 10-mm

long.

//^:^^#^~^^"^@"^"^#$:@#~"#:$@:#^~:$~^#~~#^~:^^*:""^~^\\

7.9 Clamp, suitable for holding the centrifuge tube during

weathering.

8. Reagents and Materials

8.1 Solvent—HPLC-grade pentane or cyclopentane. An-

other grade of solvent may be used provided that it meets the

requirements of 10.2.

8.1.1 Although pentane is the preferred solvent for use in

this test method, cyclopentane may be substituted for pentane

whenever the ambient temperature or altitude is too high to

enable the convenient handling of pentane.

8.1.2 Storage of solvent in a polyethylene wash bottle for

several days contaminates the solvent. Therefore, do not use

any solvent that has remained in a polyethylene wash bottle for

more than one day.

9. Hazards

9.1 Note that there is a significant fire hazard from LPG

vapors, and since the boiling point of LPG can be as low as

−41°C, there is a risk of freezing “burns.” Take appropriate

safety precautions to prevent ignition or fire, and wear suitable

protective equipment to protect against skin contact with liquid

or vaporizing LPG.

9.2 Operators should wear a grounded antistatic wrist strap.

The use of an antistatic floor mat and grounding the sample

cylinder are also advised.

10. Preparation of Apparatus

10.1 Wash all glassware that is to be used in the test in the

selected solvent.

NOTE—Coils in the drawing are extended for clarity. 10.2 Verification of cleanliness of glassware and solvent.

FIG. 2 Precooling Equipment

10.2.1 Add 10 mL of a new sample of solvent to the

centrifuge tube.

needle (ordinary medical syringe needle) or a safe, non-sharp

10.2.2 Mark the center of the filter paper with a pencil or

syringe needle to avoid a puncture hazard. Alternatively, an

other non-pentane-soluble writing tool.

equivalent liquid dispensing device capable of delivering

10.2.3 Fill the syringe or equivalent liquid dispensing de-

0.1-mL increments may be used, such as a 0.1-mL pipette.

vice (see 7.3) with a portion of the solvent drawn from the

7.4 Temperature Measuring Device, that is intrinsically

centrifuge tube and direct 0.1-mL portions of the solvent to the

safe, with accuracy equal to or better than Specification E 1 or

mark on the paper.

IP Appendix A shall be used. Thermometers conforming to

10.2.3.1 The solvent is added in 0.1-mL increments to

Specification E 1 or IP Appendix A have been found to be

confine the solvent ring to a circle about 30 to 35 mm in

satisfactory.

diameter. The filter paper should be held level during the

Low Range –38°C to + 50°C IP 1C/ASTM 5C

or IP 2C/ASTM 6C

solvent addition. One method is to place it on a 250-mL beaker.

10.2.4 Allow the solvent to evaporate for 2 min, and note

--`,,```,,,,````-`-`,,`,,`,`,,`---

High Range –20°C to + 50°C ASTM 57C

NOTE 1—When a thermometer or a water bath, or both, are not

the persistence of an oil ring.

available, for example when conducting a field test, a satisfactory 10.2.4.1 The presence of an oil ring shall be observed by

alternative for screening purposes is to warm the tip of the centrifuge tube holding the dry filter paper between the eye and a bright

with the hand. incandescent light or strong daylight.

Copyright ASTM International

Provided by IHS under license with ASTM

3

No reproduction or networking permitted without license from IHS Not for Resale

D 2158 – 05

10.2.4.2 If no oil ring appears after 1.5 mL of solvent has the eye and a bright incandescent light or strong daylight,

been added, the solvent and glassware are satisfactory. discontinue the test and go to 12.1.

10.2.4.3 The appearance of an oil ring indicates either 11.2.5 If a stain or ring is discernible, determine the volume

improperly cleaned glassware or contaminated solvent. of the solvent-residue mixture at which the oil stain or ring first

persists for 2 min on a new filter paper by adding the

11. Procedure solvent-residue mixture in 0.1-mL increments, waiting 2 min

11.1 Residue Measurement: after each addition, and inspecting the paper for an oil stain at

11.1.1 Attach the cooling coil to the LPG sample source, the end of the 2-min period.

cool the coil to below the boiling point of the sample, and flush 11.2.6 Record the volume in millilitres of the solvent-

the coil and sampling line. residue mixture required to yield a persistent oil stain or ring as

11.1.2 Rinse and cool the centrifuge tube with the material the oil stain observation.

to be sampled and then fill it to the 100-mL mark with a 11.2.7 Alternatively, if a product specification calls for

representative sample of LPG. adding a specified amount of solvent-residue mixture to the

11.1.3 Immediately insert the copper wire through a clean, filter paper, add the specified quantity in 0.1 mL increments,

slotted cork or a clean, loose-fitting plug of cotton or cleansing and report the result at the specified total amount.

tissue in the mouth of the centrifuge tube. The wire helps to 11.2.7.1 Specification D 1835 specifies that 0.3 mL of

prevent superheating and resulting bumping (erratic or exces- solvent-residue mixture shall be deposited on the filter paper in

sive boiling), and the cork (or plug) will keep out air or 0.1-mL increments.

moisture while the sample is weathering. 11.2.7.2 If there is no oil stain after the addition of 0.3 mL

11.1.4 If more than 10 mL of the sample is lost because of and a 2-min waiting period, report the result as “Pass.”

bumping, obtain a new sample and repeat the test. 11.2.7.3 If an oil stain is observed at 0.3 mL after a 2-min

11.1.5 Allow the sample to weather, using artificial heating waiting period, report the result as “Fail.”

if the ambient temperature or type of sample requires it. If, 11.3 Any solvent transferred to the wash bottle for purposes

when weathering has ceased and the tube has reached ambient of running the test shall either be used in testing during the

temperature, a visible residue remains, place the tip of the tube same day or discarded.

in a water bath at 38°C for 5 min. 11.4 It has been noted that at low ambient temperatures

11.1.6 Record the volume of any remaining residue to the (below about 5°C) materials in the gasoline boiling range will

nearest 0.05 mL, and the presence of extraneous matter, if leave an oil stain or ring that persists after 2 min. Oil stain

observed. determinations should be made in a protected area where the

--`,,```,,,,````-`-`,,`,,`,`,,`---

11.1.7 Perform the oil stain observation described in 11.2 temperature is above 5°C. If it is necessary to determine the oil

even if there is no apparent or visible residue in the centrifuge stain at temperatures below 5°C, allow 10 min for oil stain

tube. Experience has shown that there can be a thin film of oil persistence.

on the inner surface of the centrifuge tube that is difficult to see

and does not give a measurable volume, but can still give a ring 12. Report

or stain in the Oil Stain Observation procedure. 12.1 Report the results as:

11.2 Oil Stain Observation: 12.1.1 Residue on evaporation to the nearest 0.05 mL, and

11.2.1 Add sufficient solvent to the centrifuge tube contain- 12.1.2 Oil stain observation to the nearest 0.1 mL.

ing the residue described in 11.1.5 to restore the volume to 10 12.2 Alternatively, if the application of this test method calls

mL. Add the solvent from the wash bottle and carefully wash for passing or failing the oil stain requirement at a specified

down the sides of the tube. Stir well so that any residue at the volume of solvent-residue mixture, report the result at the

bottom of the tube is dissolved uniformly in the solvent. specified volume as “Pass” or “Fail” (see 11.2.7).

Stirring with the syringe needle (see 7.3) or pipette has been

found satisfactory. This mixture will be referred to as the 13. Precision and Bias

solvent-residue mixture. 13.1 Precision—Precision has not been determined on this

11.2.2 Mark the center of a clean white filter paper. method in terms of residue and oil stain results. Precision had

11.2.3 Fill the syringe or equivalent liquid dispensing de- been determined in terms of R and O numbers, as given in

vice (see 7.3), and direct 1.5 mL of the solvent-residue mixture Appendix X1.

at the center of the paper at an appropriate rate such that the 13.2 Bias—The procedure in this test method for measuring

wetted circle is maintained at about 30 to 35 mm in diameter. residues in LP Gas has no bias, because the residues are defined

If desired, steps 11.2.3 and 11.2.4 may be omitted, and the test only in terms of this test method.

continued according to 11.2.5.

11.2.4 After directing the entire 1.5 mL of residue solution 14. Keywords

onto the filter paper and at the end of a 2-min waiting period, 14.1 contaminants; liquefied petroleum gases; LPG; oil

if no oil ring persists when holding the dry filter paper between stain; residue

//^:^^#^~^^"^@"^"^#$:@#~"#:$@:#^~:$~^#~~#^~:^^*:""^~^\

Copyright ASTM International

Provided by IHS under license with ASTM

4

No reproduction or networking permitted without license from IHS Not for Resale

D 2158 – 05

APPENDIX

(Nonmandatory Information)

X1. CALCULATION OF R AND O NUMBERS

INTRODUCTION

Historically, D 2158 has included indices for R and O which give the residue and oil stain results

in whole numbers rather than the decimal results of this test method. These results have been referred

to as “normalized results.” Since no ASTM standards call for R or O results, the description and

calculation of these values have been moved to an appendix for information.

X1.1 Terminology X1.3.2 Repeatability—The difference (r) between succes-

X1.1.1 Definitions of Terms Specific to this Standard: sive test results obtained by the same operator with the same

X1.1.1.1 O Number, n, 10 divided by the oil stain observa- apparatus under constant operating conditions on identical test

tion (in millilitres). material would, in the long run, in the normal and correct

X1.1.1.2 R Number, n, the residue volume in millilitres operation of the test method, exceed the values below only in

multiplied by 200. one case in twenty:

O Number r R Number r

X1.2 Calculation and Reporting 0 to 20 4 0 to 20 5

20 to 40 6 20 to 40 10

X1.2.1 O Number—Divide 10 by the oil stain observation 40 to 100 8 40 to 60 20

obtained in 11.2.6, in millilitres, and report the result to the X1.3.3 Reproducibility—The difference (R) between two

nearest whole number. If the oil stain observation exceeds 1.5 test results independently obtained by different operators

mL, record the result as zero. operating in different laboratories on nominally identical test

X1.2.2 R Number—Multiply the residue volume obtained in material would, in the long run, in the normal and correct

11.1.5, in millilitres, by 200, and express the result to the operation of the test method, exceed the values below only in

nearest 10. one case in twenty:

O Number R R Number R

X1.3 Precision and Bias 0 to 20 6 0 to 20 10

X1.3.1 Precision has been determined in terms of the 20 to 40 8 20 to 40 20

40 to 100 12 40 to 60 30

normalized reporting units.

SUMMARY OF CHANGES

Subcommittee D02.H0 has identified the location of selected changes to this standard since the last issue

(D 2158–04) that may impact the use of this standard (approved Nov. 1, 2005).

(1) Moved references to R and O numbers to Appendix X1. (3) Revised 11.2, the Oil Stain Observation procedure.

(2) Made other wording improvements for clarity throughout (4) Revised Section 12, Report.

the standard.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

5

No reproduction or networking permitted without license from IHS Not for Resale

//^:^^#^~^^"^@"^"^#$:@#~"#:$@:#^~:$~^#~~#^~:^^*:""^~^\\

You might also like

- Unit 3 - Worksheet 2: Name Date PDDocument2 pagesUnit 3 - Worksheet 2: Name Date PDRobert B.75% (4)

- Astm D-5739 - 00 PDFDocument13 pagesAstm D-5739 - 00 PDFGeorgiana100% (1)

- D7843 16Document4 pagesD7843 16alimisaghian62100% (1)

- Astm E300-03 PDFDocument24 pagesAstm E300-03 PDFCeciliagorra100% (1)

- Astm D 4176 PDFDocument4 pagesAstm D 4176 PDFAlexander Amado QuinteroNo ratings yet

- Astm D7843 - 21Document6 pagesAstm D7843 - 21MARIVEL BASANo ratings yet

- D5837Document8 pagesD5837usamafalakNo ratings yet

- D 7647 - 10Document10 pagesD 7647 - 10Hiền Nguyễn100% (1)

- ASTM D2421 Interconveccion GLPDocument4 pagesASTM D2421 Interconveccion GLPFredy100% (1)

- Adamson and Gast - Physical Chemistry of SurfacesDocument804 pagesAdamson and Gast - Physical Chemistry of SurfacesOtro Camilo100% (3)

- Isotonic SolutionsDocument33 pagesIsotonic SolutionsChristine Annmarie TapawanNo ratings yet

- Advantages of Altuglas LPADocument4 pagesAdvantages of Altuglas LPASurendren Nair100% (1)

- Residues in Liquefied Petroleum (LP) Gases: Standard Test Method ForDocument6 pagesResidues in Liquefied Petroleum (LP) Gases: Standard Test Method ForLucía MontalvoNo ratings yet

- Astm D6038 - 2014Document4 pagesAstm D6038 - 2014alferedNo ratings yet

- Astm D 7066 - 2004Document9 pagesAstm D 7066 - 2004Guido KünstlerNo ratings yet

- ASTM 1003-95 HydrostaticLeak TestingDocument3 pagesASTM 1003-95 HydrostaticLeak TestingTOufiqueNo ratings yet

- Astm d381 Jtvo9242Document5 pagesAstm d381 Jtvo9242Nayth Andres GalazNo ratings yet

- ASTM D3921 Grasas y Aceites en AguaDocument7 pagesASTM D3921 Grasas y Aceites en AguafamturboNo ratings yet

- 22-E-1003Document3 pages22-E-1003Carlos Raul Caballero LeonNo ratings yet

- ASTM D-381 Standard Test Method For Gum Content in Fuels by Jet EvaporationDocument5 pagesASTM D-381 Standard Test Method For Gum Content in Fuels by Jet EvaporationGabriela EhlertNo ratings yet

- 10.0 D4928-12 OriginalDocument6 pages10.0 D4928-12 OriginalRuben YoungNo ratings yet

- Oil and Grease and Petroleum Hydrocarbons in Water: Standard Test Method ForDocument7 pagesOil and Grease and Petroleum Hydrocarbons in Water: Standard Test Method ForRay Emmanuelle CorsigaNo ratings yet

- Preparation of Contaminated Test Coupons For The Evaluation of Cleaning AgentsDocument4 pagesPreparation of Contaminated Test Coupons For The Evaluation of Cleaning AgentsDavid Francisco Plata DuranNo ratings yet

- D1094-00 (Reapproved 2005) Standard Test Method For Water Reaction of Aviation FuelsDocument3 pagesD1094-00 (Reapproved 2005) Standard Test Method For Water Reaction of Aviation FuelsDiego EchagarayNo ratings yet

- D 5441 - 98 - Rdu0ndetotgDocument6 pagesD 5441 - 98 - Rdu0ndetotgNguyễn Bằng NộiNo ratings yet

- ASTM D 7039-15aDocument12 pagesASTM D 7039-15aIsrael Lopez RamirezNo ratings yet

- Astm T 165Document3 pagesAstm T 165Thant ZinNo ratings yet

- Characteristic Groups in Rubber Extender and Processing Oils and Other Petroleum-Derived Oils by The Clay-Gel Absorption Chromatographic MethodDocument8 pagesCharacteristic Groups in Rubber Extender and Processing Oils and Other Petroleum-Derived Oils by The Clay-Gel Absorption Chromatographic MethodKatheryn Galarzaa'No ratings yet

- Astm D1160Document18 pagesAstm D1160Ryuzo GotoNo ratings yet

- Density, Relative Density, and API Gravity of Liquids by Digital Density MeterDocument9 pagesDensity, Relative Density, and API Gravity of Liquids by Digital Density MeterAbidin SyakirinNo ratings yet

- Determination of Vapor Pressure of Crude Oil: VPCR (Expansion Method)Document7 pagesDetermination of Vapor Pressure of Crude Oil: VPCR (Expansion Method)Cristhian Emmanuel GarridoNo ratings yet

- Standard Test Method For Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-Ray Fluorescence SpectrometryDocument9 pagesStandard Test Method For Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-Ray Fluorescence SpectrometryalexanderNo ratings yet

- Foaming Characteristics of Lubricating Oils: Standard Test Method ForDocument11 pagesFoaming Characteristics of Lubricating Oils: Standard Test Method ForTarlan AllahverdiyevNo ratings yet

- Astm D6560-17Document6 pagesAstm D6560-17Angel MurilloNo ratings yet

- D 381 - 00 - Rdm4ms0wmaDocument5 pagesD 381 - 00 - Rdm4ms0wmaLea CoriaNo ratings yet

- Furanic in transform oil ASTM D5837-1999(2005)Document3 pagesFuranic in transform oil ASTM D5837-1999(2005)Yap Poh SiewNo ratings yet

- ASTM D 93-02aDocument16 pagesASTM D 93-02aEmmanuel Mariano GómezNo ratings yet

- ASTM D4052-2022 Densidad Digital Productos Del PetróleoDocument9 pagesASTM D4052-2022 Densidad Digital Productos Del Petróleodmvaldes21No ratings yet

- Coagulated Pentane Insolubles in Used Lubricating Oils by Paper Filtration (LMOA Method)Document5 pagesCoagulated Pentane Insolubles in Used Lubricating Oils by Paper Filtration (LMOA Method)ahmed100% (1)

- Acid and Base Number by Color-Indicator Titration: Standard Test Method ForDocument7 pagesAcid and Base Number by Color-Indicator Titration: Standard Test Method ForLuis EnriqueNo ratings yet

- ASTM D 93 Punto Inflamacion PDFDocument16 pagesASTM D 93 Punto Inflamacion PDFMaria BradaNo ratings yet

- Gum Content in Fuels by Jet Evaporation: Standard Test Method ForDocument6 pagesGum Content in Fuels by Jet Evaporation: Standard Test Method ForDennise ChicaizaNo ratings yet

- Measurement of Thermal Stability of Aviation Turbine Fuels Under Turbulent Flow Conditions (Hirets Method)Document11 pagesMeasurement of Thermal Stability of Aviation Turbine Fuels Under Turbulent Flow Conditions (Hirets Method)MohanadNo ratings yet

- D4281Document6 pagesD4281saifullah629No ratings yet

- Astm D 5853 - 06 PDFDocument7 pagesAstm D 5853 - 06 PDFJulian Felipe Noguera CruzNo ratings yet

- ASTM D1265-11 Muestreo de Gases Método ManualDocument5 pagesASTM D1265-11 Muestreo de Gases Método ManualDiana Alejandra Castañón IniestraNo ratings yet

- D1401 - Standard Test Method For Water Separability of Petroleum Oils and Synthetic FluidsDocument5 pagesD1401 - Standard Test Method For Water Separability of Petroleum Oils and Synthetic FluidsEhsan ZiaeiNo ratings yet

- Astm D1401Document4 pagesAstm D1401CeciliagorraNo ratings yet

- Foaming Characteristics of Lubricating Oils: Standard Test Method ForDocument11 pagesFoaming Characteristics of Lubricating Oils: Standard Test Method ForGabriela EhlertNo ratings yet

- Distillation Range of Volatile Organic Liquids: Standard Test Method ForDocument9 pagesDistillation Range of Volatile Organic Liquids: Standard Test Method Forgravity castNo ratings yet

- D 3831 - 01 - Rdm4mzeDocument4 pagesD 3831 - 01 - Rdm4mzeAhmad KhreisatNo ratings yet

- Dropping Point of Lubricating Grease: Standard Test Method ForDocument5 pagesDropping Point of Lubricating Grease: Standard Test Method ForPrincess NobleNo ratings yet

- Gum Content in Fuels by Jet Evaporation: Standard Test Method ForDocument6 pagesGum Content in Fuels by Jet Evaporation: Standard Test Method FormuhannadNo ratings yet

- Astm D-3328 - 00 PDFDocument7 pagesAstm D-3328 - 00 PDFGeorgianaNo ratings yet

- Astm D-3328 - 00Document7 pagesAstm D-3328 - 00GeorgianaNo ratings yet

- D93-99c Inflamación Vaso Cerrado PDFDocument15 pagesD93-99c Inflamación Vaso Cerrado PDFDiego EchagarayNo ratings yet

- Volatile Content of Coatings: Standard Test Method ForDocument3 pagesVolatile Content of Coatings: Standard Test Method ForramakantNo ratings yet

- D 3710 - 95 R99 - Rdm3mtaDocument12 pagesD 3710 - 95 R99 - Rdm3mtaLuz Adriana MorenoNo ratings yet

- ASTM E 515 Standard Test Method For Leaks Using Bubble Emission TechniquesDocument3 pagesASTM E 515 Standard Test Method For Leaks Using Bubble Emission TechniquesILSEN N. DAETNo ratings yet

- Determination of Solvent Red 164 Dye Concentration in Diesel FuelsDocument4 pagesDetermination of Solvent Red 164 Dye Concentration in Diesel Fuels歐昱辰No ratings yet

- Free Water and Particulate Contamination in Distillate Fuels (Visual Inspection Procedures)Document3 pagesFree Water and Particulate Contamination in Distillate Fuels (Visual Inspection Procedures)PAURUSHNo ratings yet

- Astm d4176Document3 pagesAstm d4176PAURUSHNo ratings yet

- 5.0 D5002-18 OriginalDocument6 pages5.0 D5002-18 OriginalRuben YoungNo ratings yet

- Compendium of Analytical Nomenclature: Definitive Rules 1977From EverandCompendium of Analytical Nomenclature: Definitive Rules 1977No ratings yet

- Redox Indicators. Characteristics and ApplicationsFrom EverandRedox Indicators. Characteristics and ApplicationsRating: 5 out of 5 stars5/5 (1)

- ASTM D1267 Presion de Vapor Reid GLPDocument5 pagesASTM D1267 Presion de Vapor Reid GLPFredyNo ratings yet

- ASTM D6667 Azufre Total en GLPDocument7 pagesASTM D6667 Azufre Total en GLPFredy100% (1)

- Ge GLP Astm D 1657-02 (R07)Document5 pagesGe GLP Astm D 1657-02 (R07)Erick Leonardo Valle MendozaNo ratings yet

- VX Spectra 19mm Metrological Performance - 6620824 - 01Document10 pagesVX Spectra 19mm Metrological Performance - 6620824 - 01FredyNo ratings yet

- Experiment 2 - Electrolytic CellDocument8 pagesExperiment 2 - Electrolytic CellafifiNo ratings yet

- Steam Jet RefrigerationDocument14 pagesSteam Jet RefrigerationSAATVIK JAINNo ratings yet

- EOCQ - Ans - 17 2Document1 pageEOCQ - Ans - 17 2Куаныш ЖанадилNo ratings yet

- CY6251Document2 pagesCY6251Muthu KrishNo ratings yet

- Chapter-1 Chemical Reactions and Equations MCQsDocument18 pagesChapter-1 Chemical Reactions and Equations MCQsAkshay ShuklaNo ratings yet

- 8-Titrasi Asam BasaDocument113 pages8-Titrasi Asam BasaAfif Akmal AfkauniNo ratings yet

- Q1-W5-D5-Separating Mixtures - DistillationDocument4 pagesQ1-W5-D5-Separating Mixtures - DistillationHeidi Dalyagan DulnagonNo ratings yet

- Physical Science Chemistry Module 1Document65 pagesPhysical Science Chemistry Module 1Isnihaya AbubacarNo ratings yet

- Turbines, pumps and compressors explainedDocument5 pagesTurbines, pumps and compressors explainedJuan HeroNo ratings yet

- Sizing Calculation of Dry Electro-Static Precipitator (DESP)Document12 pagesSizing Calculation of Dry Electro-Static Precipitator (DESP)imtinanNo ratings yet

- Di Xiao PhysRevLett.108.196802Document5 pagesDi Xiao PhysRevLett.108.196802fangzhouNo ratings yet

- Strategies for Successful Design and Processing of Plastic PartsDocument112 pagesStrategies for Successful Design and Processing of Plastic PartsAnand kumar100% (1)

- NFR ParticipantsDocument707 pagesNFR ParticipantsJuan Francisco SantiagoNo ratings yet

- Ed.5.PHARMACEUTICAL ANALYSIS PDFDocument28 pagesEd.5.PHARMACEUTICAL ANALYSIS PDFShubham Sabale PatilNo ratings yet

- BOOST Theory PDFDocument127 pagesBOOST Theory PDFadrins22No ratings yet

- PHYC10004exam2019 SolutionsDocument26 pagesPHYC10004exam2019 SolutionsHank MoodyNo ratings yet

- Oxidation Behaviour of Silicon Carbide - A Review PDFDocument11 pagesOxidation Behaviour of Silicon Carbide - A Review PDFcleitononline4599No ratings yet

- Solved by Smart Exam Resources: Cambridge International General Certificate of Secondary EducationDocument16 pagesSolved by Smart Exam Resources: Cambridge International General Certificate of Secondary EducationHidayah TeacherNo ratings yet

- Bio JanasDocument16 pagesBio JanasMohd Fairus Mohd YasinNo ratings yet

- AL Chemistry 2002 Paper 2Document19 pagesAL Chemistry 2002 Paper 2api-3734333No ratings yet

- CA Lesson 2 AlkanesDocument31 pagesCA Lesson 2 AlkanesAlbaraaAliNo ratings yet

- 706 Aed 831676438Document27 pages706 Aed 831676438Online JobNo ratings yet

- Chapter 5 - Thermodynamics6Document8 pagesChapter 5 - Thermodynamics6pythagorus_banNo ratings yet

- Grade 7-Notes On Acids Bases and SaltsDocument4 pagesGrade 7-Notes On Acids Bases and SaltsshamshadNo ratings yet

- Cobalt ComplexDocument11 pagesCobalt ComplexFhazzira Ajah100% (1)

- Persistent Current and Drude Weight For The One-DiDocument12 pagesPersistent Current and Drude Weight For The One-DiAkin AkandeNo ratings yet