Professional Documents

Culture Documents

Nut Astm A563M 10S Bolt/Screw Astm A325M-1: Proof ST Proof L

Uploaded by

Debulus PROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nut Astm A563M 10S Bolt/Screw Astm A325M-1: Proof ST Proof L

Uploaded by

Debulus PRCopyright:

Available Formats

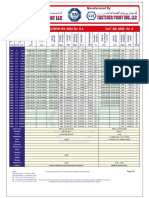

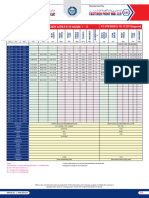

BOLT/SCREW ASTM A325M-1 NUT ASTM A563M 10S

HARDNESS

HARDNESS

DIAMETER

TORQUE *

ACCROSS

TENSILE

ATION #

STRESS

SHANK

ACCROS

WIDTH

WIDTH

STRESS

STRESS

HEIGHT

HEIGHT

ELONG-

PROOF

FLATS

FLATS

PROOF

PITCH

PROOF

PROOF

STRESS

LOAD

HEAD

HEAD

LOAD

AREA

BOLT

SIZE

2

mm mm mm mm mm mm Mpa KN Mpa N-m HRC % mm mm Mpa KN HRC

PLAIN HDG PLAIN HDG

M6 1 20.1

M8 1.25 36.6

M10 1.5 58.8

M12 1.75 84.3 600 50.6 830 81.5 25-34 14- 20.16~21.00 11.90~12.30 1245 1165 105 98 26~38

M14 2.0 115.0 600 69.0 830 129.7 25-34 14- 23.16~24.00 13.60~14.30 1245 1165 143 134 26~38

M16 2.0 157.0 15.30~16.70 26.16~27.00 9.25~10.75 600 94.2 830 202.3 25-34 14- 26.16~27.00 16.40~17.10 1245 1165 195 183 26~38

M18 2.5 192.0 600 115.2 830 278.4 25-34 14- 1245 1165 239 224 26~38

M20 2.5 245.0 19.16~20.84 33.00~34.00 11.60~13.40 600 147.0 830 394.7 25-34 14- 33.00~34.00 19.40~20.70 1245 1165 305 285 26~38

M22 2.5 303.0 21.16~22.84 35.00~36.00 13.10~14.90 600 181.8 830 536.9 25-34 14- 35.00~36.00 22.30~23.60 1245 1165 377 353 26~38

M24 3.0 353.0 23.16~24.84 40.00~41.00 14.10~15.90 600 211.8 830 682.4 25-34 14- 40.00~41.00 22.90~24.20 1245 1165 439 411 26~38

M27 3.0 459.0 26.16~27.84 45.00~46.00 16.10~17.90 600 275.4 830 998.3 25-34 14- 45.00~46.00 26.30~27.60 1245 1165 571 535 26~38

M30 3.5 561.0 29.16~30.84 49.00~50.00 17.65~19.75 600 336.6 830 1,356 25-34 14- 49.00~50.00 29.10~30.70 1245 1165 698 654 26~38

M33 3.5 694.0 600 416.4 830 1,845 25-34 14- 1245 1165 864 809 26~38

M36 4.0 817.0 35.00~37.00 58.80~60.00 21.45~23.55 600 490.2 830 2,369 25-34 14- 58.80~60.00 35.00~36.00 1245 1165 1,017 952 26~38

M39 4.0 976.0

M42 4.5 1,120.0

M45 4.5 1,310.0

M48 5.0 1,470.0

M52 5.0 1,760.0

M56 5.5 2,030.0

M60 5.5 2,360.0

M64 6.0 2,680.0

M68 6.0 3,060.0

M72 6.0 3,460.0

M76 6.0 3,890.0

M80 6.0 4,340.0

M85 6.0 4,950.0

M90 6.0 5,590.0

M95 6.0 6,270.0

M100 6.0 6,990.0

Dimensions H E A V Y H E X a s p e r A N S I/A S ME B 18.2.4.7M H E A V Y H E X a s p e r A N S I/A S ME B 18.2.4.6M

Markings ‘FPI’ ‘A325M’ ‘8S’ ‘FPI’ ‘10S’

Carbon 0.30-0.52 0.20-0.55

Manganese 0.6- 0.30-

Sulfur -0.05/-0.04 -0.05

Silicon 0.15-0.30 / 0.15-0.35

Chromium

Molybdenum

Nickle

Vanadium

Boron

Copper

Nitrogen

Phosphorus -0.04/-0.035 -0.040

Material Medium Carbon/Alloy Steel Medium Carbon or Alloy Steel

Notes * Torque value based on 75% of proof load and finish as received steel

Left hand side of '-' is minium value # Elongation in length of 4 times Diameter

right hand side of '-' is maximam value

Eg. 0.5-0.7 min is 0.5 and max is 0.7

Eg. -0.8 max is 0.8 no minimam value While every care has been taken in preparation of the information, the company accepts no liability for any loss or

Eg. 2.0- min is 2.0 no maximam value damage either direct or consequential, Please refer Original standards for details.

You might also like

- Tablas Cf574 - Sika Base AguaDocument13 pagesTablas Cf574 - Sika Base AguaDaniel PatronNo ratings yet

- Table 6 1 AWS D1 1 D1 1M 2010 PDFDocument1 pageTable 6 1 AWS D1 1 D1 1M 2010 PDFFu AdNo ratings yet

- A325m 14 PDFDocument8 pagesA325m 14 PDFAquino0% (1)

- Ford Wa 960-2004Document1 pageFord Wa 960-2004DanielMa0% (1)

- Aws - D1.1M - 2020 - Llo 268Document1 pageAws - D1.1M - 2020 - Llo 268santiago cruzNo ratings yet

- ABS NDI - Guide Section 8 Acceptance Criteria For Hull Welds 5.Document3 pagesABS NDI - Guide Section 8 Acceptance Criteria For Hull Welds 5.Dagoberto AguilarNo ratings yet

- Spesifikasi Bolt, Nut & WasherDocument7 pagesSpesifikasi Bolt, Nut & WasheragieyogaswaraNo ratings yet

- D1 - 1 2020 - Structural Welding Code-Steel - 01Document1 pageD1 - 1 2020 - Structural Welding Code-Steel - 01Trung NguyenNo ratings yet

- CBEME Prequalification DocumentDocument56 pagesCBEME Prequalification Documentnafis2uNo ratings yet

- Structural Bolts, Steel, Heat Treated 830 Mpa Minimum Tensile Strength (Metric)Document8 pagesStructural Bolts, Steel, Heat Treated 830 Mpa Minimum Tensile Strength (Metric)abohassn72No ratings yet

- Elcometer 270 Pinhole DetectorsDocument3 pagesElcometer 270 Pinhole DetectorsBarrie Van WykNo ratings yet

- ASTM A325 Heavy Hex Structural Bolt SpecificationDocument1 pageASTM A325 Heavy Hex Structural Bolt SpecificationAlberto CárdenasNo ratings yet

- ASTM A36 Steel plate propertiesDocument1 pageASTM A36 Steel plate propertiesStan HonNo ratings yet

- Fischer Anchor BoltDocument10 pagesFischer Anchor Bolticehorizon88No ratings yet

- Ansi b18.2.1 Hex Machine BoltDocument1 pageAnsi b18.2.1 Hex Machine BoltBharatNo ratings yet

- Manual Técnico de Parafusos - BOSSARDDocument85 pagesManual Técnico de Parafusos - BOSSARDRenato Caldas100% (1)

- Common Requirements For Wrought Steel Piping FittingsDocument10 pagesCommon Requirements For Wrought Steel Piping FittingsLemir LopezNo ratings yet

- Welding Domex SteelsDocument16 pagesWelding Domex Steelspozolab100% (1)

- Automatic Weld Size GaugeDocument1 pageAutomatic Weld Size GaugeLucioNo ratings yet

- Astm A759Document4 pagesAstm A759Laziz AtmaniNo ratings yet

- Aws 5.36Document2 pagesAws 5.36ManikandanNo ratings yet

- Astm D2729 PDFDocument2 pagesAstm D2729 PDFShan Adrias100% (1)

- Cast Alloy Steel Spec Ensures WeldabilityDocument6 pagesCast Alloy Steel Spec Ensures WeldabilityarunrathikaNo ratings yet

- Sampling Procedure For Impact Testing of Structural SteelDocument4 pagesSampling Procedure For Impact Testing of Structural Steeljoy gultom100% (1)

- Examination and Evaluation of Pitting Corrosion: Standard Guide ForDocument8 pagesExamination and Evaluation of Pitting Corrosion: Standard Guide Foralucard375No ratings yet

- Technical Data: Carbofol HDPE 406 1,0 S/s Smooth / Smooth OITDocument1 pageTechnical Data: Carbofol HDPE 406 1,0 S/s Smooth / Smooth OITAlex Lie100% (1)

- High-Strength Steel Bolts, Classes 10.9 and 10.9.3, For Structural Steel Joints (Metric)Document6 pagesHigh-Strength Steel Bolts, Classes 10.9 and 10.9.3, For Structural Steel Joints (Metric)Ngoc BuiNo ratings yet

- Sae J1701Document5 pagesSae J1701Marco NiNo ratings yet

- AWS D1.1 - Bend PDFDocument1 pageAWS D1.1 - Bend PDFVIVEKNo ratings yet

- Blasting &painting Pocedures MTD SOP 15 01Document1 pageBlasting &painting Pocedures MTD SOP 15 01vinothNo ratings yet

- API 2H50 Data Sheet 2012 04 02Document2 pagesAPI 2H50 Data Sheet 2012 04 02alvaedison00No ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- Astm C470.C470M 2009Document4 pagesAstm C470.C470M 2009Carlos GuerraNo ratings yet

- Ss Grade 50 - Galvanized Steel Coils & SheetsDocument1 pageSs Grade 50 - Galvanized Steel Coils & SheetshealgoseNo ratings yet

- ASTM C1147-14 CodeDocument4 pagesASTM C1147-14 CodeGene DiJoseph100% (1)

- Safety Factor of Statically Loaded Weld JointDocument2 pagesSafety Factor of Statically Loaded Weld JointMoonzeNo ratings yet

- Kelken US Metric Chart ASTM F1554 Grade 36 PDFDocument1 pageKelken US Metric Chart ASTM F1554 Grade 36 PDFVibha VeerNo ratings yet

- A 6 - A 6m - 02 QtytmdiDocument63 pagesA 6 - A 6m - 02 QtytmdiDanem HalasNo ratings yet

- Non-Asbestos Gasket Material Data SheetDocument1 pageNon-Asbestos Gasket Material Data Sheetheena jainNo ratings yet

- Bentonite Api 13a Section 9 PDFDocument1 pageBentonite Api 13a Section 9 PDFmtnguyennsNo ratings yet

- ISO/AWS/JIS welding material standards updateDocument4 pagesISO/AWS/JIS welding material standards updateHoque AnamulNo ratings yet

- API 5L Grade X52 Pipe Chemical Composition and Mechanical PropertiesDocument1 pageAPI 5L Grade X52 Pipe Chemical Composition and Mechanical PropertiesMohamed HassanNo ratings yet

- Snug-Tight Bolting Procedure for Hamon Custodis Grillage Beam ConnectionsDocument2 pagesSnug-Tight Bolting Procedure for Hamon Custodis Grillage Beam ConnectionsmrgishiNo ratings yet

- MANAURITE XM Material PDFDocument8 pagesMANAURITE XM Material PDFkbc404No ratings yet

- Access Flooring and Handrail CatalogueDocument10 pagesAccess Flooring and Handrail CatalogueSaravan KumarNo ratings yet

- Fab Gate ManualDocument16 pagesFab Gate ManualRahul LavandNo ratings yet

- Astm A105Document1 pageAstm A105Isaac SamuelNo ratings yet

- Espol 38.00 Revised 07032016Document2 pagesEspol 38.00 Revised 07032016Vinay YadavNo ratings yet

- WELDING Book AWSD1.1 Rev-3ADocument35 pagesWELDING Book AWSD1.1 Rev-3AFerdie OS100% (1)

- Bollard Catalogue PDFDocument16 pagesBollard Catalogue PDFHaris PrasetiyoNo ratings yet

- TES 101-158 - 7 - Hi PDFDocument8 pagesTES 101-158 - 7 - Hi PDFRossoNo ratings yet

- Star Core 6Document2 pagesStar Core 6jmur10No ratings yet

- Asme Sec Viii D2 Art D-2 PDFDocument10 pagesAsme Sec Viii D2 Art D-2 PDFDieguitoOmarMoralesNo ratings yet

- Anvil Fig137 U-Bolt PDFDocument1 pageAnvil Fig137 U-Bolt PDFAin AzmiNo ratings yet

- Bolt Standard BS 3692Document1 pageBolt Standard BS 3692Mai Xuan Truong0% (1)

- NUT BS 3692 Gr. 8 BOLT/SCREW BS 3692 Gr. 8.8: Marketed By: Manufactured byDocument1 pageNUT BS 3692 Gr. 8 BOLT/SCREW BS 3692 Gr. 8.8: Marketed By: Manufactured byrk_gprkavi2011No ratings yet

- 01 Bolt Screw Stud Iso 4014 4017 Gr. Iso 898 1 8.8Document1 page01 Bolt Screw Stud Iso 4014 4017 Gr. Iso 898 1 8.8Cyril J PadiyathNo ratings yet

- 03 Bolt Astm A325mDocument1 page03 Bolt Astm A325mMUSTAFA TEMEMINo ratings yet

- Forward ShieldsDocument3 pagesForward ShieldsAnniaNo ratings yet

- Morse Taper DimensionsDocument1 pageMorse Taper DimensionsGordNo ratings yet

- Pwrcell Assembly Pwrcell Configuration Guide: FeaturesDocument2 pagesPwrcell Assembly Pwrcell Configuration Guide: FeaturesDebulus PRNo ratings yet

- Features:: No Autotransformer or Battery Inverter Needed User-Selectable Modes Free System MonitoringDocument2 pagesFeatures:: No Autotransformer or Battery Inverter Needed User-Selectable Modes Free System MonitoringDebulus PRNo ratings yet

- A325 & A490 Bolt Torque SpecificationsDocument1 pageA325 & A490 Bolt Torque SpecificationsDebulus PRNo ratings yet

- Viega Propress Systems: The Global Leader in Plumbing, Heating and Pipe Joining SystemsDocument32 pagesViega Propress Systems: The Global Leader in Plumbing, Heating and Pipe Joining SystemsDebulus PRNo ratings yet

- Sanitary Clamp Data SheetDocument23 pagesSanitary Clamp Data SheetDebulus PRNo ratings yet

- AWS - Use of Measuring ToolsDocument33 pagesAWS - Use of Measuring ToolsTonyo Ayshiyu100% (11)

- Torque Chart Rev1-1Document1 pageTorque Chart Rev1-1Debulus PRNo ratings yet

- MRCET Tin Smithy Tools GuideDocument10 pagesMRCET Tin Smithy Tools GuideRishi GuptaNo ratings yet

- 4E Metals Worksheet 2023 - AnswersDocument4 pages4E Metals Worksheet 2023 - AnswersAngeline LiuNo ratings yet

- The Electric Arc FurnaceDocument22 pagesThe Electric Arc FurnaceKingsley Posiyano100% (2)

- Activity No 8 Properties of MetalsDocument5 pagesActivity No 8 Properties of MetalsILIVEFOR MONSTA7No ratings yet

- Certificate of Analysis: Characteristics Specifications Measured ValuesDocument2 pagesCertificate of Analysis: Characteristics Specifications Measured ValuesMai NguyễnNo ratings yet

- Chapter 10 - Technology of Ferronickel PDFDocument9 pagesChapter 10 - Technology of Ferronickel PDFLuis AcevedoNo ratings yet

- Minerals and Energy Resources Full Chapter ExplanationDocument63 pagesMinerals and Energy Resources Full Chapter ExplanationAnish TakshakNo ratings yet

- Cambridge IGCSE: Chemistry 0620Document14 pagesCambridge IGCSE: Chemistry 0620PizzaNo ratings yet

- Earth Science: Quarter 1 - Module 3Document42 pagesEarth Science: Quarter 1 - Module 3VillaErnestNo ratings yet

- Magnetic Properties of Materials 2.6Document6 pagesMagnetic Properties of Materials 2.6reaktorenergiNo ratings yet

- MM435 - CDP-1 - 9 - Kinetics of PassivityDocument17 pagesMM435 - CDP-1 - 9 - Kinetics of PassivityAhmad JanNo ratings yet

- Types of Ceramics: Traditional to Advanced MaterialsDocument11 pagesTypes of Ceramics: Traditional to Advanced Materialsjohn gelveroNo ratings yet

- Working of Blast FurnaceDocument3 pagesWorking of Blast Furnacehk168No ratings yet

- Aluzinc: Thermal Insulation Products - Jacketing & CladdingDocument1 pageAluzinc: Thermal Insulation Products - Jacketing & CladdingSudhansu DashNo ratings yet

- Mineral and Power Resources ShortDocument4 pagesMineral and Power Resources Shortsukritsarkar27No ratings yet

- A 470 - 03 Piezas ForjadasDocument8 pagesA 470 - 03 Piezas ForjadasWILLIAM ROMERONo ratings yet

- 9e End of Unit Test HigherDocument6 pages9e End of Unit Test HigherZain Ali100% (2)

- Cambridge O Level: Chemistry 5070/11 May/June 2021Document80 pagesCambridge O Level: Chemistry 5070/11 May/June 2021shabanaNo ratings yet

- Defects in ForgingsDocument13 pagesDefects in ForgingsMahander Pratap Singh100% (2)

- VIVA VOCE Questions FinalDocument5 pagesVIVA VOCE Questions FinalS.m. Chandrashekar100% (2)

- Mineral Processing: Chapter OutlineDocument32 pagesMineral Processing: Chapter OutlineAlejandra VeraNo ratings yet

- Is - 1762Document12 pagesIs - 1762Kamal Engineering CorporationNo ratings yet

- Implications of Heavy Mineral Assemblage To SedimentDocument20 pagesImplications of Heavy Mineral Assemblage To SedimentSanchitNo ratings yet

- Cobalt: Definition, Mineralogy and DepositsDocument19 pagesCobalt: Definition, Mineralogy and DepositsJesusSalamancaNo ratings yet

- Corrosion: Dr. Divakara S G Dept of Chemistry R V College of EngineeringDocument116 pagesCorrosion: Dr. Divakara S G Dept of Chemistry R V College of EngineeringAditi BardhanNo ratings yet

- Periodic Table of Elements in PicturesDocument1 pagePeriodic Table of Elements in PicturesynottripNo ratings yet

- Raw Materials of CementDocument3 pagesRaw Materials of CementMaster PogiNo ratings yet

- Metals Reactivity Series and Thermal DecompositionDocument5 pagesMetals Reactivity Series and Thermal DecompositionRaffaella LaxaldeNo ratings yet

- Foundry Workshop ManualDocument22 pagesFoundry Workshop Manuallakshya100% (1)

- The Discovery of Fluoride and FluorineDocument8 pagesThe Discovery of Fluoride and FluorineFuture LeadersNo ratings yet