Professional Documents

Culture Documents

01 Bolt Screw Stud Iso 4014 4017 Gr. Iso 898 1 8.8

Uploaded by

Cyril J PadiyathCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 Bolt Screw Stud Iso 4014 4017 Gr. Iso 898 1 8.8

Uploaded by

Cyril J PadiyathCopyright:

Available Formats

Marketed By: Manufactured By:

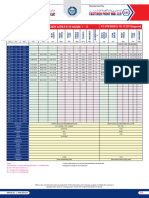

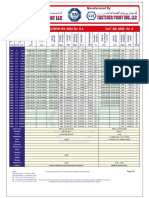

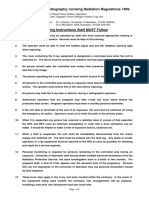

BOLT/SCREW & STUD ISO 4014/4017 Gr. ISO 898-1 8.8 NUT ISO 4032 Grade ISO 898-2 Gr. 8

HARDNESS

HARDNESS

DIAMETER

ACCROSS

TORQUE *

ACCROS

TENSILE

STRESS

ATION #

STRESS

ELONG-

STRESS

SHANK

PROOF

HEIGHT

HEIGHT

WIDTH

PROOF

WIDTH

PROOF

STRESS

PROOF

FLATS

FLATS

LOAD

PITCH

HEAD

HEAD

LOAD

AREA

BOLT

SIZE

2

mm mm mm mm mm mm Mpa KN Mpa N-m HRC % mm mm Mpa KN HRC

A/B Min~Max A/B Min~Max A/B Min~Max

M6 1 20.1 5.82/5.70~6.00 9.78/9.64~10.00 3.85/3.76~4.15/4.24 580 11.7 800 9.4 22-32 12- 9.78~10.00 4.90~5.20 855 17.2 -30

M8 1.25 36.6 7.78/7.64~8.00 12.73/12.57~13.00 5.15/5.06~5.45/5.54 580 21.2 800 22.8 22-32 12- 12.73~13.00 6.44~6.80 870 31.8 -30

M10 1.5 58.0 9.78/9.64~10.00 15.73/15.57~16.00 6.22/6.11~6.58/6.69 580 33.7 800 45.8 22-32 12- 15.73~16.00 8.04~8.40 870 50.5 -30

M12 1.75 84.3 11.73/11.57~12.00 17.73/17.57~18.00 7.32/7.21~7.68/7.79 600 50.7 830 78.8 23-34 12- 17.73~18.00 10.37~10.80 880 74.2 -30

M14 2.0 115.0 13.73/13.57~14.00 20.67/20.16~21.00 8.62/8.51~8.98/9.09 600 68.8 830 129.7 23-34 12- 20.67~21.00 12.10~12.80 880 101.2 -30

M16 2.0 157.0 15.73/15.57~16.00 23.67/23.16~24.00 9.82/9.71~10.18/10.29 600 94.5 830 195.6 23-34 12- 23.67~24.00 14.10~14.80 880 138.2 -30

M18 2.5 192.0 17.73/17.57~18.00 26.67/26.16~27.00 11.285/11.15~11.715/11.85 600 115.2 830 278.4 23-34 12- 26.16~27.00 15.10~15.80 920 176.6 -36

M20 2.5 245.0 19.67/19.48~20.00 29.67/29.16~30.00 12.285/12.15~12.715/12.85 600 147.0 830 394.7 23-34 12- 29.16~30.00 16.90~18.00 920 225.4 -36

M22 2.5 303.0 21.67/21.48~22.00 33.38/33.00~34.00 13.785/13.65~14.215/14.35 600 182.0 830 536.9 23-34 12- 33.00~34.00 18.10~19.40 920 278.8 -36

M24 3.0 353.0 23.67/23.48~24.00 35.38/35.00~36.00 14.785/14.65~15.215/15.35 600 212.0 830 682.4 23-34 12- 35.00~36.00 20.20~21.50 920 324.8 -36

M27 3.0 459.0 N/26.48~27.00 N/40.00~41.00 N/16.65~N/17.35 600 275.4 830 998.3 23-34 12- 40.00~41.00 22.50~23.80 920 422.3 -36

M30 3.5 561.0 N/29.48~30.00 N-45.00~46.00 N/18.28~N/19.12 600 337.0 830 1,356 23-34 12- 45.00~46.00 24.30~25.60 920 516.1 -36

M33 3.5 694.0 N/32.38~33.00 N/49.00~50.00 N/20.58~N/21.42 600 416.4 830 1,845 23-34 12- 49.00~50.00 27.40~28.70 920 638.5 -36

M36 4.0 817.0 N/35.38~36.00 N53.80~55.00 N/22.08~22.92 600 490.2 830 2,369 23-34 12- 53.80~55.00 29.40~31.00 920 751.6 -36

M39 4.0 976.0 N/38.38~39.00 N/58.80~60.00 N/24.58~N25.42 600 586.0 830 3,066 23-34 12- 58.80~60.00 31.80~33.40 920 897.9 -36

M42 4.5 1,120.0 N/41.38~42.00 N/63.1~65.00 N/25.58~N/26.42 600 672.0 830 3,789 23-34 12- 63.10~65.00 32.40~34.00 920 1,030 -36

M45 4.5 1,310.0 N/44.38~45.00 N/68.10~70.00 N/27.58~N/28.42 600 786.0 830 4,748 23-34 12- 68.10~70.00 34.40~36.00 920 1,205 -36

M48 5.0 1,470.0 N/47.38~48.00 N/73.10~75.00 N/29.58~N/30.42 600 882.0 830 5,684 23-34 12- 73.10~75.00 36.40~38.00 920 1,352 -36

M52 5.0 1,760.0 N/51.26~52.00 N/78.10~80.00 N/32.50~N/33.50 600 1,056 830 7,372 23-34 12- 78.10~80.00 40.40~42.00 920 1,619 -36

M56 5.5 2,030.0 N/55.26~56.00 N/82.80~85.00 N/34.50~N/35.50 600 1,218 830 9,157 23-34 12- 82.80~85.00 43.40~45.00 920 1,868 -36

M60 5.5 2,360.0 N/59.26~60.00 N/87.80~90.00 N/37.50~N/38.50 600 1,416 830 11,406 23-34 12- 87.80~90.00 46.40~48.00 920 2,171 -36

M64 6.0 2,680.0 N/63.26~64.00 N/92.80~95.00 N/39.50~N/40.50 600 1,608 830 13,816 23-34 12- 92.80~95.00 49.10~51.00 920 2,466 -36

M68 6.0 3,060.0 N/63.26~64.00 N/92.80~95.00 N/39.50~N/40.50 600 1,836 830 16,761 23-34 12- 92.80~95.00 49.10~51.00 920 2,466 -36

M72 6.0 3,460.0 600 2,076 830 20,067 23-34 12- 920 2,466 -36

M76 6.0 3,890.0 600 2,334 830 23,814 23-34 12- 920 2,466 -36

M80 6.0 4,340.0 600 2,604 830 27,967 23-34 12- 920 2,466 -36

M85 6.0 4,950.0 600 2,970 830 33,891 23-34 12- 920 2,466 -36

M90 6.0 5,590.0 600 3,354 830 40,525 23-34 12- 920 2,466 -36

M95 6.0 6,270.0 600 3,762 830 47,980 23-34 12- 920 2,466 -36

M100 6.0 6,990.0 600 4,194 830 56,304 23-34 12- 920 2,466 -36

Dimensions HEX as per ISO 4014/4017 HEX as per ISO 4032

Markings ‘FPI’ ‘M’ ‘8.8’ ‘FPI’ ‘8’

Carbon 0.25-0.55/0.20-0.55 -0.58

Manganese (<= M16) 0.25- / 0.3- (> M16)

Sulfur -0.025 (<= M16) -0.15 / -0.058 (> M16)

Silicon

Chromium

Molybdenum

Nickle

Vanadium

Boron -0.003

Copper

Nitrogen

Phosphorus -0.025 -0.06/0.048

Material Carbon / Alloy steel quenched & tempered Medium Carbon Steel

Notes: * Torque value based on 75% of proof load and ¿nish as received steel Page: 01

Left hand side of '-' is minium value

right hand side of '-' is maximam value

Eg. 0.5-0.7 min is 0.5 and max is 0.7

Eg. -0.8 max is 0.8 no minimam value

While every care has been taken in preparation of the information, the company accepts no liability for any loss or

Eg. 2.0- min is 2.0 no maximam value damage either direct or consequential, Please refer Original standards for details.

You might also like

- 03 Bolt Astm A325mDocument1 page03 Bolt Astm A325mMUSTAFA TEMEMINo ratings yet

- Bolt Standard BS 3692Document1 pageBolt Standard BS 3692Mai Xuan Truong0% (1)

- Nut Astm A563M 10S Bolt/Screw Astm A325M-1: Proof ST Proof LDocument1 pageNut Astm A563M 10S Bolt/Screw Astm A325M-1: Proof ST Proof LDebulus PR0% (1)

- NUT BS 3692 Gr. 8 BOLT/SCREW BS 3692 Gr. 8.8: Marketed By: Manufactured byDocument1 pageNUT BS 3692 Gr. 8 BOLT/SCREW BS 3692 Gr. 8.8: Marketed By: Manufactured byrk_gprkavi2011No ratings yet

- 3.14 C.KG.06 Technical Table For O.CEF.4 (R0-04.08.2003)Document10 pages3.14 C.KG.06 Technical Table For O.CEF.4 (R0-04.08.2003)ibrahim kademogluNo ratings yet

- Daily Rejection Analysis SheetDocument7 pagesDaily Rejection Analysis Sheetaman matharuNo ratings yet

- Pedestrian Truss Detail Sheet - Print PDFDocument4 pagesPedestrian Truss Detail Sheet - Print PDFfenta999No ratings yet

- Morse Taper DimensionsDocument1 pageMorse Taper DimensionsGordNo ratings yet

- Covered Walkway LongwaysDocument1 pageCovered Walkway LongwaysErnesto Lopez100% (1)

- Gas Piping System Layout: Isometric DiagramDocument1 pageGas Piping System Layout: Isometric DiagramJEZREEL MENDOZANo ratings yet

- BAFAQI1Document2 pagesBAFAQI1Wmo MuttilNo ratings yet

- Forward ShieldsDocument3 pagesForward ShieldsAnniaNo ratings yet

- Eurydice GroundplanDocument1 pageEurydice GroundplanlizbanksNo ratings yet

- Tabel Spesifikasi Pintu-Pintu Sorong Fiber Table of Specific Fiber Slide GatesDocument1 pageTabel Spesifikasi Pintu-Pintu Sorong Fiber Table of Specific Fiber Slide GatesKaryudiPrasetyoNo ratings yet

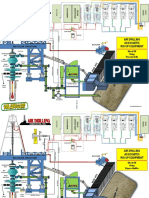

- Rig Floor Structure: Air Drilling Associates Rig Up EquipmentDocument2 pagesRig Floor Structure: Air Drilling Associates Rig Up EquipmentAlger Danielle BallonNo ratings yet

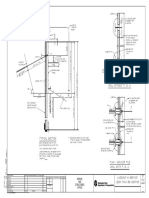

- 02 - SIDE CONN BOTTOM OP-ModelDocument1 page02 - SIDE CONN BOTTOM OP-ModelAshfaqNo ratings yet

- F51 170 VTF Accessories Typical InstallationDocument1 pageF51 170 VTF Accessories Typical InstallationkimcucspktNo ratings yet

- Door Schedule Door TypesDocument1 pageDoor Schedule Door TypesPau LlenaNo ratings yet

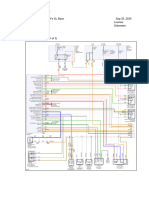

- Wiper/Washer: Ymms: Feb 20, 2020 Engine: 1.4L Eng License: Vin: 1G1BF5SM9J7162666 Odometer: 2018 Chevrolet Cruze PremierDocument3 pagesWiper/Washer: Ymms: Feb 20, 2020 Engine: 1.4L Eng License: Vin: 1G1BF5SM9J7162666 Odometer: 2018 Chevrolet Cruze PremierzizouNo ratings yet

- Ls - SB - 1000 r0 Base Plan-1081 - Power PointDocument1 pageLs - SB - 1000 r0 Base Plan-1081 - Power PointJoe Ji DongNo ratings yet

- Mandarin OrientalDocument1 pageMandarin Orientalmary.mccrary8922No ratings yet

- Frontal Wiper WasherDocument2 pagesFrontal Wiper WasherJhon ConnorNo ratings yet

- XRAY M18 PRO Modifiable-PDF Blank Setup SheetDocument1 pageXRAY M18 PRO Modifiable-PDF Blank Setup SheetTTOipNo ratings yet

- Water Supply Setting Layout Plan: Proposed (G+M) Office & Ware HouseDocument1 pageWater Supply Setting Layout Plan: Proposed (G+M) Office & Ware HouseSuhail AhamedNo ratings yet

- 2015 Hyundai Santa Fe XL Base 3.3LDocument120 pages2015 Hyundai Santa Fe XL Base 3.3LData TécnicaNo ratings yet

- SQE Single PageDocument1 pageSQE Single Pagekalyanchakravarthi.vvvNo ratings yet

- Rafter Detail: Roofing InsulationDocument1 pageRafter Detail: Roofing InsulationRODEAN HOPE LACSINo ratings yet

- STONE MASONRY AND COCONET DETAIL DALIRIG KISOLON-ModelDocument1 pageSTONE MASONRY AND COCONET DETAIL DALIRIG KISOLON-ModelQUEENIENo ratings yet

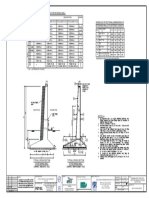

- Drawing of Retaining Wall - BridgesDocument1 pageDrawing of Retaining Wall - BridgesRajan GuptaNo ratings yet

- Pressure Plate Frame Plate Frame Plate Pressure PlateDocument6 pagesPressure Plate Frame Plate Frame Plate Pressure PlateTung Bui ThanhNo ratings yet

- Dark Sun 3.5e Character SheetDocument2 pagesDark Sun 3.5e Character Sheetapi-19828443No ratings yet

- StarFinderDroneSheet Clean 1Document1 pageStarFinderDroneSheet Clean 1AnniaNo ratings yet

- Chi Tiết Rèm R11 TỌA ĐỘ A1-A2;B7 (LOCATION A1-A2;B7) (The Fire Curtain R11)Document1 pageChi Tiết Rèm R11 TỌA ĐỘ A1-A2;B7 (LOCATION A1-A2;B7) (The Fire Curtain R11)Sy ThinhNo ratings yet

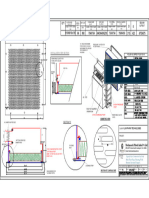

- The Gate Shall Be Operated by Rope Drum Hoist: Key PlanDocument1 pageThe Gate Shall Be Operated by Rope Drum Hoist: Key Planbalwant_negi7520No ratings yet

- Dutch Cone Penetration Test: (Data Sheet)Document2 pagesDutch Cone Penetration Test: (Data Sheet)Hylmi AndikaNo ratings yet

- Melange Residences, Hinjewadi Pune: Rainwater HarvestingDocument1 pageMelange Residences, Hinjewadi Pune: Rainwater HarvestingYukti AnandNo ratings yet

- Proposed Construction of Two (2) Storey Residential With DeckDocument1 pageProposed Construction of Two (2) Storey Residential With Deckysog808No ratings yet

- Victorias City Plaza Update3Document1 pageVictorias City Plaza Update3Calvin Chavez IIINo ratings yet

- MatraX TBR PatternsDocument9 pagesMatraX TBR PatternsHoàn VuduyNo ratings yet

- Cottage - Schedule of Doors and WindowsDocument2 pagesCottage - Schedule of Doors and WindowsBlitzer ReyesNo ratings yet

- 2014 Ram 3500 Laramie 6.7 ECMDocument8 pages2014 Ram 3500 Laramie 6.7 ECMHeladio Mar100% (1)

- Daily Accom2020 10-Q GIRLSDocument2 pagesDaily Accom2020 10-Q GIRLSMartin RodriguezNo ratings yet

- Daily Accom2020 10-Q BOYSDocument2 pagesDaily Accom2020 10-Q BOYSMartin RodriguezNo ratings yet

- Soldier Pile Steel & Timber LaggingDocument1 pageSoldier Pile Steel & Timber LaggingHendy WijayaNo ratings yet

- Hatch Opening Elevation Hatch Door Detail: R 1'-3" (T YP .)Document1 pageHatch Opening Elevation Hatch Door Detail: R 1'-3" (T YP .)Jesús Rodríguez RodríguezNo ratings yet

- Camaro Headlights - W - O High Intensity Discharge (Headlamp) - ALLDATA RepairDocument1 pageCamaro Headlights - W - O High Intensity Discharge (Headlamp) - ALLDATA RepairAbdiel AyalaNo ratings yet

- Ferrari 945Document2 pagesFerrari 945Freddy ChiriNo ratings yet

- Prestressing Sheet PDFDocument1 pagePrestressing Sheet PDFVinita KumariNo ratings yet

- Daily Accom2020 10-R GIRLSDocument2 pagesDaily Accom2020 10-R GIRLSMartin RodriguezNo ratings yet

- Veicolo Porte Codice E Variabili Dimensioni Interne Dimensioni Esterne Vehicle Doors Code and Variable Cargo Area Dimension Outside DimensionDocument1 pageVeicolo Porte Codice E Variabili Dimensioni Interne Dimensioni Esterne Vehicle Doors Code and Variable Cargo Area Dimension Outside DimensionRockin StonezNo ratings yet

- Hydraulic Computation TemplateDocument3 pagesHydraulic Computation Templatemihiretu TeferaNo ratings yet

- Pump Specs - FinalDocument1 pagePump Specs - Finaljohn patrick camoNo ratings yet

- Door List: P/J:P-618 (HULL21) / P-718 (HULL22)Document12 pagesDoor List: P/J:P-618 (HULL21) / P-718 (HULL22)harimecNo ratings yet

- Aire Acondicionado Mazda 3 2006Document2 pagesAire Acondicionado Mazda 3 2006Jhon ConnorNo ratings yet

- Ada TugasDocument1 pageAda Tugastiopan gultomNo ratings yet

- BC Sheet 04 O&BR ElectricalDocument1 pageBC Sheet 04 O&BR ElectricalAmisha SolankiNo ratings yet

- 7.0 Arslan - Lalbazar 16-04-2024Document1 page7.0 Arslan - Lalbazar 16-04-2024designocastleNo ratings yet

- 1 Solid Bridging of Floor Joists: 3 Floor Framing at Exterior WallDocument1 page1 Solid Bridging of Floor Joists: 3 Floor Framing at Exterior WallJustin Maree CamachoNo ratings yet

- B737NG - 21 00 A3 01 - 6 7 1Document1 pageB737NG - 21 00 A3 01 - 6 7 1wagdiNo ratings yet

- The Vanishing Present: Wisconsin's Changing Lands, Waters, and WildlifeFrom EverandThe Vanishing Present: Wisconsin's Changing Lands, Waters, and WildlifeDonald M. WallerRating: 4 out of 5 stars4/5 (1)

- RN-02-00001-07-11-IR-NBH-MI-000145 (01) - M.Sub For Steel Elements For Irrigation Pump StationDocument2 pagesRN-02-00001-07-11-IR-NBH-MI-000145 (01) - M.Sub For Steel Elements For Irrigation Pump StationCyril J PadiyathNo ratings yet

- Enter Data Only in Cells: White (H - Column)Document5 pagesEnter Data Only in Cells: White (H - Column)Araban SuleimanNo ratings yet

- Stylish Teaching Cover LetterDocument1 pageStylish Teaching Cover LetterCyril J PadiyathNo ratings yet

- Reference Guide To Manual Processing of INDUSTREX Films: Recommended Chemicals and Mixing InstructionsDocument2 pagesReference Guide To Manual Processing of INDUSTREX Films: Recommended Chemicals and Mixing InstructionsHz albertoNo ratings yet

- Inside WeldingDocument1 pageInside WeldingCyril J PadiyathNo ratings yet

- Welding Inspector Interview QuestionsDocument5 pagesWelding Inspector Interview QuestionsValli Raju91% (23)

- Tokio QuoteDocument5 pagesTokio QuoteCyril J PadiyathNo ratings yet

- Comments Resolution Sheet (CRS)Document27 pagesComments Resolution Sheet (CRS)Cyril J PadiyathNo ratings yet

- TWI Enrolment Form: TWI Training & Examination ServicesDocument4 pagesTWI Enrolment Form: TWI Training & Examination ServicesSamsuNo ratings yet

- Form Radiation Work Permit Free TemplateDocument1 pageForm Radiation Work Permit Free TemplateCyril J PadiyathNo ratings yet

- FANR - RG007 Ver1Document64 pagesFANR - RG007 Ver1Cyril J PadiyathNo ratings yet

- Awwa C153 PDFDocument48 pagesAwwa C153 PDFCyril J PadiyathNo ratings yet

- FANR-RG-019 Radiation Safety in Industrial RadiographyDocument31 pagesFANR-RG-019 Radiation Safety in Industrial RadiographyCyril J PadiyathNo ratings yet

- V1 V2 Cal PRCDocument5 pagesV1 V2 Cal PRCCyril J PadiyathNo ratings yet

- Queen Street Local Rules June 2011Document10 pagesQueen Street Local Rules June 2011Cyril J PadiyathNo ratings yet

- ML100740152Document7 pagesML100740152Cyril J PadiyathNo ratings yet

- Material Submittal (Supports & Grating) PDFDocument244 pagesMaterial Submittal (Supports & Grating) PDFCyril J PadiyathNo ratings yet

- National Red Oxide Primer PDFDocument3 pagesNational Red Oxide Primer PDFCyril J Padiyath100% (1)

- National Red Oxide Primer PDFDocument3 pagesNational Red Oxide Primer PDFCyril J Padiyath100% (1)

- Allianz Middle East Ship Mangament LLC: "WWE 210" 210ft Positioning (Crane) Barge 4PMDocument2 pagesAllianz Middle East Ship Mangament LLC: "WWE 210" 210ft Positioning (Crane) Barge 4PMCyril J PadiyathNo ratings yet

- ACP-2017!01!04.Lampiran Tds Hardtop XPDocument5 pagesACP-2017!01!04.Lampiran Tds Hardtop XPBayumi Tirta JayaNo ratings yet

- National Guard Epoxy Red Oxide PrimerDocument3 pagesNational Guard Epoxy Red Oxide PrimerCyril J PadiyathNo ratings yet

- Ductile Iron Pipe Installation Guide 05 2015Document134 pagesDuctile Iron Pipe Installation Guide 05 2015Anonymous R7EKGEDNo ratings yet

- Barrier 80 PDFDocument5 pagesBarrier 80 PDFBalaji GuruNo ratings yet

- Model Papers PDFDocument33 pagesModel Papers PDFSeemab Malik85% (20)

- Suggested Sample Specification For Ductile Iron Pipe & Fittings For Water and Other LiquidsDocument3 pagesSuggested Sample Specification For Ductile Iron Pipe & Fittings For Water and Other LiquidsASHIL PRABHAKARNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetCyril J PadiyathNo ratings yet

- TDS Hardtop XP GB English ProtectiveDocument5 pagesTDS Hardtop XP GB English Protective폴로 쥰 차No ratings yet

- NFPA251 ConstrucutionDocument22 pagesNFPA251 Construcutionik43207No ratings yet

- Processflowdiagram Galvanization 171001085057Document1 pageProcessflowdiagram Galvanization 171001085057Cyril J PadiyathNo ratings yet

- 1613 Nova NiroDocument1 page1613 Nova NiroAhmedRamadanNo ratings yet

- E1335Document6 pagesE1335Anonymous YwFJrk0yCNo ratings yet

- Masterrheobuild 890 tds-2 PDFDocument2 pagesMasterrheobuild 890 tds-2 PDFBnbdbbdbhhbbbvvffffnhebrbbrNo ratings yet

- L1 Unit-1 Advance WeldingDocument11 pagesL1 Unit-1 Advance WeldingSaurabh Kumar GuptaNo ratings yet

- Problems in The Cement Industry PDFDocument35 pagesProblems in The Cement Industry PDFAnujKumarVermaNo ratings yet

- Patio Planter: Woodworks: Intermediate ProjectDocument7 pagesPatio Planter: Woodworks: Intermediate ProjectRenos KonstantinouNo ratings yet

- Grout HandbookDocument122 pagesGrout HandbookBernhard Gafner100% (4)

- PPMP 2023Document8 pagesPPMP 2023KEICHIE QUIMCONo ratings yet

- Steel Comp A Ration TableDocument1 pageSteel Comp A Ration TablekazdoelahNo ratings yet

- Odakarai East Street, Kayalpattinam MunicipalityDocument7 pagesOdakarai East Street, Kayalpattinam MunicipalitykayalonthewebNo ratings yet

- Calculations Mixture 1Document2 pagesCalculations Mixture 1Pruthvik PradeepNo ratings yet

- Corp CMF WP Cleaning and Desinfection PDFDocument3 pagesCorp CMF WP Cleaning and Desinfection PDFOmerfAtaNo ratings yet

- Consumables NormsDocument24 pagesConsumables NormsHema Nandh100% (1)

- Solutions For Ch04Document16 pagesSolutions For Ch04wesleyaNo ratings yet

- Mrs. Lorina G. Advincula: JudgeDocument4 pagesMrs. Lorina G. Advincula: JudgeErnalyn dela CruzNo ratings yet

- Multiport Selector Valves CatalogueDocument4 pagesMultiport Selector Valves CatalogueShakeel AhmedNo ratings yet

- Us5591802 PDFDocument7 pagesUs5591802 PDFAl Saraaf MohammedNo ratings yet

- Gold Penny Lab ExplainedDocument3 pagesGold Penny Lab ExplainedMatthewNo ratings yet

- Food and Chemical Toxicology: Mustafa Soylak, Ayse AydinDocument7 pagesFood and Chemical Toxicology: Mustafa Soylak, Ayse Aydinlox agencyNo ratings yet

- Monitoring Shop Drawing MVACDocument2 pagesMonitoring Shop Drawing MVACEko Indra SaputraNo ratings yet

- Henkel - Loctite AA 331 - TDS PDFDocument4 pagesHenkel - Loctite AA 331 - TDS PDFDang Ngoc Tuong ViNo ratings yet

- Decabromo Diphenyl OxideDocument1 pageDecabromo Diphenyl OxideHarshavardhanNo ratings yet

- Kerosene: Prepared by Supervisor:-Mr. Shwan Ammar Askandar Waleed AdnanDocument9 pagesKerosene: Prepared by Supervisor:-Mr. Shwan Ammar Askandar Waleed AdnanWalid Adnan100% (1)

- Housekeeping-G11-Module-Lesson 3Document13 pagesHousekeeping-G11-Module-Lesson 3clarencesangatNo ratings yet

- Analisa Pekerjaan WaterproofingDocument2 pagesAnalisa Pekerjaan WaterproofingNurfandy Dewanto100% (9)

- Aba Ardex RebrandingDocument4 pagesAba Ardex RebrandingHarsa VardhanNo ratings yet

- Properties of Period 3 Elements and Their Oxides QPDocument11 pagesProperties of Period 3 Elements and Their Oxides QPfatma sNo ratings yet

- HSCO-projects Reference 2010-2015 PDFDocument5 pagesHSCO-projects Reference 2010-2015 PDF袁袁No ratings yet

- Grease Troubleshooting: A Publication of The Lubrication Engineers Technical DepartmentDocument2 pagesGrease Troubleshooting: A Publication of The Lubrication Engineers Technical Departmentmadan mohan kattaNo ratings yet

- Ultracote 635 HBDocument3 pagesUltracote 635 HBCherbee Ferrer100% (1)