Professional Documents

Culture Documents

481-Medium Voltage Power Cables

481-Medium Voltage Power Cables

Uploaded by

Joseph PoplingerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

481-Medium Voltage Power Cables

481-Medium Voltage Power Cables

Uploaded by

Joseph PoplingerCopyright:

Available Formats

Medium Voltage Power Cables

XLPE Insulated, with Longitudinal

Water Barrier, PE Sheathed

Single Core Cables for Fixed

Installations, 6/10 kV;

12/20 kV; 18/30 kV

APPLICATION:

For indoor or outdoor installation in open air in

tray, trough and conduit or for direct burial in free

draining soil or inside duct where no mechanical

damage is to be expected. Power cable for utilities

medium voltage underground distribution systems

and in commercial buildings, industrial plants,

power stations and substations. For rated voltages

U0/U(Um): 6/10(12) kV; 12/20(24) kV or 18/30(36)

kV at maximum conductor temperatures of 90 °C

for continuous normal operation and 250 °C for

short circuit.

3. Conformance to various European standards, - standard voltages: 3.6/6kV & 8.7/15 kV

STANDARDS: available upon request. - tree-retardant XLPE insulation

1. Conforms to Israeli Standard IS 1516-2: - EPR insulation

”Power cables with extruded insulation and CONSTRUCTION: - easy strippable insulation screen

their accessories for rated voltages from A copper or aluminium compacted circular - no water barrier

1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) conductor has a triple single head extruded - aluminium wire armour

– Part 2: Cables for rated voltages of smooth conductor screen, XLPE (cross-linked - PVC outer red sheath.

6 kV (Um = 7,2 kV) up to 30 kV (Um = 36 kV)” polyethylene) insulation and bonded insulation Consult us on fire retardant and /or halogen

for the types N2XS(F)2Y and NA2XS(F)2Y . screen, all dry nitrogen cured; water blocked free constructions.

2. Conforms to IEC 60502-2 Standard: metal screen made of solid bare copper wires

”Power cables with extruded insulation and uniformly spaced around the cable and a counter PACKAGING:

their accessories for rated voltages from helix copper tape; ST7 surface printed black PE Standard supply lengths are given in the tables

1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) oversheath is extruded over all. hereunder. Other bobbin lengths or cut to

– Part 2: Cables for rated voltages of The following alternatives are available upon length - available upon request.

6 kV (Um = 7,2 kV) up to 30 kV (Um = 36 kV)”. request:

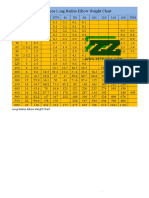

Current Rating (2)

Reactance @50Hz (5)

conductor (1 sec) (1)

conductors & screen

Max. conductor DC

Nominal insulation

No., Nominal cross

Approximate outer

Approximate cable

Minimum bending

Short Circuit rating

wires in conductor

resistance at 20°C

Minimum No. of

Catalog

Standard supply

sectional area of

Nominal sheath

In ground (4)

In ground (4)

Number

Capacitance

thickness

thickness

diameter

In air (3)

In air (3)

lengths

weight

radius

No. x mm2/mm2 mm mm mm kg/km mm Ω/km kA A A A A Ω/km μF/km m

N2XS(F)2Y 6/10 (12) kV COPPER CONDUCTOR

168030 1x35/16 6 3.4 1.8 21 750 315 0.524 5.0 197 187 235 212 0.133 0.23 1000

168049 1x50/16 6 3.4 1.8 24 900 360 0.387 7.2 236 220 282 249 0.127 0.25 1000

168075 1x70/16 12 3.4 1.8 25.5 1100 383 0.268 10.0 294 268 350 302 0.119 0.28 1000

168092 1x95/16 15 3.4 1.8 27 1450 405 0.193 13.6 358 320 426 359 0.114 0.32 1000

168131 1x120/16 18 3.4 1.8 28.5 1700 428 0.153 17.2 413 363 491 405 0.109 0.35 1000

168147 1x150/25 18 3.4 1.9 30.5 2000 458 0.124 21.5 468 405 549 442 0.106 0.37 1000

168191 1x185/25 30 3.4 1.9 33 2400 495 0.0991 26.5 535 457 625 493 0.102 0.41 1000

168239 1x240/25 34 3.4 2.0 35 2950 525 0.0754 34.3 631 526 731 563 0.098 0.46 1000

168312 1x300/25 34 3.4 2.0 37.5 3530 563 0.0601 42.9 722 591 831 626 0.095 0.50 500

168414 1x400/35 53 3.4 2.1 41 4500 615 0.0470 57.2 827 662 920 675 0.091 0.56 500

168491 1x500/35 53 3.4 2.2 44 5500 660 0.0366 71.5 949 744 1043 748 0.089 0.61 500

168627 1x630/35 53 3.4 2.3 48 7050 720 0.0283 90.1 1066 832 1162 835 0.087 0.67 500

NA2XS(F)2Y 6/10 (12) kV ALUMINIUM CONDUCTOR

168029 1x35/16 6 3.4 1.8 21 500 315 0.868 3.29 153 145 182 165 0.133 0.23 1000

168046 1x50/16 6 3.4 1.8 24 580 360 0.641 4.7 183 171 219 194 0.127 0.25 1000

168074 1x70/16 12 3.4 1.8 25.5 680 383 0.443 6.6 228 208 273 236 0.119 0.28 1000

168088 1x95/16 15 3.4 1.8 27 810 405 0.320 8.9 278 248 333 281 0.114 0.32 1000

168130 1x120/16 15 3.4 1.8 28.5 950 428 0.253 11.3 321 283 384 318 0.109 0.35 1000

PCD 45-13, October 2007

168148 1x150/25 15 3.4 1.9 30.5 1100 458 0.206 14.1 364 315 432 350 0.106 0.37 1000

168179 1x185/25 30 3.4 1.9 33 1210 495 0.164 17.4 418 357 496 394 0.102 0.41 1000 Tel: (972) 4-8466222

168238 1x240/25 30 3.4 2.0 35 1420 525 0.125 22.6 494 413 583 452 0.098 0.46 1000 Fax: (972) 4-8466286

168307 1x300/25 30 3.4 2.0 37.5 1730 563 0.100 28.2 568 466 666 506 0.095 0.50 1000

e-mail: export@synergy-cables.com

168408 1x400/35 53 3.4 2.1 41 2100 615 0.0778 37.6 660 529 755 558 0.091 0.56 1000

168490 1x500/35 53 3.4 2.2 44 2520 660 0.0605 47 767 602 868 627 0.089 0.61 1000

http://www.synergy-cables.com

168626 1x630/35 53 3.4 2.3 48 3000 720 0.0469 59.2 882 694 881 712 0.087 0.67 1000

Medium Voltage Power Cables Medium Voltage Power Cables

Current Rating (2) XLPE Insulated, with Longitudinal

Reactance @50Hz (5)

Specification

conductor (1 sec) (1)

conductors & screen

Max. conductor DC

Nominal insulation

No., Nominal cross

Water Barrier, PE Sheathed

Approximate outer

Approximate cable

Minimum Bending

Short Circuit rating

wires in conductor

resistance at 20°C

Minimum No. of

Catalog

Standard supply

sectional area of

Nominal sheath

Single Core Cables for Fixed

In ground (4)

In ground (4)

Number

Capacitance

Installations, 6/10 kV;

thickness

thickness

diameter

In air (3)

In air (3)

lengths

weight

Radius

12/20 kV; 18/30 kV

No. x mm2/mm2 mm mm mm kg/km mm Ω/km kA A A A A Ω/km μF/km m

N2XS(F)2Y 12/20 (24) kV COPPER CONDUCTOR SCOPE INSULATION OVERSHEATH

168037 1x35/16 6 5.5 1.8 26 900 390 0.524 5.0 200 187 235 213 0.144 0.16 1000 This specification describes XLPE insulated PE - Directly over the conductor screen shall be - An extruded black UV resistant PE sheath

168053 1x50/16 6 5.5 1.8 27.5 1050 413 0.387 7.2 239 222 282 250 0.137 0.17 1000 sheathed single core cables for fixed applied a homogeneous wall of XLPE shall be applied on the assembly.

168077 1x70/16 12 5.5 1.9 29 1300 435 0.268 10.0 297 271 351 303 0.129 0.19 1000 installations underground and in the air in insulation. The thickness shall be in - Properties of the sheath shall be in accordance

1680940 1x95/16 15 5.5 1.9 31 1600 465 0.193 13.6 361 323 426 360 0.123 0.21 1000

commercial, industrial and utilities plants. accordance with Israeli Standard 1516-2 and with Israeli Standard 1516-2 and

168118 1x120/16 18 5.5 2.0 33 1900 495 0.153 17.2 416 367 491 407 0.118 0.23 1000

168156 1x150/25 18 5.5 2.0 34.5 2200 518 0.124 21.5 470 409 549 445 0.114 0.25 1000

They are intended for use on single phase and IEC 60502-2 Standard. IEC 60502-2 Standard for the ST7 type.

1681790 1x185/25 30 5.5 2.1 36 2550 540 0.0991 26.5 538 461 625 498 0.110 0.27 1000 three phase installations of 6/10 kV, 12/20 kV - Properties of the insulation shall be in

1682470 1x240/25 34 5.5 2.1 38.5 3200 578 0.0754 34.3 634 532 731 568 0.105 0.30 1000 or 18/30 kV at maximum conductor accordance with Israeli Standard 1516-2 and TESTS

168306 1x300/25 34 5.5 2.2 41 3800 615 0.0601 42.9 724 599 830 633 0.102 0.32 500 temperatures of 90°C for continuous normal IEC 60502-2 Standard. The cable shall be tested in accordance with

168402 1x400/35 53 5.5 2.3 45 4750 675 0.0470 57.2 829 671 923 685 0.098 0.36 500 operation and 250 °C for short circuit - Ethylene propylene rubber insulation, in the Israeli Standard 1516-2 and

168500 1x500/35 53 5.5 2.4 48 5700 720 0.0366 71.5 953 754 1045 760 0.094 0.40 500

maximum conductor temperature. accordance with Israeli Standard 1516-2 and IEC 60502-2 Standard.

168632 1x630/35 53 5.5 2.5 53 7250 795 0.0283 90.1 1070 843 1160 848 0.092 0.44 250

NA2XS(F)2Y 12/20 (24) kV ALUMINIUM CONDUCTOR IEC 60502-2 Standard, is available upon

168038 1x35/16 6 5.5 1.8 26 700 390 0.868 3.29 154 145 183 166 0.144 0.16 1000 STANDARDS request. CHARACTERISTICS

1680460 1x50/16 6 5.5 1.8 27.5 800 413 0.641 4.7 185 172 219 195 0.137 0.17 1000 The following standards shall form a part of Mechanical resistance

168078 1x70/16 12 5.5 1.9 29 900 435 0.443 6.6 231 210 273 237 0.129 0.19 1000 this specification to the extent specified herein: INSULATION SCREEN AND LONGITUDINAL to impacts Low

1680941 1x95/16 15 5.5 1.9 31 1050 465 0.320 8.9 280 251 332 282 0.123 0.21 1000

- Israeli Standard IS 1516-2: ”Power cables WATER BARRIER Flexibility Semi-flexible

168119 1x120/16 15 5.5 2.0 33 1200 495 0.253 11.3 323 285 384 319 0.118 0.23 1000

1681491 1x150/25 15 5.5 2.0 34.5 1300 518 0.206 14.1 366 319 432 352 0.114 0.25 1000 with extruded insulation and their - The insulation screen shall consist of a non- Minimum installation

168194 1x185/25 30 5.5 2.1 36 1500 540 0.164 17.4 420 361 494 396 0.110 0.27 1000 accessories for rated voltages from 1 kV metallic extruded semi-conducting layer in temperature -20 °C

168245 1x240/25 30 5.5 2.1 38.5 1650 578 0.125 22.6 496 417 581 455 0.105 0.30 1000 (Um = 1,2 kV) up to 30 kV (Um = 36 kV) – combination with semi-conducting tape and Temperature range -40 to +90 °C

1683101 1x300/25 30 5.5 2.2 41 1950 615 0.100 28.2 569 471 663 510 0.102 0.32 1000 Part 2: Cables for rated voltages of 6 kV a metallic layer. Weather resistance Good

168410 1x400/35 53 5.5 2.3 45 2300 675 0.0778 37.6 660 535 753 564 0.098 0.36 1000 (Um = 7,2 kV) up to 30 kV (Um = 36 kV)” - The extruded semi-conducting layer shall

168499 1x500/35 53 5.5 2.4 48 2800 720 0.0605 47 766 609 866 634 0.094 0.40 1000

for the types N2XS(F)2Y and NA2XS(F)2Y. consist of smooth cross-linked polyolefin

168633 1x630/35 53 5.5 2.5 53 3300 795 0.0469 59.2 882 701 880 730 0.092 0.44 1000

N2XS(F)2Y 18/30 (36) kV COPPER CONDUCTOR - IEC 60502-2 Standard: ”Power cables with compound bonded to the insulation and

168050 1x50/16 6 8.0 2.0 33 1400 495 0.387 7.2 241 225 282 251 0.146 0.13 1000 extruded insulation and their accessories meeting the requirements of Israeli Standard

168072 1x70/16 12 8.0 2.0 35 1650 525 0.268 10.0 299 274 350 304 0.137 0.15 1000 for rated voltages from 1 kV (Um = 1,2 kV) 1516-2 and IEC 60502-2 Standard.

168095 1x95/16 15 8.0 2.1 37 2000 555 0.193 13.6 363 327 425 362 0.131 0.16 1000 up to 30 kV (Um = 36 kV)” – “Part 2: Cables - The conductor screen, the insulation and the

168125 1x120/16 18 8.0 2.1 38 2250 570 0.153 17.2 418 371 488 409 0.125 0.18 1000

for rated voltages of 6 kV (Um = 7,2 kV) up insulation screen shall be applied in a single

168150 1x150/25 18 8.0 2.2 40 2700 600 0.124 21.5 472 414 548 449 0.121 0.19 1000

168185 1x185/25 30 8.0 2.2 42 3100 630 0.0991 26.5 539 466 624 502 0.117 0.20 1000

to 30 kV (Um = 36 kV)”. head triple extrusion process with dry nitrogen

168241 1x240/25 34 8.0 2.3 44 3750 660 0.0754 34.3 635 539 728 574 0.112 0.22 500 curing.

168300 1x300/25 34 8.0 2.4 47 4300 705 0.0601 42.9 725 606 828 640 0.108 0.24 500 CONDUCTORS - A semi-conducting tape shall be applied on

168400 1x400/35 53 8.0 2.5 52 5200 780 0.0470 57.2 831 680 922 695 0.103 0.27 500 - Annealed, high conductivity copper the extruded semi-conducting insulation

168502 1x500/35 53 8.0 2.6 54 6450 810 0.0366 71.5 953 765 1045 773 0.100 0.29 500 compacted circular stranded conductor screen.

168635 1x630/35 53 8.0 2.7 60 7900 900 0.0283 90.1 1070 855 1160 861 0.098 0.32 500

according to IEC 60228, Class 2. - The metallic layer shall consist of a number

NA2XS(F)2Y 18/30 (36) kV ALUMINIUM CONDUCTOR

168047 1x50/16 6 8.0 2.0 33 1000 495 0.641 4.7 187 174 219 195 0.146 0.13 1000

- Aluminium compacted circular stranded of bare copper wires, uniformly spaced and

168073 1x70/16 12 8.0 2.0 35 1200 525 0.443 6.6 232 213 273 238 0.137 0.15 1000 conductor according to IEC 60228, helically applied on top of the semi-

168090 1x95/16 15 8.0 2.1 37 1400 555 0.320 8.9 282 254 331 283 0.131 0.16 1000 Class 2. conducting tape. An open helix applied

168129 1x120/16 15 8.0 2.1 38 1500 570 0.253 11.3 325 289 382 321 0.125 0.18 1000 copper tape shall bind the wires together.

168162 1x150/25 15 8.0 2.2 40 1850 600 0.206 14.1 367 322 429 354 0.121 0.19 1000 CONDUCTOR SCREEN - The cross sectional area of the metallic layer

168193 1x185/25 30 8.0 2.2 42 1900 630 0.164 17.4 421 364 492 399 0.117 0.20 1000

The conductors shall be covered with a layer shall be the one specified in the tables above

168242 1x240/25 30 8.0 2.3 44 2200 660 0.125 22.6 496 422 578 458 0.112 0.22 1000

of extruded smooth conducting cross-linked to provide an earth fault current path. Other

1683001 1x300/25 30 8.0 2.4 47 2500 705 0.100 28.2 568 476 659 514 0.108 0.24 1000

168411 1x400/35 53 8.0 2.5 52 2850 780 0.0778 37.6 659 541 750 570 0.103 0.27 1000 polyolefin compound, firmly bonded to the cross sectional areas can be supplied upon

168503 1x500/35 53 8.0 2.6 54 3300 810 0.0605 47 764 616 861 642 0.100 0.29 500 insulation and which shall meet the request.

168636 1x630/35 53 8.0 2.7 60 3800 900 0.0469 59.2 880 709 880 736 0.098 0.32 500 requirements of Israeli Standard 1516-2 and - A separating tape shall be applied over all.

IEC 60502-2 Standard. - The semi-conducting and separating tapes

(1) The conductor short circuit rating is based on an initial conductor temperature of 90 °C and a final temperature of 250 °C. shall be swelling to the extent required to

PCD 33-24/3.02 March 6, 2002

(2) Current rating based upon operation at 90 °C conductor, three-phase a.c. load in trefoil touching formation or flat formation with one cable diameter

enable the final cable to pass the longitudinal

clearance. The screens are bonded and earthed at both ends of the cables. According to VDE 0276-620.

(3) Cable laid in freely circulating air at 30 °C, protected against direct thermal radiation due to sun, etc. water penetration test on the screen region

(4) Cable directly buried at 0.7 m deep in soil at 20 °C, with 1 K . m/W thermal resistivity. Load factor 0.7. as specified in Annex D of the

(5) Calculated inductive reactance per core in trefoil touching formation. The screens are bonded and earthed at both ends of the cables. IEC 60502-2 Standard.

PCD 45-13, October 2007

TEMPERATURE RATING FACTORS

Ambient Temperature °C 20 25 30 35 40 45 50 55 60 65

Correction factor air 1.08 1.04 1.00 0.96 0.91 0.87 0.82 0.76 0.71 0.65

Correction factor ground 1.00 0.96 0.93 0.89 0.85 0.80 0.76 - - -

The information given in this page is subject to change without notice.

You might also like

- GBT 18442.3-2011 Static Vacuum Insulated Cryogenic Pressure Vessel - Part 3 DesignDocument25 pagesGBT 18442.3-2011 Static Vacuum Insulated Cryogenic Pressure Vessel - Part 3 DesignKarua PangkungNo ratings yet

- Department of Genetics: Covid-19 RT PCRDocument1 pageDepartment of Genetics: Covid-19 RT PCRAswathy LNo ratings yet

- Product Specification: Forbes-Bryan Low Corrosion Tray Type Deaerator - 5Mw To 400MwDocument3 pagesProduct Specification: Forbes-Bryan Low Corrosion Tray Type Deaerator - 5Mw To 400MwCarlos ACNo ratings yet

- Technical Report WritingDocument17 pagesTechnical Report WritingMayank Jain100% (1)

- Thermocompressors Preventative MaintenanceDocument4 pagesThermocompressors Preventative MaintenancealicardozoNo ratings yet

- Thermocompressor Efficiency & PerformanceDocument4 pagesThermocompressor Efficiency & PerformancerifqizafrilNo ratings yet

- Acetic AnhydrideDocument5 pagesAcetic AnhydrideChern YuanNo ratings yet

- 09-Furfural Production in Modern Lignocellulose-Feedstock Biorefineries Gianluca MarcotullioDocument20 pages09-Furfural Production in Modern Lignocellulose-Feedstock Biorefineries Gianluca Marcotulliodaibac789No ratings yet

- Thermocompressor PDFDocument4 pagesThermocompressor PDFYogesh GhanekarNo ratings yet

- 90 Degree Elbow Weight Calculation Formula and Chart - Full DimensionsDocument3 pages90 Degree Elbow Weight Calculation Formula and Chart - Full Dimensionskokkeong.chongNo ratings yet

- Custom Fabricated Metal Cones FrustumsDocument6 pagesCustom Fabricated Metal Cones FrustumsWillie BalagotNo ratings yet

- Asme-Bpvc Sec V Int Vol 58Document6 pagesAsme-Bpvc Sec V Int Vol 58mostafa aliNo ratings yet

- SIM4ME ThermodynamicsDocument137 pagesSIM4ME ThermodynamicsFA AyNo ratings yet

- Chemical Reactor Types: 1. Fundamental Types of Chemical Reactors 2. PFR Types and ConfigurationsDocument2 pagesChemical Reactor Types: 1. Fundamental Types of Chemical Reactors 2. PFR Types and ConfigurationsWancianSiaNo ratings yet

- Recovery of Acetic Acid by Means of Liquid-Liquid ExtractionDocument5 pagesRecovery of Acetic Acid by Means of Liquid-Liquid ExtractionAYALEYDENNo ratings yet

- Reactor Design For The Production of Nitrocellulose From The Nitration of CelluloseDocument8 pagesReactor Design For The Production of Nitrocellulose From The Nitration of CelluloseAngela100% (1)

- Ethanol Purification ProcessesDocument8 pagesEthanol Purification ProcessesDarwin PatricioNo ratings yet

- Distillation - Crude Oil PDFDocument1 pageDistillation - Crude Oil PDFasif rahim100% (1)

- 2:1 Ellipsoidal Head Blank Diameter: OD SF KR 1816 20 150Document1 page2:1 Ellipsoidal Head Blank Diameter: OD SF KR 1816 20 150Victor NairNo ratings yet

- Ga 250Document16 pagesGa 250g9g9No ratings yet

- ANSI B16.9 Elbow PDFDocument3 pagesANSI B16.9 Elbow PDFRamadan RashadNo ratings yet

- Din 580 - 582 - Maximum Permissible Loads PDFDocument9 pagesDin 580 - 582 - Maximum Permissible Loads PDFAntohi CatalinNo ratings yet

- Air HeatersDocument34 pagesAir HeatersNaveen KamatNo ratings yet

- 1.0 Procedure: Lab 4: Production of Acetic AnhydrideDocument9 pages1.0 Procedure: Lab 4: Production of Acetic AnhydrideHoneydaa Fitra100% (2)

- P-I Transducer - P200-P290 PDFDocument4 pagesP-I Transducer - P200-P290 PDFman_y2kNo ratings yet

- Adiabatic Production of Acetic AnhydrideDocument7 pagesAdiabatic Production of Acetic AnhydrideSunilParjapatiNo ratings yet

- CS TZ WKEW Service ManualDocument233 pagesCS TZ WKEW Service ManualAmin SantanaNo ratings yet

- Chemical Reactor Design - NotesDocument4 pagesChemical Reactor Design - NotesJanaki Devi ParratNo ratings yet

- LT26G PDFDocument4 pagesLT26G PDFraul gonzalezNo ratings yet

- HVAC Package-3 - SITC of AHU - Section - 3Document18 pagesHVAC Package-3 - SITC of AHU - Section - 3FarzanaShaik100% (1)

- R134a Water Cooled Packaged Water Chillers - Cooling Only - : UWD Series (40HP 120HP)Document39 pagesR134a Water Cooled Packaged Water Chillers - Cooling Only - : UWD Series (40HP 120HP)MarceloRiosNo ratings yet

- Dish End Blank DiaDocument3 pagesDish End Blank DiadhirajNo ratings yet

- Development of AerofoilDocument6 pagesDevelopment of Aerofoilvaisakp777No ratings yet

- Crude Oil Banyu Urip Assay PDF NewDocument1 pageCrude Oil Banyu Urip Assay PDF NewIndwiarti PaneNo ratings yet

- QJDocument56 pagesQJkylegazeNo ratings yet

- High Voltage Pspice Manual PDFDocument35 pagesHigh Voltage Pspice Manual PDFMuhammad Ahtisham AsifNo ratings yet

- NEMS-NGC-LNL-EGT-ICS-003 - Instrumentation and Control System Philosophy - R01Document28 pagesNEMS-NGC-LNL-EGT-ICS-003 - Instrumentation and Control System Philosophy - R01Belford AbuhNo ratings yet

- GERSAN Busbar Presentation enDocument24 pagesGERSAN Busbar Presentation enAnand ThiyagarajanNo ratings yet

- Inside The Power SupplyDocument41 pagesInside The Power SupplyBright UzzalNo ratings yet

- Electrodo Lincoln 7018Document2 pagesElectrodo Lincoln 7018Erick Quan Luna100% (1)

- Uniflux Heater Brochure PDFDocument8 pagesUniflux Heater Brochure PDFMichael J. BaneNo ratings yet

- Submersible Pump Type & PriceDocument1 pageSubmersible Pump Type & PriceBudi MWNo ratings yet

- Price List November 2016: Miniature Circuit Breaker - MCB Miniature Circuit Breaker - MCBDocument4 pagesPrice List November 2016: Miniature Circuit Breaker - MCB Miniature Circuit Breaker - MCBsandeepsmartNo ratings yet

- Alloy CuMg0,2Document17 pagesAlloy CuMg0,2Tarun BhatejaNo ratings yet

- Attachment 4 - 630kW 380V 4pole 50Hz Electric Motor Data SheetDocument2 pagesAttachment 4 - 630kW 380V 4pole 50Hz Electric Motor Data Sheetachmadj1405100% (1)

- LORENTZ Pressure Switch 1-5 Bar: Instruction Sheet For Wiring and AdjustingDocument1 pageLORENTZ Pressure Switch 1-5 Bar: Instruction Sheet For Wiring and AdjustingLuis RolaNo ratings yet

- 58202-mt - Advanced Process ControlDocument2 pages58202-mt - Advanced Process ControlSRINIVASA RAO GANTANo ratings yet

- Method of Reducing Carry-Over and Reducing Pressure Drop Through Steam Separators, EPRI NP-1607Document367 pagesMethod of Reducing Carry-Over and Reducing Pressure Drop Through Steam Separators, EPRI NP-1607MarioNo ratings yet

- Jai Balaji Limit Switches PDFDocument2 pagesJai Balaji Limit Switches PDFSuresh kannanNo ratings yet

- TBoxLITE Installation ManualDocument7 pagesTBoxLITE Installation ManualbrettmayNo ratings yet

- Desuperheater BrochureDocument8 pagesDesuperheater BrochurenopNo ratings yet

- Siemens Euroset 802 ManualDocument2 pagesSiemens Euroset 802 ManualAr MaNo ratings yet

- Elecs 1 - Diode CircuitsDocument103 pagesElecs 1 - Diode CircuitsAnthony CortezNo ratings yet

- VAPOR-JET Venturi BlenderDocument2 pagesVAPOR-JET Venturi BlenderCaterine Jara CeaNo ratings yet

- 483-Medium Voltage Power Cables15Document2 pages483-Medium Voltage Power Cables15Joseph PoplingerNo ratings yet

- 484-Medium Voltage Power Cables26.45kVDocument2 pages484-Medium Voltage Power Cables26.45kVJoseph Poplinger0% (1)

- Power Cables YJV22Document30 pagesPower Cables YJV22dabs_orangejuiceNo ratings yet

- 175 - Bleskoistky - GDTDocument6 pages175 - Bleskoistky - GDTMoamen MohamedNo ratings yet

- Safelink CB: Gas Insulated Ring Main UnitDocument2 pagesSafelink CB: Gas Insulated Ring Main UnitABCDNo ratings yet

- Surge Arrester For GIS ELK-3, 550 KV: Innovative and Compact Overvoltage ProtectionDocument4 pagesSurge Arrester For GIS ELK-3, 550 KV: Innovative and Compact Overvoltage Protectiondave chaudhuryNo ratings yet

- OKONITEDocument2 pagesOKONITEworkshop Ega SbyNo ratings yet

- Passive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2From EverandPassive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2No ratings yet

- Terms Definitions Abbreviations Symbols and Units For Capacitors ESCC Basic Specification No. 2133000Document8 pagesTerms Definitions Abbreviations Symbols and Units For Capacitors ESCC Basic Specification No. 2133000opplusNo ratings yet

- Product Data Sheet: Circuit Breaker Compact NSX100N, 50 Ka at 415 VAC, TMD Trip Unit 50 A, 3 Poles 3dDocument3 pagesProduct Data Sheet: Circuit Breaker Compact NSX100N, 50 Ka at 415 VAC, TMD Trip Unit 50 A, 3 Poles 3dopplusNo ratings yet

- 1LE1503-2DB09-0AJ4-Z E52+M1Y Datasheet enDocument1 page1LE1503-2DB09-0AJ4-Z E52+M1Y Datasheet enopplusNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1503-2DB09-0AJ4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1503-2DB09-0AJ4-ZopplusNo ratings yet

- ZALUX Protected LED Luminaires WEB PDFDocument64 pagesZALUX Protected LED Luminaires WEB PDFopplusNo ratings yet

- Lsa 501Document8 pagesLsa 501Lorenzo RossiNo ratings yet

- Motor Learning Theory: References: Cole & Tufano, Chapter 19 Reserve Article: Mathiowetz & Bass Haugen (1994) AJOTDocument23 pagesMotor Learning Theory: References: Cole & Tufano, Chapter 19 Reserve Article: Mathiowetz & Bass Haugen (1994) AJOTEdwin BedfordNo ratings yet

- BedZED Housing, Sutton, London BILL DUNSTER ARCHITECTS PDFDocument3 pagesBedZED Housing, Sutton, London BILL DUNSTER ARCHITECTS PDFflavius00No ratings yet

- Foundation of GuidanceDocument17 pagesFoundation of GuidanceFroilan FerrerNo ratings yet

- Analysis of Electric Go KartDocument6 pagesAnalysis of Electric Go KartIJRASETPublicationsNo ratings yet

- (Dnts2021) (Cv) - Nguyễn Thùy Linh -k204091645Document1 page(Dnts2021) (Cv) - Nguyễn Thùy Linh -k204091645Nguyễn LinhNo ratings yet

- Module 2 Trends NetworkDocument11 pagesModule 2 Trends NetworkBianca TaganileNo ratings yet

- Buku 4 Okupasi Travel ServicesDocument119 pagesBuku 4 Okupasi Travel ServicesMGMP Pariwisata Tangerang SelatanNo ratings yet

- Personal Resiliency PlanDocument3 pagesPersonal Resiliency PlanRachel Ann JimenezNo ratings yet

- Annexure-9 SPL AI & ML-3Document13 pagesAnnexure-9 SPL AI & ML-3satyam sharmaNo ratings yet

- Catalog PDFDocument226 pagesCatalog PDFAndika Arihta Pasaribu100% (1)

- Hòahpch NG: - A Mare GoDocument13 pagesHòahpch NG: - A Mare Gonguyenchimaicma123No ratings yet

- Geometry Practice Test 7 - ACT PROBLEMSDocument7 pagesGeometry Practice Test 7 - ACT PROBLEMSCarlos OrtizNo ratings yet

- Rai Community ProposalDocument11 pagesRai Community ProposalshekharNo ratings yet

- B IngDocument7 pagesB Ingsumire shiny dartokNo ratings yet

- D. Oe4625 Chapter02Document16 pagesD. Oe4625 Chapter02danielmergulhoNo ratings yet

- Shmoop Summary One Flew Over The Cuckoo's NestDocument61 pagesShmoop Summary One Flew Over The Cuckoo's NestDaniela Torres Noriega100% (1)

- An Internship Project On KLN MotorsDocument11 pagesAn Internship Project On KLN MotorsmunirajaffarNo ratings yet

- Trumpet Auditions Spring 2023Document7 pagesTrumpet Auditions Spring 2023JeffNo ratings yet

- June 2022-Demo-Dlp-Finding The Probability of Simple EventsDocument7 pagesJune 2022-Demo-Dlp-Finding The Probability of Simple EventsAngela Camille Paynante100% (1)

- Asia Medical Devices Report - Q2 2019Document41 pagesAsia Medical Devices Report - Q2 2019Ân THiênNo ratings yet

- Cause & Effect WorksheetDocument2 pagesCause & Effect WorksheetAh Gone67% (3)

- Difference Between Primary and Permanent TeethDocument15 pagesDifference Between Primary and Permanent TeetharthisaNo ratings yet

- Epa Facilities Manual Vol 3 Facilities SafetyDocument43 pagesEpa Facilities Manual Vol 3 Facilities Safetykeneth john manayagaNo ratings yet

- ECCE WritingDocument22 pagesECCE Writinggesu piero lopez mejiaNo ratings yet

- 2.classification of NBDocument16 pages2.classification of NBTesfamichael AbathunNo ratings yet

- 6.2.3.7 Packet Tracer - Configuring Multiarea OSPFv3 Instructions IGDocument3 pages6.2.3.7 Packet Tracer - Configuring Multiarea OSPFv3 Instructions IGana100% (1)

- POWER8 Overview v50 PDFDocument262 pagesPOWER8 Overview v50 PDFJohansen LeeNo ratings yet