Professional Documents

Culture Documents

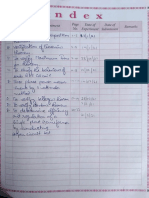

Chap-1 Siares Rizza-Mae 4ee

Uploaded by

Daphne Gesto SiaresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chap-1 Siares Rizza-Mae 4ee

Uploaded by

Daphne Gesto SiaresCopyright:

Available Formats

Name: Siares, Rizza Mae G.

Year and Section: 4EE

Subject: Material Science and Engineering

Instructor: Engr. Jessie Barreto

CHAPTER 1: INTRODUCTION

Terms Summaries

1.1 HISTORICAL PERSPECTIVE

Materials are probably more deep-seated

in our culture than most of us realize.

The development and advancement of

Transportation, housing, clothing,

societies have been intimately tied to the

communication, recreation, and food

members’ ability to produce and

production—virtually every segment of our

manipulate materials to fill their needs. In

everyday lives is influenced to one degree

fact, early civilizations have been

or another by materials. Historically, the

designated by the level of their materials

development and advancement of societies

development (Stone Age, Bronze Age,

have been intimately tied to the members’

Iron Age) With time they discovered

ability to produce and manipulate materials

techniques for producing materials that

to fill their needs. In fact, early civilizations

had properties superior to those of the

have been designated by the level of their

natural ones.

materials development (Stone Age, Bronze

Age, Iron Age).1The earliest humans had

access to only a very limited number of

materials,those that occur naturally: stone,

wood, clay, skins, and so on. With time

they discovered techniques for producing

materials that had properties superior to

those of the natural ones; these new

materials included pottery and various

metals. Furthermore, it was discovered that

the properties of a material could be altered

by heat treatments and by the addition of

other substances. At this point, materials

utilization was totally a selection process

that involved deciding from a given, rather

limited set of materials the one best suited

for an application by virtue of its

characteristics. It was not until relatively

recent times that scientists came to

Materials utilization was totally a selection

understand the relationships between the

process that involved deciding from a

structural elements of materials and their

given, rather limited set of materials the

properties.

one best suited for an application by virtue

This knowledge, acquired over

of its characteristics,materials have

approximately the past 100 years, has

evolved with rather specialized

empowered them to fashion, to a large

characteristics that meet the needs of our

degree, the characteristics of

modern and complex society; these

materials.Thus, tens of thousands of

include metals, plastics,glasses, and

different materials have evolved with rather

fibers.

specialized characteristics that meet the

needs of our modern and complex society;

these include metals, plastics,glasses, and

fibers.

The development of many technologies

that make our existence so comfortable

has been intimately associated with the

accessibility of suitable materials.

An advancement in the understanding of a

material type is often the forerunner to the

stepwise progression of a technology. For

example, automobiles would not have been

possible without the availability of

inexpensive steel or some other

comparable substitute. In our contemporary

era, sophisticated electronic devices rely

on components that are made from what

are called semiconducting materials.

1.2 MATERIALS SCIENCE AND

ENGINEERING

Sometimes it is useful to subdivide the

discipline of materials science and Materials science involves investigating

engineering into materials science and the relationships that exist between the

materials engineering subdisciplines. structures and properties of materials. In

Strictly speaking, materials science contrast, materials engineering is, on the

involves investigating the relationships that basis of these structure–property

exist between the structures and properties correlations, designing or engineering the

of materials. In contrast, materials structure of a material to produce a

engineering is, on the basis of these predetermined set of properties. Most

structure–property correlations, designing graduates in materials programs are

or engineering the structure of a material to trained to be both materials scientists and

produce a predetermined set of materials engineers.Structure is at this

properties.2 From a functional perspective, point a nebulous term that deserves some

the role of a materials scientist is to explanation. In brief, the structure of a

develop or synthesize new materials, material usually relates to the

whereas a materials engineer is called arrangement of its internal components.

upon to create new products or systems

using existing materials, and/or to develop The chapters that follow discuss

techniques for processing materials. Most properties that fall within each of these six

graduates in materials programs are classifications. In addition to structure and

trained to be both materials scientists and properties, two other important

materials engineers.Structure is at this components are involved in the science

point a nebulous term that deserves some and engineering of materials—namely,

explanation. In brief, the structure of a processing and performance. With regard

material usually relates to the arrangement to the relationships of these four

of its internal components. Subatomic components, the structure of a material

structure involves electrons within the will depend on how it is processed.

individual atoms and interactions with their A property is a material trait in terms of

nuclei. On an atomic level, structure the kind and magnitude of response to a

encompasses the organization of atoms or specific imposed stimulus. Generally,

molecules relative to one another. The next definitions of properties are made

larger structural realm, which contains independent of material shape and size.

large groups of atoms that are normally Virtually all important properties of solid

agglomerated together, is termed materials may be grouped into six

microscopic, meaning that which is subject different categories- mechanical,

to direct observation using some type of electrical, thermal, magnetic, optical, and

microscope. Finally, structural elements deteriorative.

that may be viewed with the naked eye are

termed macroscopic.

The notion of property deserves

elaboration. While in service use, all

materials are exposed to external stimuli

that evoke some type of response. For

example, a specimen subjected to forces

will experience deformation, or a polished

metal surface will reflect light. A property is

a material trait in terms of the kind and

magnitude of response to a specific

imposed stimulus. Generally, definitions of

properties are made independent of

material shape and size. Virtually all

important properties of solid materials may

be grouped into six different categories:

mechanical, electrical, thermal, magnetic,

optical, and deteriorative. For each there is

a characteristic type of stimulus capable of

provoking different responses. Mechanical

properties relate deformation to an applied

load or force; examples include elastic

modulus (stiffness), strength, and

toughness. For electrical properties, such

as electrical conductivity and dielectric

constant, the stimulus is an electric field.

The thermal behavior of solids can be

represented in terms of heat capacity and

thermal conductivity. Magnetic properties

demonstrate the response of a material to

the application of a magnetic field. For

optical properties, the stimulus is

electromagnetic or light radiation; index of

refraction and reflectivity are representative

optical properties. Finally, deteriorative

characteristics relate to the chemical

reactivity of materials.

The chapters that follow discuss properties

that fall within each of these six

classifications. In addition to structure and

properties, two other important components

are involved in the science and engineering

of materials—namely, processing and

performance. With regard to the

relationships of these four components, the

structure of a material will depend on how it

is processed. Furthermore, a material’s

performance will be a function of its

properties. Thus, the interrelationship

between processing, structure, properties,

and performance is as depicted in the

schematic.

1.3 WHY STUDY MATERIALS SCIENCE

AND ENGINEERING?

Why do we study materials? Many an

applied scientist or engineer, whether A second selection consideration is any

mechanical, civil, chemical, or electrical, deterioration of material properties that

will at one time or another be exposed to a may occur during service operation

design problem involving materials.

Examples might include a transmission

gear, the superstructure for a building, an

oil refinery component, or an integrated

circuit chip. Of course, materials scientists

and engineers are specialists who are

totally involved in the investigation and

design of materials.Many times, a materials

problem is one of selecting the right

material from the thousands that are

available.The final decision is normally

based on several criteria.First of all, the in- Significant reductions in mechanical

service conditions must be characterized, strength may result from exposure to

for these will dictate the properties required elevated temperatures or corrosive

of the material. On only rare occasions environments. Finally, probably the

does a material possess the maximum or overriding consideration is that of

ideal combination of properties. Thus, it economics,cost of a finished piece also

may be necessary to trade one includes any expense incurred during

characteristic for another. The classic fabrication to produce the desired

example involves strength and ductility; shape,Many times, a materials problem is

normally, a material having a high strength one of selecting the right material from the

will have only a limited ductility. In such thousands that are available.

cases a reasonable compromise between

two or more properties may be

necessary.A second selection

consideration is any deterioration of

material properties that may occur during

service operation. For example, significant

reductions in mechanical strength may

result from exposure to elevated

temperatures or corrosive environments.

Finally, probably the overriding

consideration is that of economics: What

will the finished product cost? A material

may be found that has the ideal set of

properties but is prohibitively expensive.

Here again, some compromise is

inevitable. The cost of a finished piece also

includes any expense incurred during

fabrication to produce the desired

shape.The more familiar an engineer or

scientist is with the various characteristics

and structure–property relationships, as

well as processing techniques of

materials,the more proficient and confident

he or she will be in making judicious

materials choices based on these criteria.

A material may be found that has the ideal

set of properties but is prohibitively

expensive. Here again, some compromise

is inevitable.

1.4 CLASSIFICATION OF MATERIALS

Solid materials have been conveniently

grouped into three basic categories:

metals, ceramics, and polymers. This

scheme is based primarily on chemical

makeup and atomic structure, and most

materials fall into one distinct grouping or

another.In addition,there are the

composites, which are engineered

combinations of two or more different

materials. A brief explanation of these

material classifications and representative

characteristics is offered next. Another

category is advanced materials—those

used in high-technology applications, such

as semiconductors, biomaterials, smart

materials, and nanoengineered materials;

these are discussed in Section 1.5.

Metals

Materials in this group are composed of

one or more metallic elements (e.g., Solid materials have been conveniently

iron,aluminum, copper, titanium, gold, and grouped into three basic categories:

nickel), and often also nonmetallic metals, ceramics, and polymers,most

elements (e.g., carbon, nitrogen, and materials fall into one distinct grouping or

oxygen) in relatively small amounts.3 another.

Atoms in metals and their alloys are

arranged in a very orderly manner (as

discussed in Chapter 3), and in comparison

to the ceramics and polymers, are relatively

dense (Figure 1.3). With

Below are the examples of Metals :

regard to mechanical characteristics, these

materials are relatively stiff (Figure 1.4) and

strong (Figure 1.5), yet are ductile (i.e.,

capable of large amounts of deformation

without fracture), and are resistant to

fracture (Figure 1.6), which accounts for

their widespread use in structural

applications. Metallic materials have large

numbers of nonlocalized electrons; that is,

these electrons are not bound to particular

atoms. Many properties of metals are

directly attributable to these electrons. For

example, metals are extremely good

conductors of electricity (Figure 1.7) and

heat, and are not transparent to visible

light; a polished metal surface has a

lustrous appearance. In addition, some of

the metals (i.e., Fe, Co, and Ni) have

desirable magnetic properties.

Figure 1.8 shows several common and

familiar objects that are made of metallic

materials. Furthermore, the types and

applications of metals and their alloys are

discussed in Chapter 11.

Ceramics

Ceramics are compounds between metallic

and nonmetallic elements; they are most

frequently oxides, nitrides, and carbides.

For example, common ceramic materials

include aluminum oxide (or alumina,

Al2O3), silicon dioxide (or silica, SiO2),

silicon carbide (SiC), silicon nitride (Si3N4),

and, in addition, what some refer to as the

traditional ceramics—those composed of

clay minerals (i.e., porcelain), as well as Ceramics are compounds between

cement and glass.With regard to metallic and nonmetallic elements,they

mechanical behavior, ceramic materials are are most frequently oxides,nitrides and

relatively stiff and strong—stiffnesses and carbides.

strengths are comparable to those of the

metals (Figures 1.4 and 1.5). In addition,

they are typically very hard. Historically,

ceramics have exhibited extreme

brittleness (lack of ductility) and are highly

susceptible to fracture (Figure 1.6).

However, newer ceramics are being

engineered to have improved resistance to

fracture; these materials are used for

cookware, cutlery, and even automobile

engine parts. Furthermore, ceramic

materials are typically insulative to the

passage of heat and electricity (i.e., have

low electrical conductivities, Figure 1.7),

and are more resistant to high

temperatures and harsh environments than

metals and polymers.

With regard to optical characteristics,

ceramics may be transparent, translucent,

or opaque (Figure 1.2), and some of the

oxide ceramics (e.g., Fe3O4) exhibit

magnetic behavior.Several common

ceramic objects are shown in Figure 1.9.

The characteristics, types, and applications

of this class of materials are discussed in

Chapters 12 and 13.

Polymers Polymers include the familiar plastic and

rubber materials. Many of them are

Polymers include the familiar plastic and

organic compounds that are chemically

rubber materials. Many of them are organic

based on carbon, hydrogen, and other

compounds that are chemically based on

nonmetallic elements (i.e., O, N, and Si).

carbon, hydrogen, and other nonmetallic

Furthermore, they have very large

elements (i.e., O, N, and Si). Furthermore,

molecular structures,often chainlike in

they have very large molecular

nature, that often have a backbone of

structures,often chainlike in nature, that carbon atoms. Some of the common and

often have a backbone of carbon atoms. familiar polymers are polyethylene (PE),

Some of the common and familiar polymers nylon, poly(vinyl chloride) (PVC),

are polyethylene (PE), nylon, poly(vinyl polycarbonate (PC), polystyrene (PS),

chloride) (PVC), polycarbonate (PC), and silicone rubber.These materials

polystyrene (PS), and silicone typically have low densities.

rubber.These materials typically have low

densities (Figure 1.3), whereas their

mechanical characteristics are generally

dissimilar to the metallic and ceramic

materials—they are not as stiff nor as

strong as these other material types

(Figures 1.4 and 1.5). However, on the

basis ofWith regard to optical

characteristics, ceramics may be

transparent, translucent, or opaque (Figure

1.2), and some of the oxide ceramics (e.g.,

Fe3O4) exhibit magnetic behavior.

their low densities, many times their

stiffnesses and strengths on a per-mass

basis are comparable to the metals and

ceramics. In addition, many of the polymers

are extremely ductile and pliable (i.e.,

plastic), which means they are easily

formed into complex shapes. In general,

they are relatively inert chemically and

unreactive in a large number of

environments. One major drawback to the

polymers is their tendency to soften and/or

decompose at modest temperatures,

which, in some instances, limits their use.

Furthermore, they have low electrical

conductivities (Figure 1.7) and are

nonmagnetic.

Composites

A composite is composed of two (or more)

individual materials, which come from the

categories previously discussed—metals,

ceramics, and polymers. The design goal

of a composite is to achieve a combination Composite is composed of two (or more)

of properties that is not displayed by any individual materials, which come from the

single material, and also to incorporate the categories previously discussed—metals,

best characteristics of each of the ceramics, and polymers. The design goal

component materials. A large number of of a composite is to achieve a

composite types are represented by combination of properties that is not

different combinations of metals, ceramics, displayed by any single material, and also

and polymers. Furthermore, some naturally to incorporate the best characteristics of

occurring materials are composites—for each of the component materials. A large

example, wood and bone. However, most number of composite types are

of those we consider in our discussions are represented by different combinations of

synthetic (or human-made) composites. metals, ceramics, and polymers.

One of the most common and familiar

composites is fiberglass, in which small

glass fibers are embedded within a

polymeric material (normally an epoxy or

polyester).4 The glass fibers are relatively One of the most common and familiar

strong and stiff (but also brittle), whereas composites is fiberglass, in which small

the polymer is more flexible. Thus, glass fibers are embedded within a

fiberglass is relatively stiff, strong (Figures polymeric material.Furthermore, some

1.4 and 1.5), and flexible. naturally occurring materials are

composites—for example, wood and

bone.

1.5 ADVANCED MATERIALS

Materials that are utilized in high-

technology (or high-tech) applications are

sometimes termed advanced materials. By

high technology we mean a device or

product that operates or functions using

relatively intricate and sophisticated

principles; examples include electronic

equipment (camcorders, CD/DVD players,

etc.), computers, fiber-optic systems,

spacecraft, aircraft, and military

rocketry.These advanced materials are

typically traditional materials whose

properties have been enhanced, and also

newly developed, high-performance

materials. Furthermore, they may be of all

material types (e.g., metals, ceramics,

polymers), and are normally expensive.

Advanced materials include

semiconductors, biomaterials, and what we

may term “materials of the future” (that is,

smart materials and nanoengineered

materials),which we discuss next. The

properties and applications of a number of

these advanced materials—for example,

materials that are used for lasers,

integrated circuits, magnetic information

storage, liquid crystal displays (LCDs), and Advanced materials are typically

fiber optics—are also discussed in traditional materials whose properties

subsequent chapters. have been enhanced, and also newly

developed, high-performance materials.

Semiconductors

Semiconductors have electrical properties

that are intermediate between the electrical

conductors (i.e., metals and metal alloys)

and insulators (i.e., ceramics and

polymers)—see Figure 1.7. Furthermore,

the electrical characteristics of these

materials are extremely sensitive to the

presence of minute concentrations of

impurity atoms, for which the

concentrations may be controlled over very

small spatial regions. Semiconductors have

made possible the advent of integrated

circuitry that has totally revolutionized the

electronics and computer industries (not to

mention our lives) over the past three

decades.

Biomaterials

Biomaterials are employed in components

implanted into the human body to replace

diseased or damaged body parts. These

materials must not produce toxic

substances and must be compatible with

body tissues (i.e., must not cause adverse

biological reactions). All of the preceding

materials—metals, ceramics, polymers,

composites, and semiconductors—may be

used as biomaterials. For example, some

of the biomaterials that are utilized in

artificial hip replacements are discussed in

the online Biomaterials Module.

Semiconductors have electrical properties

Smart Materials that are intermediate between the

electrical conductor,electrical

Smart (or intelligent) materials are a group

characteristics of these materials are

of new and state-of-the-art materials now

being developed that will have a significant extremely sensitive to the presence of

influence on many of our technologies. The minute concentrations of impurity atoms,

adjective smart implies that these materials for which the concentrations may be

are able to sense changes in their controlled over very small spatial regions.

environment and then respond to these

changes in predetermined manners—traits

that are also found in living organisms. In

addition, this “smart” concept is being

extended to rather sophisticated systems

that consist of both smart and traditional

materials.Components of a smart material

(or system) include some type of sensor

(that detects an input signal), and an

actuator (that performs a responsive and

adaptivefunction). Actuators may be called

upon to change shape, position, natural

frequency, or mechanical characteristics in

response to changes in temperature,

electric fields, and/or magnetic fields.

Four types of materials are commonly used

for actuators: shape-memory alloys,

piezoelectric ceramics, magnetostrictive

materials, and

electrorheological/magnetorheological

fluids. Shape-memory alloys are metals

that, after having been deformed, revert

back to their original shape when

temperature is changed (see the Materials

of Importance box following Section 10.9).

Piezoelectric ceramics expand and contract

in response to an applied electric field (or

voltage); conversely, they also generate an

electric field when their dimensions are

All of the preceding materials—metals,

altered (see Section 18.25).The behavior of

ceramics, polymers, composites, and

magnetostrictive materials is analogous to

semiconduct maay be used as

that of the piezoelectrics,except that they

biomaterials.

are responsive to magnetic fields.Also,

electrorheological and magnetorheological

fluids are liquids that experience dramatic

changes in viscosity upon the application of

electric and magnetic fields, respectively.

Materials/devices employed as sensors

include optical fibers .

Nanomaterials

One new material class that has fascinating

properties and tremendous technological

promise is the nanomaterials.

Nanomaterials may be any one of the four

basic types—metals, ceramics, polymers,

and composites. However, unlike these

other materials, they are not distinguished

on the basis of their chemistry, but rather,

size; the nano-prefix denotes that the

dimensions of these structural entities are

on the order of a nanometer (10–9 m)—as

a rule, less than 100 nanometers

(equivalent to approximately 500 atom

diameters). Prior to the advent of

nanomaterials, the general procedure

scientists used to understand the chemistry

and physics of materials was to begin by

studying large and complex structures, and

then to investigate the fundamental building

blocks of these structures that are smaller

and simpler. This approach is sometimes

termed “top-down” science. On the other The adjective smart implies that these

hand, with the development of scanning materials are able to sense changes in

probe microscopes (Section 4.10), which their environment and then respond to

permit observation of individual atoms and these changes in predetermined manners

molecules, it has become possible to —traits that are also found in living

design and build new structures from their organisms. In addition, this “smart”

atomiclevel constituents, one atom or concept is being extended to rather

molecule at a time (i.e., “materials by sophisticated systems that consist of both

design”). This ability to carefully arrange smart and traditional materials.

atoms provides opportunities to develop

mechanical, electrical, magnetic, and other

properties that are not otherwise possible.

We call this the “bottom-up” approach, and

the study of the properties of these

materials is termed nanotechnology.5

Some of the physical and chemical

characteristics exhibited by matter may

experience dramatic changes as particle

size approaches atomic

dimensions.example, materials that are

opaque in the macroscopic domain may

become transparent on the nanoscale;

some solids become liquids, chemically

stable materials become combustible, and

electrical insulators become conductors.

Furthermore, properties may depend on

size in this nanoscale domain. Some of

these effects are quantum mechanical in

origin, others are related to surface

phenomena—the proportion of atoms

located on surface sites of a particle

increases dramatically as its size

decreases. Because of these unique and

unusual properties, nanomaterials are

finding niches in electronic, biomedical,

sporting, energy production, and other

industrial applications. Nanomaterials may be any one of the four

basic types—metals, ceramics, polymers,

and composites. However, unlike these

Whenever a new material is developed, its other materials, they are not distinguished

potential for harmful and toxicological on the basis of their chemistry, but rather,

interactions with humans and animals must size,prior to the advent of nanomaterials,

be considered. Small nanoparticles have the general procedure scientists used to

exceedingly large surface area–to–volume understand the chemistry and physics of

ratios, which can lead to high chemical materials was to begin by studying large

reactivities. Although the safety of and complex structures, and then to

nanomaterials is relatively unexplored,there investigate the fundamental building

are concerns that they may be absorbed blocks of these structures that are smaller

into the body through the skin, lungs, and and simpler. This approach is sometimes

digestive tract at relatively high rates, and termed “top-down” science.

that some, if present in sufficient

concentrations, will pose health risks—

such as damage to DNA or promotion of

lung cancer.

1.6 MODERN MATERIALS’ NEEDS

In spite of the tremendous progress that

has been made in the discipline of

materials science and engineering within

the past few years, technological

challenges still remain, including the

development of even more sophisticated

and specialized materials, as well as

consideration of the environmental impact

of materials production. Some comment is

appropriate relative to these issues so as to

round out this perspective.

Nuclear energy holds some promise, but

the solutions to the many problems that

remain will necessarily involve materials,

such as fuels, containment structures,and

facilities for the disposal of radioactive

waste. Significant quantities of energy are

involved in transportation. Reducing the

weight of transportation vehicles

(automobiles, aircraft, trains, etc.), as well

as increasing engine operating

temperatures, will enhance fuel efficiency.

New highstrength, low-density structural

materials remain to be developed, as well

as materials that have higher-temperature The direct conversion of solar power into

capabilities, for use in engine components. electrical energy has been demonstrated.

Furthermore, there is a recognized need to Solar cells employ some rather complex

find new, economical sources of energy and expensive materials. To ensure a

and to use present resources more viable technology,materials that are highly

efficiently. Materials will undoubtedly play a efficient in this conversion process yet

significant role in these developments. For less costly must be developed.It is just

example, the direct conversion of solar beginning to be implemented in batteries

power into electrical energy has been for electronic devices and holds promise

demonstrated. Solar cells employ some as a power plant for automobiles. New

rather complex and expensive materials. materials still need to be developed for

To ensure a viable technology,materials more efficient fuel cells and also for better

that are highly efficient in this conversion catalysts to be used in the production of

process yet less costly must be developed. hydrogen.

The hydrogen fuel cell is another very

attractive and feasible energyconversion

technology that has the advantage of being

nonpolluting. It is just beginning to be

implemented in batteries for electronic

devices and holds promise as a power

plant for automobiles. New materials still

need to be developed for more efficient fuel

cells and also for better catalysts to be

used in the production of

hydrogen.Furthermore, environmental

quality depends on our ability to control air

and water pollution. Pollution control

techniques employ various materials. In

addition,materials processing and

refinement methods need to be improved

so that they produce less environmental

degradation—that is, less pollution and less

despoilage of the landscape from the

mining of raw materials. Also, in some

materials manufacturing processes, toxic

substances are produced, and the

ecological impact of their disposal must be

considered. Many materials that we use

are derived from resources that are

nonrenewable— that is, not capable of

being regenerated. These include most

polymers, for which the prime raw material

is oil, and some metals. These

nonrenewable resources are gradually technological challenges still remain,

becoming depleted, which necessitates (1) including the development of even more

the discovery of additional reserves, (2) the sophisticated and specialized materials,

development of new materials having as well as consideration of the

comparable properties with less adverse environmental impact of materials

environmental impact, and/or (3) increased production. The solutions to the many

recycling efforts and the development of problems that remain will necessarily

new recycling technologies. As a involve materials, such as fuels,

consequence of the economics of not only containment structures,and facilities for

production but also environmental impact

and ecological factors, it is becoming the disposal of radioactive waste.

increasingly important to consider the Significant quantities of energy are

“cradle-to-grave” life cycle of materials involved in transportation.

relative to the overall manufacturing

process.

1.7PROCESSING/STRUCTURE/PROPER

TIES/

PERFORMANCE CORRELATIONS

As mentioned previously (Section 1.2), the

science and engineering of materials

involves four interrelated components:

processing, structure, properties, and

performance (Figure 1.1). Inasmuch as the

remainder of the book discusses these

components for the different material types,

it has been decided to direct the readers’

attention to the treatment of individual

components for several specific materials.

Whereas some of these discussions are

found within single chapters, others are

spread out over multiple chapters. For the

latter, and for each material we have

selected, a “topic timeline” has been

created that indicates the locations (by

sections) where treatments of the four

components are to be found. Figure 1.11

presents topic timelines for the following

materials: steels, glass-ceramics, polymer

fibers, and silicon semiconductors. In

addition, at the beginning of each chapter

(in the Why Study? section), we note those

materials that have some aspect of their

processing, structure, properties, and/or

performance discussed in that chapter.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Reinforcement Plan Pedestal Plan: Saudi Arabian Oil CompanyDocument1 pageReinforcement Plan Pedestal Plan: Saudi Arabian Oil CompanyDomie Neil Bucag SalasNo ratings yet

- Rochet: Short Course For Papua New Guinea Non-Formal SectorDocument22 pagesRochet: Short Course For Papua New Guinea Non-Formal SectorKim So-HyunNo ratings yet

- Q4 HEALTH 9 Week 1Document4 pagesQ4 HEALTH 9 Week 1Daphne Gesto SiaresNo ratings yet

- 200+ TOP RADIOLOGY Online Quiz Questions - Exam Test 2023Document24 pages200+ TOP RADIOLOGY Online Quiz Questions - Exam Test 2023Ayub Alam100% (1)

- ENGLISH G9 - Q4: Week 1: Judging The Relevance and Worth of Ideas, Soundness of Author's Reasoning, Andeffectiveness of The Presentation (Part 1)Document12 pagesENGLISH G9 - Q4: Week 1: Judging The Relevance and Worth of Ideas, Soundness of Author's Reasoning, Andeffectiveness of The Presentation (Part 1)Daphne Gesto SiaresNo ratings yet

- Synthesis Paper On Nuclear PPDocument3 pagesSynthesis Paper On Nuclear PPchristinekehyengNo ratings yet

- Q4 Music 9 Week4Document4 pagesQ4 Music 9 Week4Daphne Gesto SiaresNo ratings yet

- Learning Area Grade Level Quarter Date I. Lesson Title Ii. Most Essential Learning Competencies (Melcs) Iii. Content/Core ContentDocument6 pagesLearning Area Grade Level Quarter Date I. Lesson Title Ii. Most Essential Learning Competencies (Melcs) Iii. Content/Core ContentDaphne Gesto SiaresNo ratings yet

- Cpar Module 1Document9 pagesCpar Module 1Daphne Gesto SiaresNo ratings yet

- G10 Health Week 1 2Document14 pagesG10 Health Week 1 2Daphne Gesto SiaresNo ratings yet

- September 13-October 6: Republic of The Philippines Department of Education Region Iv-A Calabarzon Division of RizalDocument4 pagesSeptember 13-October 6: Republic of The Philippines Department of Education Region Iv-A Calabarzon Division of RizalDaphne Gesto Siares100% (1)

- Statement of Financial Position 2Document25 pagesStatement of Financial Position 2Daphne Gesto SiaresNo ratings yet

- September 13-October 6: Republic of The Philippines Department of Education Region Iv-A Calabarzon Division of RizalDocument4 pagesSeptember 13-October 6: Republic of The Philippines Department of Education Region Iv-A Calabarzon Division of RizalDaphne Gesto SiaresNo ratings yet

- Week 1Document7 pagesWeek 1Daphne Gesto SiaresNo ratings yet

- Household Socio Economic Profile Cluster A.Document772 pagesHousehold Socio Economic Profile Cluster A.Daphne Gesto SiaresNo ratings yet

- Morong: University of Rizal System University of Rizal SystemDocument1 pageMorong: University of Rizal System University of Rizal SystemDaphne Gesto SiaresNo ratings yet

- Week 5Document13 pagesWeek 5Daphne Gesto SiaresNo ratings yet

- Hydroelectric Design: Presented By: Ronwell James T. Campo 4EEDocument20 pagesHydroelectric Design: Presented By: Ronwell James T. Campo 4EEDaphne Gesto SiaresNo ratings yet

- February 1, 2021-Monday: All Activities in Tle Per DayDocument14 pagesFebruary 1, 2021-Monday: All Activities in Tle Per DayDaphne Gesto SiaresNo ratings yet

- Application of Hyrdroelectricity: Izaiah Joshua B. Tentado 4eeaDocument9 pagesApplication of Hyrdroelectricity: Izaiah Joshua B. Tentado 4eeaDaphne Gesto SiaresNo ratings yet

- Learning Area Grade Level Quarter Date: Arts 9 4Document4 pagesLearning Area Grade Level Quarter Date: Arts 9 4Daphne Gesto Siares100% (1)

- Q4 Music 9 Week3 1Document4 pagesQ4 Music 9 Week3 1Daphne Gesto SiaresNo ratings yet

- Learning Area Grade Level Quarter Date: Arts 9 4THDocument4 pagesLearning Area Grade Level Quarter Date: Arts 9 4THDaphne Gesto Siares100% (3)

- Q4 HEALTH 9 Week 2Document4 pagesQ4 HEALTH 9 Week 2Daphne Gesto SiaresNo ratings yet

- Republic of The Philippines: Carlos "Botong" V. Francisco MnhsDocument3 pagesRepublic of The Philippines: Carlos "Botong" V. Francisco MnhsDaphne Gesto Siares0% (1)

- Learning Area Grade Level Quarter Date: TLE-Electrical Installation and Maintenance (EIM NCII) 9 FourthDocument6 pagesLearning Area Grade Level Quarter Date: TLE-Electrical Installation and Maintenance (EIM NCII) 9 FourthDaphne Gesto SiaresNo ratings yet

- Learning Activity Sheet/Gawaing PagkatutoDocument2 pagesLearning Activity Sheet/Gawaing PagkatutoDaphne Gesto Siares100% (1)

- Discrete Variable RepresentationDocument4 pagesDiscrete Variable RepresentationJustin BrockNo ratings yet

- (GHS SDS-en) - TAT - SOL-32 - 201901Document5 pages(GHS SDS-en) - TAT - SOL-32 - 201901Ian PrabowoNo ratings yet

- Bradley Sink Verge LVLD2Document4 pagesBradley Sink Verge LVLD2isaacgamezNo ratings yet

- CSD 303 Exam 1 Review QuestionsDocument3 pagesCSD 303 Exam 1 Review QuestionsJohn BennettNo ratings yet

- Project Work On Chemistry: Change of PH During Formation of Curd From MilkDocument16 pagesProject Work On Chemistry: Change of PH During Formation of Curd From MilkYoezer Pelden100% (1)

- How To Run A Grinding TestDocument6 pagesHow To Run A Grinding Testsealion72No ratings yet

- Establishment of The Causal Agent(s) of Spike Shedding and Stem Wilting of Pepper (Piper Nigrum L.) in Morogoro District, TanzaniaDocument15 pagesEstablishment of The Causal Agent(s) of Spike Shedding and Stem Wilting of Pepper (Piper Nigrum L.) in Morogoro District, TanzaniaAbdul ShangoNo ratings yet

- In-Situ AbstDocument5 pagesIn-Situ AbstFahim MunawarNo ratings yet

- Brief Desccription of Ammonia Urea Plants With RevampDocument48 pagesBrief Desccription of Ammonia Urea Plants With RevampGeorge Van BommelNo ratings yet

- Lecture3 PDFDocument12 pagesLecture3 PDFYogi AldinoNo ratings yet

- Courses To Study 13 X 2010Document96 pagesCourses To Study 13 X 2010hitmaaaccountNo ratings yet

- Study On Solar Irrigation System in BangladeshDocument61 pagesStudy On Solar Irrigation System in Bangladeshavocadocolor100% (2)

- Degree ExercisesDocument3 pagesDegree ExercisesArjit Kapoor100% (1)

- Bridge Final ProposalDocument14 pagesBridge Final ProposalDr. A B M Amrul KaishNo ratings yet

- Thermal EngineeringDocument23 pagesThermal Engineeringakeey4uNo ratings yet

- FILE - 20211123 - 141203 - de Thi Mau Tieng AnhDocument17 pagesFILE - 20211123 - 141203 - de Thi Mau Tieng AnhDo Le Quoc LapNo ratings yet

- Mashkoor Hussain Qureshi Ex PackagesDocument8 pagesMashkoor Hussain Qureshi Ex Packagesmussadaq raufNo ratings yet

- Equation of Motion PDFDocument2 pagesEquation of Motion PDFMazvita TakawiraNo ratings yet

- Paul Quennon HaikusDocument155 pagesPaul Quennon HaikusDiogo MizaelNo ratings yet

- Attachment - Statement HP 2023 January Cyan, Magenta, Yellow, and BlackDocument2 pagesAttachment - Statement HP 2023 January Cyan, Magenta, Yellow, and BlackWayan PartaNo ratings yet

- ENSTO клеммыDocument92 pagesENSTO клеммыenstospbNo ratings yet

- Ee 8Document8 pagesEe 8RushilNo ratings yet

- 02 - Catalogue - ENDocument27 pages02 - Catalogue - ENAlejandro SiavisnomNo ratings yet

- HUDA Policy Allowing Four BasementsDocument3 pagesHUDA Policy Allowing Four BasementsRahul JindalNo ratings yet

- Assignment On: Course Title: Course Code: Section Submitted byDocument11 pagesAssignment On: Course Title: Course Code: Section Submitted byAl MozahidNo ratings yet