Professional Documents

Culture Documents

Clays and Damage

Clays and Damage

Uploaded by

tony0 ratings0% found this document useful (0 votes)

11 views19 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views19 pagesClays and Damage

Clays and Damage

Uploaded by

tonyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 19

Clays and Damage – not necessarily

related

• Will clay create a problem? Depends on clay

type, form, location, what fluids are flowing

and how flowed?

George E. King Engineering

3/14/2009 1

GEKEngineering.com

Migrating Fines

• Sources

– kaolinite - not really that likely unless weathered!

– Smectite - very likely, but clay is rare as authogenic

deposit

– zeolites - common in younger sands, GOM area

– weathered feldspar - older sands

– micas, silts, drilling additives

George E. King Engineering

3/14/2009 2

GEKEngineering.com

Reactivity of Clays

Mineral Typical Area Cation Exchange

(M2/g) Capacity

(Meq/100 g)

Sand (up to 60 0.000015 0.6

microns)

Kaolinite 22 3 - 15

Chlorite 60 10 - 40

Illite 113 10 - 40

Smectite 82 80 - 150

Size ranges for clays depend on deposit

George configuration.

E. King Engineering

3/14/2009 3

GEKEngineering.com

CE’s affected by coatings and configurations.

Kaolinite

• Detridal - no problem in most cases

• Authogenic - depends on location and

attachment

• Worst form - highly “weathered” or

decomposed

• Worst problem - loose attachment to host

grain.

George E. King Engineering

3/14/2009 4

GEKEngineering.com

Smectite

• Detridal - depends on liquid contact area

• Authogenic - swelling clay, sheds particles

from swollen structure

• Worst form – authogenic (pore lining)

• Worst problem - swelling and particle

generation

George E. King Engineering

3/14/2009 5

GEKEngineering.com

Illite

• Detridal - little problem, watch smectite

mixtures

• Authogenic - trap for particles

• Worst form - authogenic “hairy” deposit

• Worst problem - particle trap, microporosity

George E. King Engineering

3/14/2009 6

GEKEngineering.com

Chlorite

• Detridal - little problem

• Authogenic - little problem, some worry about

acid

• Worst form - chlorite rims (free standing and

unstable) - rare deposit (Louisiana)

• Worst problem - iron content (but usually only

slowly acid soluble)

George E. King Engineering

3/14/2009 7

GEKEngineering.com

Migrating Clay Catalysts

• water salinity changes

• surfactants and mutual solvents

• overburden increases

• wettability changes

George E. King Engineering

3/14/2009 8

GEKEngineering.com

Other “Migrators”

• The following are dwarfs compared to the problems

with smectite.

– Zeolites - (common in young marine sands) - clintoptolite

– “Weathered” or altered feldspars

– one very rare form of chlorite

– a few loosely attached kaolinite bundles

– broken illites (and mixed layers)

– silt and other grains (<5 microns)

George E. King Engineering

3/14/2009 9

GEKEngineering.com

Is Clay a Problem?

• Usually not.

• Very few formations are water sensitive to a

degree that will affect production.

• Clay is a problem when it is in contact with a

reactive fluid and the effects or the reaction

significantly lower permeability (30% or

more?).

George E. King Engineering

3/14/2009 10

GEKEngineering.com

Microporosity

• Refers to the very small (non flowable?)

volume between clay platelets that can trap

and hold water.

• May explain non recovery or slow recovery of

load fluids

• May explain errors in log calculations involving

high Sw prediction and subsequent dry

hydrocarbon flows.

George E. King Engineering

3/14/2009 11

GEKEngineering.com

Kaolinite on the left and chlorite

on the right.

George E. King Engineering

3/14/2009 12

GEKEngineering.com

George E. King Engineering

3/14/2009 13

GEKEngineering.com

Migrating???

• Because fines are there means nothing

• What turns the fines loose?

– Velocity - unlikely

– salinity change in fluids - very common

– wetting change

– cleaning agents

– solvents (and mutual solvents)

– shock loads (perforating for example)

George E. King Engineering

3/14/2009 14

GEKEngineering.com

George E. King Engineering

3/14/2009 15

GEKEngineering.com

George E. King Engineering

3/14/2009 16

GEKEngineering.com

George E. King Engineering

3/14/2009 17

GEKEngineering.com

George E. King Engineering

3/14/2009 18

GEKEngineering.com

Control Shales/Clays - inhibition

• 2 to 8% KCl (Smectites require high end of range)

• 2 to 4% NH4Cl (watch emulsions with some oils -

testing with live and spent crudes suggested)

• sodium chlorides to 10 lb/gal - balance with calcium?

• Calcium chlorides to 11.4 lb/gal - watch plugging and

scale formation

• Avoid “liquid KCl” and KCl substitutes, especially in

sensitive formations

George E. King Engineering

3/14/2009 19

GEKEngineering.com

You might also like

- Geopolymer Concrete PPT-KVRDocument24 pagesGeopolymer Concrete PPT-KVRBindu Srirangam100% (3)

- A Guide To Good Quality Control Practices OnAsphalt Production and ConstructionDocument59 pagesA Guide To Good Quality Control Practices OnAsphalt Production and ConstructionAmirrudin Johari100% (1)

- Durability of ConcreteDocument31 pagesDurability of ConcreteTabish IzharNo ratings yet

- Stimulation Effect On TreatersDocument29 pagesStimulation Effect On TreaterstonyNo ratings yet

- From The Reservoir Limit To Pipeline Flow: How Hydrocarbon Reserves Are ProducedDocument41 pagesFrom The Reservoir Limit To Pipeline Flow: How Hydrocarbon Reserves Are ProducedGilberto MirelesNo ratings yet

- Cementitious Slag Makers Association: What Is GGBS?Document10 pagesCementitious Slag Makers Association: What Is GGBS?islam saadNo ratings yet

- 2 AggregatesDocument25 pages2 AggregatesKenneth Jhon TenizoNo ratings yet

- Advanced Concrete Technology Unit 1: CementDocument18 pagesAdvanced Concrete Technology Unit 1: CementSwathiKurnalNo ratings yet

- Fracturing Basics: - Damage Bypass - StimulationDocument58 pagesFracturing Basics: - Damage Bypass - StimulationrizalziNo ratings yet

- Formation Damage ExamplesDocument89 pagesFormation Damage ExamplesLaurensius Raymond SanjayaNo ratings yet

- Deleterious Substances in AggregatesDocument34 pagesDeleterious Substances in AggregatesheminNo ratings yet

- On ConcreteDocument102 pagesOn Concreteblg watersupplyNo ratings yet

- 2, Sdcs MaterialsDocument58 pages2, Sdcs MaterialsNH PNo ratings yet

- Chemical Composition of LimestoneDocument7 pagesChemical Composition of LimestoneĐặng Anh TrungNo ratings yet

- Advanced Concrete Technology - 10cv81 - ACE NotesDocument185 pagesAdvanced Concrete Technology - 10cv81 - ACE Notessaqeeb33% (3)

- RRS Notes Lecture 1Document9 pagesRRS Notes Lecture 1Jaswant SharmaNo ratings yet

- Argillaceous (Containing Alumina) and Calcareous (Containing Calcium Carbonate or Lime) MaterialsDocument31 pagesArgillaceous (Containing Alumina) and Calcareous (Containing Calcium Carbonate or Lime) MaterialsEbook RaniNo ratings yet

- Techspec Lime and ClayDocument6 pagesTechspec Lime and ClayTrina CandelariaNo ratings yet

- CE 772 Module 8-9Document51 pagesCE 772 Module 8-9Tewodros AbateNo ratings yet

- Functions of Concrete AdmixturesDocument2 pagesFunctions of Concrete AdmixturesDS20CE017Bhaskar WabhitkarNo ratings yet

- Squeeze Cementing: Forces Cement Slurry, Under Pressure, Through Perforations or Holes in The Casing or Liner .Document41 pagesSqueeze Cementing: Forces Cement Slurry, Under Pressure, Through Perforations or Holes in The Casing or Liner .Mehdi AlizadehNo ratings yet

- Concrete AggregatesDocument41 pagesConcrete AggregatesLino Angelo DimaculanganNo ratings yet

- 3.1 AggregatesDocument24 pages3.1 AggregatesJuan MarcosNo ratings yet

- Souravsingh Cen204040 PDFDocument69 pagesSouravsingh Cen204040 PDFSOURAAVNo ratings yet

- 4 Chapter 1 Cement Ae 55Document16 pages4 Chapter 1 Cement Ae 55Mohsin ShaikhNo ratings yet

- Concrete 2Document19 pagesConcrete 2Varun TripathiNo ratings yet

- CE 772 Module 7Document21 pagesCE 772 Module 7Tewodros AbateNo ratings yet

- 14-Agg-Admix 2nd HadoutDocument9 pages14-Agg-Admix 2nd HadoutZELALEMNo ratings yet

- Deterioration of Concrete Materials: Prof. Ravindra Gettu and Dr. Radhakrishna G. PillaiDocument73 pagesDeterioration of Concrete Materials: Prof. Ravindra Gettu and Dr. Radhakrishna G. PillaiPiyush SinghNo ratings yet

- Cement: C) Bogue's CompoundsDocument31 pagesCement: C) Bogue's CompoundsSafikul HossainNo ratings yet

- Importance of Sidhee Portland Pozzolana Cement PDFDocument77 pagesImportance of Sidhee Portland Pozzolana Cement PDFNovember RainNo ratings yet

- I. Soil and Soil Aggregates PDFDocument19 pagesI. Soil and Soil Aggregates PDFNicoNo ratings yet

- Concrete Materials and MixtureDocument59 pagesConcrete Materials and MixtureMei Mei100% (2)

- Durability of Geopolymer Concrete Box CulvertsDocument10 pagesDurability of Geopolymer Concrete Box Culvertshanis hanisahNo ratings yet

- Wellbore Stability & Clay MineralogyDocument48 pagesWellbore Stability & Clay MineralogySapan100% (1)

- Construction Materials and Testing Manual NewDocument89 pagesConstruction Materials and Testing Manual NewJosiah AntoninoNo ratings yet

- Durability of ConcreteDocument56 pagesDurability of ConcretefaizNo ratings yet

- Chapter - 1: Experimental Analysis of Concrete Incorporating Waste Foundry Sand and Waste Ceramic TilesDocument44 pagesChapter - 1: Experimental Analysis of Concrete Incorporating Waste Foundry Sand and Waste Ceramic TilesIrfan KhanNo ratings yet

- Advancement in Refactory - MR M C Pardhan, Tata RefactoriesDocument47 pagesAdvancement in Refactory - MR M C Pardhan, Tata RefactoriesAli HüthütNo ratings yet

- Retarding Water-Reducing Concrete AdmixtureDocument2 pagesRetarding Water-Reducing Concrete AdmixtureDS20CE017Bhaskar WabhitkarNo ratings yet

- Retarding Water-Reducing Concrete AdmixtureDocument2 pagesRetarding Water-Reducing Concrete AdmixtureDS20CE017Bhaskar WabhitkarNo ratings yet

- 05 - Aggregates & The Uses in EngineeringDocument15 pages05 - Aggregates & The Uses in Engineeringim23worldNo ratings yet

- Use of Granite Waste For The Application As Coarse Aggregate in ConcreteDocument8 pagesUse of Granite Waste For The Application As Coarse Aggregate in ConcreteEditor IJTSRDNo ratings yet

- Conspec, Inc.: AssociatesDocument73 pagesConspec, Inc.: AssociatessamuelNo ratings yet

- 3 - 23 30 Reni Mullukattil Lukose1Document8 pages3 - 23 30 Reni Mullukattil Lukose1Saikrishna rao PolasaniNo ratings yet

- Lecture - 03 CementDocument32 pagesLecture - 03 CementKeshav SomaniNo ratings yet

- Aggregate: Raju Sharma Lecturer Thapar University Patiala, PunjabDocument43 pagesAggregate: Raju Sharma Lecturer Thapar University Patiala, PunjabTakdir BhullarNo ratings yet

- Geopolymer Concrete: The Concrete of Next DecadeDocument17 pagesGeopolymer Concrete: The Concrete of Next DecadeUpadesh ShresthaNo ratings yet

- Basics Engineering of Concrete and ConstructionDocument35 pagesBasics Engineering of Concrete and ConstructionyurendraNo ratings yet

- Gujarat Technological University: Chandkheda, Ahmadabad. AffiliatedDocument14 pagesGujarat Technological University: Chandkheda, Ahmadabad. AffiliatedKaushik MajiNo ratings yet

- (P) CVE20003 - Lectures - Week 3 - Concrete - TechnologyDocument40 pages(P) CVE20003 - Lectures - Week 3 - Concrete - TechnologyFang Jie ChanNo ratings yet

- Unit 2Document25 pagesUnit 2akshata.musaleNo ratings yet

- Unit 2Document25 pagesUnit 2Akshata MusaleNo ratings yet

- Durability of Concrete: Relationship Between Durability and PerformanceDocument31 pagesDurability of Concrete: Relationship Between Durability and PerformanceMahesh MakwanaNo ratings yet

- Lecture 3 CIS 401 (Lecture Notes)Document15 pagesLecture 3 CIS 401 (Lecture Notes)history.geek.911tsNo ratings yet

- Geopolymer CementDocument11 pagesGeopolymer CementKraft DinnerNo ratings yet

- A. Introduction - Agglomerated Stone TilingDocument9 pagesA. Introduction - Agglomerated Stone Tilingshoba9945No ratings yet

- Seminar On GGBS & Silica FumeDocument10 pagesSeminar On GGBS & Silica FumeawasarevinayakNo ratings yet

- Type & Grades of CementDocument12 pagesType & Grades of CementAmit Agarwal93% (15)

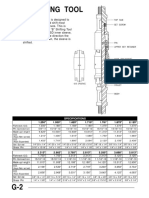

- TIC-Wireline Tools and Equipment Catalog - 部分177 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分177 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分335Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分335zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分225Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分225zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分135 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分135 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分301 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分301 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分301Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分301zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment - 部分347 PDFDocument1 pageTIC-Wireline Tools and Equipment - 部分347 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分351 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分351 PDFzbhdzpNo ratings yet