Professional Documents

Culture Documents

3 066 12 - Rosenberg

Uploaded by

Kushal BajracharyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 066 12 - Rosenberg

Uploaded by

Kushal BajracharyaCopyright:

Available Formats

Energy efficiency targets for industry

– evaluating implementation options

Anja Rosenberg Michael Kohlhaas

Climate Policy Initiative DIW Berlin

Mohrenstr. 58

10117 Berlin Wolfgang Eichhammer

Germany Fraunhofer ISI

Clemens Rohde Barbara Schlomann

Fraunhofer ISI Fraunhofer ISI

Karsten Neuhoff

DIW Berlin

Keywords

target, energy efficiency policy, energy management system nies’ decision-making process. A company will consider the

implementation of an energy efficiency measure, if the pay-

back period for additional investment cost is short enough or

Abstract sufficient financial incentives exist. We expect that by the time

The German Energy Concept of 2010 proposes measures for of the Summer Study we can report about the outcome of the

industry to advance energy efficiency in the industry sec- actual discussions in Germany.

tor e.g. energy management system (EMS). In our study, we

characterize various experiences with policy instruments to

accelerate the improvement of energy efficiency. We define Introduction

implementation options which describe how the achievement The Federal Government of Germany has set the objective to

of energy efficiency targets and financial incentives can be reduce primary energy consumption by 20 % by 2020 and by a

linked on the base of an EMS. The implementation options total of 50 % by 2050 (BMWi, BMU 2010). Since the industry

are characterized by their target type (energy efficiency im- sector is responsible for almost a third of the country’s total

provements or installation of energy efficiency measures), the energy consumption (AGEB 2011), it is expected to play an

level at which targets have to be achieved (branch or company important role in the effort to achieve these targets. The En-

level) and in the type of indicators for verification (energy ergy Concept, in place as of September 2010, proposes various

intensity improvement vs. energy efficiency investment). All measures to advance energy efficiency in the industry sector.

implementation options aim at setting pertinent incentives for The German government commissioned a set of studies in or-

energy efficiency improvement in each company. One evalu- der to translate these measures into concrete plans for imple-

ation criterion is the capability of dealing with the variance mentation (IREES 2011, Prognos 2011). This paper reports on

of energy efficiency improvements over time. We conducted our contribution (Eichhammer et al. 2011).

an analysis of the historic annual energy savings in the pe- As an initial step we compare different measures, types and

riod 2000–09. The results show a large variance, which results costs of energy savings. Defining these aspects is an essential

from the discontinuity of various impact factors. This must first step when formulating energy efficiency targets. In the

be considered, if consistent incentives for energy savings shall following, we estimate the potential for future energy savings

be provided over time. Furthermore, we evaluated the abil- in the German industry sector. There are different options for

ity to formulate effective energy efficiency targets. The study translating these potentials into actual energy efficiency targets

quantifies the energy savings potential of the German industry and energy saving measures for the German industry sector.

until 2020 under different scenarios. We discuss for each im- We explore how effective each of these options is in accelerating

plementation option how well it supports the realization of the the realization of energy savings.

resulting energy savings potentials. A third criterion relates

to the integration of energy efficiency targets into a compa-

ECEEE 2012 SUMMER STUDY on Energy efficiency in industry 305

3-066-12 Ro senberg et al 3. MATCHING POLICIES AND DRIVERS

Characterization of Energy Savings Criteria for the Measurement, Reporting and

Verification of Energy Savings

Lifetime of Energy Saving Measure

The lifetime of an energy saving measure is an important fac- Final vs. Primary Energy

tor for the impact assessment. Naturally, a short lifetime of a The consideration of final energy for the saving measurement

technical measure has no direct long-term effect. Neverthe- has the advantage of an independency of the energy carrier mix

less by a change in product demand, the overall market may for electricity production, which is another time variant vari-

change to more efficient products; operational measures have able. Concerning climate change issues, primary energy is the

no real lifetime, but need constant monitoring and verifica- more accurate approach, for the differences in GHG potential

tion. are reflected better. An energy carrier change may be an advan-

tage in terms of final energy, but may lead to increased primary

Absolute Costs of Energy Saving Measure energy consumption.

The absolute costs of an efficiency measure influence invest-

ment behaviour significantly. Measures with high absolute in- Absolute vs. Relative Savings

vestment costs are subject to strong barriers, for they are highly Energy efficiency targets in a policy context are often con-

dependent on capital availability. verted to absolute energy saving targets, for the measurement,

reporting and verification (MRV) mechanisms are much

Relative Costs of Energy Saving Measure easier to implement. However, absolute saving targets do not

The economic payback of an efficiency measure is driven by the necessarily imply an efficiency gain, but may be reached by

relative costs, which include in some way the refund from the reduced activity. In a macroeconomic context this problem

saved energy. Efficiency measures are mostly evaluated by their is of importance when large changes of economic activities

payback time, whereas the internal interest rate is the more ap- occur. This was the case in 2008 for the effects of the finan-

propriate approach. cial crisis. In a microeconomic context, the problem is even

larger, because changes in type or amount of production in

Technical and Operational Conditions for Implementation a single enterprise can heavily influence the absolute power

Measures, which achieve their savings just by their technical consumption. Therefore, a real efficiency target, which relates

implementation (such as the use of more efficient motor drives) the energy consumption to an activity index, is more accurate

have relatively small uncertainties in the impact assessment. In in reflecting the efficiency gain.

contrast, operational measures as well as technical measures, However, if an absolute target is measured against a bottom

which require systemic changes, have larger uncertainties con- up evaluation of efficiency measures, only real efficiency im-

cerning their estimated savings. provements would be accounted for and a reduction in output

would not lead to accountable savings.

Type of Energy Saved (Energy Carrier/ Type of Useful Energy)

Electricity and fuel savings have quite different impacts on Benchmarking

GHG emissions as well as on energy economy. Fuel savings are Alternatively to absolute or relative savings, benchmarks may

not subject to conversion losses and are independent of the en- be used for the MRV. They may work well for homogeneous

ergy carrier mix for electricity production. The different types products and processes, but have large implantation problems

of useful energy may also be a criterion for the evaluation of if products and processes become more diversified.

energy savings.

Aggregation Level

Reference Output If a high aggregation level is chosen, structural effects in single

When energy efficiency targets are discussed, we have to relate sectors (i.e. a change in the composition of output) may falsify

the energy consumption to an activity. This activity may be: the results of the efficiency measurement. On the other hand,

• A physical unit such as tonnage of produced goods. This data collection on an aggregated level is much easier, because

is only applicably for homogenious production conditions. national statistics generally give information on a sectoral or

sub-sectoral level.

• Economic indicators, such as turnover, production value or On a company basis, the energy consumption is easy to iden-

added value. They can be uses for heterogenic processes or tify, nevertheless the selection of a reference output may be-

sectors, but they are not as accurate as the physical units, for come problematic, because economic indicators or production

they have other influencing variables. indices are not necessarily available on a company level.

• Production indices, which are closer to the physical pro-

duction that economic indicators, for they are adjusted Reference Year vs. Reference Development

of purely economic impacts. See generally Graichen et al. As reference for a target the energy efficiency or energy con-

(2011). sumption in a base year may be chosen. This baseline is rela-

tively easy to identify and free of larger uncertainties. Neverthe-

less, a reference year calculation does not reflect autonomous

developments in any case and economic impacts, if absolute

savings are calculated. These issues are handled, if a reference

development is used, but the development of the reference is

306 ECEEE 2012 SUMMER STUDY on Energy efficiency in industry

3. MATCHING POLICIES AND DRIVERS 3-066-12 Ro senberg et al

linked to a great amount of uncertainties due to the assump- • Target: What has to be achieved?

tions needed for developing the reference. See generally Grai-

• Target measure: How is success measured?

chen et al. (2011).

• Compliance: Who has to achieve the target?

Potential Future Energy Savings in the German • Reward allocation: Who will be rewarded?

Industry Sector We discuss four options that cover a wide range of possible

The energy savings potential of the German industry sector formulations and implementations of energy efficiency targets.

until 2020 is quantified under four different framework sce- Table 2 summarizes the differences between the implementa-

narios (Eichhammer et al. 2011). The underlying model covers tion options.

all relevant cross-cutting technologies and contains also more The first two options are based on industry-specific targets

than 250 process-specific energy saving options for energy- for reducing energy intensity. These options apply a top down

intensive industries. See generally Schlomann et al. (2011), approach: an energy efficiency indicator is applied to measure

Fleiter (2011). The model differentiates the handling of barri- target achievement. This indicator reflects the energy con-

ers and the pace of technology diffusion. sumption of an industry sector or a company against its physi-

First, a market potential is calculated assuming that both, cal production, its output value or its value added. The design

monetary and non-monetary barriers, exist such as the lack of the first implementation option requires that the energy ef-

of information or certain legal provisions, which inhibit the ficiency target is achieved in average on industry sector level. If

implementation of energy savings. Under such scenario only a the achievement of sufficient energy savings can be proved by

part of the potential energy savings will be realized. an industry sector, all companies of that sector are rewarded

Second, the economic potential is estimated based on the e.g. via tax exemptions or other financial incentives. In con-

assumption that industrial actors behave like a “homo eco- trast, the second implementation option privileges only those

nomicus”. Under this scenario non-economic barriers are companies that meet the formulated energy efficiency target

irrelevant and all economic energy saving measures will be on company level.

implemented. The third implementation option is also based on an indus-

Third, the nearly economic potential is calculated under the try-specific energy efficiency target. It is similar to the second

assumption that for each investment the most energy efficient proposal regarding the target compliance at company level.

option is chosen, even if it is not yet economic. However, real- However, instead of applying an energy efficiency indicator for

istic technology diffusion rates are reflected in this scenario. monitoring target compliance, the energy savings achieved by

Furthermore, the typical operating life time of a technology or individual investments must sum up to the energy efficiency

facility is considered; an early replacement (premature capital target (bottom up approach). Those companies, which achieved

retirement) is excluded. sufficient energy savings by installing technical measures, are

Fourth, a technical potential is reported assuming an acceler- rewarded. Technical measures are cross-cutting or process spe-

ated diffusion of existing technologies. Energy efficient meas- cific technologies. This definition excludes opportunities from

ures are implemented earlier than under the other scenarios. process optimisation and potential efficiency backlogs, which

The technical potential could be even larger if all technically describe the untapped economic potential savings that can be

available energy saving options would be implemented imme- achieved by organizational measures and behavioural changes

diately, for example, if all engines would be substituted by the without (significant) investment. It is necessary to define a ref-

currently best available technology, regardless of organizational erence value for determining the additional energy savings, for

or financial frameworks. example, the specific energy consumption of an old machine or

The following table presents the estimated annual electric- a benchmark. Technical measures eligible for this implementa-

ity and fuel savings for each scenario. The figures reflect the tion option are managed on a technology list that is regularly

industry sector average. adjusted to the current market developments. The technology

lists also includes information on the average energy savings

potential of the eligible technical measures as compared to

Options for implementing energy efficiency targets standard technology.

The formulation and implementation of energy efficiency tar- For the fourth implementation option, companies must also

gets might be designed in various ways. The main questions are: conduct and prove the implementation of technical measures

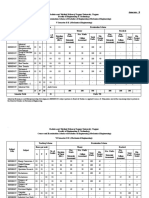

Table 1: Average annual energy saving potentials in the German industry sector between 2010–2020.

Market potential Economic potential Nearly economic Technical potential

potential

Electricity 0,52 % 1,31 % 1,53 % 1,67 %

Fossil fuels 0,48 % 0,94 % 1,04 % 1,05 %

Energy saving potentials for electricity refer to the total electricity consumption. Energy saving potentials for

fuels refer to the total fuel consumption.

ECEEE 2012 SUMMER STUDY on Energy efficiency in industry 307

3-066-12 Ro senberg et al 3. MATCHING POLICIES AND DRIVERS

Table 2: Implementation options for linking energy efficiency targets to rewards.

Option Target Target measure Compliance Reward allocation

Energy efficiency indicator All companies in the

1 Industry sectors

(Top down approach) sector

Energy efficiency indicator Individual Those companies, which

2 Industry-specific

(Top down approach) companies have achieved the target

energy efficiency

target Sum of energy savings

from installed technical Individual Those companies, which

3 measures companies have achieved the target

(Bottom up approach)

Investment in technical

Investment in eligible measures eligible against Individual Those companies which

4 energy efficiency reward scheme cap companies have pursued investment

technologies

(Bottom up approach)

to achieve energy savings on company level e.g. installation of of dealing with the variance of annual energy savings must be

a new engine. Here, the reward is directly linked to the cost considered in the design process of an implementation option,

of additional investments into implementation of technical if consistent incentives for energy efficiency improvements

measures, which are defined like in implementation option shall be provided over time. The smaller its influence on an

three. The higher the investment cost, the higher the reward implementation option is, the better can effective energy ef-

up to a certain reward scheme cap. Investment costs exceed- ficiency targets be formulated.

ing the reward scheme cap will not be “reimbursed”. Technical We observe difficulties in handling the variance of annual

measures eligible for this reward scheme are managed on a energy savings under the first and second implementation op-

technology list that is regularly adjusted to the current market tions. Both options’ performance monitoring is based on ener-

development. The technology list covers information on the gy efficiency indicators, which reflect the energy consumption

average energy savings potential and the incremental cost of of an industry sector or a company against its physical produc-

the eligible technical measures as compared to standard tech- tion, its output value or its value added. In particular, when

nology. being calculated from output value or value added the per-

All implementation options aim at setting pertinent incen- formance indicator might show a large variance due to men-

tives for energy efficiency improvement in each company. We tioned reasons such as the variance of prices. Hence, it might

assess them against three evaluation criteria. not reflect the efforts taken to improve energy efficiency. As a

consequence industry sectors or companies might not achieve

their targets in certain years, although they spent significant

Criteria 1: Ability to formulate effective energy effort, while in other years they qualify for a reward without

efficiency targets any additional work.

Incentives for energy savings can only be set by formulating Under the third and fourth implementation option energy

appropriate energy efficiency targets. Often the specific energy savings have to be achieved by installing individual technical

consumption is used as an indicator for target formulation, measures. The savings resulting from installation are calculated

for example the energy consumption of an industry sector per bottom-up. Calculated this way, the amount of annual energy

units of its output. The main challenge for applying such an in- savings shows less variance than the energy efficiency indicator

dicator to measure energy efficiency is the significant variance under the first two implementation options. Energy efficiency

of annual energy savings. It results from the discontinuity of targets formulated under the implementation options three and

investment, the variance of prices, value added with economic four can hence be more effective.

cycles, sectoral shifts, and the changes to average energy inten-

sity with capacity utilisation levels.

We conducted an analysis of the historic energy savings Criteria 2: Integration of energy efficiency targets into

achieved by 14 industry sectors and their sub-sectors in the a companies’ decision-making process

period 2000–2009. The result shows that the annual rate of en- A company will consider the implementation of an energy ef-

ergy efficiency changes at sub-sector level is a multiple of the ficiency measure, if the payback period for additional invest-

long-term average. Each industry sector experienced at least ment cost is short enough or sufficient financial incentives

one year where its specific energy consumption changed by exist (IW 2011). If the volume of financial incentives is large

more than 10 percent compared to the previous year. At com- enough, a company’s management will take the necessary or-

pany level fluctuations will even be larger. Hence, the capability ganizational steps to ensure that this benefit can be claimed.

308 ECEEE 2012 SUMMER STUDY on Energy efficiency in industry

3. MATCHING POLICIES AND DRIVERS 3-066-12 Ro senberg et al

The importance of energy efficiency targets to decision makers The first implementation option requires monitoring at in-

furthermore depends on whether the respective company or dustry sector level1. Prior experience with this exists from the

part of the company, which contributes to the target, will ben- monitoring of the voluntary agreements of German industry

efit from the reward. (RWI 2011). Under this implementation option data can be

We tested each implementation option by applying the fol- used from public statistics. This requires limited effort, but

lowing assumption: the more direct the link between financial bears the disadvantage of a time lag between target achieve-

incentives and energy efficiency improvements the more prob- ment and the compilation of public statistics for monitoring.

able the integration of energy efficiency into the decision-mak- The determination of the energy savings at company level

ing processes of companies. is based on a performance indicator under the second imple-

Since energy efficiency targets have to be met on indus- mentation option. Monitoring gets easier, if information can

try sector level under the first implementation option, the directly be provided by the accounting system of the company

strength of the incentive also depends on the accountability or by the energy management system. If necessary information

and cooperation within the sector. The qualification for a re- cannot be taken from the accounting system, the calculation

ward only partly depends on a single company’s effort. This and monitoring effort increases.

reduces the incentive on company level and might lead to The proposed design of the third and fourth implementation

free-rider behaviour. The effect is the stronger the larger the options results in more administrative complexity compared to

industry sector and the smaller the contribution of an indi- the first two options, since individual energy saving measures

vidual company to the overall energy consumption of the sec- or additional investments must be identified and evaluated.

tor. Due to competition laws, companies within an industry Verifying the installation of technical measures listed on a tech-

sector must not unify production or investment decisions or nology list is formally quite simple. An electronic organization

agree on sanction mechanisms. This might also lead to a het- of the procedure should not increase the effort to much, so that

erogeneous behaviour regarding the achievement of an energy the potentially large number of individual measures does not

efficiency target. necessarily lead to a large administrative burden. The creation

Under the second implementation option target achieve- and maintenance of such a technology list could be performed

ment is monitored on company level. For compliance intra- by an independent research organization. Alternatively, the re-

company structures which support the integration of the sponsibility might be given to an authority with relevant tech-

energy efficiency target into each investment decision are cru- nical skills.

cial. Here, the large variance of annual energy savings might

again reduce the importance of the target to the company,

since it might be achieved in some years effortless, whereas

Outcome

in others it cannot be met even with substantial investments. The main challenge in setting an energy efficiency target for

Implementation option three allows the direct link between the German industry sector is to formulate requirements so

the installation of a technical measures and its contribution to that they create sufficient incentives for improving energy ef-

target achievement. Thus, the company-wide target can serve ficiency, while being able to monitor the compliance at rea-

individual departments directly as an indicator for monitor- sonable cost, without burdening the company or the public

ing the progress achieved by the investment in energy saving management.

measures. We explored four implementation options with regards to

Under the fourth implementation option the consideration effectiveness and practicability for industry and authorities.

of energy efficiency aspects for investment decisions is strongly Two implementation options, which monitor energy efficien-

supported, since the investment costs will directly be reim- cy improvements top-down via an energy efficiency indica-

bursed up to a certain reward scheme cap. Under this design tor, prove little effective in dealing with the variance of annual

option, the integration of energy efficiency targets into a com- energy savings and in formulating effective energy efficiency

panies’ decision-making process rather depends on whether targets. The other two implementation options provide a solu-

the reward is high enough to incentivize the installation of tion to these challenges by capturing energy savings resulting

technical measures. from investments into technical measures bottom-up. There

is also a difference in performance of the implementation op-

tions with regards to enabling the integration of energy ef-

Criteria 3: Administration of timely monitoring ficiency targets into a companies’ decision-making process.

The effectiveness of an implementation option strongly depends Here, implementation options three and four provide the most

on the administration process necessary for monitoring target incentivizing solution. This high performance in criteria 1 and

compliance timely. Timely monitoring is the requirement to is- criteria 2 has a price: Implementation options three and four

sue rewards in good time, which will incentivize further invest- result in higher administrative effort, while the first imple-

ments into energy savings. (In particular, annual tax incentives mentation option ranks best here. Overall, it seems that the

require the availability of compliance data.) The demand for fourth implementation option performs best in setting per-

timely monitoring requires the fastest possible acquisition of tinent incentives for energy efficiency improvement in each

data. However, the shorter the time to collect data, the higher company (see Table 3).

the administrative burden at both – public and company side

tends to be. Therefore, we evaluate each implementation option

against the effort for data collection and reporting cycles and

1. The effectiveness and efficiency of (voluntary) industry agreements has been

the potential timeliness of monitoring. subject of a controversial debate, cf. IPCC (2007), Millock and Salanié (2001).

ECEEE 2012 SUMMER STUDY on Energy efficiency in industry 309

3-066-12 Ro senberg et al 3. MATCHING POLICIES AND DRIVERS

Table 3: Performance of implementation options according to suggested criteria.

Option Criteria 1 Criteria 2 Criteria 3

1 Low Low High

2 Low Medium Medium

3 High Medium Low

4 High High Low

The proposed options are currently discussed in the politi- Institut der deutschen Wirtschaft(IW) (2011): Energiever-

cal process. We expect that by the time of the ECEEE Summer brauch: Hemmnisse der Energieeffizienz. Umwelt-Service

Study we can report about the outcome of the discussions of the Series Nr. 3. 8. August 2011, Cologne.

German government. IPCC (2007): Contribution of Working Group III to the

Fourth Assessment Report of the Intergovernmental

Panel on Climate Change, 2007.B. Metz, O.R. Davidson,

References P.R. Bosch, R. Dave, L.A. Meyer (eds),Cambridge Univer-

AGEB (AG Energiebilanzen) (2011): Energy Balances for the sity Press, Cambridge, United Kingdom and New York,

Federal Republic of Germany 1990-2009 and Evalua- NY, USA.

tion Tables 1990-2009. DIW Berlin, EEFA, August 2011, IREES (Institute for Resource Efficiency and Energy Strate-

Cologne. gies) (2011): Untersuchung des Energiesparpotentials für

BMWI (German Federal Ministry of Economics and Technol- ein Nachfolgemodell ab dem Jahr 2013ff zu den Steuer-

ogy), BMU (German Federal Ministry for the Environ- begünstigungen für Unternehmen des Produzierenden

ment, Nature Conservation and Nuclear Safety) (2010): Gewerbes sowie der Land- und Forstwirtschaft bei der

Energy Concept for an Environmentally Sound, Reliable Energie- und Stromsteuer. October 2011, Karlsruhe.

and Affordable Energy Supply. 28. September 2010, Berlin. Millock, K. and Salanié, F. (2001): Collective Environmental

Eichhammer, W. Kohlhaas, M., Neuhoff, K. et al.: Untersuc- Agreements: An Analysis of the Problems of Free-Riding

hung des Energiesparpotentials für das Nachfolgemodell and Collusion. Nota di Lavoro 108.2000. Fondazione Eni

ab dem Jahr 2013ff zu den Steuerbegünstigungen für Enrico Mattei (FEEM). 2001.

Unternehmen des Produzierenden Gewerbes sowie der Prognos (2011): Untersuchung einer Nachfolgeregelung zur

Land- und Forstwirtschaft bei der Energie- und Strom- Energie- und Stromsteuer. October 2011, Berlin.

steuer. Research Project fe 5/11 on behalf of the German RWI (Rheinisch-Westfälisches Institut für Wirtschaftsfor-

Federal Ministry of Finance. Final Report. DIW Berlin, schung) (2011): Die Klimavorsorgeverpflichtung der

CPI Berlin, Fraunhofer ISI, November 2011, Karlsruhe, deutschen Wirtschaft – Monitoringbericht. September

Berlin. 2011, Essen.

Graichen, V. et al. (2011): Energieeffizienz in Zahlen. Final Schlomann, B. et al. (2011): Möglichkeiten, Potenziale,

Report on behalf of the German Federal Environmental Hemmnisse und Instrumente zur Senkung des Energie-

Agency. Climate Change Series 13/2011. Berlin, Karl- verbrauchs und der CO2-Emissionen von industriellen

sruhe. Branchentechnologien durch Prozessoptimierung und

Fleiter, T. et al. (2011): Where are the promising energy- Einführung neuer Verfahrenstechniken. Research and

efficient technologies? A comprehensive analysis of the Development Project FKZ 3709 46 130 on behalf of the

German energy-intensive industries: eceee summer study German Federal Environmental Agency. February 2011,

2011, June 6-11, Presquíle de Giens. Karlsruhe, Berlin.

310 ECEEE 2012 SUMMER STUDY on Energy efficiency in industry

You might also like

- Live Sound 101: Choosing Speakers and Setting Up a Sound SystemDocument14 pagesLive Sound 101: Choosing Speakers and Setting Up a Sound Systemohundper100% (1)

- Assignment-1: Energy Efficiency and ConservationDocument10 pagesAssignment-1: Energy Efficiency and ConservationSudha VermaNo ratings yet

- Effective Implementation of an ISO 50001 Energy Management System (EnMS)From EverandEffective Implementation of an ISO 50001 Energy Management System (EnMS)Rating: 4 out of 5 stars4/5 (1)

- Analysis of Energy Efficiency Aspects in Energy Man-Agement Model of Bunse in Manufacture Case StudyDocument6 pagesAnalysis of Energy Efficiency Aspects in Energy Man-Agement Model of Bunse in Manufacture Case StudyesatjournalsNo ratings yet

- Energy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamFrom EverandEnergy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamNo ratings yet

- Energy Audits in Industrial ProcessesDocument17 pagesEnergy Audits in Industrial Processessandro100% (1)

- Ch06 Allocating Resources To The ProjectDocument55 pagesCh06 Allocating Resources To The ProjectJosh ChamaNo ratings yet

- UOP Energy Management Solutions PaperDocument5 pagesUOP Energy Management Solutions PaperDeni Yudha PermanaNo ratings yet

- Energy Audit ReportDocument15 pagesEnergy Audit ReportParul ParmarNo ratings yet

- OCP - SQL&PL - SQL (Vol1)Document322 pagesOCP - SQL&PL - SQL (Vol1)api-3814149100% (1)

- Energy Management SlidesDocument37 pagesEnergy Management SlidesAaqib Ashraf100% (1)

- Issue Brief 50001 Reasons To Improve Energy PerformanceDocument26 pagesIssue Brief 50001 Reasons To Improve Energy Performancedalila AMMARNo ratings yet

- Employee WellbeingDocument6 pagesEmployee WellbeingKushal BajracharyaNo ratings yet

- Energy ManagementDocument10 pagesEnergy ManagementPratik RanjanNo ratings yet

- Designing A Metering System For Small Medium Size BuildingsDocument52 pagesDesigning A Metering System For Small Medium Size Buildingsjorge_carreraNo ratings yet

- Energy Policy: Katharina Wohlfarth, Ernst Worrell, Wolfgang EichhammerDocument11 pagesEnergy Policy: Katharina Wohlfarth, Ernst Worrell, Wolfgang EichhammerBabuNo ratings yet

- Oikonomou Et Al. (2009) - Energy Saving and Energy Efficiency Concepts For Policy MakingDocument10 pagesOikonomou Et Al. (2009) - Energy Saving and Energy Efficiency Concepts For Policy MakingRoz KrakraNo ratings yet

- Methodology in Energy ManagementDocument9 pagesMethodology in Energy ManagementJeromy CapsaNo ratings yet

- Introduction To en 16001Document7 pagesIntroduction To en 16001IndrajeetdNo ratings yet

- 3 079 16 - TherkelsenDocument11 pages3 079 16 - Therkelsenmohanad.taimourNo ratings yet

- 10 FactsDocument10 pages10 FactsAnis MsekniNo ratings yet

- Energy analysis of a UK textile mill using real-time energy dataDocument9 pagesEnergy analysis of a UK textile mill using real-time energy dataMilind KshirsagarNo ratings yet

- Ch7. Energy Conservation - Fire SafetyDocument15 pagesCh7. Energy Conservation - Fire Safetysks.in109No ratings yet

- Proven Strategies: For Saving Energy and Reducing Costs in A Retail EnvironmentDocument16 pagesProven Strategies: For Saving Energy and Reducing Costs in A Retail EnvironmentSachin PatelNo ratings yet

- Rebound EffectDocument38 pagesRebound EffectMemoonaNo ratings yet

- Guideline Kpis For Energy Consumption EffectsDocument9 pagesGuideline Kpis For Energy Consumption EffectsHamidNo ratings yet

- Guideline Kpis For Energy Consumption EffectsDocument9 pagesGuideline Kpis For Energy Consumption EffectsHamidNo ratings yet

- My Paper 11-11-22Document13 pagesMy Paper 11-11-22rameez hasanNo ratings yet

- Carpeta Del Reciclaje - Ficha - PEBDDocument6 pagesCarpeta Del Reciclaje - Ficha - PEBDAlejandro DiazNo ratings yet

- USAID-EECDP OppsForEEDocument21 pagesUSAID-EECDP OppsForEEPawan Kumar TiwariNo ratings yet

- 2-080-14 Agha PR publishedonECEEEwebsiteDocument10 pages2-080-14 Agha PR publishedonECEEEwebsiteirc.indusNo ratings yet

- Dimensions of Energy ManagementDocument7 pagesDimensions of Energy ManagementjayantabhbasuNo ratings yet

- Energy Management Solutions For Manufacturing Industry PDFDocument7 pagesEnergy Management Solutions For Manufacturing Industry PDFco2bin100% (1)

- Appliance Energy Policy Tools 2012Document27 pagesAppliance Energy Policy Tools 2012Desiyantri Siti PinundiNo ratings yet

- Optimal Selection of Energy EffiOptimal - Selection - of - Energy - Efficiency - M.pdfciency MDocument33 pagesOptimal Selection of Energy EffiOptimal - Selection - of - Energy - Efficiency - M.pdfciency Mjaviera arias valdiviaNo ratings yet

- Data Mining Approach Develops EMS for Naphtha Reforming PlantDocument9 pagesData Mining Approach Develops EMS for Naphtha Reforming PlantArash AbbasiNo ratings yet

- Energy Management EnMS GuideDocument33 pagesEnergy Management EnMS GuideStephen VivekNo ratings yet

- IEMTCModule1 Final PDFDocument7 pagesIEMTCModule1 Final PDFArih FadiNo ratings yet

- Draft Energy Audit Event 11-12-2018Document12 pagesDraft Energy Audit Event 11-12-2018Sachin RaiNo ratings yet

- IEC - IEC Work For Energy Efficiency - A4 - en - LRDocument32 pagesIEC - IEC Work For Energy Efficiency - A4 - en - LRdemetrio lopezNo ratings yet

- A Maturity Model For Energy ManagementDocument10 pagesA Maturity Model For Energy ManagementDragomir VasicNo ratings yet

- Paper ColoumnDocument5 pagesPaper ColoumnFaizan ImtiyazNo ratings yet

- Literature ReviewDocument7 pagesLiterature ReviewKIBIWOT jobNo ratings yet

- 1 s2.0 S187661021733847X Main PDFDocument7 pages1 s2.0 S187661021733847X Main PDFCristina DeluNo ratings yet

- Targets for Planning Energy ConservationDocument6 pagesTargets for Planning Energy ConservationAngelo FerrerNo ratings yet

- Dzobo Et Al. - 2018 - Energy Audit A Case Study To Reduce Lighting Cost For An Industrial SiteDocument4 pagesDzobo Et Al. - 2018 - Energy Audit A Case Study To Reduce Lighting Cost For An Industrial SiteChaoune MedNo ratings yet

- Energy Management Plan: PrefaceDocument22 pagesEnergy Management Plan: PrefaceMark Angelo UyNo ratings yet

- Chapter 1: Introduction: 1.1 Overview of The ProjectDocument4 pagesChapter 1: Introduction: 1.1 Overview of The ProjectLaksh RameshNo ratings yet

- Energy Management & Audit 2Document40 pagesEnergy Management & Audit 2Avinaba BanerjeeNo ratings yet

- Sciencedirect: An Approach For Reducing Energy Consumption in Factories by Providing Suitable Energy Efficiency MeasuresDocument6 pagesSciencedirect: An Approach For Reducing Energy Consumption in Factories by Providing Suitable Energy Efficiency MeasureskingNo ratings yet

- PNNL 25985Document252 pagesPNNL 25985Allan GomezNo ratings yet

- Journal - Critical Peak Pricing of ElectricityDocument16 pagesJournal - Critical Peak Pricing of ElectricitySirajudin HamdyNo ratings yet

- Heat IntegrationDocument68 pagesHeat IntegrationeduardaNo ratings yet

- Energy Audit and ManagementDocument5 pagesEnergy Audit and ManagementAnees Hussain100% (1)

- KPIs Energy EfficiencyDocument6 pagesKPIs Energy Efficiency3238NDNo ratings yet

- Energies: Analysis of The Brazilian Energy Efficiency Program For Electricity Distribution SystemsDocument19 pagesEnergies: Analysis of The Brazilian Energy Efficiency Program For Electricity Distribution SystemsAna Elisa Rodrigues do CoutoNo ratings yet

- Industrial Energy Audit Method and StepsDocument6 pagesIndustrial Energy Audit Method and StepsAlemat TesfayNo ratings yet

- Energy Demand Management: Associate Professor Dr. Md. HasanuzzamanDocument30 pagesEnergy Demand Management: Associate Professor Dr. Md. HasanuzzamanATHAYANo ratings yet

- Chapter 1-Energy Management: January 2015Document26 pagesChapter 1-Energy Management: January 2015Malagouda PatilNo ratings yet

- Part 4 Open Energy ManagementDocument44 pagesPart 4 Open Energy ManagementTri Akhmad FirdausNo ratings yet

- Energy in Our UniverseDocument10 pagesEnergy in Our UniversenepalsurajdahalNo ratings yet

- Energy AuditDocument7 pagesEnergy AuditSagar ThakerNo ratings yet

- EIB Working Papers 2019/02 - How energy audits promote SMEs' energy efficiency investmentFrom EverandEIB Working Papers 2019/02 - How energy audits promote SMEs' energy efficiency investmentNo ratings yet

- Comparative Study on Policies for Products’ Energy Efficiency in EU and China: Joint Statement Report Series, #6From EverandComparative Study on Policies for Products’ Energy Efficiency in EU and China: Joint Statement Report Series, #6No ratings yet

- Database Design and NormalizationDocument9 pagesDatabase Design and NormalizationKushal BajracharyaNo ratings yet

- Assessment II - Desktop ManagementDocument25 pagesAssessment II - Desktop ManagementKushal BajracharyaNo ratings yet

- Assessment Task 2 1Document9 pagesAssessment Task 2 1Kushal BajracharyaNo ratings yet

- Mid DeliveryDocument19 pagesMid DeliveryKushal BajracharyaNo ratings yet

- Database Scenario For Assessment Task 2 PortfolioDocument1 pageDatabase Scenario For Assessment Task 2 PortfolioKushal BajracharyaNo ratings yet

- Identifying NounDocument2 pagesIdentifying NounKushal BajracharyaNo ratings yet

- Data StorageDocument1 pageData StorageKushal BajracharyaNo ratings yet

- John'sDocument6 pagesJohn'sKushal BajracharyaNo ratings yet

- AnalysisDocument13 pagesAnalysisKushal BajracharyaNo ratings yet

- Landing Page: A. StructureDocument9 pagesLanding Page: A. StructureKushal BajracharyaNo ratings yet

- Wearable medical technologies have significant health impactDocument5 pagesWearable medical technologies have significant health impactKushal BajracharyaNo ratings yet

- Online Diagnostic Lab Review SystemDocument6 pagesOnline Diagnostic Lab Review SystemKushal BajracharyaNo ratings yet

- Decision Support SystemDocument5 pagesDecision Support SystemKushal BajracharyaNo ratings yet

- Cyber SecurityDocument9 pagesCyber SecurityKushal BajracharyaNo ratings yet

- DescriptionDocument1 pageDescriptionKushal BajracharyaNo ratings yet

- Alpha Car RentalDocument4 pagesAlpha Car RentalKushal BajracharyaNo ratings yet

- Investment ManagementDocument1 pageInvestment ManagementKushal BajracharyaNo ratings yet

- Amazing CookDocument18 pagesAmazing CookKushal BajracharyaNo ratings yet

- Tea Export From NepalDocument1 pageTea Export From NepalKushal BajracharyaNo ratings yet

- Java CodeDocument3 pagesJava CodeKushal BajracharyaNo ratings yet

- SunglowDocument7 pagesSunglowKushal BajracharyaNo ratings yet

- London Stock ExchangeDocument1 pageLondon Stock ExchangeKushal BajracharyaNo ratings yet

- Stock ExchangeDocument1 pageStock ExchangeKushal BajracharyaNo ratings yet

- Wealth ManagementDocument1 pageWealth ManagementKushal BajracharyaNo ratings yet

- WealthDocument1 pageWealthKushal BajracharyaNo ratings yet

- Stock TraderDocument1 pageStock TraderKushal BajracharyaNo ratings yet

- Tangible PropertyDocument1 pageTangible PropertyKushal BajracharyaNo ratings yet

- What Is The Best Way To Create An Ecommerce Website?Document15 pagesWhat Is The Best Way To Create An Ecommerce Website?Kushal BajracharyaNo ratings yet

- Financial AssetDocument1 pageFinancial AssetKushal BajracharyaNo ratings yet

- Psychrometrics Drying Problems SEODocument5 pagesPsychrometrics Drying Problems SEOStephanie Torrecampo Delima100% (2)

- Wagner Spring 2014 CS 161 Computer Security Midterm 1: (Last) (First)Document7 pagesWagner Spring 2014 CS 161 Computer Security Midterm 1: (Last) (First)Ahsan RamzanNo ratings yet

- ExcelDocument1 pageExcelJosh KempNo ratings yet

- Republic of The Philippines, Petitioner, vs. Sandiganbayan, Major General Josephus Q. Ramas and Elizabeth Dimaano, RespondentsDocument23 pagesRepublic of The Philippines, Petitioner, vs. Sandiganbayan, Major General Josephus Q. Ramas and Elizabeth Dimaano, RespondentsKenzo RodisNo ratings yet

- KEB GM 2014 3 - enDocument109 pagesKEB GM 2014 3 - envankarpNo ratings yet

- Llave de Impacto PDFDocument21 pagesLlave de Impacto PDFmasterfiera1No ratings yet

- Baja2018 Unisa Team3 Design ReportDocument23 pagesBaja2018 Unisa Team3 Design ReportDaniel MabengoNo ratings yet

- Pengembangan Lembar Kegiatan Siswa Berbasis Online Berbantuan Geogebra Book Untuk Siswa SMA Kelas X Pada Materi TrigonometriDocument15 pagesPengembangan Lembar Kegiatan Siswa Berbasis Online Berbantuan Geogebra Book Untuk Siswa SMA Kelas X Pada Materi TrigonometriNovita Rizki YustianiNo ratings yet

- Analysis Report PDFDocument4 pagesAnalysis Report PDFJever BorjaNo ratings yet

- Andrija Kacic Miosic - Razgovor Ugodni Naroda Slovinskoga (1862)Document472 pagesAndrija Kacic Miosic - Razgovor Ugodni Naroda Slovinskoga (1862)paravelloNo ratings yet

- AfghanistanLML OnlinDocument117 pagesAfghanistanLML Onlinعارف حسینNo ratings yet

- PH of Fatty Quaternary Ammonium Chlorides: Standard Test Method ForDocument2 pagesPH of Fatty Quaternary Ammonium Chlorides: Standard Test Method ForAl7amdlellahNo ratings yet

- Juno Gi BrochureDocument2 pagesJuno Gi BrochureJerry VagilidadNo ratings yet

- Mechanical Engineering Semester SchemeDocument35 pagesMechanical Engineering Semester Schemesantvan jagtapNo ratings yet

- Sensory Marketing: How Toothpaste Brands Appeal to the SensesDocument17 pagesSensory Marketing: How Toothpaste Brands Appeal to the SensesNavodi RathnasingheNo ratings yet

- Minhaj University Lahore: Paper: ICT BSCS Smester-1 Section C Instructor: Kainat Ilyas Exam: Mid-Term Total Marks: 25Document4 pagesMinhaj University Lahore: Paper: ICT BSCS Smester-1 Section C Instructor: Kainat Ilyas Exam: Mid-Term Total Marks: 25Ahmed AliNo ratings yet

- Absorbance at 405Nm: United States PatentDocument20 pagesAbsorbance at 405Nm: United States Patentfelipe_fismed4429No ratings yet

- Meritor 210 220 230 240 2SpeedSingleAxlesDocument27 pagesMeritor 210 220 230 240 2SpeedSingleAxlesYhojan DiazNo ratings yet

- Handbook of Research On Emerging Pedagogies For The Future of Education, Trauma-Informed, Care, and Pandemic Pedagogy Aras BozkurtDocument535 pagesHandbook of Research On Emerging Pedagogies For The Future of Education, Trauma-Informed, Care, and Pandemic Pedagogy Aras BozkurtBrenda MoysénNo ratings yet

- Veritas d1.6.1 FinalDocument28 pagesVeritas d1.6.1 FinalgkoutNo ratings yet

- Java Programming: Lab Assignment 2Document17 pagesJava Programming: Lab Assignment 2Sanjana chowdary50% (4)

- Group Assignment For Quantitative: Analysis For Decisions MakingDocument45 pagesGroup Assignment For Quantitative: Analysis For Decisions Makingsemetegna she zemen 8ተኛው ሺ zemen ዘመንNo ratings yet

- Editable Classroom Officers TemplateDocument6 pagesEditable Classroom Officers TemplateRachelle AbalosNo ratings yet

- PACiS GTW EN O C80Document170 pagesPACiS GTW EN O C80paradiseparasNo ratings yet

- SMAI Assignment 7 Report - 20161204 PDFDocument6 pagesSMAI Assignment 7 Report - 20161204 PDFAliNo ratings yet

- Pilkington Profilit Techn Info enDocument12 pagesPilkington Profilit Techn Info enSalmonelo Abdul RamosNo ratings yet

- Unified Glare Rating As A Measure of Visual ComfortDocument4 pagesUnified Glare Rating As A Measure of Visual ComforthoangacNo ratings yet