Professional Documents

Culture Documents

Sistema de Admision - Mbe900-05a

Uploaded by

Fernando NunezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sistema de Admision - Mbe900-05a

Uploaded by

Fernando NunezCopyright:

Available Formats

MBE 900 SERVICE MANUAL

7.1 EXHAUST MANIFOLD

The following procedures describe the removal and installation of the exhaust manifold.

7.1.1 Exhaust Manifold Removal

Remove exhaust manifold as follows:

1. Disconnect the air cleaner pipe from the turbocharger.

All information subject to change without notice. (Rev. 2005)

6SE414 0404 Copyright © 2005 DETROIT DIESEL CORPORATION From Bulletin 6-MBE900-05 7-3

7.1 EXHAUST MANIFOLD

2. Remove the turbo compressor outlet pipe from the turbocharger and the charge air

cooler. On 6-cylinder engines, remove the mounting bracket for the charge air pipe.

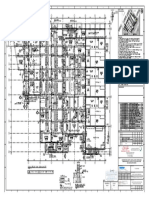

See Figure 7-1.

NOTE:

The 4-cylinder engine is shown; the 6-cylinder engine is similar.

1. Gasket 6. Turbocharger Heat Shield

2. Oil Supply Line 7. Oil Return Hose

3. Exhaust Manifold 8. Exhaust Brake Cylinder

4. Turbo Compressor Outlet Pipe 9. Exhaust Brake Air Line

5. Exhaust Manifold Bolt 10. Exhaust Pipe

Figure 7-1 Exhaust Manifold Removal

3. Remove the turbocharger oil supply and return lines.

(Rev. 2005) All information subject to change without notice.

7-4 From Bulletin 6-MBE900-05 6SE414 0404 Copyright © 2005 DETROIT DIESEL CORPORATION

MBE 900 SERVICE MANUAL

[a] Remove the turbocharger oil supply line from the turbocharger and the oil filter.

[b] Remove the oil return line from the cylinder block and the turbocharger. Collect

any oil that runs out.

[c] Plug all holes with a clean shop towel (turbocharger, oil filter, and cylinder block).

4. Disconnect the air line from the exhaust brake cylinder. Remove the exhaust pipe from

the exhaust brake valve housing.

5. Using the exhaust manifold socket set (J-46379), remove the exhaust manifold and

turbocharger, as an assembly, from the engine. See Figure 7-2.

Figure 7-2 Exhaust Manifold Socket Set (J-46379)

NOTE:

In most cases, the long socket can be used. Use the shorter socket when necessary

to gain access.

6. Remove and discard the gaskets.

7. Remove the turbocharger from the exhaust manifold and discard nuts. Cap any holes in

the turbocharger to prevent dust or dirt from entering.

8. Measure the shank length of the exhaust manifold bolts. If they exceed 47.5 mm (1.87

in.), replace the bolts.

7.1.2 Exhaust Manifold Installation

Install the exhaust manifold as follows:

All information subject to change without notice. (Rev. 2005)

6SE414 0404 Copyright © 2005 DETROIT DIESEL CORPORATION From Bulletin 6-MBE900-05 7-5

7.1 EXHAUST MANIFOLD

1. Using new nuts, install the turbocharger on the exhaust manifold using the torque values

listed in Table 7-1.

Description Part Torque Values

Turbocharger to Exhaust 4-Cylinder Engines 30 N·m (22 lb·ft)

Manifold Nuts 6-Cylinder Engines 50 N·m (37 lb·ft)

M6 Bolt 10 N·m (7 lb·ft)

Turbocharger Oil Supply Line

M8 Bolt 40 N·m (30 lb·ft)

Table 7-1 Turbocharger Torque Values

2. Position the new gaskets on the engine exhaust ports.

NOTE:

MBE 900 engines require that the joining strip on the exhaust manifold gaskets be

installed toward the bottom of the exhaust manifold due to interference with engine

brackets.

3. Install the exhaust manifold and turbocharger assembly on the engine. Using the exhaust

manifold socket set (J-46379), tighten the bolts in three stages as listed in Table 7-2.

Size Tightening Stage Torque Value

Stage 1 10 N·m (7 lb·ft)

M10 Stage 2 55 N·m (41 lb·ft)

Stage 3 additional 90 degrees

Table 7-2 Tightening Stages for Exhaust Manifold Bolts

NOTE:

Clean the sealing surfaces of the exhaust pipe before installing.

4. Connect the air line at the exhaust brake cylinder. Install the exhaust pipe at the exhaust

brake valve housing.

5. Install the turbocharger oil supply and return lines. The torque values are

listed in Table 7-1.

[a] Fill the turbocharger housing with oil at the opening for the oil supply line.

NOTE:

Do not attempt to add oil at the air intake opening.

[b] Turn the turbocharger wheel several times to coat the bearings with oil.

[c] Install the turbocharger oil supply line at the turbocharger and the oil filter.

[d] Install the oil return line at the turbocharger and the cylinder block.

(Rev. 2005) All information subject to change without notice.

7-6 From Bulletin 6-MBE900-05 6SE414 0404 Copyright © 2005 DETROIT DIESEL CORPORATION

MBE 900 SERVICE MANUAL

6. Install the turbo compressor outlet pipe at the turbocharger and the charge air cooler. On

6-cylinder engines, install the turbo compressor outlet pipe bracket.

7. Connect the air cleaner pipe at the turbocharger and the air cleaner.

PERSONAL INJURY

To avoid injury before starting and running the engine,

ensure the vehicle is parked on a level surface, parking

brake is set, and the wheels are blocked.

PERSONAL INJURY

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

Always start and operate an engine in a well ventilated

area.

If operating an engine in an enclosed area, vent the

exhaust to the outside.

Do not modify or tamper with the exhaust system or

emission control system.

8. Start the engine and make sure there is oil pressure. Shut down the engine and check

for leaks.

All information subject to change without notice. (Rev. 2005)

6SE414 0404 Copyright © 2005 DETROIT DIESEL CORPORATION From Bulletin 6-MBE900-05 7-7

7.2 EXHAUST BRAKE ASSEMBLY

7.2 EXHAUST BRAKE ASSEMBLY

To increase braking performance, the engine can be equipped with an exhaust brake on the

turbocharger in conjunction with constant-throttle valves on the cylinder head. The exhaust

back-pressure is used by the exhaust brake to increase braking performance.

7.2.1 Exhaust Brake Assembly Removal

Remove the exhaust brake assembly as follows:

1. Remove the four hex head bolts that fasten the heat shield to the exhaust brake valve

housing and turbocharger. Remove the heat shield. See Figure 7-3 for the 4-cylinder

engine and Figure 7-4 for the 6-cylinder engine.

1. Exhaust Brake Valve Housing 4. Exhaust Brake Cylinder

2. Turbocharger 5. Exhaust Brake Air Line

3. Heat Shield 6. Exhaust Pipe

Figure 7-3 Exhaust Brake Assembly Removal, 4-Cylinder Engines

(Rev. 2005) All information subject to change without notice.

7-8 From Bulletin 6-MBE900-05 6SE414 0404 Copyright © 2005 DETROIT DIESEL CORPORATION

You might also like

- Specifications For Concrete Construction ACI 301-20: Field Reference ManualDocument6 pagesSpecifications For Concrete Construction ACI 301-20: Field Reference ManualIRFAN NAZIR50% (2)

- Detroit s60 Valve AdjustmentDocument12 pagesDetroit s60 Valve AdjustmentÑengo Flow Full Record50% (2)

- Eng 99C6778 PDFDocument551 pagesEng 99C6778 PDFFroylan Ochoa93% (14)

- Detroit s60 Valve Adjustment PDFDocument12 pagesDetroit s60 Valve Adjustment PDFDiego Monroy50% (2)

- Service Manual VM D700222Document314 pagesService Manual VM D700222Yohao Cahuana Durand100% (5)

- Service and Training Manual for 99AX Reciprocating Booster AssemblyDocument34 pagesService and Training Manual for 99AX Reciprocating Booster AssemblyFernando NunezNo ratings yet

- John Deere Fuel Injection Pump Repair & Installation PDFDocument8 pagesJohn Deere Fuel Injection Pump Repair & Installation PDFscheisshandy33% (3)

- DIESEL ENGINE ISUZU 4JG2 Service ManualDocument48 pagesDIESEL ENGINE ISUZU 4JG2 Service ManualArmando Orta90% (10)

- 150 7122meredes Benz 904 Engine Service ManualDocument73 pages150 7122meredes Benz 904 Engine Service ManualIsaque Mateus75% (20)

- 3784A KXX K4J K4M Clio Motor ManualDocument32 pages3784A KXX K4J K4M Clio Motor ManualDavid NebainNo ratings yet

- U - D700-754E UK - Service-Ed - 5 - 07-2011 PDFDocument299 pagesU - D700-754E UK - Service-Ed - 5 - 07-2011 PDFAlex Varas100% (3)

- Epa07 Mbe 900 Workshop Manual (Ddc-Svc-Man-0034)Document155 pagesEpa07 Mbe 900 Workshop Manual (Ddc-Svc-Man-0034)Jose Amador Guardado100% (3)

- Kia Sorento Engine (XM) InfoDocument61 pagesKia Sorento Engine (XM) Inforeluma0% (1)

- Cylinder Head - InstallDocument6 pagesCylinder Head - InstallLeonardo PerezNo ratings yet

- 4-MBE900-04a Compresor EgrDocument36 pages4-MBE900-04a Compresor EgrGerson AquinoNo ratings yet

- Manual Del OperadorDocument146 pagesManual Del OperadorFernando NunezNo ratings yet

- Replacing The Turob Pedistal Seals 7.3 DieselDocument3 pagesReplacing The Turob Pedistal Seals 7.3 DieselSt Julian LloydNo ratings yet

- Ford Edge 2008-2009 PDFDocument462 pagesFord Edge 2008-2009 PDFEnedine RamirezNo ratings yet

- Cylinder Head Assembly: Service and RepairDocument6 pagesCylinder Head Assembly: Service and RepairJose PichinteNo ratings yet

- Yamaha DS7 (72) RD250 (73) R5C (72) RD350Document113 pagesYamaha DS7 (72) RD250 (73) R5C (72) RD350Igor Majksner100% (5)

- Manual Reparación Turbo GARRETDocument24 pagesManual Reparación Turbo GARRETFelipe Lepe MattaNo ratings yet

- Tecbrake Installation Guide For Caterpillar 3406, 3406B and 3406CDocument18 pagesTecbrake Installation Guide For Caterpillar 3406, 3406B and 3406CJunior Lester100% (2)

- Expo 2.4Document27 pagesExpo 2.4Percy RojasNo ratings yet

- Install Cylinder HeadDocument6 pagesInstall Cylinder Headrahmat sanusiNo ratings yet

- 18SP635Document8 pages18SP635giovanni ampueroNo ratings yet

- Excessive Crankcase PressureDocument8 pagesExcessive Crankcase PressureabelNo ratings yet

- Ajuste de Valvulas PDFDocument8 pagesAjuste de Valvulas PDFRoberto Rincon Robles100% (1)

- Fuel SistemDocument55 pagesFuel SistemRodolfo AlbertoNo ratings yet

- 1993 Engines Eurovan - 2.5L 5-CylinderDocument20 pages1993 Engines Eurovan - 2.5L 5-Cylinderfrancesco pavanNo ratings yet

- Install Cylinder HeadDocument5 pagesInstall Cylinder HeadbagoesNo ratings yet

- 1.6L 4cyl Diesel & Turbo DieselDocument18 pages1.6L 4cyl Diesel & Turbo DieselLeomir BrandaoNo ratings yet

- CH 8 - Lubricating Oil Pump, Oil Filter & CoolerDocument33 pagesCH 8 - Lubricating Oil Pump, Oil Filter & CoolerEnrrique LaraNo ratings yet

- Torque Converter C-300 OWI - Service ManualDocument12 pagesTorque Converter C-300 OWI - Service Manualaldino020203100% (3)

- Engine Disassembly Assembly 1Document9 pagesEngine Disassembly Assembly 1Moaed KanbarNo ratings yet

- Quick Installation Guide 01Document17 pagesQuick Installation Guide 01Harish SivakumarNo ratings yet

- Jet Kit InstallDocument2 pagesJet Kit InstallmihaisimoNo ratings yet

- Manual de Motor Elantra-Tiburón 1998 G4GRDocument6 pagesManual de Motor Elantra-Tiburón 1998 G4GRRodolfo SilvaNo ratings yet

- Compressor WabcoDocument6 pagesCompressor Wabcoruben_cruz_34No ratings yet

- Rocker Shaft and Push Rods - InstallDocument5 pagesRocker Shaft and Push Rods - InstallRajan MullappillyNo ratings yet

- WEBMTNV000 - 1fuel Pump YanmarDocument4 pagesWEBMTNV000 - 1fuel Pump YanmarAugusto Oliveira100% (1)

- PT Cruiser 2009 2.2LDocument275 pagesPT Cruiser 2009 2.2LPatrik MendozaNo ratings yet

- 3412C Fuel System Pruebas y AjustesDocument13 pages3412C Fuel System Pruebas y AjustesJuan Carlos Inga VasquezNo ratings yet

- Elecon Scoop Coupling Installation Maintenance ManualDocument21 pagesElecon Scoop Coupling Installation Maintenance ManualVignesh VenkatasubramanianNo ratings yet

- Oil Pump: Removal ProcedureDocument40 pagesOil Pump: Removal Proceduremiguelx69No ratings yet

- Flywheel 2 PDFDocument4 pagesFlywheel 2 PDFvictoverNo ratings yet

- Series 60 - Section 6.3 Intake ManifoldDocument7 pagesSeries 60 - Section 6.3 Intake ManifoldJuan RiveraNo ratings yet

- 3 MBE900 04aDocument10 pages3 MBE900 04aJorge A Salinas100% (1)

- A32 emDocument75 pagesA32 emLevin Tan HtNo ratings yet

- Engine Mechanical: Go To Table of Contents Go To Quick Reference IndexDocument75 pagesEngine Mechanical: Go To Table of Contents Go To Quick Reference IndexOmar RodriguezNo ratings yet

- DT466 Valve AdjustmentDocument15 pagesDT466 Valve Adjustmentחנניה מוסNo ratings yet

- Power Take-Off (PTO)Document28 pagesPower Take-Off (PTO)adrianram1No ratings yet

- Tecbrake Installation Guide For Caterpillar 3406, 3406B and 3406CDocument18 pagesTecbrake Installation Guide For Caterpillar 3406, 3406B and 3406Cdimitriap100% (1)

- Specifications: 2008 Ford Edge SE 2008 Ford Edge SEDocument6 pagesSpecifications: 2008 Ford Edge SE 2008 Ford Edge SECarlos VelázquezNo ratings yet

- Engine Overhaul 2.2LDocument29 pagesEngine Overhaul 2.2LalbertoNo ratings yet

- 3408 Automatic Timing Advance PDFDocument6 pages3408 Automatic Timing Advance PDFmanu luvungaNo ratings yet

- Ajuste Valvulas e Inyectores DetroitDocument6 pagesAjuste Valvulas e Inyectores DetroitGabriel Duarte100% (19)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Combustion Engines: An Introduction to Their Design, Performance, and SelectionFrom EverandCombustion Engines: An Introduction to Their Design, Performance, and SelectionNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- StopeMate Ops & Serv.Document60 pagesStopeMate Ops & Serv.Fer Nuñez100% (1)

- 5 MBE900 04aDocument36 pages5 MBE900 04aRoger Lechado Garcia100% (1)

- 3 MBE900 04aDocument10 pages3 MBE900 04aJorge A Salinas100% (1)

- 2-MBE900-04a (1) Sistema de Lubricaciode AceiteDocument30 pages2-MBE900-04a (1) Sistema de Lubricaciode AceiteGerson AquinoNo ratings yet

- ARIES Drill Parts ManualDocument202 pagesARIES Drill Parts ManualFernando Nunez100% (1)

- Catalogo Baleros Timken PDFDocument834 pagesCatalogo Baleros Timken PDFArturo TogoNo ratings yet

- SKF SealDocument460 pagesSKF SealEddie Boyz100% (1)

- BW1114QuickReferenceCatalog PDFDocument140 pagesBW1114QuickReferenceCatalog PDFAgustin ParadisoNo ratings yet

- What Is Global WarmingDocument6 pagesWhat Is Global WarmingFernando NunezNo ratings yet

- Manual EatonDocument92 pagesManual Eatonruben_cruz_34100% (1)

- El Compas Construction UpdateDocument12 pagesEl Compas Construction UpdateFernando NunezNo ratings yet

- TRSM0660 1007 PDFDocument124 pagesTRSM0660 1007 PDFmancorabechNo ratings yet

- AWS Solution Architect-Associate (AWSSA-C002) : IntroductionDocument2 pagesAWS Solution Architect-Associate (AWSSA-C002) : IntroductionIsmail SayyedNo ratings yet

- Data Sheet - Ozone Generator Water SystemDocument3 pagesData Sheet - Ozone Generator Water SystemleeNo ratings yet

- Ascendance VillivakkamDocument3 pagesAscendance Villivakkamsonaiya software solutionsNo ratings yet

- Automatic Weather StationDocument8 pagesAutomatic Weather StationMyat Tun OoNo ratings yet

- HLE A4L Grade HLE A3L Grade PDFDocument1 pageHLE A4L Grade HLE A3L Grade PDFRichardAngelCuencaPachecoNo ratings yet

- Tn9400 p25 Trunking Core NetworkDocument4 pagesTn9400 p25 Trunking Core NetworkFreddy VergaraNo ratings yet

- Question Paper 2 PDFDocument4 pagesQuestion Paper 2 PDFfotickNo ratings yet

- CH 17Document45 pagesCH 17amarmudirajNo ratings yet

- Liebert NPS-IDocument38 pagesLiebert NPS-IMahesh KumbharNo ratings yet

- Social Security System Manila registrationDocument1 pageSocial Security System Manila registrationBJ SERRANONo ratings yet

- Key Plan:: North True NorthDocument1 pageKey Plan:: North True Northraj vaddiNo ratings yet

- ServiceNow Sample Resume 3Document7 pagesServiceNow Sample Resume 3Chiranjeevi ChNo ratings yet

- Huawei LTE CountersDocument14 pagesHuawei LTE CountersRocky33% (3)

- Adec 1600Document84 pagesAdec 1600Sudiono Ajb50% (2)

- Ashish VermaDocument6 pagesAshish VermaAshish VermaNo ratings yet

- Mindray DC-40 Ultrasound BrochureDocument4 pagesMindray DC-40 Ultrasound Brochure张妍No ratings yet

- Field Trip Lesson PlanDocument3 pagesField Trip Lesson Planapi-340148167No ratings yet

- Classifications of Air Conditioning System: Based On Major FunctionDocument67 pagesClassifications of Air Conditioning System: Based On Major Functionjet latorreNo ratings yet

- Oracle® Goldengate: Tutorial For Oracle To OracleDocument19 pagesOracle® Goldengate: Tutorial For Oracle To OracleNainika KedarisettiNo ratings yet

- Acoustic Emission Sensing in Wireless Sensor NetworksDocument143 pagesAcoustic Emission Sensing in Wireless Sensor NetworksakozyNo ratings yet

- IvaraEXPIntegration OracleDocument175 pagesIvaraEXPIntegration OracleAlejandroZappaNo ratings yet

- Method Statement For Drainage Pipe SystemDocument15 pagesMethod Statement For Drainage Pipe SystemaNo ratings yet

- Empowerment Technologies Q3 M13Document16 pagesEmpowerment Technologies Q3 M13Joanne Marielle Veloria100% (1)

- Civil Engineering in Indoor SubstationDocument12 pagesCivil Engineering in Indoor SubstationfarhanNo ratings yet

- Service Bulletin: PurposeDocument3 pagesService Bulletin: PurposejussmeeeNo ratings yet

- Service Manual S6 GSM / PCN: Private Communication Systems Mobile PhonesDocument30 pagesService Manual S6 GSM / PCN: Private Communication Systems Mobile PhonesSilviu BadulescuNo ratings yet

- Understanding SelfDocument16 pagesUnderstanding SelfCharlie P Calibuso Jr.No ratings yet

- Oracle Apps Accounting Calendar SetupDocument3 pagesOracle Apps Accounting Calendar SetupRoopu PillariNo ratings yet