Professional Documents

Culture Documents

COMP/41-5: Predicting The Azeotropic of Citronellal Enrichment Using Process Simulator

Uploaded by

Dicky GabrielOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

COMP/41-5: Predicting The Azeotropic of Citronellal Enrichment Using Process Simulator

Uploaded by

Dicky GabrielCopyright:

Available Formats

International Conference On Chemical Sciences (ICCS-2007)

Innovation In Chemical Sciences For Better Life

Yogyakarta-Indonesia, 24-26 May, 2007

COMP/41-5

PREDICTING THE AZEOTROPIC OF CITRONELLAL ENRICHMENT USING

PROCESS SIMULATOR

Joddy Arya Laksmono*, Egi Agustian, Indri Badria Adilina

Process Technology and Synthesis of Essential Oil Research Group

Research Center for Chemistry – Indonesian Institute of Sciences

Kawasan PUSPIPTEK Serpong, Tangerang, Banten, Indonesia 15314

ABSTRACT

In the laboratory, we have found three main components of citronella oil, citronellal, citronellol, and geraniol.

Citronellal enrichment is generally obtained by fractionation unit. Those three components are usually obtained in

azeotropic system. In the preliminary study, we have found that citronellal in the distillate with concentration of more

than 90% was mixed with other components, mainly citronellol and geraniol. Gas chromatography was used for

analysis of citronellal component. In this study, we have predicted the azeotropic system in fractionation unit for

citronellal enrichment as an illustration using ChemCAD process simulator. The result of citronellal enrichment

simulation will be discussed in this paper.

Keywords: Citronellal enrichment, azeotropic, simulation, ChemCAD.

INTRODUCTION Fractionation distillation is separation of liquid

mixture according to main compound vapor pressure

Citronella oil is one of the most interesting essential difference. Fractionation is process series evaporation

oil, mainly it will be used in any industry of flavor and flash stages, which is arranged in series of vapor and

fragrance’s, cosmetics, pharmaceutical, food, and so on. liquid, due to reversible flow from every stage to next

Essential oil, usually has a vary components in their stage. In this condition, liquid will flow to the next

mixture. Furthermore, separation and purification of the bottom stage and vapor will go to the next stage above.

essential oil mixtures will be difficult to separate. In fractionation distillation system was completed with

Physically, many components in the essential oil have reflux unit to increase fraction quality [3].

same boiling point and chemical structured, or have a The Vapor-Liquid Equilibrium (VLE) is an

boiling point near to the other components. We used important role for design of fractionation unit. In this

original Java citronella oil (Cymbopogon winterianus paper, we are determining the VLE for separation of

Jowitt) as a raw material for separation simulation in the citronella oil to produce citronellal, citronellol, and

laboratory. The smell of oil of citronella repels blood- geraniol. Design of columns for separating azeotropic

feeding mosquitoes, ticks, and fleas. As a non-toxic systems includes the analysis of feasible separations of

substance, many people prefer citronella to other a mixture of a given composition xf,I, that is, the

chemical repellants such as DEET (N, N-diethyl-meta- determination of the feasible compositions of overhead

toluamide). Citronella oil appears in many products and bottom products. The answer to this key question

designed to protect humans, pets, and open-air spaces of rectification theory depends on three factors: the

from the public health risks posed by mosquitoes and features of the field of vapor–liquid equilibrium ratios,

ticks. A concerned person could use sprits on their the mode of separation which is liquid essential oil, and

clothing, lotion or soap on their skin, treated collars on the scheme of the column (specifically, whether the

their pets, and candles or pellet bags surrounding their column has one feed) [4,5,6].

picnic [1]. In this work, we are aim the equilibrium data for

Main component of citronella oil are citronellal, separation of citronella oil using batch vacuum

citronellol, and geraniol. The physical properties of their fractionation at low pressure, and also a dimension

components shown that, citronella has a relative higher data for the column, such as outside and inside

different boiling point toward citronellol and geraniol. diameter, height, theoretical tray number, and so on.

Kindly this component has a 20 oC different boiling The data are consisted of Txy, xy graphics. The

temperature due to citronellol dan geraniol. Furthermore, equilibrium data was assessed using ChemCAD

citronellol and geraniol has a relative nearly in their simulator. We was simulated the separation process in

boiling point, and then this both components are already two step dynamics condition using Cubic State

in mixture after separated from citronellal. The mixtures Equation.

of citronellol and geraniol could be named as rhodinol [2].

* Corresponding author. Tel: +62-21-7560929, Fax : +62-21-

7560549; Email address : joddy_arya_laksmono@yahoo.com

2 Proceeding of ICCS 2007, Yogyakarta-Indonesia, 24-25 May 2007

EXPERIMENTAL SECTION to produced three main component was used a batch

vacuum fractionator in the vacuum pressure condition

Materials 40 – 80 mbar and temperature was 120 oC – 150 oC.

Citronella oil which is original Java essential oil was We assumed that the separation has a binary system

supplied from local commercial home industry with citronellal-rhodinol. This process was determined the

concentrations of citronellal 32.15%, citronellol 12.95%, physical properties of citronellal, citronellol, and

and geraniol 20.54%. The physical properties of geraniol, and also to simulated the separation process

citronella oil have shown in the table 1. in order to appropriate data of higher purity and yield of

there three main components. Products were analyzed

Apparatus and method by GC. Then, we have an optimum condition from the

The unit operation was used a batch vacuum experiment. We used the optimum condition and

fractionation with capacity 2 L (VTU High Temperature component’s physical properties which was produced

Fractionator Model Pilodist 104 which is shown in figure from the process for simulation, and then we was

1. A simulator ChemCAD 5.0.2 version which is released simulation using ChemCAD simulator to give a

by ChemStation, Inc. Gas chromatography Shimadzu 14 predictive Vapor-Liquid Equilibrium (VLE) for citronellal-

A, column innowax, length 30 m capillary, column rhodinol binary system.

temperature 50 oC – 230 oC with heating rate 2 oC/min

and hold time at 230 oC in 30 min., injector temperature RESULT AND DISCUSSION

280 oC, FID detector temperature 280 oC, and helium as

a gas carrier with rate 4 ml/min. The calculated values were obtained from the

First step, we was determined the physical equilibrium equations:

properties of citronella oil raw material using

conventional method and GC. Separation of citronella oil ( ⎣ )

y i Φ i P = xi γ i PiS ΦSi exp ⎡⎢ν iL P − PiS / RT ⎤⎥

⎦

(1)

Where P = 80 mbar, xi and yi are the mass fractions of

Table 1. Physical properties of citronella oil as raw component i in the liquid and vapor phase,

material. respectively, γi is its activity coefficient, ν iL , its liquid

No. Parameter Results

1 Density 20oC (gr/cm3) 0.8826 molar volume, Φ i and ΦSi , its fugacity coefficients

2 Viscosity (cP) 9.01 under unsaturated and saturated conditions,

Refractive index (20oC)

S

3 1.4664 respectively for pure i and Pi , its vapor pressure at

4 Ester value 31,01 saturation [7,8,9].

5 Acid value 1,13 The simulation process separation of citronella oil

6 Optical rotation -1.275 was conducted in two steps. These were according to

7 Appearance Clearly dark yellow the numerical solution which was giving convergences

8 Solubility in alcohol 95% 1:1 clear and so on of the dynamic simulation. Figure 2 and 3 has shown

the dynamic simulation for this process. Figure 2 was

9 Fatty oil Negative

shown that mass fraction of three components;

10 Kruing oil Negative citronellal, citronellol, and geraniol are respectively

constants in step 1 during the process until 4.5 hours

1.

2.

Agitation Motor

Magnetic stirrer

process time. This was indicating that equilibrium

3. Heating mantle condition could be reached out since the temperature

4. Feed flask

5. Thermocouple in feed flask of process is constant; this condition would be giving a

6. Distillation column

7. Heating mantle constant mass fraction in the distillate during

8.

9.

Cooler

Manometer U tube indicator

equilibrium condition. Step two of simulation process

10. Thermocouple was shown that the separation has a dynamic section

11. Reflux’s unit

12. Manometer U tube and separation of citronellal, citronellol, and geraniol

13. Condensor

14. Vacuum sensor has occurred, figure 3. Citronellal component was

15.

16.

Vacuum pipe

Distillate cooler 21. Control pan separated to give a high purity and has not

17.

18.

Bottle product’s

Fraction flask

22. Trap tube

23. Controlled

contaminated with other components. However,

19. Fraction separator 24. Vacuum pu separation process of citronellol and geraniol has

occurred less than citronellal separation. Citronellol and

geraniol were giving a nearly concentration at the end

Figure 1. Pilot plant batch vacuum fractionation unit flow of process. This was caused that boiling point of both

diagram in the Research Center for Chemistry – components is nearly.

Indonesian Institute of Sciences.

Joddy Arya Laksmono, et al.

Proceeding of ICCS 2007, Yogyakarta-Indonesia, 24-25 May 2007 3

Figure 2. First step simulation processes in the batch Figure 4. T-XY diagram for citronellal-citronellol binary

vacuum fractionation unit. system at a constant vacuum pressure 80 mbar.

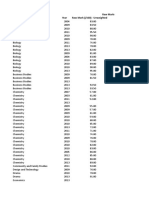

Table 2. xy data for citronellal-citronellol with K value

model: SRK.

Mass Fractions

T Deg C P mbar X1 Y1

148.53481 80.00000 0.00000 0.00000

146.65231 80.00000 0.04939 0.11889

144.85136 80.00000 0.09884 0.22398

143.12856 80.00000 0.14835 0.31707

141.48044 80.00000 0.19793 0.39970

139.90329 80.00000 0.24757 0.47320

138.39354 80.00000 0.29727 0.53875

136.94756 80.00000 0.34705 0.59735

135.56178 80.00000 0.39688 0.64986

Figure 3. Step 2 simulation processes that indicating the 134.23282 80.00000 0.44678 0.69704

dynamic process. 132.95738 80.00000 0.49675 0.73953

131.73257 80.00000 0.54678 0.77790

The separation of citronella-citronellol system has 130.55487 80.00000 0.59687 0.81262

been in the miscible system. At the molecular level 129.42181 80.00000 0.64703 0.84412

appreciable negative deviations from Raoult’s law reflect 128.33075 80.00000 0.69726 0.87277

stronger intermolecular forces between unlike than 127.27905 80.00000 0.74755 0.89888

between like pairs of molecules. Conversely, appreciable 126.26440 80.00000 0.79791 0.92273

positive deviations result for solutions in which 125.28468 80.00000 0.84833 0.94457

intermolecular forces between like molecules are 124.33779 80.00000 0.89882 0.96461

stronger than between unlike. In this latter case the 123.42182 80.00000 0.94938 0.98303

forces between like molecules may be so strong in 122.53481 80.00000 1.00000 1.00000

comparison with those between unlike molecules as to

prevent complete miscibility. In this event the mixture

Since only one degree of freedom remains, x1

would form two separated liquid phases over some may be regarded as the only independent variable in

composition range. either case. The equation for the liquid phase of a

All data processing was performed using

binary system in this experiment at constant vacuum

ChemCAD simulator 5.0.2 version. Figure 4. shown a pressure condition was seems in the below [11,12]:

Vapor-Liquid Equilibrium (T-xy) curve for binary

citronellal-citronellol system equilibrium. The equilibrium ⎛ ∆H ⎞ dT d ln γ 1 d ln γ 2

−⎜ 2 ⎟ dx

= x1 + x2 (2)

of vapor-liquid for this system was occurred in the range ⎝ RT ⎠ 1 dx1 dx1

of temperature 121 oC – 149 oC under the vacuum The temperature profile along the column height

condition. The curve gives information for scaling up was observed and simulated, figure 6. The temperature

data. range in each stage was observed relatively constant.

Vapor-Liquid Equilibrium for a binary system, the These were needed to reach a steady-state operation

phase rule specifies that there are but two degrees of of the column. This is important due to the possibly flat

freedom. Data for such system are invariably taken at temperature changes in spite of large composition

either constant pressure or at constant temperature.

Joddy Arya Laksmono, et al.

4 Proceeding of ICCS 2007, Yogyakarta-Indonesia, 24-25 May 2007

Figure 5. xy weigth fraction citronellal-citronellol system. Figure 7. Residu curve map citronellal, citronellol, and

geraniol component by SRK at constant vacuum

pressure 80 mbar.

Table 3. Batch vacuum fractionation simulation

calculation results.

Operation Step 1:

Stream Name Pot Charge Accumulator Pot Residue Distillate

Temp C 27.1525 73.3527 106.2513 73.3543

Pres mbar 80.0000 8.3332 24.6658 8.3332

Enth MJ -30.199 -23.557 -18.680 -0.51210

Vapor mole fraction 0.00000 0.00000 0.00000 0.00000

Total kmol 1.1102 0.5520 0.4928 0.0120

Total kg 171.5441 85.1462 76.3215 1.8510

Total std L m3 0.1995 0.0992 0.0886 0.0022

Flowrates in kmol

CITRONELLAL 0.8419 0.5520 0.2251 0.0120

CITRONELLOL 0.1490 0.0000 0.1487 0.0000

GERANIOL 0.1192 0.0000 0.1190 0.0000

Figure 6. Stage temperature profile in the batch vacuum

fractionation during citronellal-citronellol system Operation Step 2:

separation. Stream Name Accumulator Pot Residue Distillate

Temp C 80.8966 123.4819 101.1986

variations. Before sampling and simulation the Pres mbar 8.3332 24.6658 8.3332

temperature profile, the column top pressure and the Enth MJ -22.234 -0.083731 -0.26895

pressure drop were measured. After sampling the Vapor mole fraction 0.00000 0.00000 0.00000

Total kmol 0.4920 0.0023 0.0060

volume streams at the top of the column and below the Total kg 76.1443 0.3493 0.9317

packing were measured. Total std L m3 0.0885 0.0004 0.0011

The measured streams were compared with those Flowrates in kmol

obtained from the energy balances around the CITRONELLAL 0.2899 0.0000 0.0000

CITRONELLOL 0.1254 0.0003 0.0031

condenser and the reboiler, so that the heat and mass GERANIOL 0.0767 0.0020 0.0029

loss from the column could be calculated. The

compositions of samples were analyzed with gas CONCLUSION

chromatography.

This simulation was used 36 stages in vacuum The simulation of citronellal-citronellol-geraniol

fractionation column, and we tried to simulated was performed with ChemCAD. The essential content

citronellal-citronellol-geraniol separation behaviors. of this paper is a listing of bundles of experimental to

Binary system of citronellal-citronellol separation has found a physical properties which is useful for

shown without azeotropic curves. However, figure 7. was simulation data, and simulation this separation

shown that citronellol-geraniol binary system has phenomenon obtained with binary in non-ideal system,

indicating an azeotropic in (0.879, 0.121) coordinate at in bubble cap tray column and at vacuum pressure.

148.476 oC. Citronellal, citronellol, and geraniol have Also valuable technical information is provided for

had a bubble point at 80 mbar vacuum pressure, construction of pilot scale fractionation column. The

122.534 oC, 148.534 oC, and 150.804 oC respectively. results should be fitted with an experimental data to

Joddy Arya Laksmono, et al.

Proceeding of ICCS 2007, Yogyakarta-Indonesia, 24-25 May 2007 5

find an accurate data for vapor-liquid equilibrium system. 6. Alberto Arce, Jose´Mart´ınez-Ageitos, Eva Rodil,

Ana Soto, Phase Equilibria Involved in Extractive

ACKNOWLEDGEMENT Distillation of 2-methoxy-2-

methylpropaneqmethanol Using 1-butanol as

This research was funded from Indonesian Entrainer, Fluid Phase Equilibria, 171, 2000, 207–

government, and we should proudly thanks for this 218.

opportunity. We are pleased to Mr. Tasrif for GC data 7. F. B. Petlyuk, Simple Methods for Predicting

processing and to Mr. Yogi Hermawan with his fruitful Feasible Sharp Separations of Azeotropic

discussion. Mixtures, Theoretical Foundations of Chemical

Engineering, Vol. 32, No. 3, 1998, pp. 245–253.

REFERENCES Translated from Teoreticheskie Osnovy

Khimicheskoi Tekhnologii, Vol. 32, No. 2, 1998,

1. Egi Agustian, Asep Kadarohman, Anny Sulaswatty, pp. 279–287. Original Russian Text Copyright ©

Fractionation of Citronellal from Citronella oil Using 1998 by Petlyuk.

Vacuum Distillation Technique, Prosiding Seminar 8. Arjun Vadapalli, J.D. Seader, A Generalized

Fundamental dan Aplikasi Teknik Kimia 2004, Framework for Computing Bifurcation Diagrams

Surabaya, 7 – 8 Desember. Using Process Simulation Programs, Computers

2. Sitorus, M., Esterifikasi Rodinol dari Minyak Sereh and Chemical Engineering, 25, (2001), 445–464.

dengan Anhidrida Asam Karboksilat, Thesis S2 – 9. F. G. Smith III, R. A. Dimenna, Simulation of a

Universitas Gajah Mada, Yogyakarta, 1995. Batch Chemical Process Using Parallel

3. Haznan Abimanyu, Anny Sulaswatty, Wuryaningsih Computing with PVM and Speedup, Computers

dan Egi Agustian., Teknologi Distilasi Terfraksi and Chemical Engineering, 28, (2004), 1649–

Dalam Pemurnian Komponen Minyak Atsiri, 1659.

Prosiding Pemaparan Hasil Litbang Ilmu 10. R. Schneider, F. Sander, A. Go´rak, Dynamic

Pengetahuan Teknik 2003, Bandung. Simulation of Industrial Reactive Absorption

4. Sami Pelkonen, Andrzej Górak, André Processes, Chemical Engineering and

Ohligschläger, Ruth Kaesemann, Experimental Processing, 42, (2003), 955-964.

Study on Multicomponent Distillation in Packed 11. Perry, R.H & D. Green, 1984. Perry’s Chemical

Columns, Chemical Engineering and Processing, Engineering Handbook. Mc Graw-Hill Company,

40, (2001), 235-243. New York.

5. P. Pöllmann, M.H. Bauer, and E. Blaβ, 12. J.M. Smith, H.C. Van Ness, Introduction to

Investigation of Vapor-Liquid Equilibrium of Non- Chemical Engineering Thermodynamics, 3rd Ed.

ideal Multicomponent Systems, Gas. Sep. Purif., McGraw-Hill International book company, 290-

Vol. 10, No. 4, pp. 225-241, 1996. 364, 1975, Singapore.

Joddy Arya Laksmono, et al.

You might also like

- Predicting The Azeotropic of Citronellal Enrichment Using Process Simulator PDFDocument5 pagesPredicting The Azeotropic of Citronellal Enrichment Using Process Simulator PDFmacleod230286No ratings yet

- Kurniawan 2019 J. Phys. Conf. Ser. 1321 022038 PDFDocument6 pagesKurniawan 2019 J. Phys. Conf. Ser. 1321 022038 PDFAlpin HidayatullohNo ratings yet

- Eden 2018 IOP Conf. Ser. Mater. Sci. Eng. 349 012067 PDFDocument9 pagesEden 2018 IOP Conf. Ser. Mater. Sci. Eng. 349 012067 PDFAisyah NurmafajahNo ratings yet

- Isolation of Citral From Lemongrass Oil Using Steam Distillation Statistical Optimization by Response Surface MethodologDocument10 pagesIsolation of Citral From Lemongrass Oil Using Steam Distillation Statistical Optimization by Response Surface MethodologKinjarapu YamunaNo ratings yet

- Volatile Components of Clove Essential Oil Eugenia Caryophyllus Spreng Neutral FractionDocument8 pagesVolatile Components of Clove Essential Oil Eugenia Caryophyllus Spreng Neutral FractionTheo MartinezNo ratings yet

- Storage Stability of α-tocopherol Extracted from Heated and Un-heated Palm Oil MesocarpDocument10 pagesStorage Stability of α-tocopherol Extracted from Heated and Un-heated Palm Oil MesocarpTanwarat ChaikaewNo ratings yet

- Chemical Composition of Bergamot Citrus Bergamia Risso Essential Oil Obtained by HydrodistillationDocument4 pagesChemical Composition of Bergamot Citrus Bergamia Risso Essential Oil Obtained by HydrodistillationandreaNo ratings yet

- IOP Conf Series: Effect of Cosolvents & Surfactant in Aromatic ExtractionDocument8 pagesIOP Conf Series: Effect of Cosolvents & Surfactant in Aromatic Extractionعامر طايس سعيد عبد الجبارNo ratings yet

- MUlecular Distilation UnitDocument6 pagesMUlecular Distilation UnitElly SufriadiNo ratings yet

- Brazilian Journal of Chemical EngineeringDocument8 pagesBrazilian Journal of Chemical Engineeringcarol choquecallataNo ratings yet

- SSRN Id3874836Document10 pagesSSRN Id3874836Anirban BhowalNo ratings yet

- CitronellaDocument7 pagesCitronellaSatryo WibisonoNo ratings yet

- 10 1016@j Tca 2014 01 009 PDFDocument5 pages10 1016@j Tca 2014 01 009 PDFUsiel VidalNo ratings yet

- Extraction and Refining of Essential Oil From Australian Tea Tree, Melaleuca Alterfornia, and The Antimicrobial Activity in Cosmetic ProductsDocument8 pagesExtraction and Refining of Essential Oil From Australian Tea Tree, Melaleuca Alterfornia, and The Antimicrobial Activity in Cosmetic ProductsHiền Đăng NguyễnNo ratings yet

- Chen 2008Document8 pagesChen 2008Yunita PujiastutiNo ratings yet

- 2019 Hura CrepitansDocument8 pages2019 Hura CrepitansNONVIHO GuévaraNo ratings yet

- 1 s2.0 S0360544218322072 MainDocument9 pages1 s2.0 S0360544218322072 MaincemilNo ratings yet

- Distillation of Essential Oils From Mentha X PiperetaDocument8 pagesDistillation of Essential Oils From Mentha X PiperetageorgeNo ratings yet

- J. Chem. ThermodynamicsDocument11 pagesJ. Chem. ThermodynamicsSantiago LeãoNo ratings yet

- (Zeitschrift FR Naturforschung B) Supercritical CO2 Extraction of Essential Oil From Clove Bud Effect of Operation Conditions On The Selective Isolation of Eugenol and Eugenyl AcetateDocument5 pages(Zeitschrift FR Naturforschung B) Supercritical CO2 Extraction of Essential Oil From Clove Bud Effect of Operation Conditions On The Selective Isolation of Eugenol and Eugenyl AcetateZia Uzlifatul Fauzia Al HasanNo ratings yet

- Physicochemical Properties of Palm Stearin and Palm Mid Fraction Obtained by Dry FractionationDocument5 pagesPhysicochemical Properties of Palm Stearin and Palm Mid Fraction Obtained by Dry FractionationkirdipNo ratings yet

- Chemical Composition of Bergamot Citrus Bergamia Risso Essential Oil Obtained by HydrodistillationDocument4 pagesChemical Composition of Bergamot Citrus Bergamia Risso Essential Oil Obtained by HydrodistillationDewi KilisuciNo ratings yet

- Oxidative Stability of Perilla Oils From Roasted SeedsDocument7 pagesOxidative Stability of Perilla Oils From Roasted SeedsMai LinhNo ratings yet

- Recovered Oil From Palm-Pressed Fiber: A Good Source of Natural Carotenoids, Vitamin E, and SterolsDocument4 pagesRecovered Oil From Palm-Pressed Fiber: A Good Source of Natural Carotenoids, Vitamin E, and SterolsumegeeNo ratings yet

- Modelling The Kinetics of Steam Distillation of Essential Oils From Lemon Grass (Cymbopogon SPP.)Document9 pagesModelling The Kinetics of Steam Distillation of Essential Oils From Lemon Grass (Cymbopogon SPP.)saliomar2000No ratings yet

- Batistella2002 Article MolecularDistillationProcessFo PDFDocument11 pagesBatistella2002 Article MolecularDistillationProcessFo PDFSrđan TufegdžićNo ratings yet

- CHEM 31.1ex3 Organic ChemistryDocument8 pagesCHEM 31.1ex3 Organic ChemistryrpableoNo ratings yet

- Journal of Tropical Pharmacy and Chemistry: The Optimization of Essential Oil Extraction From Java CardamomDocument5 pagesJournal of Tropical Pharmacy and Chemistry: The Optimization of Essential Oil Extraction From Java CardamomYeremia Florensius MalauNo ratings yet

- Essential Oil Composition of Thymus Vulgaris L. and Their UsesDocument12 pagesEssential Oil Composition of Thymus Vulgaris L. and Their UsesAlejandro 20No ratings yet

- Physicochemical Properties and Vapor-Liquid Equilibrium Data For Steam-Distilled Lemon Essential OilDocument6 pagesPhysicochemical Properties and Vapor-Liquid Equilibrium Data For Steam-Distilled Lemon Essential OilJonatan SRNo ratings yet

- Extraction of Essential Oil From Neem Seed by Using Soxhlet Extraction MethodsDocument5 pagesExtraction of Essential Oil From Neem Seed by Using Soxhlet Extraction MethodsIjaems JournalNo ratings yet

- 4375-Article Text-17142-1-10-20140908Document8 pages4375-Article Text-17142-1-10-20140908nityaNo ratings yet

- Lectura 4-Study of The Fusel Oil Distillation ProcessDocument16 pagesLectura 4-Study of The Fusel Oil Distillation ProcessNatalia Moreno MorenoNo ratings yet

- Neem leaf oil extraction optimizationDocument8 pagesNeem leaf oil extraction optimizationTIVIYAH THEVAR 1017No ratings yet

- About The Extraction in Microwave Field of The Essential Oils and Beta-Carotene From CarrotsDocument4 pagesAbout The Extraction in Microwave Field of The Essential Oils and Beta-Carotene From CarrotsBINGOFIQUNAC 2020No ratings yet

- Aniline From Nitrobenzene 1Document11 pagesAniline From Nitrobenzene 1Neha MiracleNo ratings yet

- Synthesis of - Terpineol From Turpentine by Hydration in A Batch ReactionDocument6 pagesSynthesis of - Terpineol From Turpentine by Hydration in A Batch ReactionPhạm NgânNo ratings yet

- Physical Refining of Crude Palm OilDocument13 pagesPhysical Refining of Crude Palm Oilaffeena100% (1)

- The Effect of Solvent Type and Extraction Time on Essential Oil Yield from Clove BudsDocument7 pagesThe Effect of Solvent Type and Extraction Time on Essential Oil Yield from Clove BudsIka SanjiwaniNo ratings yet

- Quim. Nova, Vol. 31, No. 3, 527-529, 2008Document3 pagesQuim. Nova, Vol. 31, No. 3, 527-529, 2008Tanato TartaroNo ratings yet

- 1 s2.0 S0378381205003651 Main PDFDocument5 pages1 s2.0 S0378381205003651 Main PDFأبى جزاك الله خيراNo ratings yet

- Optimization Carotenoids Isolation of The Waste Crude Palm Oil Using - Amylase, - Amylase, and CellulaseDocument6 pagesOptimization Carotenoids Isolation of The Waste Crude Palm Oil Using - Amylase, - Amylase, and CellulaseInternational Organization of Scientific Research (IOSR)No ratings yet

- Modeling Steam Distillation of Essential OilDocument9 pagesModeling Steam Distillation of Essential OilThomas Yoga AlfanioNo ratings yet

- The Effect of Extraction Time, Solvent Ratio and Solvent Type on Clove Essential Oil Yield, Density, Refractive Index and CompositionDocument7 pagesThe Effect of Extraction Time, Solvent Ratio and Solvent Type on Clove Essential Oil Yield, Density, Refractive Index and CompositionIiestiey D'snazzyNo ratings yet

- Synthesis of Liquid Menthol by Hydrogenation of deDocument4 pagesSynthesis of Liquid Menthol by Hydrogenation of deLâm LêviNo ratings yet

- Synthesis of - Terpineol From TurpentineDocument5 pagesSynthesis of - Terpineol From TurpentineDinesh KumarNo ratings yet

- Formulation and Evaluation of Langsat Lansium Domesticum Corr Peel Ethanol Extracts Lotion As Anti Mosquito RepellentDocument10 pagesFormulation and Evaluation of Langsat Lansium Domesticum Corr Peel Ethanol Extracts Lotion As Anti Mosquito RepellentNurul Rizky VannyNo ratings yet

- Giovanni Dugo, Antonella Verzera, Ildefow D'alcontres, Antonella Cotroneo and FicarraDocument9 pagesGiovanni Dugo, Antonella Verzera, Ildefow D'alcontres, Antonella Cotroneo and FicarraРусланNo ratings yet

- Journal Ekstraksi Super Kritis PDFDocument7 pagesJournal Ekstraksi Super Kritis PDFAfifah S NNo ratings yet

- A New Process For Extraction of Essential Oil From Citrus Peels Microwave Hydrodiffusion and GravityDocument5 pagesA New Process For Extraction of Essential Oil From Citrus Peels Microwave Hydrodiffusion and Gravitymurdanetap957No ratings yet

- Jurnal Terbit Di Chemtech, Januari 2017 I Ketut Budaraga, (12 26) V10N1CTDocument15 pagesJurnal Terbit Di Chemtech, Januari 2017 I Ketut Budaraga, (12 26) V10N1CTketut2No ratings yet

- Food Chemistry: Mostafa Khajeh, Yadollah Yamini, Fatemeh Sefidkon, Naader BahramifarDocument5 pagesFood Chemistry: Mostafa Khajeh, Yadollah Yamini, Fatemeh Sefidkon, Naader BahramifarAlex AlejoNo ratings yet

- ST 11 PDFDocument8 pagesST 11 PDFAdriana StNo ratings yet

- Flavour Fragr J 1997 v12 p173Document4 pagesFlavour Fragr J 1997 v12 p173Kharisul IhsanNo ratings yet

- Jurnal Bahan Alam TerbarukanDocument8 pagesJurnal Bahan Alam TerbarukanMuhamad Zunanda AjiNo ratings yet

- Recycling of Used Lubricating Engine Oil by A Solvent Extraction ProcessDocument8 pagesRecycling of Used Lubricating Engine Oil by A Solvent Extraction ProcessTJPRC PublicationsNo ratings yet

- Essential Oils in Food Processing: Chemistry, Safety and ApplicationsFrom EverandEssential Oils in Food Processing: Chemistry, Safety and ApplicationsSeyed Mohammed Bagher HashemiNo ratings yet

- The Total Synthesis of Natural ProductsFrom EverandThe Total Synthesis of Natural ProductsJohn ApSimonNo ratings yet

- Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerFrom EverandThermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerNo ratings yet

- Proses Pemurnian Fraksi Kaya Rhodinol Minyak Sereh Wangi Menggunakan Spinning Band DistillationDocument10 pagesProses Pemurnian Fraksi Kaya Rhodinol Minyak Sereh Wangi Menggunakan Spinning Band DistillationDicky GabrielNo ratings yet

- Indones. J. Chem., 2020, 20 (4), 960 - 966: AbstractDocument7 pagesIndones. J. Chem., 2020, 20 (4), 960 - 966: AbstractDicky GabrielNo ratings yet

- ch5 Problems Solution PDFDocument4 pagesch5 Problems Solution PDFNovia Larasati100% (1)

- Kelly Services Indonesia 2019 Salary Guide PDFDocument52 pagesKelly Services Indonesia 2019 Salary Guide PDFNova Mufida100% (3)

- Vacuum and Pressure FiltrationDocument30 pagesVacuum and Pressure FiltrationDicky GabrielNo ratings yet

- Tailor Welded BlanksDocument52 pagesTailor Welded BlanksYuvaraj YuvarajNo ratings yet

- NRD Idg Gy Fiyf FofkDocument7 pagesNRD Idg Gy Fiyf FofkMERA MENTALNo ratings yet

- Technical Datasheet 0027141131 003Document4 pagesTechnical Datasheet 0027141131 003Faizal SetiawanNo ratings yet

- Commissioning FPFH SettingDocument6 pagesCommissioning FPFH SettingYulius IrawanNo ratings yet

- Concepts - Essential Elements of Theories PDFDocument5 pagesConcepts - Essential Elements of Theories PDFKarlHeinrichNo ratings yet

- Ds311 Specification Sheet EnglishDocument4 pagesDs311 Specification Sheet EnglishAntonio BocanegraNo ratings yet

- ABS Rules For Piping and FittingsDocument2 pagesABS Rules For Piping and Fittingsmaha100% (1)

- MANAGEMENT CONTROL SYSTEMS IN NON-PROFITSDocument26 pagesMANAGEMENT CONTROL SYSTEMS IN NON-PROFITSPranita NarainNo ratings yet

- Zaib Baig: EducationDocument1 pageZaib Baig: Educationapi-316869427No ratings yet

- Inside Earth's LayersDocument2 pagesInside Earth's Layersansh parasharNo ratings yet

- TX AsiaDemandForecast 2018Document12 pagesTX AsiaDemandForecast 2018Muhammad AsadNo ratings yet

- Modelling of Agglomerating Systems: From Spheres To FractalsDocument13 pagesModelling of Agglomerating Systems: From Spheres To FractalsSandra BazanNo ratings yet

- CYPE Box CulvertsDocument4 pagesCYPE Box CulvertsEng Venance MasanjaNo ratings yet

- Basic Electrical-Chapter 3 TheoryDocument13 pagesBasic Electrical-Chapter 3 TheorySankar RijalNo ratings yet

- Learning in Artificial IntelligenceDocument6 pagesLearning in Artificial IntelligenceAnikNo ratings yet

- MBenz E320 W211 CDI OM648 Specifications1Document31 pagesMBenz E320 W211 CDI OM648 Specifications1rodolfodiazNo ratings yet

- Modern Methods of TrainingDocument30 pagesModern Methods of Trainingpatridsouza8875% (4)

- Treadmill Error Code GuideDocument19 pagesTreadmill Error Code GuideŞener MutluNo ratings yet

- Vasos Amortiguadores - Sedical PDFDocument1 pageVasos Amortiguadores - Sedical PDFLuis DomdNo ratings yet

- Axiatonal Lines Connection IntroductionDocument9 pagesAxiatonal Lines Connection IntroductionDavid Lopes100% (1)

- Raw To Scaled Mark DatabaseDocument10 pagesRaw To Scaled Mark DatabaseKelly ChuNo ratings yet

- PSD SiemensDocument45 pagesPSD Siemensbrijendra2185% (13)

- 2 - Class UnpackingDocument22 pages2 - Class UnpackingPhuong Linh ToNo ratings yet

- Negasi Aregawi PpintDocument16 pagesNegasi Aregawi PpintMilkias MenaNo ratings yet

- 11 - NRG - Cathodic Protection DesignDocument15 pages11 - NRG - Cathodic Protection DesignBalan100% (1)

- 151430X PDFDocument5 pages151430X PDFIndra RosadiNo ratings yet

- Development of High Temperature Superconducting Transformers PDFDocument6 pagesDevelopment of High Temperature Superconducting Transformers PDFBen McConnellNo ratings yet

- University of Oxford, Financial Statements 2017-2018 PDFDocument120 pagesUniversity of Oxford, Financial Statements 2017-2018 PDFRano Digdayan MNo ratings yet

- Analysis of Salem PossessedDocument4 pagesAnalysis of Salem PossessedCharity BurgessNo ratings yet