Professional Documents

Culture Documents

M-25 Grenade Patent

Uploaded by

nilton cardona0 ratings0% found this document useful (0 votes)

11 views6 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views6 pagesM-25 Grenade Patent

Uploaded by

nilton cardonaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

United States Patent (19) 11 Patent Number: 4,932,328

Pinkney et al. 45) Date of Patent: Jun. 12, 1990

54 RELOADABLE STUN GRENADE Primary Examiner-Harold J. Tudor

(75) Inventors: Barry D. Pinkney; Donald L. Attorney, Agent, or Firm-Renner, Otto, Boisselle &

Sklar

Anderson, both of Jefferson, Ohio

73 Assignee: Def-Tec Corporation, Rock Creek, 57 ABSTRACT

Ohio Stun grenade includes a steel housing having a steel

(21) Appl. No.: 369,303 tubular body with steel end members brazed to the ends

of the tubular body, and a brass collar member thread

22 Filed: Jun. 21, 1989 ably received in a threaded central opening in one of the

(51) Int. Cl.......................... F42B 8/12; F42B 12/00 end members for supporting an explosive charge in the

(52) U.S.C. .................................... 102/482; 102/368; housing. At the inner end of the collar member is a

102/487; 102/498 cylindrical portion to which a tubular container filled

58) Field of Search ............... 102/334, 367, 368, 369, with the explosive charge is attached. The outer diame

102/370, 395,353,445, 473, 482, 487,498,502, ter of the tubular container is less than the minimum

A. 529; 89/1, 11; 446/397-400 diameter of the threaded opening in the one end mem

ber to permit the tubular container to be inserted

56) References Cited through the threaded opening while attached to the

U.S. PATENT DOCUMENTS collar member. At the outer end of the collar member is

1,539,609 5/1925 Taylor ................................. 102A98 a threaded recess for threaded receipt of a fuse member

3,492,945 2/1970 Filippi................................. 102/498 externally of the housing. A flash hole in the collar

3,505,959 4/1970 Lohnert et al. ..................... 102/487 member directs a flash which is produced when the fuse

3,599,571 8/1971 Richardson ......................... 102/368 member is activated into the tubular container to ignite

FOREIGN PATENT DOCUMENTS

the explosive charge.

2007339 5/1979 United Kingdom ................ 102/487 24 Claims, 1 Drawing Sheet

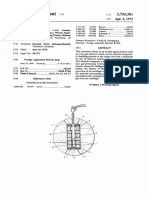

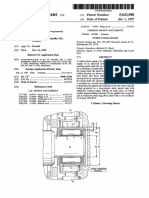

U.S. Patent Jun. 12, 1990 4,932,328

1.

4,932,328

2

directing the force of the explosion out through the

RELOADABLE STUN GRENADE ends of the housing rather than through the sides.

To the accomplishment of the foregoing and related

BACKGROUND OF THE INVENTION ends, the invention, then, comprises the features herein

This invention generally relates to a stun grenade 5 after fully described and particularly pointed out in the

intended for use by trained law enforcement personnel claims, the following description and the annexed draw

and the like during tactical entry of barricaded or other ings setting forth in detail a certain illustrative embodi

high risk suspect areas. When detonated, the grenade ment of the invention, this being indicative, however, of

produces a loud report accompanied by a brilliant flash

10

but one of the various ways in which the principles of

that disorients those persons affected. the invention may be employed.

Stun grenades of this type are generally known. BRIEF DESCRIPTION OF THE DRAWINGS

However, there is a need for a stun grenade that can

easily be reloaded for both relatively low cost tactical In the annexed drawings:

and training purposes. Also, there is a need for a stun FIG. 1 is a fragmentary longitudinal section through

grenade that substantially eliminates the possibility of 15

a preferred form of stun grenade constructed in accor

one or more parts thereof being propelled as a projectile dance with this invention;

by the force of the explosion. Furthermore, there is a FIG. 2 is an enlarged fragmentary longitudinal sec

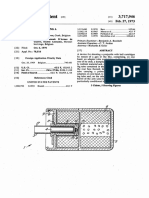

need for a stun grenade that can be thrown directly tion through the reload portion of the stun grenade of

through most windows and screens without having to FIG. 1;

break the window or cut the screen beforehand. 20

FIG. 3 is an enlarged top plan view of the stun gre

SUMMARY OF THE INVENTION made of FIG. 1 as seen from the plane of the line 3-3

With the foregoing in mind, it is a principal object of thereof with the reload portion removed; and

this invention to provide a stun grenade that can safely FIG. 4 is an enlarged bottom plan view of the stun

be reloaded and reused a number of times thus making 25 grenade of FIG. 1 as seen from the plane of the line 4-4

thereof.

it cost effective for use for both tactical and training

purposes. DETAILED DESCRIPTION OF THE

Another object is to provide such a stun grenade that PREFERRED EMBODIMENT

substantially eliminates the possibility of any part Referring now in detail to the drawings, and initially

thereof becoming a projectile by the force of the explo 30 to FIG. 1, a preferred form of stun grenade in accor

S.O.

Still another object is to provide such a stun grenade dance with this invention is generally indicated by the

that can be thrown directly through most windows and reference numeral 1 and includes a housing 2 consisting

screens without first having to break the window or cut of a tubular steel body 3 having steel end members 4, 5

the screen. 35 brazed to the ends thereof. Although the dimensions of

Still another object is to provide such a stun grenade the steel tubing 3 may vary within limits, its outer diam

that protects the explosive charge from live gunfire hits. eter should be of a size that fits comfortably within the

Yet another object is to provide such a stun grenade palm of the user's hand. Also, the strength of the tubing

that minimizes accidental injury by directing the force should be such that it will not only withstand the inter

of the explosion out through the ends of the grenade nal blast pressures when an explosive charge 6 con

rather than through the sides. tained therein is detonated, but will also protect the

These and other objects of the present invention may explosive charge against being hit by live gunfire.

be achieved by providing the stun grenade with a steel Moreover, the weight of the stun grenade should be

housing that can be reloaded with an explosive charge a such that it can readily be thrown directly through most

number of times for low cost tactical and training pur 45 windows and screens without prior breaking or cutting.

poses. To that end, a special collar member is thread To that end, the tubular body 3 is desirably made out of

ably received in a threaded central opening in one end inch drawn over mandrel (D.O.M.) welded steel tub

of the steel housing. At the inner end of the collar is a ing having an outer diameter (O.D.) of approximately

reduced diameter cylindrical end portion to which a ls inches and an inner diameter (I.D.) of approximately

cardboard tube containing the desired amount of explo 50 1 inches and an overall length of approximately 4

sive charge is attached for insertion through such inches.

threaded opening in the steel housing. At the outer end The end members 4, 5 are also desirably made out of

of the collar is a threaded recess for threaded engage a suitable steel having the desired strength to withstand

ment by a fuse member exteriorly of the housing. At the the force of the blast, such as 12L14 steel, and include

bottom of the recess is a flash hole for directing the flash 55 cylindrical end portions 9, 10 having an O.D. slightly

that is produced when the fuse is activated into the less than the I.D. of the steel tubing 3 for close sliding

cardboard tube to ignite the explosive charge. An adhe receipt in the ends thereof and flanges 11, 12 at the

sive tab that is easily burned through by the flash is opposite end extending radially outwardly beyond the

desirably placed over the flash hole in the collar to cylindrical portions 9, 10 a distance substantially corre

prevent any portion of the explosive charge from get sponding to the thickness of the tubing 3 for abutting

ting up inside the collar during storage and handling. engagement against the ends thereof with the O.D. of

The steel housing is also desirably sufficiently strong the flanges 11, 12 substantially flush with the O.D. of

to protect the explosive charge from live gunfire hits the tubing 3. Such cylindrical portions 9, 10 may, for

and allows the grenade to be thrown directly through example, have a length of approximately inch and the

most windows and screens without prior breaking of 65 flanges 11, 12 a thickness of approximately inch. Also,

the windows or cutting of the screens. Accidental in semi-annular grooves 15, 16 having a maximum width

jury is also minimized by constructing the grenade so and depth, for example, of approximately 0.070 inch,

that no parts can fly off during the explosion and by are provided in the O.D. of the cylindrical portions 9,

3

4,932,328

4.

10 intermediate the length thereof for receipt of copper readily burns through the tab 32 and ignites the explo

brazing wire 17 which, when heated in the grooves sive charge 6.

after the end members 4, 5 have been inserted into the To prevent moisture from entering the recess 27 in

ends of the tubing 3, causes the end members 4, 5 to be the collar member 21 when the fuse member 28 is

brazed to the ends of the steel tubing 3 along substan threaded into the recess, a gasket 33 may be provided at

tially the entire length of the cylindrical portions 9, 10 the inner end of the threads 34 on the fuse member 28.

and width of the flanges 11, 12 around substantially Also for safety reasons, the collar member 21 is desir

their entire peripheries to provide a secure joint there ably made out of brass to eliminate any risk of sparking

between. during assembly and disassembly of the fuse member 28,

To mount an explosive charge 6 of the desired size 10 collar member 21 and housing 2. Making the collar

within the steel housing 2, end member 4 has a threaded member 21 out of brass has the further advantage that it

central opening 20 therethrough (see FIGS. 1 and 3) for will not rust so that the collar member 21 can easily be

threaded engagement by a special collar member 21 removed from the housing 2 to permit reloading of the

which, as clearly shown in FIGS. 1 and 2, includes an housing 2 with a new explosive charge 6 and fuse men

external threaded portion 22 for threaded engagement 15 ber 28 (hereafter sometimes referred to collectively as a

in the threaded opening 20 and a non-circular head 23 at reload 35) for reuse of the housing 3 for low cost tacti

the axial outer end thereof to facilitate tightening and cal and training purposes.

loosening of the collar member 21 within the threaded To prevent the stun grenade housing 2 from being

opening 20. At the axial inner end of the collar member 20 blown apart by the force of the explosive charge when

21 is a cylindrical end portion 24 of reduced diameter to detonated, pressure reliefholes are provided in the end

provide for attachment of a cardboard tube 25 or the members 4, 5 which direct the energy out through the

like containing the explosive charge 6 to such cylindri ends of the housing 2 rather than through the sides

cal end portion 24. The O.D. of the cylindrical end formed by the steel tubing 3 which is impervious. As

portion 24 is slightly less than the minimum diameter of best seen in FIG.3, a plurality of pressure reliefholes 36

are provided in the end member 4 which contains the

the threaded opening 20 in the end member 4 so that the 25 threaded

cardboard tube 25 with explosive charge 6 contained member 5,opening 20 for the reload 35. The other end

on the other hand, desirably has a single

therein can freely be inserted into the interior of the pressure relief

housing 2 while attached to the collar member 21 and ter (see FIGS. hole 1

37 extending through the axial cen

and 4). Also, the area of the pressure

the collar member 21 screwed into the threaded open 30 relief hole 37 is desirably substantially the same as the

ing 2 to support the explosive charge 6 within the hous combined areas of all of the pressure relief holes 36 in

ing 2. In the preferred embodiment disclosed herein, the the end member 4 to substantially

threaded opening 20 has inchX 14 threads and the acting on the stun grenade 1 whenbalance the pressures

the explosive charge

cylindrical end portion 24 has an O.D. of approximately 6 is detonated so that the stun grenade 1 will not be

0.675 inch and an axial length of approximately 0.450 35 blown around by the force of the explosion.

inch for supporting a cardboard tube 25 having an O.D.

of approximately 0.750 inch and a length of approxi 36Although the number and size of pressure reliefholes

mately 3 inches which is sufficient to hold approxi holes 36 shouldmember

in the end

be

4 may vary within limits, such

sufficiently large so that they do not

mately 15 ounces of a standard mix of flash powder. At become plugged by the ash which is produced when the

the bottom of the tube 25 is a cardboard plug 26 which explosive charge 6 is ignited. However, the size of the

may be glued in place to retain the explosive charge 6 holes 36 is limited by the available wall thickness of the

within the tube. To attach the cardboard tube 25 to the end member 4 taking into account the depth of the

collar member 21, the tube 25 is slid over the collar end threaded opening 20 and brazing wire groove 15. In the

portion 24 and pushed up against the bottom of the preferred embodiment disclosed herein, six such pres

threads 22 and secured in place with a suitable adhesive. 45 sure relief holes 36 are provided in the end member 4,

Within the outer end of the collar member 21 is a each having a minimum diameter of approximately

threaded recess 27 for threaded receipt of a fuse mem 15/64 inch. If smaller diameter holes were provided,

ber 28 to support the fuse member 28 exteriorly of the some plugging of the holes 36 could result from the ash.

housing 2 when the collar member 21 is threaded into Accordingly, it is desirable to make the holes 36 as large

the housing opening 20 as shown in FIG. 1. Fuse mem 50 as the wall thickness of the end member 4 will permit,

ber 28 may be a standard military type fuse member with approximately 15/64 inch being a minimum diame

including a fuse lever 29 held in place by a removable ter.

pin 30. When the pin 30 is removed, fuse lever 29 is More than one pressure relief hole may also be pro

released, which causes a delayed flash that travels vided in the end member 5. However, providing a sin

through a flash hole 31 in the collar member 21 and 55 gle relatively large center hole 37 having a diameter, for

ignites the flash powder 6 in the tube 25. Flash hole 31 example, of approximately inch, makes it easier to

is desirably between approximately 1/16 inch and inch perform pull tests on the housing 2 by inserting a grip

in diameter, to assure ignition of the explosive charge 6 per through the relatively large center hole 37 in end

while preventing excess pressure from entering the member 5 and threading another part of the test appara

collar member 21 and possibly ejecting the fuse 28 as a 60 tus into the enlarged threaded opening 20 in the end

projectile. member 4. Moreover, mylar self-adhesive tape 38, 39 or

For safety reasons, a self-adhesive tab or tape 32 the like, which may be die cut to the desired shape, are

made, for example, of chrome mylar, is desirably ap desirably applied to the end members 4, 5 to cover the

plied to the bottom of the collar member 21 to cover the pressure relief holes 36, 37 therein as schematically

flash hole 31 so that none of the explosive charge 6 65 shown in solid lines in FIG. 1 and in phantom lines in

contained within the cardboard tube 25 gets up in the FIGS. 3 and 4 to keep out moisture and insects or the

collar recess 27. The flash that is produced by the fuse like which might otherwise interfere with the proper

member 28 when the fuse member 28 is activated functioning of the stun grenade 1.

5

4,932,328

6

The overall dimensions of the fully assembled stun 2. The stun grenade of claim 1 wherein said recess in

grenade 1 shown in FIG. 1 may of course vary within said collar member is internally threaded for threaded

certain limits. However, as previously indicated, the engagement by a threaded end portion of said fuse

stun grenade 1 should be of a size that fits comfortably member.

within the palm of the user's hand. The stun grenade 5 3. The stun grenade of claim 1 further comprising

may, for example, have an overall outer diameter of tape means on said collar member covering said flash

approximately 1.98 inches and an overall length of ap hole means to prevent any of said explosive charge from

proximately 5.95 inches. Also, the total weight of the entering said recess through said flash hole means.

stun grenade 1 is desirably approximately 25.7 ounces, 4. The stun grenade of claim 1 wherein there are a

which is sufficient to permit the stun grenade to be 10 plurality of circumferentially spaced pressure reliefhole

thrown through most windows and screens without means in said one end member.

prior breaking or cutting. 5. The stun grenade of claim 4 wherein each of said

To use the stun grenade 1, the pin 30 is removed pressure reliefhole means in said one end member has a

while continuing to hold the fuse lever 29 securely minimum diameter of approximately 15/64 inch.

against the steel housing 2 until thrown. Then, the stun 15 6. The stun grenade of claim 4 wherein there are six

grenade 1 should be thrown underhand to an area of said pressure reliefhole means in said one end mem

which is free of personnel and ignitable material. After ber.

the explosive charge 6 has gone off, the grenade 1 can 7. The stun grenade of claim 4 wherein there is a

be retrieved and reloaded a number of times simply by 20 single pressure reliefhole means in said other end mem

unscrewing the collar member 21 from the housing 2 ber which has an area substantially equal to the com

and replacing same with a new reload 35 including the bined areas of all of said pressure relief hole means in

same or different collar member 21 with cardboard tube said one end member.

25 containing a new explosive charge 6 attached to the 8. The stun grenade of claim 7 wherein said single

inner end 24 of the collar member and a new fuse mem pressure reliefhole means in said other end member has

ber 28 attached to the outer end of the collar member. 25 a diameter of approximately inch, and each of said

From the foregoing, it will now be apparent that the pressure relief hole means in said one end member has a

steel housing for the stun grenade of the present inven diameter of approximately 15/64 inch.

tion has the advantage that it can be reloaded a number 9. The stun grenade of claim 1 wherein said tubular

of times for low cost tactical and training purposes. 30 body is made of inch drawn over mandrel welded

Also, the steel housing protects the explosive charge steel tubing.

from live gunfire hits and can be thrown directly 10. The stun grenade of claim 1 wherein said end

through most windows and screens without prior members are made of 12L14 steel.

breaking or cutting. Moreover, accidental damage is 11. The stun grenade of claim 1 wherein said end

minimized by directing the energy out of the ends of the 35 members are brazed to the ends of said tubular body.

steel housing rather than through the sides. 12. The stun grenade of claim 11 wherein each of said

Although the invention has been shown and de end members includes a cylindrical end portion closely

scribed with respect to a certain preferred embodiment, slidably received in the ends of said tubular body, and a

it is obvious that equivalent alterations and modifica flange at the other end in abutting engagement with the

tions will occur to others skilled in the art upon the ends of said tubular body.

reading and understanding of the specification. The 13. The stun grenade of claim 12 wherein the outer

present invention includes all such equivalent alter diameter of each of said flanges is substantially flush

ations and modifications, and is limited only by the with the outer diameter of said tubular body.

scope of the claims. 14. The stun grenade of claim 12 further comprising

What is claimed is: 45 external groove means intermediate the ends of said

1. A reloadable stun grenade comprising a metal cylindrical portions of said end members for receipt of

housing including a metal tubular body having first and copper brazing wire in said groove means prior to inser

second metal end members secured to opposite ends of tion of said end members in the ends of said tubular

said body, a threaded opening in one of said end mem body and applying heat thereto to braze said end mem

bers, a collar member threadably engageable in said 50 bers to said tubular body.

threaded opening, said collar member having a cylindri 15. The stun grenade of claim 14 wherein said end

cal inner end portion, a tubular container filled with an members are brazed to the ends of said tubular body

explosive charge attached to said cylindrical inner end substantially throughout the length of said cylindrical

portion, said tubular container having a diameter portions and the width of said flanges which are in

slightly less than the diameter of said threaded opening 55 abutting engagement with the ends of said tubular body.

to permit said tubular container to be inserted through 16. The stun grenade of claim 1 wherein there are a

said threaded opening while attached to said collar plurality of relatively small pressure reliefhole means in

member, a recess in an outer end portion of said collar said one end member and a single larger pressure relief

member for threadably supporting a fuse member exte hole means in said other end member having an area

riorly of said housing when said collar member is substantially equal to the combined areas of all of said

threaded into said threaded opening in said one end pressure relief hole means in said one end member.

member, flash hole means in said collar member for 17. The stun grenade of claim 16 wherein said pres

directing a flash which is produced when said fuse sure relief hole means in said other end member is in

member is activated into said tubular container to ignite substantial coaxial alignment with said threaded open

said explosive charge, and pressure relief hole means in 65 ing in said one end member.

said end members for relieving the energy that is pro 18. The stun grenade of claim 1 wherein said explo

duced when said explosive charge is ignited out sive charge comprises approximately 15 ounces of flash

through the ends of said housing. powder.

7

4,932,328

8

19. The stun grenade of claim 1 wherein said collar the energy that is produced when said explosive charge

member has external threads axially outwardly of said is ignited out through the ends of said housing.

cylindrical inner end portion which, threadably, engage 22. The stun grenade of claim 21 wherein said end

said threaded opening in said one end member, and said members are brazed to the ends of said tubular body

tubular container is pushed up against the bottom of said substantially throughout the length of said cylindrical

external threads and adhesively secured to said cylindri portions and width of said flanges which are in abutting

cal inner end portion. engagement with the ends of said tubular body.

20. The stun grenade of claim 1 wherein said collar 23. The stun grenade of claim 21 wherein there are a

member is made of brass. plurality of said pressure relief hole means in said one

21. A stun grenade comprising a housing including a 10 end member and a single pressure relief hole means in

tubular steel body having first and second steel end the other end member which has an area substantially

members brazed to opposite ends of said body, means equal to the combined areas of all of said pressure relief

for reloading said housing with an explosive charge hole means in said one end member.

through one of said end members and for supporting a 24. The stun grenade of claim 23 wherein said means

fuse member externally of said housing for igniting said 15 for reloading said housing with an explosive charge and

explosive charge upon activating said fuse member, for supporting a fuse member externally of said housing

each of said end members including a cylindrical por comprises collar means threadably engageable in a

tion closely slidably received in the ends of said tubular threaded central opening through said one end member,

body, and a flange in abutting engagement with the ends said plurality of pressure relief hole means in said one

of said tubular body, external groove means intermedi 20 end member being circumferentially spaced around said

ate the ends of cylindrical portions for receipt of braz threaded central opening, and said single pressure relief

ing wire prior to insertion of said end members into the hole means in said other end member being in substan

ends of said tubular body and applying heat thereto to tially coaxial alignment with said threaded central open

braze said end members to said tubular body, and pres ing in said one end member.

sure reliefhole means in said end members for relieving 25 k k ck k

30

35

45

50

55

60

65

You might also like

- (A Oe Émgoueogmo: +2 (ll/l4fl2Document6 pages(A Oe Émgoueogmo: +2 (ll/l4fl2wewewewNo ratings yet

- Us 4299169Document3 pagesUs 4299169dfdfsdNo ratings yet

- United States Patent (19) (11 3,724,381: Assignee: Dynamit Nobel AktiengesellschaftDocument4 pagesUnited States Patent (19) (11 3,724,381: Assignee: Dynamit Nobel AktiengesellschaftSmokeNo ratings yet

- US3387560 - Rocket AmmunitionDocument3 pagesUS3387560 - Rocket AmmunitionHosiah BlackfordNo ratings yet

- United States Patent (191 (11) Patent Number: 5,259,288: Vatsvog (45) Date of Patent: Nov. 9, 1993Document13 pagesUnited States Patent (191 (11) Patent Number: 5,259,288: Vatsvog (45) Date of Patent: Nov. 9, 1993fghdfjerNo ratings yet

- Us 4711181Document5 pagesUs 4711181dfdfsdNo ratings yet

- Us 4394836Document4 pagesUs 4394836ererNo ratings yet

- EP0773421A2Document9 pagesEP0773421A2Jacob MillerNo ratings yet

- Us 5153374Document5 pagesUs 5153374ererNo ratings yet

- Dec. 22, 1953 R. T. Catlin Etal: AmmunitionDocument4 pagesDec. 22, 1953 R. T. Catlin Etal: Ammunitionkahj juliNo ratings yet

- United States Patent, (191: FindleyDocument6 pagesUnited States Patent, (191: Findleywan nazrolNo ratings yet

- United States Patent (19) : (73) Assignee: NKK Corporation, Tokyo, JapanDocument7 pagesUnited States Patent (19) : (73) Assignee: NKK Corporation, Tokyo, JapanErin GokNo ratings yet

- Us 5214237Document5 pagesUs 5214237lucas diz quintanaNo ratings yet

- Braverman Pen Gun Patent and DrawingDocument5 pagesBraverman Pen Gun Patent and DrawingJon LewisNo ratings yet

- United States Patent: Noveske (10) Patent N0.: (45) Date of PatentDocument9 pagesUnited States Patent: Noveske (10) Patent N0.: (45) Date of Patentduffy5555No ratings yet

- Us 3717946Document4 pagesUs 3717946ererNo ratings yet

- US4635530Document9 pagesUS4635530RR ObamaNo ratings yet

- Manufacturing Method For Cooling Channels - PatentsDocument5 pagesManufacturing Method For Cooling Channels - PatentsAbhi KrishNo ratings yet

- TEPZZ 6 - 54Z A T: European Patent ApplicationDocument30 pagesTEPZZ 6 - 54Z A T: European Patent ApplicationJin SongNo ratings yet

- US4483464Document6 pagesUS4483464Joao LemesNo ratings yet

- Us 4964232Document14 pagesUs 4964232bob wongNo ratings yet

- Hollow Charge - US Patent 4942819Document9 pagesHollow Charge - US Patent 4942819warrior_2008No ratings yet

- United States Patent 19: Snedeker Et Al. Date of PatentDocument9 pagesUnited States Patent 19: Snedeker Et Al. Date of PatentMary HullNo ratings yet

- United States Patent (10) Patent No.: US 6,412,231 B1Document10 pagesUnited States Patent (10) Patent No.: US 6,412,231 B1Sharvin ZacariasNo ratings yet

- United States Patent (10) Patent No.: US 6,923,629 B2: Ahn Et Al. (45) Date of Patent: Aug. 2, 2005Document9 pagesUnited States Patent (10) Patent No.: US 6,923,629 B2: Ahn Et Al. (45) Date of Patent: Aug. 2, 2005DaikinllcNo ratings yet

- Oxygen Gas Cartridge, US5100014, Nippon Tansan Gas Co LTDDocument3 pagesOxygen Gas Cartridge, US5100014, Nippon Tansan Gas Co LTDJong Rok AhnNo ratings yet

- US2442773Document3 pagesUS2442773Jean DelaronciereNo ratings yet

- US4753444Document5 pagesUS4753444Hadi KoraniNo ratings yet

- Us 5610365Document5 pagesUs 5610365dgfhjsdg hfsdhyjNo ratings yet

- United States Patent: Price (45) Date of Patent: Apr. 22, 2008Document11 pagesUnited States Patent: Price (45) Date of Patent: Apr. 22, 2008Aslam KhanNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 7,213,519 B2 Wiley Et Al. (45) Date of Patent: May 8, 2007Document26 pagesUnited States Patent: (12) (10) Patent N0.: US 7,213,519 B2 Wiley Et Al. (45) Date of Patent: May 8, 2007fghdfjerNo ratings yet

- United States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994Document6 pagesUnited States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994mohammadreza91No ratings yet

- X III 110111113////////////////////////////11ml: (12) Ulllted States Patent (10) Patent N0.: US 8,453,633 B2Document9 pagesX III 110111113////////////////////////////11ml: (12) Ulllted States Patent (10) Patent N0.: US 8,453,633 B2djsfNo ratings yet

- US3841371-metal InsertDocument5 pagesUS3841371-metal InsertgauravNo ratings yet

- United States Patent (19) : HoenigDocument5 pagesUnited States Patent (19) : HoenigminiselNo ratings yet

- United States Patent (19) : 73 Assignee: Monogram Industries, Inc., CulverDocument5 pagesUnited States Patent (19) : 73 Assignee: Monogram Industries, Inc., CulverFayçal MahieddineNo ratings yet

- Ester: United States PatentDocument5 pagesEster: United States PatentwewewewNo ratings yet

- US4219241Document7 pagesUS4219241aungkyawzoreNo ratings yet

- Us2511005 PDFDocument2 pagesUs2511005 PDFchecolonoskiNo ratings yet

- ESME. Vehicle. A Housing Enclose Achineratched To: United States Patent (19) 11 Patent Number: 5,293,806Document7 pagesESME. Vehicle. A Housing Enclose Achineratched To: United States Patent (19) 11 Patent Number: 5,293,806Karla LinoNo ratings yet

- US7997020Document16 pagesUS7997020Ger Adinolfi-FebreNo ratings yet

- Us4380197 PDFDocument8 pagesUs4380197 PDFsoNo ratings yet

- United States PatentDocument8 pagesUnited States PatentClaudinei MayerNo ratings yet

- United States Patent (19) : 11) Patent Number: 5,309,815 (45) Date of Patent: May 10, 1994Document16 pagesUnited States Patent (19) : 11) Patent Number: 5,309,815 (45) Date of Patent: May 10, 1994Слэйтер Строительная компанияNo ratings yet

- United States Patent: (10) Patent No.: US 8,281,598 B2Document9 pagesUnited States Patent: (10) Patent No.: US 8,281,598 B2Hicham OuakilNo ratings yet

- Sling GunDocument7 pagesSling GunMinh100% (1)

- United States Patent 19Document6 pagesUnited States Patent 19mahmoud EissaNo ratings yet

- United States Patent: (10) Patent N0.: (45) Date of PatentDocument7 pagesUnited States Patent: (10) Patent N0.: (45) Date of PatentShameekaNo ratings yet

- US460Document5 pagesUS460bbNo ratings yet

- Wear and Erosion in Large Caliber Gun BarrelsDocument15 pagesWear and Erosion in Large Caliber Gun Barrelscjnjr1No ratings yet

- United States Patent 19Document9 pagesUnited States Patent 19Claudinei MayerNo ratings yet

- Dokumen BerhargaDocument14 pagesDokumen BerhargaFDS_03No ratings yet

- 5.well PerforationDocument13 pages5.well Perforationakshitppe11No ratings yet

- United States PatentDocument13 pagesUnited States Patent63No ratings yet

- Glue GunDocument9 pagesGlue GunNaranLoganNo ratings yet

- United States PatentDocument6 pagesUnited States PatentDaikinllcNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- HHGHFDocument8 pagesHHGHFpavlosmakridakis2525No ratings yet

- Us5361479 PDFDocument5 pagesUs5361479 PDFmohammadreza91No ratings yet

- Department of The Army TM 9-1370-208-10 Photoflash Cartridges, Surface Flares AND Miscellaneous Pyrotechnic ItemsDocument51 pagesDepartment of The Army TM 9-1370-208-10 Photoflash Cartridges, Surface Flares AND Miscellaneous Pyrotechnic ItemsJuanK ANo ratings yet

- M67 Delay Fragmentation Hand GrenadeDocument2 pagesM67 Delay Fragmentation Hand GrenadeJuanK ANo ratings yet

- Grenade M-67Document13 pagesGrenade M-67JuanK ANo ratings yet

- Hoja de Datos Granada M-67Document1 pageHoja de Datos Granada M-67JuanK ANo ratings yet

- ABC's of Component TestingDocument17 pagesABC's of Component TestingDee RajaNo ratings yet

- Handbook of Medical PhysicsDocument250 pagesHandbook of Medical PhysicsRana M ArslanNo ratings yet

- Handouts General MathematicsDocument70 pagesHandouts General Mathematicskhalid4vuNo ratings yet

- STM32 HTTP CameraDocument8 pagesSTM32 HTTP Cameraengin kavakNo ratings yet

- Bihar Public Service CommissionDocument2 pagesBihar Public Service CommissionrahulNo ratings yet

- Klangfarbenmelodie Amongst The Darmstadt Circle: Atmosphères at The Donaueschinger Musiktage, He WroteDocument48 pagesKlangfarbenmelodie Amongst The Darmstadt Circle: Atmosphères at The Donaueschinger Musiktage, He WroteBrandon McguireNo ratings yet

- Ibm Rs G8124eDocument40 pagesIbm Rs G8124edanibrbNo ratings yet

- Vector Worksheet 10 AnsDocument13 pagesVector Worksheet 10 AnsMegan GohNo ratings yet

- ANALOG & DIGITAL INTEGRATED CIRCUIT (ADIC) Model Question PaperDocument3 pagesANALOG & DIGITAL INTEGRATED CIRCUIT (ADIC) Model Question PaperMATHANKUMAR.SNo ratings yet

- No of BerthsDocument16 pagesNo of BerthsSamer ElabdNo ratings yet

- 4.01 Petrochemical and Offshore - ASTM D 1500 ColorDocument2 pages4.01 Petrochemical and Offshore - ASTM D 1500 Colorsetiawanaji407No ratings yet

- KR C1 A: Technical DataDocument11 pagesKR C1 A: Technical Dataayxworks eurobotsNo ratings yet

- D2LU6C04Document34 pagesD2LU6C04Sani PoulouNo ratings yet

- Palo Alto - How To Configure Captive PortalDocument17 pagesPalo Alto - How To Configure Captive PortalDanny MannoNo ratings yet

- Activated Carbon PDFDocument10 pagesActivated Carbon PDFDavid JoeventusNo ratings yet

- Arranging Fractions Lesson PlanDocument5 pagesArranging Fractions Lesson PlanSusan TalusigNo ratings yet

- DPP - Electricity (Prashant Kirad)Document12 pagesDPP - Electricity (Prashant Kirad)Abhinav SinghNo ratings yet

- Qip Ice 16 Ignition - SystemsDocument60 pagesQip Ice 16 Ignition - SystemsAjay KumarNo ratings yet

- Gozak - LeonidovDocument14 pagesGozak - LeonidovMartí ARNo ratings yet

- ANSI/ASME/ASA B16.5 Flange Slip On-RFDocument2 pagesANSI/ASME/ASA B16.5 Flange Slip On-RFtisnaNo ratings yet

- AssingmentDocument10 pagesAssingmentMuhd KhairulNo ratings yet

- Twelve Principles of AnimationDocument5 pagesTwelve Principles of AnimationSanket ShethNo ratings yet

- Fouke & Murphy 2016 The Art of Yellowstone ScienceDocument308 pagesFouke & Murphy 2016 The Art of Yellowstone ScienceVale Vega100% (1)

- 4 Database-Adm-Courses 2019 FA WebDocument4 pages4 Database-Adm-Courses 2019 FA WebGlenden KhewNo ratings yet

- S N Ne C Las Es L: Quantitative AptitudeDocument33 pagesS N Ne C Las Es L: Quantitative AptitudeanuragNo ratings yet

- Vedic Maths 1Document5 pagesVedic Maths 1Ajmal AshrafNo ratings yet

- Batch 2017 4th Semester CSEDocument28 pagesBatch 2017 4th Semester CSEAzeem KhanNo ratings yet

- Data Structure 4Document7 pagesData Structure 4Jiten ThakurNo ratings yet

- Best of Beadwork 12 Flat and Tubular Herringbone Stitch ProjectsDocument34 pagesBest of Beadwork 12 Flat and Tubular Herringbone Stitch ProjectsElena Dita93% (15)

- Ultrasonic InterferometerDocument34 pagesUltrasonic InterferometerkumargpalaniNo ratings yet