Professional Documents

Culture Documents

Robotic Manipulators

Uploaded by

shaik roshan0 ratings0% found this document useful (0 votes)

12 views4 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views4 pagesRobotic Manipulators

Uploaded by

shaik roshanCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

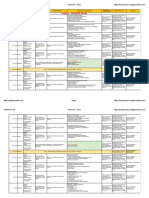

Robotic manipulators

are capable of performing repetitive tasks at

speeds and accuracies that far exceed those of human operators.

They are now widely used in manufacturing processes such as spot

welding and painting. To perform their tasks accurately and reliably,

manipulator hand (or end-effector) positions and velocities are

controlled digitally. Each motion or degree of freedom (DOF) of the

manipulator is positioned using a separate position control system.

All the motions are coordinated by a supervisory computer to

achieve the desired speed and positioning of the end effector. The

computer also provides an interface between the robot and the

operator that allows programming the lower-level controllers and

directing their actions.

This two link robotic arm study is intended to analyze the relationship between the desired and

actual motion and path taken by the robot during operation. Using the linearized EOM and the

coefficients of the cubic polynomial, the simulation of the manipulator to move from position 1 to

position 2. The polynomials for the two-segment continuous-acceleration trajectory of the

manipulator can be used to analyze the comparison between the desired and actual x versus y path.

The analysis in this study creates a visualization of the robot’s physical constraints and how they

affect its operation. One can employ this analysis to understand when and why error associated with

the manipulator occurs during the robot’s operation.

The dynamic equations of a robotic manipulator represent a

complex, nonlinear and multivariable system. One of the first

methods of controlling such systems was inverse dynamics, which

is also known as the special case of a linearization method of

feedback based on cancelling nonlinearity in a dynamic system.

However, variability and uncertainty are barriers to exact dynamic

inversion. Therefore the control of inverse dynamics has limited

practical validation.

Variable impedance control is one of the most popular approaches

to robotic manipulator control because of its independence from the

system model. However, impedance control lacks optimality and

robustness due to several disadvantages: the painstaking work of

adjusting impedance parameters (unique to each subject with

amputation), difficulty in detecting subphases in one step, lack of

feedback and passivity

To overcome this difficulty, control techniques based on the

passivity property of Euler-Lagrange equations were observed.

Especially for robust and adaptive control problems, this passive

approach is a great advantage over the inverse dynamics method.

This motivates the design of robust passivity-based regulators for

prosthetic devices, formally guaranteeing the convergence of

system error trajectories and quantitatively establishing robustness

to known perturbations. For this reason, robust passivity-based

control has received considerable attention as a powerful control

law that guarantees stability and efficient monitoring of arbitrary

trajectories despite uncertainties in the system model parameters.

These control models have also been used in the development of

active prosthetics for the lower extremities and have shown results.

the robot end effector is controlled to move to a neighborhood around the desired position by using

the Cartesian-space feedback only. A Cartesianspace region is formulated to enclose the desired

position, where the robot region is specified outside the Cartesianspace region and the human

region is specified inside the Cartesian-space region. After the end-effector transits from the robot

region to the human region, the robot becomes passive, and human identify the desired position

and guide the end effector to move to the desired position.

The link flexibility of a robotic manipulator must be considered in

modeling and control when the manipulator is of a large dimension

or lightweight. Large manipulators play important roles in many

applications, such as construction automation, environmental

applications and space engineering. Lightweight arms have great

potential in the design of high-performance industrial robotic

manipulators since they allow high speed operation and

low energy consumption. However, due to the complexity of the link

deformation, which is a distributed parameter system, accurate

modeling and high performance control of flexible manipulators

pose a major challenge in practical design.

Due to the complexity involved with link deformation however,

establishing the exact dynamic model even for one link flexible

manipulators is unrealistic, and certain simplifying approximations

about the link deformation have to be made. In addition to small

deformation, the most commonly used assumption in the robotic

literature is that it can be satisfactorily modeled by the Euler–

Bernoulli beam theory. Under such an assumption, the effects of

both rotary inertia and shear deformation of a flexible link are

neglected. However, it is well known in mechanics, particularly in

beam and plate theory, that both of them have significant effects on

the dynamic behavior of flexible structures

fractional-order PID (FOPID) controller tuned with adaptive

weighted particle swarm optimization (AWPSO) and genetic algorithms

(GAs) on two different models. The first application is the temperature

control for continuous stirred tank reactor. The second application

demonstrates a car active suspension system. The FOPID controller

parameters include three parameters as a PID controller and another two

parameters to furnish the FOPID structure. The parameters of the FOPID

controller (the PID part) for each application have been, first, estimated

and tuned using the AWPSO and the other two parameters for the FOPID

controller have been, optimally, estimated using the GA. The transient

behavior of the two applications has shown an acceptable behavior

compared to the conventional PI/PID controllers tuned by the AWPSO

only. Three different error criteria have been selected for the two

applications to testify the optimum tuned parameters of the two different

classes of controllers. These error criteria are the integral square error, the

integral absolute error, and integral time absolute error.

A major challenge to do so from an algorithm point of view is that

the instrument appearance is difficult to model over time. Initially,

methods relied on knowing the instrument geometry to track the

instrument [123,124]. Alliteratively, visual survoing has been the

basis of a number of methods in order to overcome the need to

know the instrument structure beforehand [125,126]. Unfortunately,

such methods have difficulties in dealing with prolonged tracking

time and require failure-checking systems. More recent methods

have leveraged machine learning methods to provide fast and

robust solutions

To approach

Using the MATLAB program a code was written to analyze the robot’s motion in the xy plane and

changes in the angular velocity and acceleration of both joints and the end effector. The MATLAB

code is designed to develop the various graphs that follow to simulate the location on both joints

and end effector with respect to time and determine the true effects of the robot’s physical

constraints as they relate to the actual motion versus the ideal motion of the robot. The

transformation matrices are designed to capture the relationship between the reference frames of

the links of the robot. The associated kinematic equations of the robot are used to determine the

joint parameters that provide a desired position for the end effector. The positions of motion,

constant variables, gains of each joint’s proportional controller and transfer functions are defined

prior to the development of the linear and nonlinear EOM. The respective plots which follow are

developed to illustrate how the two link robot moves in 2D space and what region in its workspace

does it encounter error associated with the end effector not reaching the desired end position. Some

plots are developed to identify causes of error related to the robot’s operation and physical

constraints.

You might also like

- Advances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFrom EverandAdvances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFarrokh Janabi-SharifiNo ratings yet

- Robust Hybrid Positionforce Control of Redundant Robots 1999Document17 pagesRobust Hybrid Positionforce Control of Redundant Robots 1999Syafri GtNo ratings yet

- International Journal of Engineering Science: Farooq M, Dao Bo WangDocument13 pagesInternational Journal of Engineering Science: Farooq M, Dao Bo Wangphyco1954No ratings yet

- Mechanical Structural Analysis AND Design Optimization: OF Industrial RobotsDocument29 pagesMechanical Structural Analysis AND Design Optimization: OF Industrial RobotsAhsan AmjadNo ratings yet

- Evolvable Mechanics Hardware Tools For Evolutionary RoboticsDocument7 pagesEvolvable Mechanics Hardware Tools For Evolutionary Roboticsdinu petreNo ratings yet

- Markovian-Based Fault-Tolerant Control For Wheeled Mobile ManipulatorsDocument11 pagesMarkovian-Based Fault-Tolerant Control For Wheeled Mobile Manipulatorshub23No ratings yet

- Robot Dynamics PDFDocument4 pagesRobot Dynamics PDFAlvin KiruiNo ratings yet

- Study On Jacobian, Singularity and Kinematics Sensitivity of TheDocument24 pagesStudy On Jacobian, Singularity and Kinematics Sensitivity of TheMaziarNo ratings yet

- Robot Manipulator Guidance ControlDocument19 pagesRobot Manipulator Guidance ControlWilliam VenegasNo ratings yet

- A New Variable Structure PID-Controller Design For Robot ManipulatorsDocument9 pagesA New Variable Structure PID-Controller Design For Robot ManipulatorsMehdi DalirNo ratings yet

- 6DOF Robot ManipulatorDocument18 pages6DOF Robot ManipulatorKarthik DmNo ratings yet

- Model-Assisted Extended State Observer-Based CompuDocument12 pagesModel-Assisted Extended State Observer-Based CompumezianeNo ratings yet

- PUMA-560 Robot Manipulator Position Sliding Mode Control Methods Using MATLAB/SIMULINK and Their Integration Into Graduate/Undergraduate Nonlinear Control, Robotics and MATLAB CoursesDocument45 pagesPUMA-560 Robot Manipulator Position Sliding Mode Control Methods Using MATLAB/SIMULINK and Their Integration Into Graduate/Undergraduate Nonlinear Control, Robotics and MATLAB CoursesAI Coordinator - CSC JournalsNo ratings yet

- Mechanical Systems and Signal Processing: Zhi-Cheng QiuDocument19 pagesMechanical Systems and Signal Processing: Zhi-Cheng QiuLakshmi Ganesh SudikondaNo ratings yet

- Chiou 2005Document27 pagesChiou 2005NardenioMartinsNo ratings yet

- Wlding RobotDocument8 pagesWlding Robotameer hamzaNo ratings yet

- Gregory 2012Document21 pagesGregory 2012Rommel RegesNo ratings yet

- Robust Control of Nonholonomic Wheeled Mobile Robot With Past Information: Theory and ExperimentDocument11 pagesRobust Control of Nonholonomic Wheeled Mobile Robot With Past Information: Theory and Experimentspandan_roy_1989No ratings yet

- On Numerical Modelling and Error Compensation For General Gough-Stewart PlatformsDocument12 pagesOn Numerical Modelling and Error Compensation For General Gough-Stewart PlatformsDuskoNo ratings yet

- Gan 2019Document23 pagesGan 2019MarinelNo ratings yet

- Modelling of Mobile Robot DynamicsDocument9 pagesModelling of Mobile Robot Dynamicskostya_4524No ratings yet

- Electronics 07 00256Document26 pagesElectronics 07 00256tou kaiNo ratings yet

- Robot Manipulator Control and Computational Cost: Technical Reports (CIS)Document40 pagesRobot Manipulator Control and Computational Cost: Technical Reports (CIS)Mauricio RamosNo ratings yet

- Integrated Task Planning and Control For Mobile ManipulatorsDocument18 pagesIntegrated Task Planning and Control For Mobile ManipulatorsmanikandanmfgNo ratings yet

- An Acceleration-Based State Observer For Robot Manipulators With Elastic JointsDocument7 pagesAn Acceleration-Based State Observer For Robot Manipulators With Elastic JointsJyotirekha PatiNo ratings yet

- Robust Adaptive Control For Mobile Manipulators: International Journal of Automation and Computing February 2011Document7 pagesRobust Adaptive Control For Mobile Manipulators: International Journal of Automation and Computing February 2011Chandrasekar ElankannanNo ratings yet

- A Dual Quaternion Linear-Quadratic Optimal Controller For Trajectory TrackingDocument6 pagesA Dual Quaternion Linear-Quadratic Optimal Controller For Trajectory TrackingGerardo HernándezNo ratings yet

- Applied Sciences: Practical Adaptive Sliding-Mode Control Approach For Precise Tracking of Robot ManipulatorsDocument16 pagesApplied Sciences: Practical Adaptive Sliding-Mode Control Approach For Precise Tracking of Robot ManipulatorsOmokhafe TolaNo ratings yet

- Inverse Kinematics Software Design and Trajectory Control Programming of SCARA Manipulator RobotDocument22 pagesInverse Kinematics Software Design and Trajectory Control Programming of SCARA Manipulator Robotvishakha bangareNo ratings yet

- Modelling of Mobile Robot Dynamics: JANUARY 2010Document10 pagesModelling of Mobile Robot Dynamics: JANUARY 2010NguyễnĐạtNo ratings yet

- Modeling, Identification and Control of a Redundant Planar 2-DOF Parallel ManipulatorDocument11 pagesModeling, Identification and Control of a Redundant Planar 2-DOF Parallel ManipulatorMarco Antonio Ruiz GascaNo ratings yet

- 2019 KSJ IJAMT v101 pp243-259Document17 pages2019 KSJ IJAMT v101 pp243-259Viktor SokolovNo ratings yet

- Chapter # 1: Introduction To Robotics Mechanics & ControlDocument51 pagesChapter # 1: Introduction To Robotics Mechanics & ControlAli AliNo ratings yet

- Research Article: A Two-Wheeled Self-Balancing Robot With The Fuzzy PD Control MethodDocument14 pagesResearch Article: A Two-Wheeled Self-Balancing Robot With The Fuzzy PD Control MethodMurat Yasar ERTASNo ratings yet

- Low-Cost Accelerometers For Robotic Manipulator PerceptionDocument7 pagesLow-Cost Accelerometers For Robotic Manipulator PerceptionAbbé BusoniNo ratings yet

- PaperDocument4 pagesPaperRebira AgaNo ratings yet

- Modi Ed Power Rate Sliding Mode Control For Robot Manipulator Based On Particle Swarm OptimizationDocument13 pagesModi Ed Power Rate Sliding Mode Control For Robot Manipulator Based On Particle Swarm OptimizationIAES International Journal of Robotics and AutomationNo ratings yet

- Compliance Control of Tele-RobotDocument7 pagesCompliance Control of Tele-RobotUshnish SarkarNo ratings yet

- Modeling and Control of a DC Motor Coupled to a Non-Rigid JointDocument19 pagesModeling and Control of a DC Motor Coupled to a Non-Rigid JointccNo ratings yet

- Position Control: 1999 John Wiley & Sons, IncDocument31 pagesPosition Control: 1999 John Wiley & Sons, IncKenpachi ZarakiNo ratings yet

- EEE 1207 021 6 DOF Robotic Arm ManipulatorDocument7 pagesEEE 1207 021 6 DOF Robotic Arm ManipulatorUNsha bee komNo ratings yet

- Mod and IdentificationDocument12 pagesMod and IdentificationNaeem Ali SajadNo ratings yet

- A Simulation and Experimental Study On Wheeled Mobile Robot Path Control in Road Roundabout EnvironmentDocument17 pagesA Simulation and Experimental Study On Wheeled Mobile Robot Path Control in Road Roundabout EnvironmentThanh Pham TuanNo ratings yet

- Proceedings of The 9th WSEAS International Conference On APPLICATIONS of ELECTRICAL ENGINEERINGDocument7 pagesProceedings of The 9th WSEAS International Conference On APPLICATIONS of ELECTRICAL ENGINEERINGIbrahim SadohNo ratings yet

- Slotine Li Tac 88Document9 pagesSlotine Li Tac 88Linh Chi NguyenNo ratings yet

- Dynamic Model Identification For Industrial Robots: Integrated Experiment Design and Parameter EstimationDocument14 pagesDynamic Model Identification For Industrial Robots: Integrated Experiment Design and Parameter Estimationسمية عصامNo ratings yet

- RoboticsDocument18 pagesRoboticslakshmigsr6610100% (1)

- Global Uncalibrated Visual Servoing ForDocument9 pagesGlobal Uncalibrated Visual Servoing Forlenardorosasco96No ratings yet

- Torque Minimization of a 2 DOF Robot Using GRG AlgorithmDocument5 pagesTorque Minimization of a 2 DOF Robot Using GRG AlgorithmAnkit GoratelaNo ratings yet

- Motion Control of Single Link Flexible Joint Robot Manipulator Using ANFIS MATLAB SimulationDocument10 pagesMotion Control of Single Link Flexible Joint Robot Manipulator Using ANFIS MATLAB SimulationMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Project Segway 3 WheelDocument26 pagesProject Segway 3 WheelMohit ChetwaniNo ratings yet

- Controller Design ThesisDocument4 pagesController Design Thesisaprilgriffinbeaumont100% (2)

- Cartesian Nonlinear Model Predictive Control of Redundant Manipulators Considering ObstaclesDocument6 pagesCartesian Nonlinear Model Predictive Control of Redundant Manipulators Considering ObstaclesSHISHIR CHANDRA DAS 1809019No ratings yet

- EEE 1207 021 6 DOF Robotic Arm ManipulatorDocument7 pagesEEE 1207 021 6 DOF Robotic Arm ManipulatorCarlos Rodriguez RNo ratings yet

- Performance Comparison Between Fuzzy Logic Controller (FLC) and PID Controller For A Highly Nonlinear Two-Wheels Balancing RobotDocument6 pagesPerformance Comparison Between Fuzzy Logic Controller (FLC) and PID Controller For A Highly Nonlinear Two-Wheels Balancing RobotVignesh RamakrishnanNo ratings yet

- Energy Comparison of Controllers Used For A Differential Drive Wheeled Mobile RobotDocument13 pagesEnergy Comparison of Controllers Used For A Differential Drive Wheeled Mobile RobotElias GarcíaNo ratings yet

- Stiffness Metrics For Design of 3-RRR Flexible Manipulator: K.V.Varalakshmi, Dr.J.SrinivasDocument7 pagesStiffness Metrics For Design of 3-RRR Flexible Manipulator: K.V.Varalakshmi, Dr.J.SrinivasIJMERNo ratings yet

- El 16 1 05Document9 pagesEl 16 1 05Mauricio RamosNo ratings yet

- Adaptive Control of Mobile Manipulator To Track Horizontal Smooth Curved Apply For Welding ProcessDocument10 pagesAdaptive Control of Mobile Manipulator To Track Horizontal Smooth Curved Apply For Welding ProcessAJER JOURNALNo ratings yet

- Preparation of Papers For JCARME: A. Author, B. Author and C. AuthorDocument3 pagesPreparation of Papers For JCARME: A. Author, B. Author and C. Authorshaik roshanNo ratings yet

- Multiple-Unit Artificial Retina Chipset System To Benefit The Visually ImpairedDocument28 pagesMultiple-Unit Artificial Retina Chipset System To Benefit The Visually ImpairedPrashanth BaskaranNo ratings yet

- Underwater Control of MobileDocument46 pagesUnderwater Control of Mobileshaik roshanNo ratings yet

- Humanoid-Robot Aswath, Et - AlDocument5 pagesHumanoid-Robot Aswath, Et - Alshaik roshanNo ratings yet

- INSIGHTS IAS MISSION 2022Document28 pagesINSIGHTS IAS MISSION 2022Ashish Singh100% (1)

- Frontiers of Biomechatronics 19RA721 3-0-0-3: Text Books/ReferencesDocument1 pageFrontiers of Biomechatronics 19RA721 3-0-0-3: Text Books/Referencesshaik roshanNo ratings yet

- PDFenDocument45 pagesPDFenshaik roshanNo ratings yet

- Chapter 8Document28 pagesChapter 8Hervis FantiniNo ratings yet

- Rover with ultrasonic sensor and Bluetooth moduleDocument5 pagesRover with ultrasonic sensor and Bluetooth moduleshaik roshanNo ratings yet

- Ni2013 Development of Labview Based Gesture Driven Robotic ArmDocument4 pagesNi2013 Development of Labview Based Gesture Driven Robotic ArmSachin PatilNo ratings yet

- Cover Pageof Lab Assignments CryptoDocument10 pagesCover Pageof Lab Assignments CryptoMaster ManNo ratings yet

- Logic Programming: - About The CourseDocument68 pagesLogic Programming: - About The CourseABeerNo ratings yet

- Information System and Value Chain of MacDonald'sDocument10 pagesInformation System and Value Chain of MacDonald'sYasir Ayaz100% (5)

- 3.9.1 Crash 2019 11 29 07 45 35 1575009935671Document3 pages3.9.1 Crash 2019 11 29 07 45 35 1575009935671johnNo ratings yet

- 6880309T87 AMobileDSMDocument265 pages6880309T87 AMobileDSMAyon BaxterNo ratings yet

- Case Management Information System - Kosovo Case StudyDocument4 pagesCase Management Information System - Kosovo Case Studynewguyat77No ratings yet

- Computer ScienceDocument10 pagesComputer ScienceAchyut ShuklaNo ratings yet

- NGO Darpan How To Signup EnglishDocument10 pagesNGO Darpan How To Signup EnglishSkyhigh GoneNo ratings yet

- Sign Language RecognitionDocument9 pagesSign Language RecognitionIJRASETPublicationsNo ratings yet

- Csgo EnglishDocument610 pagesCsgo EnglishVeZ xNo ratings yet

- Name:-Shushant SonwaniDocument56 pagesName:-Shushant Sonwanishushantsonwani416No ratings yet

- RPC System with 450mm DAC ColumnsDocument27 pagesRPC System with 450mm DAC Columnsshanmukha2007No ratings yet

- Broadcom VMware PresentationDocument20 pagesBroadcom VMware PresentationMRIDUL GOELNo ratings yet

- Docker Run Reference: Detached (-D)Document3 pagesDocker Run Reference: Detached (-D)Diandra BilkisNo ratings yet

- Discuss The Difference Between Object Oriented Design and Object Oriented Analysis With The Help of Suitable Diagram?Document7 pagesDiscuss The Difference Between Object Oriented Design and Object Oriented Analysis With The Help of Suitable Diagram?vineet kholaNo ratings yet

- Big Data Analytics White PaperDocument38 pagesBig Data Analytics White PaperDaniela StaciNo ratings yet

- PMP+Exam+Prep+ +Agile+ContentDocument578 pagesPMP+Exam+Prep+ +Agile+ContentOsny JeanNo ratings yet

- Virtualization and The CloudDocument21 pagesVirtualization and The CloudAli Çakıcı100% (1)

- Performance: Thinkpad P15V Gen 1Document6 pagesPerformance: Thinkpad P15V Gen 1HOSSANo ratings yet

- Aadhar Card..Document1 pageAadhar Card..Siddharth DixitNo ratings yet

- KAWAI R-ROM Switcher InstallDocument3 pagesKAWAI R-ROM Switcher InstallMiguel ViscarraNo ratings yet

- KPIs IN SCAFFOLDING OPERATIONSDocument6 pagesKPIs IN SCAFFOLDING OPERATIONSSalman KhanNo ratings yet

- Case Study 4Document4 pagesCase Study 4Tracy zorcaNo ratings yet

- Soft Skills Project PlanDocument9 pagesSoft Skills Project Planapi-601533359No ratings yet

- Tarea 1 Operaciones MatDocument2 pagesTarea 1 Operaciones MatJosué CamposNo ratings yet

- Asymptotic NotationsDocument23 pagesAsymptotic NotationsVikram SinghNo ratings yet

- S5735-S8P2X-IA200H1 Quick Start GuideDocument16 pagesS5735-S8P2X-IA200H1 Quick Start GuideChristian Javier Lopez DuranNo ratings yet

- Little Navmap User Manual enDocument384 pagesLittle Navmap User Manual enEmin bojecNo ratings yet

- A Complete Data Science Interview With 100 QuestionsDocument57 pagesA Complete Data Science Interview With 100 QuestionsAbhinav Kumar100% (1)

- Aiken Complete CatalogueDocument55 pagesAiken Complete CatalogueAli RizviNo ratings yet