Professional Documents

Culture Documents

SQF Preventive Control Audit Checklist

Uploaded by

EstherRuizFrancoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SQF Preventive Control Audit Checklist

Uploaded by

EstherRuizFrancoCopyright:

Available Formats

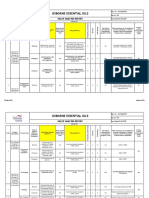

Company Number: Click here to enter text.

Audit Number: Click here to enter text.

This template contains a number of items that are in the PC Rule that are different than the SQF Code. Completing this addendum should

provide the supplier an idea of how they stand in regards to the FSMA Preventive Controls Rule for Human Food. It does not guarantee

compliance, nor does it absolve the supplier from ensuring that they meet all aspects of the FSMA Preventive Controls Rule for Human Rule. The

addendum is voluntary and will not be scored.

*Primary Responses are Compliant, Noncompliant and N/A. Suppliers can add responses to the ‘Supplier Response’ fields if assessed a

Noncompliant.

Preventive Controls for Human Food/SQF Code Addendum

Summary of Additional

PC Rule SQF Code Primary Response Evidence Supplier Response

Requirements

Human food by-products

for use as animal food

need to be held under

conditions that will

protect it against

contamination.

2.4.3.1 -

§ 117.95 By-products Containers and equipment

Food Click here to enter

for Use as Animal cannot become sources of Choose an item. Click here to enter text.

Safety Plan text.

Food contamination (suitable,

cleaned, maintained),

materials protected from

contamination from trash,

identified, labelled and

shipping containers

examined prior to use.

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 1

The owner, operator, or

2.1.3.1 - agent in charge of the

Food facility has signed and

§ 117.310

Safety dated the Preventive Click here to enter

Signed and Dated Choose an item. Click here to enter text.

Managem Controls food safety plan text.

Food Safety Plan

ent System when initially drafted and

when any modification

occurs.

All records need to

include:

information that

identifies the site;

the date and the

time of the

activity

§ 117.305 2.2.2 - Click here to enter

documented; Choose an item. Click here to enter text.

Record Identification Records text.

the signature or

initials of the

person performing

the activity; and

the identity of the

product and the

lot code.

§ 117.315 2.2.2 - Required records are Choose an item. Click here to enter text. Click here to enter

Record Retention Records retained onsite for at text.

least two years after

the date they are

prepared.

Records that relate to

the general adequacy

of the equipment or

processes being used

by a facility, including

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 2

the results of scientific

studies and

evaluations, must be

retained by the facility

for at least two years

after their use is

discontinued.

The record retention

policy indicates that if

the site closes for a

prolonged period, the

written food safety

plan can be

transferred to some

other reasonably

accessible location but

must be returned to

the plant or facility

within 24 hours for

official review upon

request.

§ 117.126 2.4.3 - One member of the Choose an item. Click here to enter text. Click here to enter

Food Safety Plan Food food safety plan text.

Safety Plan development team

needs to be a of the

The contents

food safety plan must

include:

o Hazard

analysis

o Identified

preventive

controls

For identified

hazards requiring

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 3

a preventive

control, the

following must be

included in the

food safety plan:

o Supply chain

program;

o Recall plan;

o Procedures

for

monitoring;

o Corrective

action

procedures;

o Verification

procedures;

§ 117.130 2.4.3 - The hazard analysis Choose an item. Click here to enter text. Click here to enter

Hazard Analysis Food must consider known text.

Safety Plan or reasonably

foreseeable hazards

and known or

reasonably

foreseeable hazards

that may be present in

the food and include

biological, chemical

(including radiological)

and physical hazards.

Intentional

contamination for

economic gain must

be considered in the

hazard analysis.

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 4

The hazard analysis

must include an

evaluation of

environmental

pathogens whenever a

ready-to-eat food is

exposed to the

environment prior to

packaging and the

packaged food does

not receive a

treatment or have

some sort of control

measure to

significantly minimize

the pathogen.

Preventive controls must

be identified and

implemented and include

controls for CCPs or other

points that are

2.4.3 – appropriate for food

Food safety.

Safety Plan Preventive controls

§ 117.135 2.4.1 – include, as appropriate to Click here to enter

Choose an item. Click here to enter text.

Preventive Controls Food the facility and the food: text.

Legislation - Process controls;

(Regulatio - Food allergen

n) controls;

- Sanitation

controls;

- Supply chain

controls; or

- Other.

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 5

Each preventive control

identified within the

written food safety plan

must have in place the

following management

plans:

§ 117.140 2.4.3 -

monitoring, Click here to enter

Management of the Food Choose an item. Click here to enter text.

corrective actions text.

Preventive Controls Safety Plan

(including

corrections, as

applicable),

verification,

supply chain and

record review.

The facility must establish

and implement a written,

2.4.5 - risk-based supply-chain

§ 117.405

Incoming program for those Click here to enter

Supply Chain Program Choose an item. Click here to enter text.

Goods and products or ingredients text.

Requirements

Services where a supply-chain

preventive control has

been identified.

§ 117.410 The supply-chain program Choose an item. Click here to enter text. Click here to enter

Requirements of the must be written and text.

Supply Chain Program include:

- Conducting

- supplier

Documenting

supplier

verification

activities; and

- Verification and

documentation of

a supply-chain

control applied by

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 6

a facility other

than the site

through

verification,

review and

assessment of

documentation.

Suppliers of ingredients

and raw materials

§ 117.420 requiring a supply-chain Click here to enter

Choose an item. Click here to enter text.

Approved Suppliers control must be approved text.

prior to receiving the

product.

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 7

Supplier verification

activities for product

requiring a supply-chain

control include one of the

following:

an annual onsite

audit of food

safety practices

conducted by a

§ 117.410 qualified auditor;

Click here to enter

Supplier Verification sampling and Choose an item. Click here to enter text.

text.

Activities testing of the

supplier’s product

for the identified

hazard;

a review of the

supplier’s food

safety records; or

other procedures

based on the

associated risk.

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 8

A supplier may conduct

and document sampling

and testing of product

that requires a hazard to

be controlled by the

supplier, as a verification

§ 117.415

activity and provide that Click here to enter

Receiving Facility Choose an item. Click here to enter text.

documentation to the text.

Responsibilities

receiving facility. The

receiving facility must

review and assess that

documentation, and then

document the review and

assessment.

Onsite audits, if necessary

must be conducted by a

qualified auditor as

defined in the Rule, unless

the facility has

documentation showing

that other appropriate

§ 117.435 Click here to enter

verification activities are Choose an item. Click here to enter text.

Onsite Audit text.

being used to control the

hazard.

The onsite audit, if

deemed necessary, is

conducted before the raw

material or ingredient is

used and at least annually.

When an entity other than

§ 117.415 the certified site receives

Click here to enter

Responsibilities of the Brokers products on their behalf, Choose an item. Click here to enter text.

text.

Receiving Facility the receiving facility must

have in place written

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 9

procedures for receiving

the product and must

document that the written

procedures for receiving

the product are being

followed by the entity.

The site must also

determine and/or conduct

appropriate supplier

verification activities. The

receiving facility must

review and assess the

entity’s applicable

documentation, and then

document that review and

assessment.

§ 117.160 2.5.2 - Validation of the process Choose an item. Click here to enter text. Click here to enter

Validation Validation preventive controls needs text.

& to be performed or

Effectivene overseen by a preventive

ss controls qualified

individual (PCQI) and must

be conducted prior to

implementation of the

food safety plan or within

90 calendar days after

production of the

applicable food first

begins, unless otherwise

justified by the PCQI.

Validation is also required

whenever a change to a

control measure or

combination of control

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 10

measures could impact

whether the control

measure or combination

of control measures, when

properly implemented,

will effectively control the

hazards; and whenever a

reanalysis of the food

safety plan reveals the

need to do so.

The preventive controls

qualified individual (PCQI)

must review monitoring

§ 117.165

2.4.8 – and corrective action

Verification of Click here to enter

Product records within seven Choose an item. Click here to enter text.

Implementation and text.

Release working days after the

Effectiveness

records are created or

within a justified

reasonable timeframe.

§ 117.165(b)(2) 2.5.6 - - Be scientifically Choose an item. Click here to enter text. Click here to enter

Verification of Product valid text.

Implementation and Sampling, - Identify the test

Effectiveness Inspection microorganism

and - Specify the

Analysis procedures for

identifying

samples, including

their relationship

to specific lots of

product

- Include the

procedures for

sampling,

including the

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 11

number of

samples and the

sampling

frequency

- Identify the test(s)

conducted,

including the

analytical

method(s) used

- Identify the

laboratory

conducting the

testing

- Include the

corrective action

procedures.

If a product requiring a

2.6.3 - preventive control must

Product be recalled an

§ 117.139 Click here to enter

Withdrawa effectiveness check must Choose an item. Click here to enter text.

Recall Plan text.

l and be conducted to verify

Recall that the product recall has

been carried out.

Other gases mechanically

introduced into food, if

used, must be treated in

§ 117.40

11.5.7 - Air such a way that the Click here to enter

Mechanically Choose an item. Click here to enter text.

Quality product is not text.

Introduced Gases

contaminated with

unlawful indirect food

additives.

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 12

© 2016 SQF Institute (A Division of the Food Marketing Institute) Page 13

You might also like

- A Food Safety Approach For Suppliers To The Food IndustryDocument23 pagesA Food Safety Approach For Suppliers To The Food IndustryMasthan GM100% (1)

- Food Allergen RiskDocument5 pagesFood Allergen RiskVenkat Subba RaoNo ratings yet

- Auditing Guide: Active Pharmaceutical Ingredients Committee (APIC)Document26 pagesAuditing Guide: Active Pharmaceutical Ingredients Committee (APIC)Ngoc Sang HuynhNo ratings yet

- Food Defense Guidelines: August 27, 2010 2010 AIB International, IncDocument49 pagesFood Defense Guidelines: August 27, 2010 2010 AIB International, IncEdward SnyderNo ratings yet

- Foreign Supplier Evaluation FormDocument1 pageForeign Supplier Evaluation Formamir ShehzadNo ratings yet

- Computer System ValidationDocument2 pagesComputer System Validationanon_544896262No ratings yet

- Allergen Risk Assessment Analysis Report-StagewiseDocument8 pagesAllergen Risk Assessment Analysis Report-StagewiseSiva SuryaNo ratings yet

- Form 5420 5 General Food Defense PlanDocument11 pagesForm 5420 5 General Food Defense PlanBenjamin AlecNo ratings yet

- PchfHazard Analysis and Risk-Based Preventive Controls For Human Food: Guidance For Industry Guidance Full 01-17-2018Document306 pagesPchfHazard Analysis and Risk-Based Preventive Controls For Human Food: Guidance For Industry Guidance Full 01-17-2018nicole_diazrNo ratings yet

- BSBMGT617 AssignmentDocument42 pagesBSBMGT617 AssignmentAnu Saroch100% (2)

- Withdrawal ManualDocument47 pagesWithdrawal Manualatvenu16160No ratings yet

- Food Fraud: Impact On FlavorsDocument37 pagesFood Fraud: Impact On Flavorssowmya.mas1542No ratings yet

- Prelim Exam - Auditing and Assurance: Specialized Industries Class: Bachelor of Science in Accountancy - 3rd YearDocument10 pagesPrelim Exam - Auditing and Assurance: Specialized Industries Class: Bachelor of Science in Accountancy - 3rd YearJeremae Ann Ceriaco100% (1)

- Critical Elements For EMPDocument54 pagesCritical Elements For EMPGaganpreet KaurNo ratings yet

- Zone 1 Sampling For Spp. in Fresh Produce Operations:: ListeriaDocument10 pagesZone 1 Sampling For Spp. in Fresh Produce Operations:: Listeriaamir ShehzadNo ratings yet

- Iso 3834Document2 pagesIso 3834Jaay Vel0% (1)

- A Cheese Company: (Links To Logs)Document2 pagesA Cheese Company: (Links To Logs)mahsen2000No ratings yet

- Bodily Fluids Spillage: Standard Operating ProcedureDocument5 pagesBodily Fluids Spillage: Standard Operating ProcedureLinda Setya Wati100% (1)

- sfc2017 Environmental MonitoringDocument74 pagessfc2017 Environmental MonitoringLuis Gutiérrez100% (2)

- Food Defense Supplier Guidelines 1 11Document12 pagesFood Defense Supplier Guidelines 1 11Ahmed Hassan ShehataNo ratings yet

- Audit Risk ModelDocument12 pagesAudit Risk ModelDennis NjonjoNo ratings yet

- Recall Procedure CMODocument4 pagesRecall Procedure CMOSatya KumarNo ratings yet

- Allergen Control Program - EnglishDocument1 pageAllergen Control Program - EnglishOrlando Clar Ralaisoa100% (1)

- FSVP SopDocument7 pagesFSVP SopWangu100% (1)

- Guide To Environmental Microbiological MonitoringDocument29 pagesGuide To Environmental Microbiological MonitoringzyrtylNo ratings yet

- Hygiene and Sanitary Conditions in A Meat Processing Plant PDFDocument30 pagesHygiene and Sanitary Conditions in A Meat Processing Plant PDFsureshNo ratings yet

- Audit: Role and Responsibilities of Auditor in Clinical Trial As Per Ich GCPDocument7 pagesAudit: Role and Responsibilities of Auditor in Clinical Trial As Per Ich GCPGeethika GummadiNo ratings yet

- Food Fraud Vulnerability Assessment CCDDocument2 pagesFood Fraud Vulnerability Assessment CCDReidy SolanoNo ratings yet

- FSSC 22000 Scheme Version 6 WORDDocument84 pagesFSSC 22000 Scheme Version 6 WORDKawtar FAOUZYNo ratings yet

- M. S. Asia Group Page 1 of 1 Document No.: SOP/ANA/PDP Effective Date: 21-6-2021 Rev. No.: 0 Document Title: Product Defense PlanDocument1 pageM. S. Asia Group Page 1 of 1 Document No.: SOP/ANA/PDP Effective Date: 21-6-2021 Rev. No.: 0 Document Title: Product Defense Plannurhafizah jabarNo ratings yet

- Food Traceability Withdrawals and Recalls GuidanceDocument56 pagesFood Traceability Withdrawals and Recalls GuidanceQualidade SegurançaNo ratings yet

- An Introduction To Internal Audits PDFDocument7 pagesAn Introduction To Internal Audits PDFCesar RodriguezNo ratings yet

- PAS 220 To 223 - PRPs ComparisonDocument1 pagePAS 220 To 223 - PRPs ComparisonMark Kwan100% (1)

- Env6 - Zoning Requirements, Pathogen Environment Monitoring For Dairy SuppliersDocument37 pagesEnv6 - Zoning Requirements, Pathogen Environment Monitoring For Dairy SuppliersMarianyNo ratings yet

- BSI Allergen Risk Assessment (1) .NHDXSZDocument7 pagesBSI Allergen Risk Assessment (1) .NHDXSZRosinanteNo ratings yet

- HACCP Presentation 01 11 2016Document13 pagesHACCP Presentation 01 11 2016njuguna63No ratings yet

- Environmental Monitoring ProgramDocument8 pagesEnvironmental Monitoring Programmonik manuelNo ratings yet

- FSSC 22000 Scheme Requirements: Detailed Changes Between V4 and V4.1Document30 pagesFSSC 22000 Scheme Requirements: Detailed Changes Between V4 and V4.1danuNo ratings yet

- Checklist Auditoria SQF 2010Document21 pagesChecklist Auditoria SQF 2010cramirez48No ratings yet

- Clauses Comparision Between ISO 22000-2018 With ISO 9001-2015Document6 pagesClauses Comparision Between ISO 22000-2018 With ISO 9001-2015arulj75No ratings yet

- SBL PDFDocument419 pagesSBL PDFMuhammad Imran100% (2)

- QA 5.15 Allergens Materials Handling General ProcedureDocument3 pagesQA 5.15 Allergens Materials Handling General ProcedureangeldrandevNo ratings yet

- 8 Sample Haccp Annual Meeting TemplateDocument1 page8 Sample Haccp Annual Meeting TemplateJulius MuhimboNo ratings yet

- GG039 GlobalG.A.P. Food Defense Risk Assessment SampleDocument11 pagesGG039 GlobalG.A.P. Food Defense Risk Assessment SampleBhuvanesh Waran100% (2)

- Case Studies On HaccpDocument28 pagesCase Studies On HaccpAnonymous OPix6Tyk5INo ratings yet

- OPRP 2 Management of Pest ControlDocument2 pagesOPRP 2 Management of Pest ControlAnggerNo ratings yet

- FSSC 22000 GUIDELINE - FSSC CertificationDocument14 pagesFSSC 22000 GUIDELINE - FSSC CertificationFelix MwandukaNo ratings yet

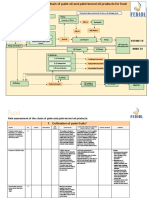

- Risk Assessment Palm Food FEDIOL Final 160522Document18 pagesRisk Assessment Palm Food FEDIOL Final 160522Jayashri chitteNo ratings yet

- Gap BRCv9 BlankDocument49 pagesGap BRCv9 BlankVasil TsonkovNo ratings yet

- Listeria Monocytogenes Guidance On: Environmental Monitoring and Corrective Actions in At-Risk FoodsDocument35 pagesListeria Monocytogenes Guidance On: Environmental Monitoring and Corrective Actions in At-Risk FoodsGaganpreet KaurNo ratings yet

- Introduction To Environmental Monitoring ProgramsDocument4 pagesIntroduction To Environmental Monitoring Programsmarmaduke32No ratings yet

- Commit To Food Safety: LeadershipDocument3 pagesCommit To Food Safety: LeadershipYannNo ratings yet

- Haccp Plan ReviewDocument4 pagesHaccp Plan ReviewHSC QA/QC100% (1)

- BRCGS Standard For Packaging and Packaging MaterialsDocument6 pagesBRCGS Standard For Packaging and Packaging Materialshunain zafarNo ratings yet

- FSQ in Food Storage and Distribution PracticesDocument19 pagesFSQ in Food Storage and Distribution PracticesberiNo ratings yet

- Management-Institutional Records & ReportsDocument18 pagesManagement-Institutional Records & ReportsmagieNo ratings yet

- Checklist: Detailed Evaluation ReportDocument46 pagesChecklist: Detailed Evaluation ReportAmira Smine100% (1)

- Brcgs For Storagedistribution Issue 4 Draft1Document68 pagesBrcgs For Storagedistribution Issue 4 Draft1Dr. Polixenia Udubasa100% (1)

- Traceability Complete FinalDocument14 pagesTraceability Complete Finalmdsanchezo8373No ratings yet

- BRCGS ENG General GuideDocument12 pagesBRCGS ENG General GuideMar Gonzalez PardosNo ratings yet

- PRP Verification Check List: Appendix 2Document114 pagesPRP Verification Check List: Appendix 2jacky786No ratings yet

- Yum! GAP Guidelines1Document13 pagesYum! GAP Guidelines1shani31No ratings yet

- Aud Agile Eng m04 Pnotes Conducting An AuditDocument24 pagesAud Agile Eng m04 Pnotes Conducting An AuditMohamed ElsawyNo ratings yet

- Access Business Group Raw Material Questionnaire: (Broker, Grower, Manufacturer, Other)Document9 pagesAccess Business Group Raw Material Questionnaire: (Broker, Grower, Manufacturer, Other)Sutha Tamil NambeNo ratings yet

- Sv. Dimdang Nyos Form 1. Sanitation Audit FormDocument20 pagesSv. Dimdang Nyos Form 1. Sanitation Audit FormDira SeptianaNo ratings yet

- Kandhar Beverages PVT - LTD Saha-Vulnerabilty Assesment: 1-Uncertai N, Reaso Nable Certain, 3 - Very CertainDocument15 pagesKandhar Beverages PVT - LTD Saha-Vulnerabilty Assesment: 1-Uncertai N, Reaso Nable Certain, 3 - Very CertainAnonymous Zxhseb19No ratings yet

- HACCP Training GuideDocument8 pagesHACCP Training GuidemaspanuciNo ratings yet

- Umair Ali (BC 15059)Document78 pagesUmair Ali (BC 15059)Ansab MughalNo ratings yet

- Preweek Auditing Theory 2014Document86 pagesPreweek Auditing Theory 2014Angelica AllanicNo ratings yet

- Rules For APFMIS ActDocument83 pagesRules For APFMIS ActRavindra Reddy BhumaNo ratings yet

- Auditing NotesDocument9 pagesAuditing NotesShubham Khess100% (1)

- Iso 9000 14000Document36 pagesIso 9000 14000varun_ikNo ratings yet

- CAT2Document146 pagesCAT2STYXNo ratings yet

- Statistical Sampling - A Useful Audit ToolDocument7 pagesStatistical Sampling - A Useful Audit ToolHBL AFGHANISTANNo ratings yet

- Conduct A Night Audit: D1.HFO - CL2.06 Trainee ManualDocument54 pagesConduct A Night Audit: D1.HFO - CL2.06 Trainee ManualPhttii phttiiNo ratings yet

- CV Sadiq 2010Document4 pagesCV Sadiq 2010Tijani Raheemot AjedoyinNo ratings yet

- RFQ-CP - November 2017Document12 pagesRFQ-CP - November 2017KshirabdhiTanayaSwainNo ratings yet

- Chapter 9 Cabrera Applied AuditingDocument5 pagesChapter 9 Cabrera Applied AuditingCristy Estrella50% (4)

- Annual Report 2016 17 PDFDocument164 pagesAnnual Report 2016 17 PDFrupesh2404No ratings yet

- Audithow Com Auditing of Operating ExpensesDocument8 pagesAudithow Com Auditing of Operating ExpensesMunyaradzi Onismas ChinyukwiNo ratings yet

- Hafiz Muhammad Saad: Personal DetailsDocument2 pagesHafiz Muhammad Saad: Personal Detailsw4s33mNo ratings yet

- Brief Contents: Strategy Evaluation 284Document8 pagesBrief Contents: Strategy Evaluation 284Abigail RodriguezNo ratings yet

- Millat Tractors LTD - Annual Report 2008Document131 pagesMillat Tractors LTD - Annual Report 2008Monis Ali100% (2)

- Zairi 2000Document7 pagesZairi 2000Thị Trà My NguyễnNo ratings yet

- AuditDocument5 pagesAuditKyanna Mae LecarosNo ratings yet

- Final Pro-Forma Opcr 3-3-22Document16 pagesFinal Pro-Forma Opcr 3-3-22Abraham JunioNo ratings yet

- Index Internal Auditor 2004 - 2016Document222 pagesIndex Internal Auditor 2004 - 2016pembazak100% (1)

- 10.1108@maj 09 2019 2405Document36 pages10.1108@maj 09 2019 2405Rusli RusliNo ratings yet