100% found this document useful (1 vote)

2K views2 pagesProduct Identification-SOP

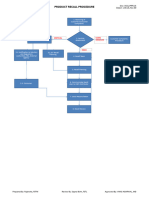

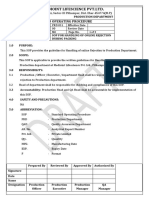

This standard operating procedure outlines the product identification system used by XXXX Corporation. It describes how purchased, in-process, and final products are identified using unique numbers, codes, labels, or tags. Product identification is maintained from receipt of materials through production, assembly, storage, and shipment to allow for traceability. Engineering and production records are used to correlate part numbers to drawings and work orders to individual manufactured products.

Uploaded by

Saravana kumar NagarajanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

2K views2 pagesProduct Identification-SOP

This standard operating procedure outlines the product identification system used by XXXX Corporation. It describes how purchased, in-process, and final products are identified using unique numbers, codes, labels, or tags. Product identification is maintained from receipt of materials through production, assembly, storage, and shipment to allow for traceability. Engineering and production records are used to correlate part numbers to drawings and work orders to individual manufactured products.

Uploaded by

Saravana kumar NagarajanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd