Professional Documents

Culture Documents

SOP-QC-002 - Finished Product Release Plan

SOP-QC-002 - Finished Product Release Plan

Uploaded by

JUAN GUZMANOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP-QC-002 - Finished Product Release Plan

SOP-QC-002 - Finished Product Release Plan

Uploaded by

JUAN GUZMANCopyright:

Available Formats

Standard Operating Procedure

Title: Assembly Finished Product Release Plan No.: SOP-QC-002

Effective: 8/02/2022 Revision 1 Page: 1 of 2

1. Purpose

This document will outline the process for the release of finished product(s) from a QC Hold

once a disposition has been made.

2. Application

The responsibilities for execution of this process fall under DTTP QC Assembly.

3. Definitions

3.1 Disposition: It is the management’s decision to correct, fix, repurpose or scrap the

product on hold

3.2 Rework: Inspecting units for the specific defect(s) outlined in the MAPICS notes and

correcting the defects when found

4. Requirements

4.1 Once a disposition has been made and executed the responsibility for the release of

product(s) will fall to QC Assembly. Form QA-037 will be used to monitor and record the

release process as required.

4.2 If the final disposition was to release product as is, form QA-037 is not necessary. The

release shall be communicated via E-mail by a Quality Engineer, or Quality Manager.

4.3 If the final decision was to rework, The Quality Auditor will verify recorded units in the

form and release from Mapics

4.4 The QC representative will sign off form QA-037 as proof of release. The form will then

be archived for reference purposes.

Master Document Location: http://web.goodmanmfg.com

Printed copies are uncontrolled and for reference purposes only

Standard Operating Procedure

Title: Assembly Finished Product Release Plan No.: SOP-QC-002

Effective: 8/02/2022 Revision 1 Page: 2 of 2

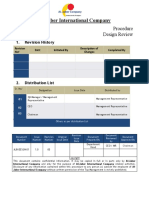

5. Revision Table

Revision Change Description Revision Date

01 Initial Release 5/31/2019

02 Rewrote the SOP to clarify the process 08/02/2022

Approval(s)

John Valence 08/02/2022

Quality Director Date

Master Document Location: http://web.goodmanmfg.com

Printed copies are uncontrolled and for reference purposes only

You might also like

- CMA FormatDocument7 pagesCMA FormatRamakrishnan NatarajanNo ratings yet

- Socialist Phenomenon - Igor ShafarevichDocument331 pagesSocialist Phenomenon - Igor ShafarevichMarkus-Heike Kreitzer100% (3)

- Sop For Destruction of Sample After Analysis.Document5 pagesSop For Destruction of Sample After Analysis.vasant ugale100% (1)

- Barr Quality ManualDocument83 pagesBarr Quality ManualMNo ratings yet

- OFF Page Submission WebsitesDocument17 pagesOFF Page Submission WebsitesAman Goyal100% (2)

- AGG-ST-052 Autokiniton Process Approval Sign-Off PPAPDocument19 pagesAGG-ST-052 Autokiniton Process Approval Sign-Off PPAPRamesh DenonNo ratings yet

- Iso CONTROL OF DOCUMENTSDocument10 pagesIso CONTROL OF DOCUMENTSMuhammad AwaisNo ratings yet

- Change Management ProcedureDocument4 pagesChange Management ProcedureQuality Unit 1 Ajay PandeyNo ratings yet

- Procedure For Management Review MeetingDocument3 pagesProcedure For Management Review MeetingQuality Unit 1 Ajay PandeyNo ratings yet

- Sop-Ad-03 - Management ReviewDocument6 pagesSop-Ad-03 - Management Reviewapi-278193171No ratings yet

- 15 (QSP-QA - 07) Process & Product AuditDocument3 pages15 (QSP-QA - 07) Process & Product AuditBASAVA ENGINEERING100% (1)

- Jovellana Proposal PDFDocument4 pagesJovellana Proposal PDFLyjie BernabeNo ratings yet

- Sop-Dc-01 - Control of DocumentDocument15 pagesSop-Dc-01 - Control of Documentapi-278193171No ratings yet

- BMR PraperationDocument9 pagesBMR PraperationwondwossengNo ratings yet

- VMPDocument15 pagesVMPshah241No ratings yet

- Design ApprovalDocument19 pagesDesign ApprovalGD(Systems)100% (2)

- Hold Time Study 1Document3 pagesHold Time Study 1aboemadaldeenNo ratings yet

- Procedure For Design ReviewDocument12 pagesProcedure For Design ReviewImtiyaz AkhtarNo ratings yet

- Sop 003 For Analysis of Rinse SampleDocument3 pagesSop 003 For Analysis of Rinse Samplevasant ugale100% (1)

- STUDY MATERIAL AccountingcomClass XIDocument144 pagesSTUDY MATERIAL AccountingcomClass XImalathi SNo ratings yet

- Strategic Planning ProcessDocument9 pagesStrategic Planning ProcessRajaNo ratings yet

- SP-1171 Specification For Quality Assurance Requirements For Product and Service - Rev2Document26 pagesSP-1171 Specification For Quality Assurance Requirements For Product and Service - Rev2shashi_nsp100% (2)

- JPEP01231B0002 Control Procedure For Department Standard DocumentDocument4 pagesJPEP01231B0002 Control Procedure For Department Standard DocumentAmeya RevOsNo ratings yet

- Quality System Manual: Uncontrolled UncontrolledDocument83 pagesQuality System Manual: Uncontrolled UncontrolledEngr Saeed AnwarNo ratings yet

- Validation Master PlanDocument27 pagesValidation Master PlanPrashansa Shrestha86% (14)

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Procedure For Management ReviewDocument8 pagesProcedure For Management Reviewndayiragije JMVNo ratings yet

- CalibrationDocument6 pagesCalibrationListen TawandaNo ratings yet

- Updated Closer IATFDocument8 pagesUpdated Closer IATFSandeep Verma100% (1)

- AC7140 Rev CDocument73 pagesAC7140 Rev CRanga100% (1)

- Mts Journal v33 q1 Jan2017Document107 pagesMts Journal v33 q1 Jan2017Bagus Deddy Andri100% (2)

- Change Order PDFDocument5 pagesChange Order PDFRonald Menacho AraujoNo ratings yet

- QP-004 Management Review ProcessDocument3 pagesQP-004 Management Review Processesraa asemNo ratings yet

- Sop-Ad-01 - Internal AuditDocument6 pagesSop-Ad-01 - Internal Auditapi-278193171No ratings yet

- FPC AsfDocument24 pagesFPC AsfSherif YehiaNo ratings yet

- Quality Control ManualDocument15 pagesQuality Control ManualJBStringerNo ratings yet

- 02 Cleaning Validation of Double Cone Blender CLV 02Document2 pages02 Cleaning Validation of Double Cone Blender CLV 02Ravi Yadav100% (2)

- 06100-FO8-Audit-Report 27001 27017 v2.0Document59 pages06100-FO8-Audit-Report 27001 27017 v2.0komal sableNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Script For UN Day NewDocument2 pagesScript For UN Day NewKaye Raner Macaya100% (6)

- PQPDocument49 pagesPQPAbhishek RajaNo ratings yet

- PR.07.00 Management of Change ProcedureDocument3 pagesPR.07.00 Management of Change ProcedureFahmi AbdullahNo ratings yet

- Qa002 07Document8 pagesQa002 07Sridhar NandipatiNo ratings yet

- C&A Final InspectionDocument13 pagesC&A Final InspectionAmirulNo ratings yet

- CBDD QAQC Manual (Rev G-2010Document18 pagesCBDD QAQC Manual (Rev G-2010lightsonsNo ratings yet

- Final Procedure QC Retroactive Added...Document11 pagesFinal Procedure QC Retroactive Added...Rehan RehmanNo ratings yet

- QIP V3 - QSB - Supplier Presentation 30 January2017Document46 pagesQIP V3 - QSB - Supplier Presentation 30 January2017Ali ZamaniNo ratings yet

- J910-DT03-P0ZEN-040005 SQCP-0104 (Risk Control) - Rev.1Document8 pagesJ910-DT03-P0ZEN-040005 SQCP-0104 (Risk Control) - Rev.1valent aviolandaNo ratings yet

- Quality Manual With Supporting ProceduresDocument58 pagesQuality Manual With Supporting ProceduresAbdisalamNo ratings yet

- QMS-01 Issue 2 Rev 0 Procedure For QMS Management ReviewDocument11 pagesQMS-01 Issue 2 Rev 0 Procedure For QMS Management ReviewbanglvhNo ratings yet

- KTB-BD-006-V01 Manage Customer SatisfactionDocument5 pagesKTB-BD-006-V01 Manage Customer Satisfactioninfo.glconsultinqNo ratings yet

- 2.PR-GM 02 Document Control ProcedureDocument8 pages2.PR-GM 02 Document Control ProcedureFULGENCE RUHARARANo ratings yet

- FLVL-QHSE-SOP-F-008 Audit Compliance ReportDocument4 pagesFLVL-QHSE-SOP-F-008 Audit Compliance ReportmanjunathaNo ratings yet

- Sop Change ManagementDocument3 pagesSop Change ManagementHanitha (Digital & Technology)No ratings yet

- Sop HR 02Document3 pagesSop HR 02nagham yahyaNo ratings yet

- 2) Change ControlDocument4 pages2) Change ControlSagar DaundNo ratings yet

- DM DCLD RD DP21 2125 IC Fly Ash As Per BS EN 450 1 R6Document9 pagesDM DCLD RD DP21 2125 IC Fly Ash As Per BS EN 450 1 R6m.basim.technitalNo ratings yet

- Requirements For Preparing and Implement 22MDZD v2 1Document10 pagesRequirements For Preparing and Implement 22MDZD v2 1MohamedNo ratings yet

- Quality Management PlanDocument14 pagesQuality Management PlanPradeep GoswamiNo ratings yet

- 02 - Procedure For MRMDocument2 pages02 - Procedure For MRMfaisal bhattyNo ratings yet

- Skyworks SystemmanualDocument31 pagesSkyworks SystemmanualColinNo ratings yet

- brcgs079 Position Statement and Protocol On Unannounced Audits Meeting The Gfsi Benchmark v3 16062022Document15 pagesbrcgs079 Position Statement and Protocol On Unannounced Audits Meeting The Gfsi Benchmark v3 16062022AsavariNo ratings yet

- SWAS Circular R EM 004 Elements of The Management System (QEHS)Document18 pagesSWAS Circular R EM 004 Elements of The Management System (QEHS)Karina OspinaNo ratings yet

- Quality Management: Team 2Document10 pagesQuality Management: Team 2Tuệ NhiNo ratings yet

- Corrective Action Plan Procedure AB-DOC-21-024.0Document6 pagesCorrective Action Plan Procedure AB-DOC-21-024.0SALES AL ABERNo ratings yet

- Management Review Procedure (Pms-P002) : 1.0 SCOPEDocument2 pagesManagement Review Procedure (Pms-P002) : 1.0 SCOPEAdhavan M AnnathuraiNo ratings yet

- 220 V2a MFMS 00203Document1 page220 V2a MFMS 00203Carlos GustavoNo ratings yet

- SITE AUDIT REPORT - ISSD - PaintingDocument2 pagesSITE AUDIT REPORT - ISSD - PaintingBALAKRISHANANNo ratings yet

- Management ReviewDocument2 pagesManagement Reviewpranesh kadamNo ratings yet

- AAH-GWS-051-Lower Door AssyDocument4 pagesAAH-GWS-051-Lower Door AssyJUAN GUZMANNo ratings yet

- AAH-GWS-126 AWST - TXV PreparationDocument11 pagesAAH-GWS-126 AWST - TXV PreparationJUAN GUZMANNo ratings yet

- AAH-GWS-040-Motor TorqueDocument5 pagesAAH-GWS-040-Motor TorqueJUAN GUZMANNo ratings yet

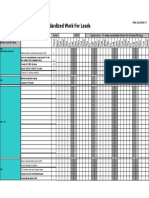

- Form AAH-004 Lead Standard WorkDocument1 pageForm AAH-004 Lead Standard WorkJUAN GUZMANNo ratings yet

- La CaseDocument18 pagesLa CaseCamille Yasmeen SamsonNo ratings yet

- Living in The Environment 17th Edition Miller Test Bank Full Chapter PDFDocument42 pagesLiving in The Environment 17th Edition Miller Test Bank Full Chapter PDFFredMurphybgzr100% (14)

- Justice and Psychic Harmony in The RepublicDocument18 pagesJustice and Psychic Harmony in The Republicsecretcandy0% (1)

- B.tech II Sem Students ListDocument29 pagesB.tech II Sem Students ListUjjWal MahAjanNo ratings yet

- Kelas Kimiawi Gugus Rumus Rumus Struktural Awalan Akhiran ContohDocument6 pagesKelas Kimiawi Gugus Rumus Rumus Struktural Awalan Akhiran ContohRizky RaditNo ratings yet

- New Trends in CSI: Presentation To Namibia CSI Conference 18-19 September 2013Document19 pagesNew Trends in CSI: Presentation To Namibia CSI Conference 18-19 September 2013Ismail FaizNo ratings yet

- Judgement DayDocument10 pagesJudgement DayPaul SavvyNo ratings yet

- Philippines Weather Forecast - FINAL - Bhs InggrisDocument3 pagesPhilippines Weather Forecast - FINAL - Bhs InggrisKhinmg SoeNo ratings yet

- TLS PSKDocument6 pagesTLS PSKGeorges karamNo ratings yet

- Events Leading To The Murder of Nisar Baloch A Shehri Activist1Document35 pagesEvents Leading To The Murder of Nisar Baloch A Shehri Activist1citizensofpakistanNo ratings yet

- Duties and ResponsibilitiesDocument7 pagesDuties and Responsibilitiesvivian apolinarioNo ratings yet

- العقوبات الواردة في قانون المرور الكويتي دراسة مقارنة مع بعض الدول العربية والأجنبيةDocument21 pagesالعقوبات الواردة في قانون المرور الكويتي دراسة مقارنة مع بعض الدول العربية والأجنبيةSamar MNo ratings yet

- Face Recognition Attendance System ThesisDocument7 pagesFace Recognition Attendance System Thesisidmwergld100% (2)

- Hyundai Essay 1Document9 pagesHyundai Essay 1taimoorawan2038No ratings yet

- Concepts of Citizenship The Meaning of CitizenshipDocument2 pagesConcepts of Citizenship The Meaning of CitizenshipBurning RoseNo ratings yet

- 01 The Changing Paradigm of ManagementDocument13 pages01 The Changing Paradigm of ManagementNurulWardhani11No ratings yet

- How I Hacked Facebook With A Word DocuemntDocument7 pagesHow I Hacked Facebook With A Word DocuemntleoblackpereiraNo ratings yet

- The Expansion and Reorganization of The Agricultural BureaucracyDocument31 pagesThe Expansion and Reorganization of The Agricultural BureaucracyJC CulisNo ratings yet

- Barangay Project Proposal 1Document5 pagesBarangay Project Proposal 1Elyka Mae LatapNo ratings yet

- The Adventures of Huckleberry Finn. Chapters 1-7Document3 pagesThe Adventures of Huckleberry Finn. Chapters 1-7ИванNo ratings yet

- Mohammed Darwis Haikal Bin JAMALUDDIN 1316257Document5 pagesMohammed Darwis Haikal Bin JAMALUDDIN 1316257Drweisz Haikal100% (1)