100% found this document useful (5 votes)

3K views4 pagesChange Management Procedure

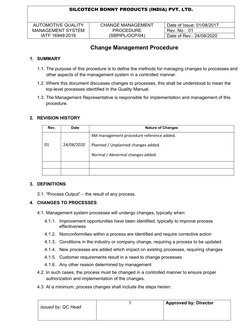

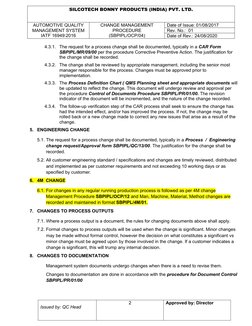

1. The procedure defines the methods for managing planned and unplanned changes to processes and documentation in a controlled manner.

2. Key steps in the change management process include documenting the request, obtaining approvals, updating documentation, and verifying the change had the intended effect.

3. The procedure addresses changes to processes, outputs, orders/contracts, documentation, as well as planned/unplanned and normal/abnormal changes. Risks from changes are recorded in the Risk Register.

Uploaded by

Quality Unit 1 Ajay PandeyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (5 votes)

3K views4 pagesChange Management Procedure

1. The procedure defines the methods for managing planned and unplanned changes to processes and documentation in a controlled manner.

2. Key steps in the change management process include documenting the request, obtaining approvals, updating documentation, and verifying the change had the intended effect.

3. The procedure addresses changes to processes, outputs, orders/contracts, documentation, as well as planned/unplanned and normal/abnormal changes. Risks from changes are recorded in the Risk Register.

Uploaded by

Quality Unit 1 Ajay PandeyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd