Professional Documents

Culture Documents

Sop For Destruction of Sample After Analysis.

Uploaded by

vasant ugaleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sop For Destruction of Sample After Analysis.

Uploaded by

vasant ugaleCopyright:

Available Formats

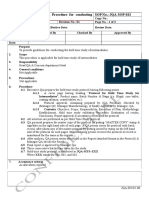

GLINT COSMETICS PVT.

LTD

Plot Nos. C-216/217/218, TTC Industrial Area, M.I.D.C.

Turbhe, Navi Mumbai -400705, Maharashtra, India.

STANDARD OPERATING PROCEDURE

QUALITY SOP No. : SOP/QC/001-01

DEPARTMENT

CONTROL Effective Date :

SOP FOR DESTRUCTION OF Review Date :

TITLE SAMPLE AFTER ANALYSIS Supersedes : SOP/QC/001-00

Page No. : 1 of 5

1. OBJECTIVE

To describe the standard operating procedure for destruction of sample after analysis.

2. SCOPE

This procedure is applicable for destruction of sample after analysis in Quality Control Department

at Glint Cosmetics Pvt. Ltd Turbhe Navi Mumbai.

3. RESPONSIBILITY

Sr. No. Activity Responsibility

1. To carry out this procedure as defined. Quality Control Department

To ensure proper and timely execution of procedure.

2. Quality Control Head

Review and Implementation of SOP

Approval of the SOP

3. Quality Assurance Head

Overall responsible for implementation.

4. ACCOUNTABILITY

Head Quality Control

5. ABBREVIATIONS & DEFINITIONS

5.1 Abbreviations

SOP - Standard Operating Procedure

QA - Quality Assurance

e.g. - Example

cGMP - Current Good Manufacturing Practices

NA - Not Applicable

QC - Quality Control

Prepared By Reviewed By Approved By

Sign & Date

Designation& Department

Format No.: SOP/QA/001-02/F01

GLINT COSMETICS PVT. LTD

Plot Nos. C-216/217/218, TTC Industrial Area, M.I.D.C.

Turbhe, Navi Mumbai -400705, Maharashtra, India.

STANDARD OPERATING PROCEDURE

QUALITY SOP No. : SOP/QC/001-01

DEPARTMENT

CONTROL Effective Date :

SOP FOR DESTRUCTION OF Review Date :

TITLE SAMPLE AFTER ANALYSIS Supersedes : SOP/QC/001-00

Page No. : 2 of 5

5.2 Definition

5.2.1 Specification: A specification often refers to a set of documented requirements to be satisfied by a

material, design, product, or service.

5.2.2 cGMP: current Good Manufacturing Practices is defined as that part of quality assurance which

ensures that products are consistently produced and controlled to the quality standards appropriate to

their intended use and as required by the marketing authorization.

5.2.3 Owner: The author is the owner of the SOP. He / She is responsible for accuracy / correctness of SOP.

5.2.4 Approval: Written sanction or delegated power of opinion because of recognized Knowledge,

expertise and hierarchical authority. This is the act of bringing the SOP in force.

6. MATERIALS & EQUIPMENT

6.1 Materials

NA

6.2 Equipment

NA

7. PROCEDURE

7.1 Raw material

7.1.1 Analyst himself shall deface the identification label of left over quantity of sample bags and glass

containers with a permanent ink marker and transfer the same to a separate tray labeled as "Samples

for destruction" kept in wash area.

7.1.2 Wear a facemask, safety-goggles and surgical hand gloves.

7.1.3 Peel off labels and discard in a dustbin.

7.1.4 Segregate the sample containers as per the type of material.

7.1.5 Open the bottles containing liquid samples and collect the contents in bin. Add plenty of water, and

drain the contents in the wash basin and flush with plenty of water.

Prepared By Reviewed By Approved By

Sign & Date

Designation& Department

Format No.: SOP/QA/001-02/F01

GLINT COSMETICS PVT. LTD

Plot Nos. C-216/217/218, TTC Industrial Area, M.I.D.C.

Turbhe, Navi Mumbai -400705, Maharashtra, India.

STANDARD OPERATING PROCEDURE

QUALITY SOP No. : SOP/QC/001-01

DEPARTMENT

CONTROL Effective Date :

SOP FOR DESTRUCTION OF Review Date :

TITLE SAMPLE AFTER ANALYSIS Supersedes : SOP/QC/001-00

Page No. : 3 of 5

7.1.6 Send the glass bottles for crushing in scrap yard.

7.1.7 Open the bags containing solid samples and slowly pour the contents in a bin half filled with tap water.

7.1.8 Stir the mixture with a stirrer until all the contents of the bin are dispersed.

7.1.9 Follow the same procedure for all the remaining containers.

7.1.10 Drain the contents of the bin into the wash basin and flush with plenty of water. Wash the bin with

water and drain the water into the wash basin.

7.1.11 Send the plastic bags to a scrap yard for shredding.

7.2 Packaging material

7.2.1 Analyst himself shall transfer the left over quantity of sample to a separate tray labeled as "Samples

for destruction" kept in packaging material testing area.

7.2.2 Segregate and destroy the contents of the tray as per table given bellow.

Material Destruction procedure

Printed packaging material like

Tear off manually into four pieces and discard in dustbin.

labels,

Glass vials / bottles Send to scrap yard and crush using a crushing machine.

Cut the plugs using scissors into two pieces and send to scrap

rubber plugs

yard for shredding.

Deface printed matter with black ink marker. Cut shipper into 3-4

Shippers/ Bottles

pieces, and send to scrap yard for shredding.

Caps Crush to deform shape and send to scrap yard for disposal.

Aluminum seals Crush to deform shape and send to scrap yard for disposal.

7.3 Intermediates, semi-finished products and finished product

7.3.1 Analyst himself shall deface the identification label of left over quantity of sample bags and glass

containers with a permanent ink marker and transfer to a separate tray labeled as "Samples for

Prepared By Reviewed By Approved By

Sign & Date

Designation& Department

Format No.: SOP/QA/001-02/F01

GLINT COSMETICS PVT. LTD

Plot Nos. C-216/217/218, TTC Industrial Area, M.I.D.C.

Turbhe, Navi Mumbai -400705, Maharashtra, India.

STANDARD OPERATING PROCEDURE

QUALITY SOP No. : SOP/QC/001-01

DEPARTMENT

CONTROL Effective Date :

SOP FOR DESTRUCTION OF Review Date :

TITLE SAMPLE AFTER ANALYSIS Supersedes : SOP/QC/001-00

Page No. : 4 of 5

destruction" kept in wash area.

7.3.2 Wear a facemask, safety-goggles and surgical hand gloves.

7.3.3 Peel off labels and discard in a dustbin.

7.3.4 In case of powders open the containers and slowly pour the contents in a bin half filled with tap water.

7.3.5 Stir the mixture with a stirrer until all the contents of the bin are dispersed.

7.3.6 Drain the contents of the bin into the wash basin and flush with plenty of water wash the bin with

water and drain the water into the wash basin.

7.3.7 Send the plastic bags to scrap yard for shredding.

7.3.8 Soak glass bottles in bin containing soap solution.

7.3.9 Remove the labels of the glass bottles.

7.3.10 Send the glass bottles for crushing in scrap yard.

8. REFERENCE

NA

9. ANNEXURE/FORMAT

9.1 Quantity of control sample withdrawn Format No SOP/QC/001/F01

9.2 Control sample storage log book Format No SOP/QC/001/F02

9.3 Control sample destruction record Format No SOP/QC/001/F03

9.4 Control sample retrieval record Format No SOP/QC/001/F04

9.5 Control sample physical verification Format No SOP/QC/001/F05

9.6 Expired sample record Format No SOP/QC/001/F06

Prepared By Reviewed By Approved By

Sign & Date

Designation& Department

Format No.: SOP/QA/001-02/F01

GLINT COSMETICS PVT. LTD

Plot Nos. C-216/217/218, TTC Industrial Area, M.I.D.C.

Turbhe, Navi Mumbai -400705, Maharashtra, India.

STANDARD OPERATING PROCEDURE

QUALITY SOP No. : SOP/QC/001-01

DEPARTMENT

CONTROL Effective Date :

SOP FOR DESTRUCTION OF Review Date :

TITLE SAMPLE AFTER ANALYSIS Supersedes : SOP/QC/001-00

Page No. : 5 of 5

10. REVISION HISTORY

Effective Date of

Sr. Change Control

superseded Superseded No. Description of change

No No

document

1. SOP/QC/001-01 00 SOP revised

Prepared By Reviewed By Approved By

Sign & Date

Designation& Department

Format No.: SOP/QA/001-02/F01

You might also like

- SOP - QA-007 SOP For Out of Specification (OOS) For Pharmaceutical ResultsDocument5 pagesSOP - QA-007 SOP For Out of Specification (OOS) For Pharmaceutical Resultsد.عمر خليل العباسي100% (2)

- 023-SOP For Conducting Hold Time StudyDocument3 pages023-SOP For Conducting Hold Time StudyAshok Lenka100% (2)

- Sop 003 For Analysis of Rinse SampleDocument3 pagesSop 003 For Analysis of Rinse Samplevasant ugale100% (1)

- 32 Prepare FP Specification 032Document2 pages32 Prepare FP Specification 032ASHOK KUMAR LENKANo ratings yet

- Cleaning of Sampling BoothDocument4 pagesCleaning of Sampling Boothasit_m100% (3)

- Sop For Analytical Method Validqation and VerificationDocument7 pagesSop For Analytical Method Validqation and Verificationvasant ugale100% (3)

- Batch Release (VHS QA 027 R0)Document8 pagesBatch Release (VHS QA 027 R0)Ajay patel Patel100% (1)

- BMR PraperationDocument9 pagesBMR PraperationwondwossengNo ratings yet

- SOP For Handling of Out of Specification Results in Microbiological Testing - Pharmaceutical GuidelinesDocument4 pagesSOP For Handling of Out of Specification Results in Microbiological Testing - Pharmaceutical Guidelinesalnzeer omerNo ratings yet

- Aphrin Pfs BPR p1 v-1Document13 pagesAphrin Pfs BPR p1 v-1ShagorShagorNo ratings yet

- Acceptance & Rejection Criteria Procedure (21!03!15) UpdatedDocument4 pagesAcceptance & Rejection Criteria Procedure (21!03!15) UpdatedMohamedNo ratings yet

- Sop-Qa-038-00-Stability StudiesDocument22 pagesSop-Qa-038-00-Stability Studiesnareshph28No ratings yet

- Hold Time Study 1Document3 pagesHold Time Study 1aboemadaldeenNo ratings yet

- Ezetimibe VPGQC14061 00 YaDocument16 pagesEzetimibe VPGQC14061 00 YaDany RockNo ratings yet

- Out of Specifications IIDocument39 pagesOut of Specifications IIHaekal Ramadhan100% (1)

- SOP On TrainingDocument6 pagesSOP On TrainingarunNo ratings yet

- Raw Material Requisition Slip - For MergeDocument1 pageRaw Material Requisition Slip - For Mergeasit_mNo ratings yet

- SOP of Stability Study - 1Document5 pagesSOP of Stability Study - 1YousifNo ratings yet

- Clean RoomDocument19 pagesClean Roomhouas menasriaNo ratings yet

- Annual Product Quality Review APQR FormatDocument9 pagesAnnual Product Quality Review APQR FormatDr.Sivakumar Selvaraj100% (1)

- Process Validation Interim / Final Report: (Enter Product Title, Number & Strength) Product CodeDocument4 pagesProcess Validation Interim / Final Report: (Enter Product Title, Number & Strength) Product CodevanessaNo ratings yet

- Product Quality Review or Annual Product Review-1Document6 pagesProduct Quality Review or Annual Product Review-1nataarajan praveen100% (1)

- Stability Study Guidance ProtocolDocument10 pagesStability Study Guidance ProtocolManish shankarpure100% (1)

- SOP For Analyst ValidationDocument5 pagesSOP For Analyst ValidationGencay Ergin100% (1)

- Standard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisDocument11 pagesStandard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisAbuNo ratings yet

- Temperature Mapping Protocol: Lincoln Parenteral LTDDocument7 pagesTemperature Mapping Protocol: Lincoln Parenteral LTDRajender SinghNo ratings yet

- Temperature Mapping For FG StoreDocument19 pagesTemperature Mapping For FG Storemehrdarou.qaNo ratings yet

- Title: Cleaning Validation Report For - ToDocument41 pagesTitle: Cleaning Validation Report For - TocpkakopeNo ratings yet

- Pharmaceutical Master Validation Plan The Syed Imtiaz 57743816Document3 pagesPharmaceutical Master Validation Plan The Syed Imtiaz 57743816Dandung RuskarNo ratings yet

- CV Protocol-Coated TabletsDocument22 pagesCV Protocol-Coated Tabletsqaheadjml007No ratings yet

- Cleaning ValidationDocument17 pagesCleaning ValidationMollidain SandeepNo ratings yet

- 9 C Validation Protocol TABLETDocument20 pages9 C Validation Protocol TABLETMohammed ZubairNo ratings yet

- Prosses Validation Protocol For Albendazole SuspensionDocument25 pagesProsses Validation Protocol For Albendazole Suspensionمحمد عطاNo ratings yet

- SOP of Glassware HandlingDocument1 pageSOP of Glassware HandlingPrince Moni100% (2)

- Hold Time Study ProtocolDocument9 pagesHold Time Study ProtocolMubarak Patel100% (1)

- 02 LC of Double Cone Blender 02Document2 pages02 LC of Double Cone Blender 02Ravi YadavNo ratings yet

- RM-Method Validation ProtocolDocument12 pagesRM-Method Validation ProtocolShagorShagorNo ratings yet

- Dispensing of Raw Materials Version 02 (GMF 095)Document4 pagesDispensing of Raw Materials Version 02 (GMF 095)ShagorShagor100% (1)

- VAL-115 Process Validation For Liquid and Solid Dosage Manufacturing SampleDocument3 pagesVAL-115 Process Validation For Liquid and Solid Dosage Manufacturing SampleMarwa Ahmed100% (2)

- Qad Sop 129Document4 pagesQad Sop 129Hemendra DaveNo ratings yet

- Quality AssuranceDocument3 pagesQuality AssuranceDevanshi JadaunNo ratings yet

- SOP For Microbiological Good Laboratory PracticesDocument10 pagesSOP For Microbiological Good Laboratory PracticesknbiolabsNo ratings yet

- Process Validation Protocol (500 MG Tablet)Document6 pagesProcess Validation Protocol (500 MG Tablet)Mohammed Zubair100% (1)

- Analytical Report For Ketofast 10 TabletDocument20 pagesAnalytical Report For Ketofast 10 TabletShagorShagorNo ratings yet

- Ezetimide AMTP G13 012Document8 pagesEzetimide AMTP G13 012Dany RockNo ratings yet

- Out of SpecificationDocument7 pagesOut of SpecificationMichelle Morgan LongstrethNo ratings yet

- Hold Time Study SOP Indian Pharma 1Document3 pagesHold Time Study SOP Indian Pharma 1ziadddNo ratings yet

- Aphrin 500 MG Capsule BPR 1Document12 pagesAphrin 500 MG Capsule BPR 1ShagorShagor100% (1)

- Cleaning Validation Protocol TEMPLATEDocument9 pagesCleaning Validation Protocol TEMPLATEnatavceNo ratings yet

- Protocol Jacketed MFG Tank LV02Document7 pagesProtocol Jacketed MFG Tank LV02pooja aswal100% (3)

- List of SOP's Template 28.12.2017Document84 pagesList of SOP's Template 28.12.2017kalaiarasi ravichandranNo ratings yet

- BMR SuspensionsDocument16 pagesBMR SuspensionsMohammed Zubair0% (1)

- Department: M.R. & Quality Control Document Title: Control of Non-Conforming ProductDocument3 pagesDepartment: M.R. & Quality Control Document Title: Control of Non-Conforming ProductJamil VoraNo ratings yet

- SOP of Stability Study - 2Document3 pagesSOP of Stability Study - 2YousifNo ratings yet

- UntitledDocument9 pagesUntitledJinna SmaNo ratings yet

- Out of Specification (OOS) and Out of Trend (OOT) Analysis in Pharmaceutical Manufacturing Investigations (MIR) : A OverviewDocument9 pagesOut of Specification (OOS) and Out of Trend (OOT) Analysis in Pharmaceutical Manufacturing Investigations (MIR) : A OverviewDHiana100% (2)

- Labaid Pharmaceuticals Limited: Standard Operating ProcedureDocument8 pagesLabaid Pharmaceuticals Limited: Standard Operating ProceduremasumNo ratings yet

- SN-QC-SOP-042 SoP For Cleaning & Sanitization of Pharmaceutical FacilityDocument14 pagesSN-QC-SOP-042 SoP For Cleaning & Sanitization of Pharmaceutical Facilitydaizhussain004100% (1)

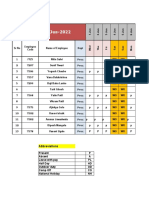

- 0083 006 06 Monthly Attendance June 22finalDocument4 pages0083 006 06 Monthly Attendance June 22finalvasant ugaleNo ratings yet

- 21201-9200-0003-Process-URS Review Tracking Sheet - 08.06.2022Document1 page21201-9200-0003-Process-URS Review Tracking Sheet - 08.06.2022vasant ugaleNo ratings yet

- EPCE Approval Table:: Template No.14800-0003-0904-Ver-2 (ISO: Excel-External-0003-Ver-2)Document2 pagesEPCE Approval Table:: Template No.14800-0003-0904-Ver-2 (ISO: Excel-External-0003-Ver-2)vasant ugaleNo ratings yet

- Glimpses On Compressed Air System Validation TestDocument8 pagesGlimpses On Compressed Air System Validation Testvasant ugaleNo ratings yet

- HDFC Bank LTD Repayment Schedule: Date: 04/07/2022Document5 pagesHDFC Bank LTD Repayment Schedule: Date: 04/07/2022vasant ugaleNo ratings yet

- Annexure-F Instruments URS 2Document187 pagesAnnexure-F Instruments URS 2vasant ugaleNo ratings yet

- Technical Data Sheet: Thermo Scientific General Purpose Freezer/RefrigeratorDocument1 pageTechnical Data Sheet: Thermo Scientific General Purpose Freezer/Refrigeratorvasant ugaleNo ratings yet

- ' Bayer Pharmaceuticals Application FomsDocument3 pages' Bayer Pharmaceuticals Application Fomsvasant ugaleNo ratings yet

- 20177-1001-0501 - Process Work Hr. Estimation-Ver-1Document4 pages20177-1001-0501 - Process Work Hr. Estimation-Ver-1vasant ugaleNo ratings yet

- Sop For Analytical Method Validqation and VerificationDocument7 pagesSop For Analytical Method Validqation and Verificationvasant ugale100% (3)

- QRM Decontamination Autoclave FinalDocument23 pagesQRM Decontamination Autoclave Finalvasant ugaleNo ratings yet

- Analyst Qualification (Modified)Document6 pagesAnalyst Qualification (Modified)vasant ugale75% (4)

- Rolleri Bending CatalogueDocument155 pagesRolleri Bending CatalogueМУДРЫЙКИЛЛЕРNo ratings yet

- Quiz 4 SOLDocument2 pagesQuiz 4 SOLimagineimfNo ratings yet

- Standard Purchasing Specification: Commodities That May Be SpecifiedDocument2 pagesStandard Purchasing Specification: Commodities That May Be SpecifiedJha SàñkátNo ratings yet

- Request For Certificate of Involuntary Separation For SSS (Responses) For 01 June 2022Document82 pagesRequest For Certificate of Involuntary Separation For SSS (Responses) For 01 June 2022blue militiaNo ratings yet

- DL Group ProfileDocument16 pagesDL Group Profilemichael wambuaNo ratings yet

- Korindo ADocument8 pagesKorindo ATeuku Muhammad Iqbal AnwarNo ratings yet

- Company Stats Aus, NZ, CanDocument255 pagesCompany Stats Aus, NZ, Cansourabh6chakrabort-1No ratings yet

- Agmark Report On Madep Staff Trip To Kenya April 2013Document23 pagesAgmark Report On Madep Staff Trip To Kenya April 2013mustafa chirwaNo ratings yet

- Agri-Tourism Baby ThesisDocument1 pageAgri-Tourism Baby ThesisArjee Louie Jimenez83% (12)

- Supplementary Form For Business Names Failure To Re RegisterDocument3 pagesSupplementary Form For Business Names Failure To Re RegisterAtisang Tonny SethNo ratings yet

- BSSE 3rd SemesterDocument42 pagesBSSE 3rd SemesterAhtishamNo ratings yet

- 1 Gem RLB PDFDocument23 pages1 Gem RLB PDFp v mahawanaNo ratings yet

- Analysis of Consumer Behavior, Satisfaction & Competitive StrategyDocument35 pagesAnalysis of Consumer Behavior, Satisfaction & Competitive StrategyAbhijeet GodseNo ratings yet

- TQM Implementation in ToyotaDocument15 pagesTQM Implementation in ToyotaSaikat GhoshNo ratings yet

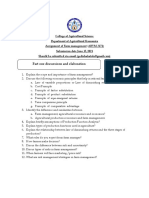

- Farm Management AssignmentDocument3 pagesFarm Management Assignmentgedisha katola100% (1)

- BNP Paribas Oil and Gas" Sector PolicyDocument12 pagesBNP Paribas Oil and Gas" Sector PolicyComunicarSe-ArchivoNo ratings yet

- Foreignalpha 2014Document21 pagesForeignalpha 2014Palash KukwasNo ratings yet

- History of The Municip Ality of Mapand AnDocument14 pagesHistory of The Municip Ality of Mapand AnCatalina G. SerapionNo ratings yet

- Farm Audit Checklist-BasilDocument6 pagesFarm Audit Checklist-BasilPeachyNo ratings yet

- Daily ReportDocument3 pagesDaily ReportJoseph AbousafiNo ratings yet

- Draft of Local Ordinance in The CommunityDocument4 pagesDraft of Local Ordinance in The Communityjaanice iwaizumiNo ratings yet

- Most Essential Learning Competencies (Melcs) : Pecial Urricular RogramsDocument16 pagesMost Essential Learning Competencies (Melcs) : Pecial Urricular RogramsLeon AipTel100% (2)

- SMPFC SEC Form 17-A (Annual Report For The Year 2017 Filed With SEC On April 13, 2018) PDFDocument215 pagesSMPFC SEC Form 17-A (Annual Report For The Year 2017 Filed With SEC On April 13, 2018) PDFFelicity FuentesNo ratings yet

- Arcor - Sustainability Report 2015Document153 pagesArcor - Sustainability Report 2015José Muñoz0% (1)

- Guideline For IT Vendor Management ProcedureDocument4 pagesGuideline For IT Vendor Management Procedureinez shitaNo ratings yet

- Coimbatore Millet Tiruvila With Past ImageDocument5 pagesCoimbatore Millet Tiruvila With Past ImageAnu V PillaiNo ratings yet

- Introduction To Managerial Accounting Canadian 5th Edition Brewer Solutions ManualDocument25 pagesIntroduction To Managerial Accounting Canadian 5th Edition Brewer Solutions ManualMaryJohnsonsmni100% (59)

- Confirmation of Purchase of Insurance: (Including Premium For Extra Coverage Whenever Is Applicable, SST and Stamp Duty)Document11 pagesConfirmation of Purchase of Insurance: (Including Premium For Extra Coverage Whenever Is Applicable, SST and Stamp Duty)habibahkadim00No ratings yet

- HIMC Co., Ltd. Catalog enDocument12 pagesHIMC Co., Ltd. Catalog endenny saputraNo ratings yet

- Cesar Chavez: His Fight For The Farm WorkersDocument4 pagesCesar Chavez: His Fight For The Farm WorkersTSUNAMISETNo ratings yet