Professional Documents

Culture Documents

SBRS-3XG

Uploaded by

VICTOR FQOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SBRS-3XG

Uploaded by

VICTOR FQCopyright:

Available Formats

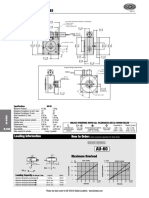

SBRS-(3X)G Dual Wall WOER Tube

Dimensions

Size Expanded After Recovery Standard Package

Internal Internal Total Wall Adhesive Spool Length

Inch Diameter Diameter Thickness Thickness M/spool

mm mm mm mm

SBRS-(3X)G 3/32

1/8

3/16

2.4

3.2

4.8

2,4

3,2

4,8

0.8

1.0

1.6

0.85±0.15

0.95±0.15

1.10±0.15

0.40±0.10

0.40±0.10

0.40±0.10

200

200

100

Dual Wall Adhesive-Lined Heat-Shrink Polyolefin Tubing 1/4 6.4 6,4 2.2 1.20±0.15 0.45±0.12 100

5/16 7.9 7,9 2.7 1.35±0.15 0.50±0.12 100

3/8 9.5 9,5 3.2 1.45±0.20 0.50±0.12 50

1/ 2 12.7 12,7 4.2 1.70±0.20 0.50±0.12 1.22 OR 25M/Roll

5/8 15 15 5.2 1.80±0.20 0.55±0.15 1.22 OR 25M/Roll

Adhesive lined heat shrink tubing with environmental sealing capability for 3/4 19.1 19,1 6.3 2.00±0.20 0.55±0.15 1.22 OR 25M/Roll

1 25.4 25,4 8.5 2.10±0.25 0.55±0.15 1.22 OR 25M/Roll

a wide variety of electrical applications, including automotive and marine 1-1/4 30 30 10.2 2.20±0.25 0.60±0.15 1.22 OR 25M/Roll

1-1/2 39 39 13.5 2.40±0.25 0.60±0.15 1.22 OR 25M/Roll

wire harness, wire splices, breakouts, and connector-to-cable transitions. 2 50 50 17 2.70±0.25 0.70±0.15 1.22 OR 25M/Roll

5/2 64 64 21 3.00±0.30 0.70±0.15 1.22 OR 25M/Roll

3 75 75 25 3.00±0.30 1.00±0.20 1.22 OR 25M/Roll

7/2 90 90 30 3.00±0.30 1.00±0.20 1.22 OR 25M/Roll

3:1 4

5

100

125

100

125

34

42

3.00±0.30

3.00±0.30

1.00±0.20

1.00±0.20

1.22 OR 25M/Roll

1.22 OR 25M/Roll

Features

● 3:1 shrink ratio

● Low longitudinal shrinkage

● Flame retardant (out jacket only)

Technical Data

● Super sealing against water, moisture or other contaminates Property Test Method Stantard

● Continuous operating temperature:-45℃-125℃ Tensile Strengtn(MPa) ASTM D2671 ≥10.4

Elongation(%) ASTM D2671 ≥300

● Shrink Temperature:125℃ Tensile Strengtn after aging (MPa) UL224 158℃X168hr ≥7.3

Elongation after aging(%) UL224 158℃X168hr ≥200

Flammability ASTM D2671B Self-extinguish within 30s

Dieletric strength(kv/mm) IEC243 ≥15

14

Volume resistivity(Ω.cm) ASTM D876 ≥1X10

Hot Melt Adhesive Property

Property Test Method Stantard

Water Absorption ASTM D570 <0.5%

Sofening Point(℃) ASTM E28 90±5

Strength of pearing(PE) ASTM D 1000 80N/25mm

Strength of pearing(AL) ASTM D 1000 120N/25mm

A03 Product Catalogue www.woer.com A04

You might also like

- Tir A9 14 PDFDocument99 pagesTir A9 14 PDFGino Tironi100% (7)

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Codes and StandardsDocument1 pageCodes and StandardsSuresh MechNo ratings yet

- Counterfort Retaing Wall of 6 M Height Design & CostDocument20 pagesCounterfort Retaing Wall of 6 M Height Design & CostDavid CruzaleguiNo ratings yet

- Sill Plate/Nailer Connection Design Based On NDS 2018Document18 pagesSill Plate/Nailer Connection Design Based On NDS 2018NameNo ratings yet

- Hardness Experiment ReportDocument15 pagesHardness Experiment ReportsinabirecikNo ratings yet

- ICorr CED CT06 ApplicationOfIntumescentCoatings Issue1 PDFDocument17 pagesICorr CED CT06 ApplicationOfIntumescentCoatings Issue1 PDFJoe Gaffney100% (1)

- r134 - r22-r404A-R290 (Diagramas de Molier 1)Document4 pagesr134 - r22-r404A-R290 (Diagramas de Molier 1)Miguel Carlin Jimenez100% (2)

- Applied Time Series Econometrics: A Practical Guide for Macroeconomic Researchers with a Focus on AfricaFrom EverandApplied Time Series Econometrics: A Practical Guide for Macroeconomic Researchers with a Focus on AfricaRating: 3 out of 5 stars3/5 (1)

- Rubble-Mound BreakwaterDocument1 pageRubble-Mound BreakwaterlocasNo ratings yet

- Din 1623-05Document11 pagesDin 1623-05dietersimaNo ratings yet

- Flexible Adhesive-Lined Heat-Shrink TubingDocument1 pageFlexible Adhesive-Lined Heat-Shrink TubingVICTOR FQNo ratings yet

- Ground Floor Plan: - Raymund S. DullaDocument1 pageGround Floor Plan: - Raymund S. DullaRaymund DullaNo ratings yet

- WithOutliersHistograms PDFDocument1 pageWithOutliersHistograms PDFRobert PapakNo ratings yet

- AccesoDocument1 pageAccesoMal isaNo ratings yet

- Univariate HistogramsDocument1 pageUnivariate HistogramsRobert PapakNo ratings yet

- Plano Pedro Ojeda MiradorDocument1 pagePlano Pedro Ojeda MiradorcesarNo ratings yet

- โครงสร้างหลังคาDocument13 pagesโครงสร้างหลังคาsarafan leewanNo ratings yet

- Levantamiento HÁBITAT (1) - ModelDocument1 pageLevantamiento HÁBITAT (1) - ModelAna Paula HNo ratings yet

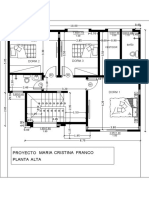

- Planta AltaDocument1 pagePlanta AltaJesus DiazNo ratings yet

- Metode de Cercetare: - Curs 4Document22 pagesMetode de Cercetare: - Curs 4Nicoleta Eugenia BursucNo ratings yet

- SBRSMDocument1 pageSBRSMVICTOR FQNo ratings yet

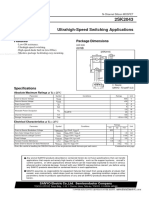

- The Tolerance Unless Classified 0.3mm: Outline Dimension & Block DiagramDocument1 pageThe Tolerance Unless Classified 0.3mm: Outline Dimension & Block DiagramadilNo ratings yet

- Low-Frequency Amplifier Applications: Package Dimensions FeaturesDocument4 pagesLow-Frequency Amplifier Applications: Package Dimensions FeaturesautreraNo ratings yet

- Heat Shrinkable TubingDocument1 pageHeat Shrinkable TubingAlex RamirezNo ratings yet

- Arquitectura PlanoDocument1 pageArquitectura PlanoRoy CorderoNo ratings yet

- Layout Genset SecondaryDocument1 pageLayout Genset SecondarySri RahayuNo ratings yet

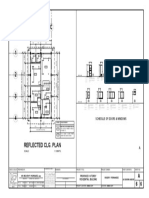

- Schedule of Doors & Windows: Scale: 1:130MTSDocument1 pageSchedule of Doors & Windows: Scale: 1:130MTSAngelico EkleoNo ratings yet

- CONDOMINIO MendezlDocument1 pageCONDOMINIO MendezlCanaviri Samuel ElianNo ratings yet

- Psychrometric ChartDocument1 pagePsychrometric ChartbariscNo ratings yet

- PVC Schedule 80 12 3Document1 pagePVC Schedule 80 12 3Viet DangNo ratings yet

- Document data table with column labelsDocument1 pageDocument data table with column labelsShare workNo ratings yet

- AU-60 Emergency Stop Modules: How To Order: Loading InformationDocument5 pagesAU-60 Emergency Stop Modules: How To Order: Loading InformationBe HappyNo ratings yet

- Grosor LineasDocument1 pageGrosor Lineasbrenda oocchiuzzoNo ratings yet

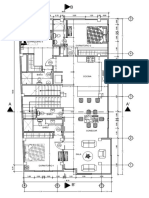

- Floor plan design with room dimensions and labelsDocument1 pageFloor plan design with room dimensions and labelsFariz KoboiNo ratings yet

- Polibio DepartamentosDocument1 pagePolibio Departamentoscarlos romeroNo ratings yet

- Basement Plan: Proposed Two (2) - Storey Commercial Building With RoofdeckDocument1 pageBasement Plan: Proposed Two (2) - Storey Commercial Building With Roofdeckdante mortelNo ratings yet

- Tarea 2.informe de La Primera Inspección Ocular de La EdificaciónDocument3 pagesTarea 2.informe de La Primera Inspección Ocular de La EdificaciónDaniel OrtegaNo ratings yet

- Rangamati Boundary Wall LayoutDocument1 pageRangamati Boundary Wall LayoutMirajul AnwarNo ratings yet

- Ultrahigh-Definition Color Display Horizontal Deflection Output ApplicationsDocument4 pagesUltrahigh-Definition Color Display Horizontal Deflection Output ApplicationsManuel MartinezNo ratings yet

- Plano Arquitectonico Zapatas VIV Multifamiliar EebrDocument1 pagePlano Arquitectonico Zapatas VIV Multifamiliar EebrNorman BrancoNo ratings yet

- PADocument1 pagePAmispadres2022No ratings yet

- Duplex09 PBDocument1 pageDuplex09 PBDenice LópezNo ratings yet

- Analysis of numerical data patternsDocument1 pageAnalysis of numerical data patternsyousriNo ratings yet

- RoomDocument1 pageRoomtalisman chiefNo ratings yet

- Plano Casa 8x12 1p 3d 3b Verplanos - Com 004Document1 pagePlano Casa 8x12 1p 3d 3b Verplanos - Com 004Miguel AlfaroNo ratings yet

- Rafter 02 Detail Steel Girts Detail: Fin. Second Floor LineDocument1 pageRafter 02 Detail Steel Girts Detail: Fin. Second Floor LineLab Dema-alaNo ratings yet

- BasuraDocument1 pageBasuraAndres seisNo ratings yet

- Enterprise Logo and Building PlansDocument1 pageEnterprise Logo and Building PlansIne Martiana RastutiNo ratings yet

- Schedule of Doors and Windows: Engr. Allen Robert M. WaganDocument1 pageSchedule of Doors and Windows: Engr. Allen Robert M. WaganAllen Robert WaganNo ratings yet

- Detailed technical drawing dimensionsDocument1 pageDetailed technical drawing dimensionsWilson Boñón ChávezNo ratings yet

- Trabajo de Ind - CivilDocument1 pageTrabajo de Ind - Civilrenzo figueroa salasNo ratings yet

- Atap Spandek T=0.30mm Rencana StrukturDocument9 pagesAtap Spandek T=0.30mm Rencana Strukturputra wiraNo ratings yet

- Architectural floor plan measurementsDocument1 pageArchitectural floor plan measurementscarlos romeroNo ratings yet

- Universidad Nacional Federico Villarreal: Mercado Vecinal MódulosDocument1 pageUniversidad Nacional Federico Villarreal: Mercado Vecinal MóduloscesarNo ratings yet

- 02 PlanDocument1 page02 PlanIllya IchaouNo ratings yet

- Renovation Sheets-Layout1Document1 pageRenovation Sheets-Layout1Ichaou Illya haladou danjaNo ratings yet

- Garden Design PlansDocument1 pageGarden Design PlansIllya IchaouNo ratings yet

- Paucarcolla 4Document1 pagePaucarcolla 4wendyNo ratings yet

- Intergrowth21 Newborn Size Reference Charts (Girls)Document2 pagesIntergrowth21 Newborn Size Reference Charts (Girls)Anonymous MWd5UOUuiyNo ratings yet

- 100m2 PDFDocument1 page100m2 PDFHv ScNo ratings yet

- Alan Copa Unidad Habitacional 3Document1 pageAlan Copa Unidad Habitacional 3Mamani Copa Alan AlejandroNo ratings yet

- Alan Copa Unidad Habitacional 3Document1 pageAlan Copa Unidad Habitacional 3Mamani Copa Alan AlejandroNo ratings yet

- Footing Plan Option 02Document1 pageFooting Plan Option 02vinodNo ratings yet

- K2043 SanyoSemiconductorCorporationDocument4 pagesK2043 SanyoSemiconductorCorporationPedro AntonioNo ratings yet

- Grados: Rad Ia Ne SDocument4 pagesGrados: Rad Ia Ne SJean Pierre AHNo ratings yet

- Data Sheet 3RT2025-2BB44Document12 pagesData Sheet 3RT2025-2BB44VICTOR FQNo ratings yet

- Sbrs-CapsDocument1 pageSbrs-CapsVICTOR FQNo ratings yet

- SBRS-DZDocument1 pageSBRS-DZAlejandro FonsecaNo ratings yet

- SBRS-3X, 4XGFDocument1 pageSBRS-3X, 4XGFVICTOR FQNo ratings yet

- RSFR HDocument1 pageRSFR HVICTOR FQNo ratings yet

- SBRSMDocument1 pageSBRSMVICTOR FQNo ratings yet

- Conexiones Exotérmicas Nvent Erico CadweldDocument2 pagesConexiones Exotérmicas Nvent Erico CadweldVICTOR FQNo ratings yet

- Conexiones Exotérmicas Nvent Erico CadweldDocument2 pagesConexiones Exotérmicas Nvent Erico CadweldVICTOR FQNo ratings yet

- Chemical Purification Methods ListDocument8 pagesChemical Purification Methods ListMd.Mehdi MasudNo ratings yet

- ISO 3834 5 Ver EDocument10 pagesISO 3834 5 Ver ESrinivasa RaghavanNo ratings yet

- PIPES FITTINGS, VALVES AND PUMPS (SCHMIDTDocument16 pagesPIPES FITTINGS, VALVES AND PUMPS (SCHMIDTMoca PhoenixNo ratings yet

- ChemicalDocument232 pagesChemicalhendra93No ratings yet

- Determination of Coefficient of Linear Expansion of A Metal RodDocument5 pagesDetermination of Coefficient of Linear Expansion of A Metal RodJustas Petrauskas50% (2)

- Butt 2000Document100 pagesButt 2000kasra7No ratings yet

- Junction Diode Characteristics ReviewDocument55 pagesJunction Diode Characteristics ReviewSanthosh DheerajNo ratings yet

- Biodiesel Synthesis Mass and Cost AnalysisDocument3 pagesBiodiesel Synthesis Mass and Cost AnalysisJasmine YiuNo ratings yet

- Introduction and Basic Concepts: Heat and Mass Transfer: Fundamentals & ApplicationsDocument34 pagesIntroduction and Basic Concepts: Heat and Mass Transfer: Fundamentals & ApplicationsNaveen KumarNo ratings yet

- Pearl-Shaped Precision NTC Thermistor For Temperature MeasurementDocument4 pagesPearl-Shaped Precision NTC Thermistor For Temperature MeasurementRodrigoNo ratings yet

- Orca Share Media1554262372568Document8 pagesOrca Share Media1554262372568Ivy Mendoza PagcaliwanganNo ratings yet

- Biogas - Instructables Methane For BiogasDocument19 pagesBiogas - Instructables Methane For Biogaslouis adonis silvestreNo ratings yet

- Hydrocarbons (Alkanes and Alkenes)Document16 pagesHydrocarbons (Alkanes and Alkenes)Soham NagNo ratings yet

- FAILUREDocument20 pagesFAILUREMarcharlie PadillaNo ratings yet

- Steel ProblemsDocument7 pagesSteel ProblemsNilava Das100% (1)

- Mil PRF 5606hDocument25 pagesMil PRF 5606hApanreza VitalyNo ratings yet

- Mto Lab Manuals - All ExperimentsDocument121 pagesMto Lab Manuals - All ExperimentsAnmol JainNo ratings yet

- Grout Rev.c PDFDocument6 pagesGrout Rev.c PDFMithun UdayanarayanaNo ratings yet

- AbDocument1 pageAbMs. BNo ratings yet

- O Level Physics 2023-2025 ATP TipsDocument7 pagesO Level Physics 2023-2025 ATP TipsAmy WolmesNo ratings yet

- CBN/Diamond Coated Carbide Insert GuideDocument10 pagesCBN/Diamond Coated Carbide Insert GuideChellamuthu MechNo ratings yet

- Understanding The Results of An Intelligent Pig InspectionDocument18 pagesUnderstanding The Results of An Intelligent Pig InspectionLeonardo VazNo ratings yet