Professional Documents

Culture Documents

Concrete Cover - Spacers

Uploaded by

María Fernanda Mata0 ratings0% found this document useful (0 votes)

88 views4 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

88 views4 pagesConcrete Cover - Spacers

Uploaded by

María Fernanda MataCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Specifically improved durability of reinforced concrete structures

Specifically improved durability of come into use if the consultant or

reinforced concrete structures. architect expressly demands their use

for the purpose of securing the con-

by Dipl.-Ing. Rainer Böllinghaus, crete cover. For a long time, even in

managing director at Gebr. Seifert Europe, exactly defining the type of

GmbH, Europe's leading manufactu- spacer to be used was neglected, by

rer of rebar spacers. comparison to other products such as,

for instance, reinforcement, anchor

This article describes in detail efforts channels and fixing or lifting inserts.

in Europe, in particular in Germany

to optimise and standardise use of For a number of years, within the

rebar spacers with regard to increa- Spacer Project Group, whose mem-

sing the durability of reinforced con- bers consist of Germany's leading

crete components. construction associations, manufactu-

rers of prefabricated concrete compo-

Introduction nents, universities, manufacturers and

construction companies with renow-

It has long been recognised in Ingress of moisture to the reinforce- ned names such as Hochtief, Philip

Western Europe that the thickness and ment incurs corrosion which creates Holzmann, Dyckerhoff & Widmann,

surface cracking along the line of rein- Strabag Hoch- und Ingenieurbau,

sealing capability of the concrete forcement.

cover over the steel reinforcement has Europe's leading manufacturer of spa-

a deciding influence on the durability When the first industrially manufac- cers - Seifert, the University of Essen,

as well as on the level of fire protec- tured spacers were introduced, it see- the German Specialist Association for

tion of buildings constructed using med that a firm seating of the spacer Prefabricated Concrete Units, the

reinforced concrete or prestressed and the stress loading capability in a Institute for Steel Reinforcement and

concrete. In order to ensure the neces- horizontal or vertical direction as a many more have been occupied with

sary thickness of the concrete cover, result of formwork and reinforcement standardising spacers with regard to

spacers are required which are placed pressure were the most important cri- requirements, description, recom-

between the formwork and reinfor- teria for selection. This was initially mendation, inspection and quality

cing steel. more important than spacers of a con- control. Standardisation is in particu-

structionally superior design which lar intended to assist planners of sup-

The required concrete cover depends were thus more suited to the relevant porting frameworks whose responsi-

on the one hand on the diameter of the area of use. bility it is to select suitable spacers

reinforcing steel, on the other hand on with regard to performance class and,

direct influences from the surroun- Over the years, manufacturers such as if necessary, special requirements.

ding area of the reinforced concrete. Seifert have, after various testing, Also the manager at the building site,

In this respect it is of significance proved that an optimum product whose task it is to order and use the

whether a concrete part is, for design can prevent or reduce a host of spacers, as well as the consultant who

instance, on the inside of a building corrosive developments to a negli- has to check the installation of the

or on the outside, if this part of the gible level such as, for instance, car- spacers according to requirement by

construction is subject to periodic bonation (figure 1) or surrounding way of approval of the reinforcement.

damp penetration or if aggressive damp penetration through and along

chemicals come into contact with the the spacer. In contrast to an interna- DIN 1045 or the information sheet of

concrete. tional trend towards spacer construc- the German Concrete Association

tion becoming thinner, weaker and "Concrete Covering and Reinforce-

In order to at least partly fulfil a cor- simpler, Seifert in particular has put ment" already stipulates installing

rosion protection requirement, at the great emphasis on technical details reinforcement using a predefined

stage where this was initially recogni- right from the beginning. nominal measurement or installation

sed, wooden or concrete blocks were measurement of the concrete cover, in

made at the building site in order to such a way that the concrete cover in

ensure a distance, obviously adequate the finished building component is

but not yet exactly defined, between maintained with adequate safety. This

the reinforcement and the subsequent of course requires spacers which

concrete surface. Within a relatively ensure maintaining the concrete cover

short time however, it was understood before and during concrete work and

that the exact definition of the concre- which after completion do not impair

te cover in particular depends on the the usability and durability of the

Figure 1 Spacer with carbonation brake

reinforcement and the surroundings, building component.

and that the form and type of spacers In spite of the relative cheapness of

used are of significant importance in using spacers, they are still neglected

respect to the durability of reinforced in some countries, or merely thin pla-

concrete structures. stic wheels or unstable plastic chairs

For this reason, for every precisely In the process of almost 100 years point-type, line-shaped, or flat-sha-

defined instance of application, suita- development work, Seifert Research ped. Supports are installation compo-

ble spacers are to be installed in such has developed the largest spacer line nents which secure the top reinforce-

a way that they do not move or rotate world-wide for horizontal, vertical, ment in position, e.g. supporting

and so that they accept the forces top and bottom reinforcement as well cages, line-shaped or curved lattices,

acting on them during construction as for formwork (figure 3). This tried lattice supports or individual hystools

work in their designated position at all and tested line of spacers and special (figure 4). Supports for the top rein-

temperatures and with negligible products allows installation in all forcement can either stand on the

deformation. The spacers available on areas of use in insitu-cast and precast formwork or are stood into the bottom

the market generally consist of cement applications, taking individual condi- reinforcement. Position securing devi-

mortar, possibly reinforced with fib- tions into consideration such as envi- ces are installation components which

res, plastic (usually polyethylene) or ronmental influences, chemical secure the distance between the two

mortar set in reaction resin (figure 2). aggression, temperature deviations reinforcement layers in concrete walls

etc. and the respective technical requi- or individual reinforcement positions,

rements during construction. e.g. stirrup bolts, S-shaped hooks.

Terminology

The concrete cover is the concrete

Figure 2 Common concrete and plastic layer between a reinforcing bar and

spacers available on the market

the concrete surface. The minimum

Although spacers are unavoidable measurement of the concrete cover

inhomogenous units in concrete, they (minc) is the minimum sufficiently

must not significantly impair the sea- safe distance between the concrete

Figure 4 Supports for top reinforcement

ling qualities of the concrete cover in surface and the rebar. The nominal

the finished building component. The measurement of the concrete cover

Spacer requirements

widely held assumption that use of (nomc) is the sum of the minimum

concrete spacers leads to a kind of measurement and a lead measurement

Spacers vary in design, size, material,

"fusion" with the surrounding concre- (nomc = minc + ∆c).

types of application and in their cha-

te is a fallacy, as many tests have pro-

The lead measurement of the concrete racteristics when inside and outside

ved. Concrete spacers, as well as pla-

cover ∆c is intended to cover unavoi- concrete. Table 1 is a classification list

stic spacers, remain an inhomogenous

dable deviations in measurement due of spacers according to the type of

unit, whereas plastic spacers, due to

to bending and installing the reinfor- contact area.

their constructional design, give better

anchorage in concrete. Equally, com- cement, the type of spacers and instal-

plex testing has disproved the second ling them, production of the form- To begin with, one must differentiate

fallacy, namely that plastic spacers are work as well as placing and compac- between spot supporting single spa-

negatively acting foreign bodies. ting the concrete. The lead measure- cers and large-area supporting spacers

ment ∆c does not contain the unavoi- (figure 5).

The load-bearing capacity of spacers dable measuring errors during non-

depends on the material characteri- destructive verification measurement

stics and on the shape of the spacer as of the finished concrete component.

well as on the temperature at the res-

pective load. Material specific charac- The placing measurement nomcv of

teristics of concrete spacers are, for the reinforcement is the "spacer mea- Fig. 5 Point-type and area-type spacers

instance, that no deformation takes surement" of the concrete cover. It is

place under load, but that sudden bre- deduced from the nominal measure- With single spacers, generally at least

akage may occur. Furthermore, con- ments nomcl of the vertical bars and 4 spacers are used per m2. If the spa-

crete spacers have a tendency to beco- nomcq of the horizontal bars (stirrups). cers carry a heavy load or if in the

me porous, in particular at temperatu- It is usually the setpoint distance bet- case of thin reinforcement danger

res below freezing point, and to being ween the outer reinforcement bars and exists that the reinforcement may for

highly hygroscopic. Plastic spacers on concrete surface. The thickness or instance be trodden down between the

the other hand have a reduced tenden- height of the spacers is measured spacers, then more spacers must be

cy towards breakage, tend to not be used accordingly. In the case of area-

according to this setpoint distance. In

hygroscopic, but do tend towards type spacers or of line-shaped spacers

order to be able to differentiate from

deformation under load, in particular the distances between the spacers for

the required nominal measurements

at higher temperatures.

(setpoint measurements) the selected medium rebar diameter thicknesses

placing measurement (actual measu- should not exceed 70 cm. For bar dia-

rement) is described as nomcv. meters up to 6 mm Ø, a distance of 50

cm between the spacers should not be

Spacers are installation components exceeded.

which secure the required placing

measurement of the concrete cover

between the outer reinforcement bars

and the formwork. Spacers can be

Figure 3 Excerpt from the Seifert line

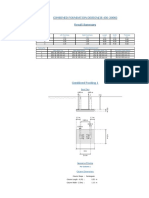

Table 1 mixed concrete usage (e.g. for reinfor-

Classification list of spacers cements carrying human loads; spa-

cers bearing a load when the form-

A C2 work is tensioned; for outside loads

which are temporarily stored on the

placed reinforcement etc.)

Standard requirements with regard to

B1 D1 inspection loads and permissible

deformation are described in detail in

Table 2 on the next page.

B2 D2

A Wheel-shaped C1 Line-shaped, not f.

C1 B1 Spot-support, C2 Line-shaped, f.

not fastened D1 Area-type, not f.

B2 Spot-supporting, D2 Area-type, fastened

fastened Figure 6 Testing of plastic spacers

If spacers are used in reinforced con-

To secure the concrete cover with building component, melting has no crete components which in a state of

regard to thickness and sealing capa- significant impact on the fire-resi- damp penetration are frequently sub-

bility, the spacers must have a suffi- stance capability of the building com- jected to temperature variations above

cient load-bearing capability and tilt ponent. and below freezing point with or with-

resistance depending on the respective out salt, then the spacers embedded in

load pressure and temperature effect, Performance classification the concrete must additionally be of a

if necessary, must be able to be ade- higher frost-resistance level. The resi-

quately fastened to the reinforcement The loads to which a spacer is subjec- stance capability counts as being ful-

bar and must have a minimum spring ted in practice may vary greatly accor- filled if, after due inspection no cracks

backlash so that after striking form- ding to the type of use. Thus, on brid- appear and only negligible chipping

work, the concrete layer next to the ge constructions with very heavy rein- has occurred.

surface is not pressed off. forcement and high concrete covers,

for instance, loads of 100 kg and more If spacers are installed in water-resi-

Furthermore, they should be formed per spacer are taken into account, stant reinforced concrete components

in such a way that they can only be whereas when reinforcing inside or in components which are intended

used for one placing measurement cv walls constructed when building to offer a high resistance to chemical

and so that the concrete completely apartments for instance, loads of only aggression, then the spacer must addi-

surrounds the spacer and does not 5 - 10 kg per spacer occur. On vertical tionally itself offer a high resistance to

segregate as a result of the spacer. The areas, the load capability depends on chemical aggression. Water penetrati-

following are of utmost importance: the type of formwork and reinforce- on of the spacer in the concrete may,

sufficient resistance to the alkaline ment. With columns, side areas of cei- according to the DBV (German Con-

content of the concrete, as well as the ling joists and stiffly braced walls it is crete Association) information sheet,

requirement that the spacer be made necessary to take into consideration not exceed the maximum permissible

of a material which itself is not corro- that the reinforcement cage, when the value as stated in DIN 1045.

sive and which does not cause further formwork is tensioned, puts a sub-

corrosion to the reinforcement and stantial load on individual spacers. In If spacers are used in reinforced con-

which damages neither freshly wor- such cases, with spacers for vertical crete components which are exposed

ked nor hardened concrete. The Insti- reinforcement, high loads are taken to higher temperature (e.g. outside

tute for Construction Technology in into account similar to those for hori- building components, containers in

Berlin verifies the unreserved accep- zontal reinforcement. industrial building concrete and fair-

tability of plastic spacers: "There are faced concrete), the DBV information

no reservations regarding the use of Minimum requirements are defined in sheet states that for the following

plastic spacers in concrete, reinforced two performance classes. alternating temperature loads, no

concrete and prestressed concrete in cracking and chipping in the area of

respect to fire protection, as long the No increased requirements exist for the spacer embedded in the concrete

plastic in question is not polyvinyl performance class L1 with regard to may occur. Tests have shown that

chloride.". load-bearing capability and tilt resi- microscopic cracks as a result of dif-

stance, e.g. for use in cases where the ferent temperature expansion rates in

In case of fire the following applies: in reinforcement is not subject to traffic plastic and concrete have no negative

the case of higher temperatures (e.g. a load. In contrast, for performance influence on the durability of buil-

fire) a plastic spacer may melt. As the class L2 increased demands are made dings. A mathematical example shows

thickness of the spacer is usually on load bearing capability and tilt that for a plastic spacer with an assu-

small in relation to the thickness of the resistance; standard spacers for site- med contact width of 1 cm only a very

minor change in volume results, even work against soft layers (e.g. insula- Summary

when the temperature varies in the ting boards), spacers with a larger The decisive criteria for selecting spa-

order of 50° C. Thus, in the case of contact area must be used (figure 9). cers should always be: fulfilment of

this temperature variation the said pla- the function "Guarantee of the requi-

stic spacer expands by only 0.035 mm red distance between formwork and

to 0.065 mm. The concrete cannot be reinforcement for ensuring the neces-

damaged by such diminutive expansi- sary concrete cover". If e.g. the load

on measurements as it is known that bearing capability of the individual

cracks in concrete below 0.25 mm in spacer is not sufficient, then either

width have no damaging effect. another spacer with a larger load bea-

Fig. 9 Spacer with larger contact area

ring capability should be selected or

If spacers are used in reinforced con- When reinforcing in vertical building the number of spacers per area should

crete which is intended as "designed components, spacers should be selec- be correspondingly increased in order

concrete" (fair-faced concrete), then ted so that after placing the fresh con- to distribute the load. A spacer which

the contact area on the formwork must crete beneath the spacers no damaging has to accept a high load necessarily

be as small as possible (figure 7) and voids occur. When arranging long requires a large contact area on the

the spacer may only be slightly pres- line-shaped spacers in the area of a formwork. The spacer will later on be

sed into the formwork. Furthermore, tension zone, cracks in the concrete, more or less visible in the concrete.

the spacer may only make a slight in particular in the area of the spacers, This fact has consequences in fair-

impression on the concrete surface. must be taken into account. For this faced concrete and must be taken into

reason, short line-shaped spacers consideration at the planning stage. A

should be used, with sufficient stagge- firm seating of the spacer is also of

ring to each other. Line-shaped spa- great importance. Even the most stable

cers in the pressure zone of building spacer cannot fulfil its function if it

components subject to flexing may changes its position when the concrete

only be installed parallel to the direc- is being poured. The ideal spacer for all

tion of tension, in the case of vertical areas of use under all conditions does

installation the usable height decrea- not yet exist. Selection of a spacer can

ses and an indenting effect with nega- therefore generally only be a compro-

Fig. 7 Praxifix spacer (pointed legs) tive concentration in tension additio- mise which takes the individual condi-

nally results. tions at hand into consideration.

Recommendations for selecting

spacers Table 2 Special thanks to Seifert Germany for

Standard requirements providing photos and test results.

As a rule, cement mortar spacers are,

Standard requirements with

with regard to stability of form, less

regard to inspection load Performance class L1 Performance class L2

sensitive to load and temperature and permissible deformation

variations than plastic spacers. They

Inspection loads

should be preferred for building com- - static short-time test 250 N1 1.000 N1

ponents with very high static and ther- - tilt resistance – 500 N

mal loads and in the case of high con- - creep test – 350 N2 / 175 N3

straining loads from the formwork Permissible deformation

(e.g. tunnel formwork). - nom cv ≤ 20 mm 1 mm 1 mm

- nom cv ≤ 20 mm 2 mm 2 mm

Firmly clipped spacers or single spa- 1

In the case of stiffly formed spacers, e.g. concrete spacers, the mean value of the measured bearing load must be doubled.

cers fastened with wire should always 2

Spot-supporting spacer

3

Line-shaped spacer

be fastened at the intersection of the

reinforcement (figure 8), as they can Table 3 contains recommendations according to building components and spacer type groups.

easily rotate when fixed to normal Ceilings, foundations,

Building component Supports Walls Beams floor slabs

reinforcement bars. Spacers which are

not fixed can move out of position Formwork vertical vertical horiz./vert. horizontal

when the formwork is cleaned and Reinforcement horizontal horiz./vert. horiz./vert. horizontal

thus become ineffective. Spacer type groups

A Wheels K1) K1) L L L L

B1 spot-supporting

not fastened

(block, trestle)

L L L K L K

spot-supporting (block, trestle)

B2 fastened J2) J2) J

) 2)

J J2) J

C1 line-shaped, not fastened L L L J L J

Figure 8 Spacer clipped on at C2 line-shaped, fastened J J K J K J

crosspoint of the reinforcement D1 area-supporting, not fastened L L L J L J

Spacers must be formed and fastened D2 area-supporting, fastened J J K J K J

in such a way that the placing measu- J recommended, K partially suitable, L unsuitable

rement is also maintained in the case

1) Caution, frequently insufficient tilt resistance when tensioning the formwork

of sectional weakening (e.g. by trape- 2) If tilting or pushing is not feasible

zium rails). In the case of concrete 3) With max. length (350 mm or < 2d or <1/4 x building component width)

You might also like

- Rebuild-Vol 10Document20 pagesRebuild-Vol 10ahtin618100% (1)

- Prestressed Concrete Design Techniques and ApplicationsDocument2 pagesPrestressed Concrete Design Techniques and ApplicationsBojo FamaNo ratings yet

- Ground Anchors and Soil Nails in Retaining StructuresDocument2 pagesGround Anchors and Soil Nails in Retaining StructurespuspanathanNo ratings yet

- Erect Precast Concrete Cladding Level IIDocument4 pagesErect Precast Concrete Cladding Level IIGudetaNo ratings yet

- Post Tensioning in Building StructuresDocument21 pagesPost Tensioning in Building StructuresLuan Truong VanNo ratings yet

- Remoreras - Module 3 ResearchDocument23 pagesRemoreras - Module 3 ResearchChristian RemorerasNo ratings yet

- Prestrest ConcreteDocument6 pagesPrestrest ConcreteWan ImranNo ratings yet

- Reinforced Jet-Grouted Piles Analysis and DesignDocument10 pagesReinforced Jet-Grouted Piles Analysis and Designjuan carlos molano toroNo ratings yet

- ACI-373r 97Document26 pagesACI-373r 97Pablo Augusto Krahl100% (1)

- Iron-Based Shape Memory Alloys for Shear Reinforcement of BridgesDocument16 pagesIron-Based Shape Memory Alloys for Shear Reinforcement of BridgesSAMUEL ALBERTO ZAMBRANA MALDONADONo ratings yet

- Design and Construction With Grouted Reinforced MasonrytDocument6 pagesDesign and Construction With Grouted Reinforced MasonrytDakonjaNo ratings yet

- Concrete Is The Most Widely Used Structural Material in The World With An AnnualDocument9 pagesConcrete Is The Most Widely Used Structural Material in The World With An AnnualMisty Odom100% (1)

- Reinforced jet-grouted piles analysis and designDocument11 pagesReinforced jet-grouted piles analysis and designHüseyin EkiciNo ratings yet

- Seismic Design of Cold Formed Steel Structures in Residential ApplicationsDocument3 pagesSeismic Design of Cold Formed Steel Structures in Residential ApplicationsKristijanRunevskiNo ratings yet

- Research Architectural: Tech VDocument6 pagesResearch Architectural: Tech VMark DanielNo ratings yet

- 2014 09 BFT Varianten Precast Element Production 1 7Document10 pages2014 09 BFT Varianten Precast Element Production 1 7Rodrigo LameirasNo ratings yet

- ResumenDocument4 pagesResumencparragomez08No ratings yet

- Reported by ACI Committee 223: Chapter 1-Introduction, P. 223-2Document28 pagesReported by ACI Committee 223: Chapter 1-Introduction, P. 223-2Pooja ChoudharyNo ratings yet

- Fundamentals of PrecastingDocument4 pagesFundamentals of Precastingsankar_rao333No ratings yet

- .Precast Concrete ConnectionsDocument3 pages.Precast Concrete Connectionsparamarthasom1974No ratings yet

- Hoi - Thao T11-03 LuuDocument22 pagesHoi - Thao T11-03 LuuvuhachauNo ratings yet

- Pre-Tensioning and Post-Tensioning in Prestressed Concrete DesignDocument5 pagesPre-Tensioning and Post-Tensioning in Prestressed Concrete DesignLIZA MARIE QUINDAONo ratings yet

- Precast Concrete and Prestressed Concrete: Report Submitted By: Group IiDocument6 pagesPrecast Concrete and Prestressed Concrete: Report Submitted By: Group IiVaishnavi SikchiNo ratings yet

- Koster Aquatecnic KOSTER AMS 2 Liquid Film Other KOESTER Waterproofing Report 2007 1Document8 pagesKoster Aquatecnic KOSTER AMS 2 Liquid Film Other KOESTER Waterproofing Report 2007 1Engineer FazalNo ratings yet

- 93 S37 PDFDocument7 pages93 S37 PDFPaul KohanNo ratings yet

- Concrete Cover For Reinforcement WorksDocument7 pagesConcrete Cover For Reinforcement Worksaashik.esnNo ratings yet

- Durability Provisions For Vicroads Structural Concrete: F. Andrews-Phaeoonos, Mieaust.Document14 pagesDurability Provisions For Vicroads Structural Concrete: F. Andrews-Phaeoonos, Mieaust.jeffNo ratings yet

- Post-Installed Reinforcement Connections at Ultimate and Serviceability Limit StatesDocument13 pagesPost-Installed Reinforcement Connections at Ultimate and Serviceability Limit StatesCeranNo ratings yet

- CIVIL INTERSHIP REPORTDocument17 pagesCIVIL INTERSHIP REPORTEBIN JACOB ANISH CE A 16-20No ratings yet

- PAPERDocument16 pagesPAPERjpzb1892No ratings yet

- Two Stage Method ConcreteDocument5 pagesTwo Stage Method ConcreteReynhard WijayaNo ratings yet

- Connections1 19 Technicalarticle WELDADocument5 pagesConnections1 19 Technicalarticle WELDAGrzesiek GórnikNo ratings yet

- 1 s2.0 S1359836816329249 MainDocument12 pages1 s2.0 S1359836816329249 Mainziwen liuNo ratings yet

- Engineer TermsDocument8 pagesEngineer TermsBintang RamadhanNo ratings yet

- 10.1002 Suco.201700157Document10 pages10.1002 Suco.201700157MashaNo ratings yet

- Precast Segment Study of Hyderabad Metro Rail ProjectDocument66 pagesPrecast Segment Study of Hyderabad Metro Rail Projectashwini0393No ratings yet

- Precast Concrete WallsDocument3 pagesPrecast Concrete WallsInzaghi BirdNo ratings yet

- GFRC SECTION APA HANDBOOKDocument15 pagesGFRC SECTION APA HANDBOOKJorge PenichéNo ratings yet

- Libro de Reforzamiento HORMIGON ARMADO 2022-6Document25 pagesLibro de Reforzamiento HORMIGON ARMADO 2022-6David Magne MamaniNo ratings yet

- Employing Nonlinear Response History Analysis of ASCE 7-16 On A Tall BuildingDocument11 pagesEmploying Nonlinear Response History Analysis of ASCE 7-16 On A Tall BuildingSaeed TariverdiloNo ratings yet

- CONICET Digital Nro. ADocument13 pagesCONICET Digital Nro. AespanruyaNo ratings yet

- ARCH402 Nora Ahmd 21902492Document16 pagesARCH402 Nora Ahmd 2190249221902492No ratings yet

- R23 Design of High Performance Anchored Retaining Walls To EC7 Egan Mothersille 2015Document6 pagesR23 Design of High Performance Anchored Retaining Walls To EC7 Egan Mothersille 2015xcvNo ratings yet

- D-Product Watch Crigler Post Tension Revisit1Document4 pagesD-Product Watch Crigler Post Tension Revisit1khx2No ratings yet

- Name:Rasal Nikhil Gautam REG - NO:17BPI0046 Course Code:MEE2036 Project ReviewsDocument20 pagesName:Rasal Nikhil Gautam REG - NO:17BPI0046 Course Code:MEE2036 Project ReviewsNikhil RasalNo ratings yet

- Architecture Building ConstructionDocument9 pagesArchitecture Building Construction08DALVI PRASHANINo ratings yet

- Projek RC 1Document5 pagesProjek RC 1Hani BarjokNo ratings yet

- Seminor On Prestressed ConcreteDocument43 pagesSeminor On Prestressed ConcreteNatarajan SaravananNo ratings yet

- Development and Application of Precast Concrete Double Wall System To Improve Productivity of Retaining Wall ConstructionDocument12 pagesDevelopment and Application of Precast Concrete Double Wall System To Improve Productivity of Retaining Wall ConstructionVasthy Jael Diaz GellNo ratings yet

- Seismic Design of Lightly Reinforced Precast Concrete Rectangular Wall Panel 2002Document19 pagesSeismic Design of Lightly Reinforced Precast Concrete Rectangular Wall Panel 2002Maria Danelia AlvarezNo ratings yet

- 2011 03 Mccowan Kivela PDFDocument11 pages2011 03 Mccowan Kivela PDFFranklyn GenoveNo ratings yet

- Print RepairDocument10 pagesPrint RepairSalil DeshpandeNo ratings yet

- Experimental Results On Mechanical Behaviour of Metal Anchors in Historic Stone MasonryDocument13 pagesExperimental Results On Mechanical Behaviour of Metal Anchors in Historic Stone MasonryVidyadhar BommeriNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Rehabilitation of Concrete Structures with Fiber-Reinforced PolymerFrom EverandRehabilitation of Concrete Structures with Fiber-Reinforced PolymerNo ratings yet

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Elastic, Plastic and Yield Design of Reinforced StructuresFrom EverandElastic, Plastic and Yield Design of Reinforced StructuresNo ratings yet

- Ceramic Matrix Composites: Fiber Reinforced Ceramics and their ApplicationsFrom EverandCeramic Matrix Composites: Fiber Reinforced Ceramics and their ApplicationsWalter KrenkelNo ratings yet

- S M W C: ASTM C 1602/C 1602M-04 - Standard Specification For Mixing Water Used in The Production ofDocument6 pagesS M W C: ASTM C 1602/C 1602M-04 - Standard Specification For Mixing Water Used in The Production ofsaurimoNo ratings yet

- European Ecolabel For Indoor Paints and VarnishesDocument2 pagesEuropean Ecolabel For Indoor Paints and VarnishesMaría Fernanda MataNo ratings yet

- Water Absorption, Vapour DiffusionDocument2 pagesWater Absorption, Vapour DiffusionMaría Fernanda MataNo ratings yet

- Historical Structural Steelwork Handbook Lib574 PDFDocument80 pagesHistorical Structural Steelwork Handbook Lib574 PDFMotlatjo RakgothoNo ratings yet

- Suspended CeilingsDocument10 pagesSuspended CeilingsMaría Fernanda MataNo ratings yet

- An Experimental Comparison of RC Beam-Column Joints IncorporatingSpliceDocument11 pagesAn Experimental Comparison of RC Beam-Column Joints IncorporatingSpliceAbhishek KumarNo ratings yet

- Aeroelasticity20202021 Ex9Document2 pagesAeroelasticity20202021 Ex9Arianna PascaleNo ratings yet

- Design of Cantilever Retaining Wall: Preliminary ProportionsDocument6 pagesDesign of Cantilever Retaining Wall: Preliminary ProportionsMuhammed NaseefNo ratings yet

- Zuellig Building's Green FeaturesDocument12 pagesZuellig Building's Green FeaturesTj FelicianoNo ratings yet

- Combined Foundation Design (Is 456-2000) Result SummaryDocument30 pagesCombined Foundation Design (Is 456-2000) Result Summaryarchetype designNo ratings yet

- 03 Stresses Under Centric Loading StudentDocument7 pages03 Stresses Under Centric Loading Studentmr.arvin03No ratings yet

- DN-016-Rev 0-Design Procedure of RC BeamsDocument82 pagesDN-016-Rev 0-Design Procedure of RC BeamsAbdullah Abdel-MaksoudNo ratings yet

- Determination of Flow Rate of Water in Concrete by Rilem Tube MethodDocument12 pagesDetermination of Flow Rate of Water in Concrete by Rilem Tube MethodKishore Nayak k100% (1)

- Unit 9 (DESIGN OF SHEAR REINFORCEMENT)Document29 pagesUnit 9 (DESIGN OF SHEAR REINFORCEMENT)Zara Nabilah76% (25)

- 99% Design Narrative of Qalat Distribution LineDocument9 pages99% Design Narrative of Qalat Distribution Linesm.kdh.nsNo ratings yet

- New Solution in Large Space Comfort: Specifications Option ListDocument4 pagesNew Solution in Large Space Comfort: Specifications Option ListArthur OliveiraNo ratings yet

- Fluid Dynamics - Is There A Way To Fill Tank 2 From Tank 1 Through Gravity Alone - Physics Stack ExchangeDocument3 pagesFluid Dynamics - Is There A Way To Fill Tank 2 From Tank 1 Through Gravity Alone - Physics Stack ExchangeBADRI VENKATESHNo ratings yet

- (BS EN 15885 - 2010) - Classification and Characteristics of Techniques For Renovation and Repair of Drains and Sewers.Document44 pages(BS EN 15885 - 2010) - Classification and Characteristics of Techniques For Renovation and Repair of Drains and Sewers.GatotNo ratings yet

- IPENZ PN19-SeismicResistancePressureEquipmentFinalDocument138 pagesIPENZ PN19-SeismicResistancePressureEquipmentFinalnikhil0104No ratings yet

- C 773 - 88 R99 - QZC3MWDocument3 pagesC 773 - 88 R99 - QZC3MWCecy LópezNo ratings yet

- Phe TS19 10 23Document17 pagesPhe TS19 10 23K. CHANDRASEKHARNo ratings yet

- M008 La Rotisserie S-01Document1 pageM008 La Rotisserie S-01dasmindpcqboNo ratings yet

- New Series 6000Document78 pagesNew Series 6000Kintu MunabangogoNo ratings yet

- BURGOS ULO3aDocument3 pagesBURGOS ULO3aPeter Carl BurgosNo ratings yet

- Tinywow - PROEDI 1000 HWS + PW LOOP REVERSE OSMOSIS SYSTEM + DISTRIBUTION 2.2 - 5949721Document18 pagesTinywow - PROEDI 1000 HWS + PW LOOP REVERSE OSMOSIS SYSTEM + DISTRIBUTION 2.2 - 5949721Yacine MokhtariNo ratings yet

- Design of Tension MemberDocument37 pagesDesign of Tension MemberTariq HasanNo ratings yet

- Oxidation Ditch PresentationDocument12 pagesOxidation Ditch PresentationAngelina PranotoNo ratings yet

- Investigation Into The Performance of Statistics House in The 14 November 2016 Kaikoura EarthquakeDocument36 pagesInvestigation Into The Performance of Statistics House in The 14 November 2016 Kaikoura EarthquakeFinnFan8No ratings yet

- Geotechnical Investigation Report for Proposed Integrated Industrial Township ProjectDocument229 pagesGeotechnical Investigation Report for Proposed Integrated Industrial Township ProjectSAMRIDDHI SAHUNo ratings yet

- AISI S200-07 Standard and Commentary (1st Printing) PDFDocument46 pagesAISI S200-07 Standard and Commentary (1st Printing) PDFthjozsefNo ratings yet

- CSPIF Ground Slab Cracking Report - 2019-SAR-01 - 03Document56 pagesCSPIF Ground Slab Cracking Report - 2019-SAR-01 - 03seii.chenNo ratings yet

- Retaining Wall Structure: G.C.BeheraDocument38 pagesRetaining Wall Structure: G.C.BeheraMugara Waitega PeterNo ratings yet

- 1CP01 MDS - Kel CV Itp SS08 - SL23 - GF 000002 (C01)Document6 pages1CP01 MDS - Kel CV Itp SS08 - SL23 - GF 000002 (C01)Pavlos InglesisNo ratings yet

- BRIDGE DESIGN MANUALDocument49 pagesBRIDGE DESIGN MANUALdulancivil100% (11)

- Truss BridgeDocument18 pagesTruss BridgeAkashNo ratings yet