Professional Documents

Culture Documents

Tomorrow's Mobility: Week 2 - Session 9 - Battery Pack Design

Uploaded by

Zaché le JusteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tomorrow's Mobility: Week 2 - Session 9 - Battery Pack Design

Uploaded by

Zaché le JusteCopyright:

Available Formats

Tomorrow’s Mobility

Sustainable Technologies for the automotive sector

Week 2 – Session 9 – Battery Pack Design

Guillermo Ballesteros

Introduction

I- Battery voltage and capacity

II- Battery power

III- Battery efficiency

Conclusion

© IFPEN / IFP School 2018

Introduction

This lesson focuses on battery packs, especially the main parameters to design them.

I- Battery voltage and capacity

The optimization of the electric system drive takes into account the needs of the power electronics,

the electric machine, and the battery pack.

If the voltage used is high, the current flowing through the inverter is low and the active

components, like transistors and diodes, are smaller. This contributes to reduce the size of the

semiconductor switches. It also reduces the power dissipated by the power electronic converter.

Correspondingly, the losses in the electric machine are reduced when the current is low.

With small components, the price of the power electronic converter is reduced. The integration is

also easier. At the same time, an increase in the voltage requires more modules and cells, to be

connected in series. Consequently, the number of connections increases and the battery

management system is more complex. Thus, the cost of the battery pack is increased.

Battery Pack Design

High voltage

Current flowing through the inverter is low

Small diodes

and transistors

Size Higher Lower

reduction efficiency cost

More complex battery Higher cost

management system

Week 2 – Session 9 – Battery Pack Design, p. 1

1

© IFPEN / IFP School 2018

For the electric machine, as we have seen, voltage has no effect on the size, the price or the

performance. Therefore, the choice of the voltage is a trade-off, between the price of the power

electronic converter, and the price of the battery pack, as it is between the performance of the

power electronic converter and the complexity of the battery pack.

Battery Pack Power

Price of the Power Performance of the

Price of the Complexity of the

Electronics power electronic

Battery Pack battery pack

Converter converter

The capacity is the amount of energy contained inside the battery. It is proportional to the range or

autonomy of the vehicle.

Capacity is proportional to Range

Today, electric vehicles consume between 100 and 200 Wh per km. This energy is affected by the

battery mass, and by the mass of the vehicle itself. The heavier the battery, the lower the efficiency

of the system. One can consider that around 40% of the energy is used to move the battery, due to

its high weight. Efficiency is also reduced by losses, due to the electric current circulating through

the battery pack, because of its internal resistance.

Week 2 – Session 9 – Battery Pack Design, p. 2

2

© IFPEN / IFP School 2018

Capacity and Range

Autonomy New European Driving Cycle (km)

On-board energy battery (kWh)

Depending on the specifications, it is possible to calculate the required battery pack capacity, taking

into account the weight, including its effect on the efficiency, and the range of the vehicle. To reach

high capacity, cells must be connected in parallel. The total capacity of the battery pack will be

equal to the sum of the capacities of the cells connected in parallel together.

II- Battery power

Power is necessary for accelerations, or climbing up-hills, for transport of passengers, and

merchandise. For the same acceleration need, the power need increases with the transported

weight and the slope of the road.

Battery Pack Power

Power

is necessary for:

Climbing a

Accelerations mountain or

pulling

caravans

The power need can be calculated with a simplified formula, taking into account these parameters:

Vehicle weight with passengers, luggage and goods

Acceleration need (in tow, on the road and on the high way)

Front surface of the vehicle

Cx: penetration coefficient

Week 2 – Session 9 – Battery Pack Design, p. 3

3

© IFPEN / IFP School 2018

Ro : air density

With these parameters, it is possible to roughly calculate the power needed. It is quite obvious that,

for battery electric vehicles, the battery capacity, is a key element of the design of the electric drive.

The power need is largely satisfied, because the battery usually has high capacity.

III- Battery efficiency

One last thing: Li-ion technology is extremely sensitive to the temperature. The efficiency of this

technology is usually around 90%. If the temperature increases over 40°C, not only the efficiency is

reduced, but also the reliability and the performance are impacted.

Battery Pack Efficiency

<40°C

Conclusion

The key points of this lesson are:

It is important to reduce the current value flowing through the inverter, so the size of the

drive train is reduced. For this, high voltage batteries are recommended.

However, when the battery voltage is high, the cost and the weight are increased.

Additionally, the number of connections increases and the battery management system is

more complex.

The battery capacity is the KEY element in the Electric drive train design.

Finally, a particular attention must be paid to the thermal management. Indeed, safety and

reliability depend on the temperature. For Li-ion batteries, the temperature must be kept

under 40°C.

Week 2 – Session 9 – Battery Pack Design, p. 4

4

© IFPEN / IFP School 2018

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- 2 (A) - TAC32 ManualDocument244 pages2 (A) - TAC32 ManualNick100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Vocabulary - Information Technology IIIDocument4 pagesVocabulary - Information Technology IIIHussam JouiniNo ratings yet

- Tomorrow's Mobility: Week 2 - Session 8 - Battery FundamentalsDocument6 pagesTomorrow's Mobility: Week 2 - Session 8 - Battery FundamentalsZaché le JusteNo ratings yet

- Pictures 1542275741194-SyntW3V27+Mooc+2018Document9 pagesPictures 1542275741194-SyntW3V27+Mooc+2018Zaché le JusteNo ratings yet

- Tomorrow's Mobility: Week 3 - Session 4 - Hybrid Vehicles ArchitecturesDocument6 pagesTomorrow's Mobility: Week 3 - Session 4 - Hybrid Vehicles ArchitecturesZaché le JusteNo ratings yet

- Tomorrow's Mobility: Week 3 - Session 6 - Trends in Hybrid VehiclesDocument7 pagesTomorrow's Mobility: Week 3 - Session 6 - Trends in Hybrid VehiclesZaché le JusteNo ratings yet

- Tomorrow's Mobility: Week 3 - Session 2 - Introduction To Hybrid VehiclesDocument10 pagesTomorrow's Mobility: Week 3 - Session 2 - Introduction To Hybrid VehiclesZaché le JusteNo ratings yet

- Tomorrow's Mobility: Week 3 - Session 3 - Hybridization LevelsDocument5 pagesTomorrow's Mobility: Week 3 - Session 3 - Hybridization LevelsZaché le JusteNo ratings yet

- Tomorrow's Mobility: Week 2 - Session 4 - Electric Machine DesignDocument5 pagesTomorrow's Mobility: Week 2 - Session 4 - Electric Machine DesignZaché le JusteNo ratings yet

- Tomorrow's Mobility: Week 2 - Session 6 - Power Electronic DesignDocument7 pagesTomorrow's Mobility: Week 2 - Session 6 - Power Electronic DesignZaché le JusteNo ratings yet

- Tomorrow's Mobility: Week 2 - Bonus Session - Electromagnetism FundamentalsDocument4 pagesTomorrow's Mobility: Week 2 - Bonus Session - Electromagnetism FundamentalsZaché le JusteNo ratings yet

- Tomorrow's Mobility: Week 2 - Session 3 - Electric Machine FundamentalsDocument5 pagesTomorrow's Mobility: Week 2 - Session 3 - Electric Machine FundamentalsZaché le JusteNo ratings yet

- Tomorrow's Mobility: Week 2 - Session 2 - Electric Drives For Electric VehiclesDocument4 pagesTomorrow's Mobility: Week 2 - Session 2 - Electric Drives For Electric VehiclesZaché le JusteNo ratings yet

- InstructionManual STJ EDocument61 pagesInstructionManual STJ ENuraini LusiNo ratings yet

- Dev ListDocument7 pagesDev ListJaime Andrés GarcíaNo ratings yet

- Multilayer Pcbs in EagleDocument19 pagesMultilayer Pcbs in EagleKhushal KharadeNo ratings yet

- Transmission Line Input ImpedanceDocument9 pagesTransmission Line Input ImpedancePaul Shine EugineNo ratings yet

- Design of An Isolated Bidirectional Active Cell Balancing Circuit For Lithium Ion BatteriesDocument6 pagesDesign of An Isolated Bidirectional Active Cell Balancing Circuit For Lithium Ion BatteriestgangwarNo ratings yet

- Syllubus For Data Networks and ProtocolsDocument2 pagesSyllubus For Data Networks and ProtocolsSELVAKUMAR RNo ratings yet

- RF02 Universal ISM Band FSK Transmitter: DescriptionDocument24 pagesRF02 Universal ISM Band FSK Transmitter: DescriptionMUHAMMAD SISWANTORONo ratings yet

- 3 MP 8030Document31 pages3 MP 8030Mariano SanchezNo ratings yet

- Alexander-Sadiku: Fundamentals of Electric CircuitsDocument25 pagesAlexander-Sadiku: Fundamentals of Electric CircuitsUmar FarooqNo ratings yet

- User's Manual: Intelligent Solar Charge ControllerDocument14 pagesUser's Manual: Intelligent Solar Charge Controllermailvipinck123No ratings yet

- HP Compac 4000 Pro Small PCDocument4 pagesHP Compac 4000 Pro Small PCHebert Castañeda FloresNo ratings yet

- Deh 5200SD - Deh 5250SD - Deh 5290SDDocument80 pagesDeh 5200SD - Deh 5250SD - Deh 5290SDAllnightlonificationNo ratings yet

- Dell Inspiron 3520 10316-1 DV15 HR 48.4IP16.011Document60 pagesDell Inspiron 3520 10316-1 DV15 HR 48.4IP16.011Bala MuruganNo ratings yet

- Grigorie2008 PDFDocument10 pagesGrigorie2008 PDFManasi NaikNo ratings yet

- Tektro WFM601 Manuel USDocument216 pagesTektro WFM601 Manuel US12BAcNo ratings yet

- Ms 8167 C 70Document58 pagesMs 8167 C 70Marian StanicaNo ratings yet

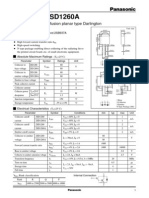

- NPN Transistor-13042 Panasonic 2sd1260Document2 pagesNPN Transistor-13042 Panasonic 2sd1260AnnalisavivianaNo ratings yet

- Bipolar Junction Transistors (BJT) : Electronic Circuit Design 1Document44 pagesBipolar Junction Transistors (BJT) : Electronic Circuit Design 1Nhật NamNo ratings yet

- Lan Design 1 NotesDocument2 pagesLan Design 1 Noteshht7879No ratings yet

- Cell Phone Jammer: By:-Ganesh Pathak Pallavi Mantri Rohit Patil Pawan KumarDocument16 pagesCell Phone Jammer: By:-Ganesh Pathak Pallavi Mantri Rohit Patil Pawan KumarvishalsinghvivekNo ratings yet

- HP 1702Document143 pagesHP 1702kperen100% (1)

- RX RegenDocument8 pagesRX RegenhgbarieroNo ratings yet

- iF320S iF310S iF410S iF420S: Instruction ManualDocument20 pagesiF320S iF310S iF410S iF420S: Instruction ManualEduardo MazzoniNo ratings yet

- hc5fw300-s sp1Document7 pageshc5fw300-s sp1harigopalk12No ratings yet

- Application VT1005 PW8001 Solar E1 220829Document3 pagesApplication VT1005 PW8001 Solar E1 220829Joel DsouzaNo ratings yet

- CMX 138 e 1Document68 pagesCMX 138 e 1serga333No ratings yet

- SM2135E ZH-CN en-US TranslatedDocument9 pagesSM2135E ZH-CN en-US TranslatedAdnan KutsiNo ratings yet