Professional Documents

Culture Documents

Iec-62264 Based Quality Operations Management

Iec-62264 Based Quality Operations Management

Uploaded by

tss13723Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iec-62264 Based Quality Operations Management

Iec-62264 Based Quality Operations Management

Uploaded by

tss13723Copyright:

Available Formats

WEB ISSN 2535-003X

SCIENTIFIC PROCEEDINGS XIV INTERNATIONAL CONGRESS "MACHINES. TECHNOLОGIES. MATERIALS." 2017 - SUMMER SESSION PRINT ISSN 2535-0021

IEC-62264 BASED QUALITY OPERATIONS MANAGEMENT ACCORDING THE

PRINCIPLES OF INDUSTRIAL INTERNET OF THINGS

Prof. Dr. Batchkova I. A., Assoc. Prof. Dr. Gocheva D. G., Eng. Georgiev D.

Dept. of Industrial Automation, University of Chemical Technology and Metallurgy

Bul. Kl. Ohridski 8, Sofia, Bulgaria

idilia@uctm.edu, dani@uctm.edu

Abstract: Manufacturing Operations Management (MOM) systems as central information and data hub play a very important role for an

easy and seamless transition to Industrial Internet of Things (IIoT) applications. IIoT is mainly used in the context of Industry 4.0, that

pursues the organization and management of value-added processes in the manufacturing industry with means of digitalization. The main

aim of the proposed paper is to suggest some modifications to the IEC 62264 based models and architectures using RAMI 4.0 reference

architecture in order to follow the basic principles of IoT and achieving the main advantages of IIoT.

Keywords: INTERNET OF THINGS, OPERATIONS MANAGEMENT, QUALITY, REFERENCE ARCHITECTURE, ISO/IEC 62264

1. Introduction functional descriptions and only some modifications are needed to

achieve an IIoT application.

Achievements in industry are closely related to the use of the

latest developments in information and communication technology. Manufacturing Operations Management (MOM) systems are

Regardless of the progress made in using ICT, modern enterprises key element in achieving IIoT applications, or also known smart

are characterized by a relatively static IT architecture that cannot factories. They are increasingly used for real-time control and

cope with the changes and uncertainties, lack of flexibility of visualization of production sequences, linking the manufacturing

hardware and software systems as well as rigid boundaries between facilities with the business information systems and staying in the

cooperating companies. It has been found that the advanced Internet middle of automation pyramid. IEC 62264 standard supports the

of Things (IoT) paradigm can address these issues by ensuring development and use of MOM, providing standard models and

reliable data collection and sharing, ubiquitous computing, and terminology for describing the activity models of manufacturing

computing clouds using powerful resources to solve a variety of operations management and interfaces between the business

decision-making tasks that abound in production systems. systems of an enterprise and its manufacturing operations and

control systems, in order to integrate them [6, 7]. Quality operations

IoT is an Internet extension that provides immediate access to management is an important set of activities in the frame of MOM

information about physical objects and leads to innovative services and is very suitable for a transition to IioT application.

with high efficiency and productivity [1]. IoT is also known as

ubiquitous computing, ambient intelligence, and distributed The main aim of the proposed paper is to suggest some

electronics. The core concept is that everyday objects can be modifications to IEC 62264 based models and architectures in

equipped with identifying, sensing, networking and processing respect to the Quality operations management using RAMI 4.0

capabilities that will allow them to communicate with one another reference architecture in order to follow the basic principles of IoT

and with other devices and services over the Internet to achieve and achieving the main advantages of IIoT.

some useful objective.[2] The paper is organized in 4 parts. After the introduction, in part

The Industrial Internet of Things (IIoT) is the industrial 2 the basic principle of IIoT are proposed. Part 3 discusses the

application of IoT paradigm and is mainly used in the context of ISO/IEC 62264 standard as a part in the IIoT architecture with a

Industry 4.0. Industry 4.0 describes a new industrial revolution with special attention on the quality operations management. In Part 4 of

a focus on automation, innovation, data, cyber-physical systems, the paper the suggested approach is described. Finally some

processes and people. Considering a faster adoption of the new conclusions are made.

concept by industry, it is desirable to ensure a smooth transition to

new technologies through the use of transition technologies and

2. Basic Principles of Industrial Internet of Things

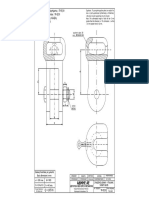

standards to achieve the IIoT objectives without major investment. Tom Bradicich [8] defines 7 basic principles of IoT, as shown in

For this reason, there are plenty of prerequisites in the industry: Fig.1:

embedded devices and controllers, wireless sensor networks, RFID

“Big Analog Data” - The IoT will include vast numbers of

technologies and more. While hardware industry is relatively

heterogeneous predominately analog devices and sensors,

prepared for a transition to IIoT, there are serious challenges to

generating enormous quantities of variable analog data that is the

software and architectures. An important step in the right direction

oldest, fastest, and biggest of all big data. Analog data needs to be

is to use reference architecture that aims to achieve interoperability,

treated differently than digital data, and the unresolved problem is

simplify development, and facilitate implementation. Some of the

the extraction of business value from big analog data.

most popular reference architectures are: RAMI4.0 [3], IIRA [4],

IoT-A [5]. While IoT-A focuses on the functional and informational “Perpetual Connectivity” - the IoT presents perpetual

aspects of the architecture, RAMI4.0 of the Working Group for connectivity to the product and user, supporting 3 main

Industry 4.0 and IIRA of the Industrial Internet Consortium are functionalities:

industry-focused. Between the last two reference architectures exist • Monitor - continuous observing and checking the progress or

some similarities and intersections, and there is an agreement quality of products, users on the market or industrial settings,

between organizations to precisely identify the interoperability allowing their systematic review;

features between the two architectural paradigms and try to align • Maintain – to keep equipment in a good condition trough

them, as well for defining standardization requirements and using convenient push of upgrades, fixes patches and management;

common test beds. The approach, proposed in this paper is based on • Motivate – the ongoing connection to users or workers shows the

RAMI 4.0 model, because it is built upon existing standards and way to force or motivate others to take some actions, purchase a

product, accessories, etc.

431 YEAR I, VOLUME VI, P.P. 431-434 (2017)

WEB ISSN 2535-003X

SCIENTIFIC PROCEEDINGS XIV INTERNATIONAL CONGRESS "MACHINES. TECHNOLОGIES. MATERIALS." 2017 - SUMMER SESSION PRINT ISSN 2535-0021

“Really Real Time”- IoT blends the world of Operational PLM ERP SCM CRM

Technology with the world of Information Technology, following a Enterprise application integration

4 tier generalized solutions architecture for the IoT, and its related

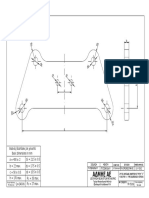

ISO/IEC 62264 Part 1 and 2 Object model information

data flows:

• Tier 1: Sensor/actuator (wired, wireless); Product definition

(what to make)

Product capability

(what and how

much is available to

Product schedule

(what to make and

Product response

(what was made and

• Tier 2: Internet gateways, Data acquisition systems (data

use) used)

make)

ISO/IEC 62264 Part 3 Activity models of Manufacturing Operations

aggregation, A/D, measurement, control actuation);

Maintenance

• Tier 3: Edge IT (analytics, pre-processing); Inventory

Production

• Tier 4: Data center/Cloud (Analytics, management, archive). Quality

“The Spectrum of Insight”(Спектър на прозрение) - Data

Resource Management

Performance Analysis

Data collection

Dispatching

analytics will be executed at 4 main domains

Scheduling

Execution

Definition

Tracking

• At the sensor in the I/O channel;

• At the gateway or DAQ device;

• At the edge server or PC;

• At the data center or cloud. Process Control (Field instruments, DCS, PLC, sensors, etc.)

“Immediacy Versus Depth” - Using advanced computer

techniques and depending on the type of tasks solved, a Fig.2: ISO/IEC 62264 Manufacturing Architecture [9]

compromise between speed and depth has to be found (so known

“immediacy of insight vs. depth of insight”). Some tasks require According ISO/IEC 62264 the activities in manufacturing

immediate access to data and results from simple calculations, while operations management are divided into four main areas:

others require more time to extract deep knowledge. Production operation management, Maintenance operations

“Shift Left” - computation and data analytics will migrate to the management, Quality operations management and Inventory

lower tiers in the 4 Tier generalized solutions architecture of the operations management. For all areas a common activity model of 8

IoT, enabling components and machines to gain self-awareness and activities (definition, planning, dispatching, resource provision,

self-predictiveness. implementation, data collection, tracking and analysis) is suggested.

“The Next ‘V’” - The IoT eliminates time and place constraints The interrelationships between the four areas of MOM and the links

allowing access from disparate geographic locations and with the main categories of information exchange defined in the

representing the “Visibility” of Big Data. Such a way IoT adds a standard are presented in Fig.3.

next “V” to the traditional “V’s” of Big Data, which are: variety Level 4

Performance

(mix of structures), volume (large amounts), velocity (high speed, Production

Quality Test

Quality Test

Schedule

Production

Response

Request

high sample rates), value (importance of analysis, which was

Quality

previously limited by technology). Product Test

Definition

Definition Quality Test Request

Production Quality

Operations Quality Test Response Operations

Production Management st

Management Quality Test

Capability De Te t Capability

ta ty

ile ali ues

d Qu Req

Maintenance

Ma Ma

Request

Maintenance

in int

Response

Inventory

Response

Re ten

Inventory

Request

sp an en

on ce an Ma

se ce in

Sc R ten

he equ anc

du es e

st le t

Te e

ty

Inventory ali ons

Qu esp Maintenance

Control R

Definition Inventory Maintenance Definition

Maintenance Request

Operations Operations

Inventory Management Maintenance Response Management Maintenance

Capability Capability

Maintenance

Maintenance

Response

Response

Inventory

Inventory

Request

Request

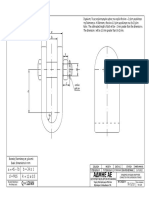

Fig.3: Interrelations between the areas of manufacturing operations

management [7]

Fig.1: Basic principles of IoT 3.2. Quality operations management according ISO/IEC 62264

Quality operations management in the ISO/IEC 62264 standard

3. IEC-62264 standard as a part of IIoT is defined as a set of activities, which coordinate, manage and track

3.1. Short review and analysis of ISO/IEC-62264 Standard the functions that measure and report quality. Quality operations

management activities include: assessment of raw materials,

ISO/IEC 62264 (ANSI/ISA-S95) series of standards [6, 7] offer intermediate and finished products, collection and maintenance of

the technology and a vendor independent way to exchange data and data records, use of analysis, real-time decision making,

information. These standards are an agreement between leading classification and certification tests, validation of measurements,

companies (SAP AG, Eli Lilly, The Foxboro Co., Hewlett-Packard, maintenance of statistics for quality management.

Honeywell, Rockwell Automation, IBM Corp., Oracle Corp., ABB

etc.) to create a common framework and guidelines for design and The activity model for quality operations management,

integration of systems. The standard ISO/IEC 62264 facilitate to presented in Fig.4, defines what quality verification activities

separate business process from production processes and to separate should be performed and the relative sequence of activities without

the exchanged information from specific implementation of specifying the way they are to be performed. The information

manufacturing systems and specific implementations of the related to the quality operations management according to the

business systems. The standard provides standard models and activity model is associated with the level 2 functions in the

terminology for describing the interfaces between the business following categories: parameters and procedures, automatic

systems of an enterprise and its manufacturing-control systems commands for performing tests and obtaining results from them.

(Fig.2). Activities related to manufacturing operations management Information flows from and to level 3 are classified as test

(Level 3) integrate planning and logistics (level 4) and control definitions, resources, queries, and quality test results. The standard

functions defined on Level 2. defines 8 types of activities related to the functions of the operations

432 YEAR I, VOLUME VI, P.P. 431-434 (2017)

WEB ISSN 2535-003X

SCIENTIFIC PROCEEDINGS XIV INTERNATIONAL CONGRESS "MACHINES. TECHNOLОGIES. MATERIALS." 2017 - SUMMER SESSION PRINT ISSN 2535-0021

management systems for quality testing (Fig.3): Quality test • Transparent (visible) factory - In his role as a central

definition, Quality test resource, Detailed quality test scheduling, information and data hub, the MOM systems connect the business

Quality test dispatching, Quality test execution, Quality test data level in the form of the ERP system to the shop floor, thus ensuring

collection, Quality test performance analysis and Quality test mutual understanding and ultimately more transparency.

tracking. • Reactive factory (decentralization and autonomy) – based on

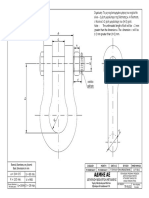

Quality test Quality test Quality test Quality test

identification of disturbances, detailed scheduling and reactive

definitions capability request response control

• Self-regulating factory - achieve more control loops and

Detailed decentralization of tasks, control and the corresponding

quality test responsibilities. However, central synchronization is essential.

scheduling

• Functional networking factory – based on interface between

Quality

Quality test product development and production that is between PLM (product

test resource

tracking

management

lifecycle management system) and MOM system, as well

Quality integrated quality assurance, a production-oriented energy

Quality test

performance

dispatching management as well as the broadening of the viewing space to

analysis

Quality Quality suppliers and customers - that is, to the complete supply chain.

test definition test data

management collection

The analysis of the above steps shows that paramount in

Quality test

execution building IIoT applications is the implementation of IEC 62264

management based МOM system that supports the realization of three from all

Quality

Test Test Quality

parameters and

procedures

commands responses specific data four steps. However, in order to achieve Step 3, it is necessary to

solve the task of decentralizing the hierarchical model proposed in

Quality test level 1-2 functions

IEC 62264 standard according to the idea, presented in Fig.6. There

are different approaches to successful decentralization in order to

Fig.4: Activity model of quality operations management [7] enhance integration and collaboration between decentralized

components and to achieve self-X features of the system. The most

3.3. ISO/IEC 62264 as a part of RAMI4.0 successful and reliable approaches are those of Service Oriented

Architecture (SOA) [10] and multi-agent systems (MAS) [11], as

The reference architectural model RAMI 4.0, proposed for well the emerging infrastructures for fog or edge computing [12,

Industry 4.0 and shown in Fig.5, is three-dimensional and describes 13]. MAS are widely used in the design of distributed

the crucial aspects of Industry 4.0 [3]. The “Hierarchy level” axis manufacturing control systems with the purpose to enhance the

includes the hierarchy levels defined in the ISO/IEC 62264 horizontal and vertical integration of the enterprise systems. A short

standard, including all different functionalities in the factory. In the survey of the applied approaches is given in [14]. The fog

RAMI 4.0 the functionalities are extended to the “product” computing extends the cloud computing closer to the enterprises

according IEC 61512 standard and to “connected world”. The left network and is a horizontal, system-level architecture that

horizontal axis represents the life cycle of the facilities and distributes computing, storage, control and networking functions

products, based on the IEC 62890 standard and the vertical axis closer to the users along a cloud-to-thing continuum [12]. Very

represents the six layers for decomposing into its properties. The often the fog and edge computing are used interchangeably, but

reference model allows a step-by-step migration from present into between them there is a difference in respect to the involved

the world of Industry 4.0. RAMI 4.0 integrates different user pushing intelligence and processing capabilities [13]. While the fog

perspectives and provides a common understanding of Industry 4.0 computing pushes intelligence down to the local area network level

technologies. It is a foundation for the following next steps towards of network architecture, processing data in a fog node or IoT

Industry 4.0: thing identification, unified semantics and common gateway, the edge computing uses for this purpose edge gateway or

syntax for data, defining of QoS components, communication appliance directly into devices like programmable automation

connections and protocols. controllers.

Fig.6: Transformation of automation pyramid

The IT structure of an IIoT components according RAMI 4.0 is

represented on the vertical axis and consists of six layers. This

Fig.5: Activity model of quality operations management [3]

layers help to visualize business processes, functional descriptions,

data mappers, the communication behavior including Quality of

4. Quality operations management as IIoT Service (QoS), and the linking of assets via an integration layer.

application The data generated during production and in some cases customer-

specific data for a specific instance is also considered as an asset.

For achieving an IIoT application of quality operations

management system, a smooth migration path from existing The structure and sequence of operations at the functional level

deployments to emerging future internet technologies is needed. for Work Centers follows the proposed IEC 62264 based activity

There is a consensus on the main steps to be taken [9], namely: model, and in Fig.7a the activities and operations realized at this

stage of development are presented. These are mainly related to

433 YEAR I, VOLUME VI, P.P. 431-434 (2017)

WEB ISSN 2535-003X

SCIENTIFIC PROCEEDINGS XIV INTERNATIONAL CONGRESS "MACHINES. TECHNOLОGIES. MATERIALS." 2017 - SUMMER SESSION PRINT ISSN 2535-0021

checking and evaluating the quality of intermediate and final quality of end products and efficiency of manufacturing system.

products, collecting and maintaining records, reporting on The use of IEC 62264 based models and terminology shorten the

classification results, using "at-time" analysis for decision-making development time and reusability of models and architectures. The

in real time in terms of technology mode and specific technology transition from object-oriented models to semantic models enhances

map. According to the information from the business level for the the interoperability of IIoT components at the different levels of

quality of raw materials and product requirements, an intermediate RAMI 4.0 reference architecture. The use of reasoning mechanisms

quality assurance procedure for intermediates has been established and the creation of rules based on the formalism of descriptive logic

with the help of the resource database. The information stored in the support the creation of a knowledge-based system capable of

database can be analyzed using various means of information responding to changes in the product quality and quality assurance

processing and decision making. Tracking the change of procedures. In addition the quality operations management systems

information is essential for the future implementation of the detailed comprise quality analysis functionalities and are a source for new

scheduling of quality assurance procedures. information; they can assist with optimizing the quality parameters.

The systems offer a rational functional supplement for detailed

scheduling of quality assurance procedures and controlling all

quality parameters in real time for ensuring process and product

quality transparency.

6. References

1. Bandyopadhyay D., Sen J., Internet of things: Applications and

challenges in technology and standardization, Wireless Pers.

Commun., vol. 58, pp. 49–59, 2011.

2. Whitmore A., Agarwal A., Xu L. D., The Internet of Things - а

survey of topics and trends, Inf. Syst. Front (2015) 17:261–274.

3. VDI/VDE/ZVEI, GMA Status Report: Reference architectural

model Industry 4.0 (RAMI4.0), 2015, https://www.vdi.de/.../VDI-

GMA_Statusreport_Referenzarchitektur.

4. IIC Working TWG and SWG, Industrial Internet Reference

Architecture (IIRA), IIC, 2015, www.iiconsortium.org/IIRA-1-

7-ajs.pdf.

Fig.7: IT structure of quality operations management system based 5. IoT-A 7FP project, Internet of Things Reference Architecture

on RAMI 4.0 IoT-A, 2012, www.meet-iot.eu/deliverables-IOTA/D1_3.pdf

The quality operations management systems use a large amount 6. ISO/IEC 62264-1 (2013), “Enterprise-Control System

of data from different data models. These models address different Integration, Part 1: Models and Terminology, CEN/CENELEC

problems, have different users, may have been designed at different Management Centre, Brussels.

times, or may have come from different plant areas. In order to 7. ISO/IEC 62264-3 (2007), “Enterprise-Control System

integrate and use these models, semantic technologies are used, Integration, Part 3: Activity models of manufacturing operations

based on the development of IEC 62264 based meta-ontology management, CEN/CENELEC Management Centre, Brussels.

(Fig.7b) and different domain ontologies, as well an ontology for

8. Bradicich T., The 7 Principles of the Internet of Things (IoT),

quality operations management, according to the standard model in

2015, available at: http://blog.iiconsortium.org/2015/07/the-7-

ISO/IEC 62264 Part 4: Object Models and Attributes of

principles-of-the-internet-of-things-iot.html.

Manufacturing Operations Management [16] and integrate it with

the meta-ontology. In this way the quality management information, 9. Clark D., ISA S95 - Invensys Operations Management,

structured by the basic classes in the meta-ontology: “Material”, Invensys presentation-6/8/2010.

“Equipment”, “ProcessSegment” is connected with the five main 10. Kletti J., In four steps to the Smart Factory (in German), White

interface classes, defining the relations Production-Process-Product: paper of MPDV, March, 2016, request under

“ProductDefinition”, “ProductionCapability”, “ProductionSchedule”, http://mpdv.info/wpnews.

“ProcessSegmentCapability” and “ProductionPerformance” ensuring

the main tasks in quality operation management: Quality test 11. Lojka T., Bundzel M., Zolotová I., Service-oriented

definition management. Quality test resource management, Detailed Architecture and Cloud Manufacturing, Acta Polytechnica

quality test scheduling, Quality test dispatching, Quality test Hungarica, Vol. 13, No. 6, pp.25-44, 2016.

execution management, Quality test data collection, Quality test 12. Castellini P., Cristalli C., Foehr M., Leitao P., Paone N.,

tracking, Quality performance analysis. The ontological approach Schjolberg I., Tjønnås J., Turrin C., Wagner T., Towards the

allows the creation of a knowledge-based system able to identify integration of process and quality control using multi-agent

changes in the quality and to support decision-making through the technology, IECON 2011 - 37th Annual Conference on IEEE

integration of domain ontology and semi-structured data, including Industrial Electronics Society, 7-10 Nov. 2011, pp.374-379.

data from laboratory analyzes of raw materials and end products. 13. OpenFog Consortium, OpenFog Reference Architecture for Fog

Integration of different models and data ensures flexible Computing, February 2017, www.OpenFogConsortium.org.

communication between enterprise information systems by ensuring

interoperability and mutual exchange of information. The aggregate 14. Greenfield D., Fog Computing vs. Edge Computing: What’s the

model provides data sharing capabilities and the ability to retrieve Difference?, https://www.automationworld.com/fog-computing-

information from distributed heterogeneous sources for decision vs-edge-computing-whats-difference.

making, Key Performance Indicators (KPIs) calculations, and 15. Leitao P., Karnouskos S., Ribeiro L., Lee J., Strasser T.,

optimization of manufacturing and business processes. Colombo A. W., Smart Agents in Industrial Cyber-Physical

Systems, 2016, Proceedings of the IEEE, (104), 5, 1086-1101.

5. Conclusions

16. ISO/IEC 62264-4 (2015), “Enterprise-Control System

The transformation of MOM systems and especially quality Integration, Part 4: Object Models and Attributes of

operations management systems according to the basic principles manufacturing operations management, CEN/CENELEC

and reference architecture of IIoT for their integration into the Management Centre, Brussels.

structure of IIoT applications is an important step in achieving high

434 YEAR I, VOLUME VI, P.P. 431-434 (2017)

You might also like

- How To Use ChatGPT Effectively A Guide To Master Generative AIDocument10 pagesHow To Use ChatGPT Effectively A Guide To Master Generative AIBirkimsaNo ratings yet

- Software-defined data center The Ultimate Step-By-Step GuideFrom EverandSoftware-defined data center The Ultimate Step-By-Step GuideNo ratings yet

- Road Ahead For Augmented Reality (PWC)Document8 pagesRoad Ahead For Augmented Reality (PWC)Gina Smith0% (1)

- IDC Futurescapes Predictions 2018 PDFDocument25 pagesIDC Futurescapes Predictions 2018 PDFVasilis KoutsoubasNo ratings yet

- 2002-10 ISA S95 Part 3 OverviewDocument12 pages2002-10 ISA S95 Part 3 OverviewDo Van TuNo ratings yet

- Augmented Reality SEMINAR REPORT SubmittDocument65 pagesAugmented Reality SEMINAR REPORT SubmittIQFA mughalNo ratings yet

- Forrester Wave RES138050Document20 pagesForrester Wave RES138050Jorge GarzaNo ratings yet

- ISA-95 Integration Standards A Complete Guide - 2019 EditionFrom EverandISA-95 Integration Standards A Complete Guide - 2019 EditionNo ratings yet

- Internet of Things: Visualise The ImpactDocument34 pagesInternet of Things: Visualise The ImpactPetarKrešimirBarbaNo ratings yet

- 1963-Petroleum and Gas Industry Manpower RequirementsDocument119 pages1963-Petroleum and Gas Industry Manpower Requirementsgiorgis072No ratings yet

- FRACAS Military Standard PDFDocument17 pagesFRACAS Military Standard PDFFirdaus TahirNo ratings yet

- Unleashing The Power of Data With Iot and Augmented RealityDocument24 pagesUnleashing The Power of Data With Iot and Augmented RealityAbhiseka MohapatraNo ratings yet

- Virtual Furniture Using Augmented Reality TechniqueDocument3 pagesVirtual Furniture Using Augmented Reality TechniqueEditor IJRITCCNo ratings yet

- 2020 DX IDC FutureScape - 2020 Webcon PPT FinalDocument11 pages2020 DX IDC FutureScape - 2020 Webcon PPT FinalAnuj MehrotraNo ratings yet

- IoT Worldwide Regional 2014 2020 ForecastDocument29 pagesIoT Worldwide Regional 2014 2020 ForecastRaja Sekhar SharmaNo ratings yet

- Re-Inventing Business Analysis: New Skills?: Planning and MonitoringDocument11 pagesRe-Inventing Business Analysis: New Skills?: Planning and MonitoringknotseloNo ratings yet

- Thesis MVZ v1.0 PDFDocument134 pagesThesis MVZ v1.0 PDFericNo ratings yet

- The Intelligent Enterprise For The High Tech IndustryDocument28 pagesThe Intelligent Enterprise For The High Tech IndustryLuis RamosNo ratings yet

- Click: Interactive PDF - Instead of SCR Olling!Document19 pagesClick: Interactive PDF - Instead of SCR Olling!Mozzy Crazzy100% (1)

- International Journal of Computational Engineering Research (IJCER)Document4 pagesInternational Journal of Computational Engineering Research (IJCER)International Journal of computational Engineering research (IJCER)No ratings yet

- A Big Data Enabled Load-Balancing Control For Smart Manufacturing of Industry 4.0Document10 pagesA Big Data Enabled Load-Balancing Control For Smart Manufacturing of Industry 4.0alexanderfortis8628No ratings yet

- Mes2.0 SepasoftDocument2,917 pagesMes2.0 SepasoftDiaz greyNo ratings yet

- CMM Nokia CapacityDocument57 pagesCMM Nokia CapacityHernan BatiNo ratings yet

- Key Performan Indicators SoftwareIndustry1.2Document8 pagesKey Performan Indicators SoftwareIndustry1.2Aaron_GeaNo ratings yet

- Accenture Connected Business OnlineDocument8 pagesAccenture Connected Business OnlinejosephchainesNo ratings yet

- Microsoft Azure Media ServiceDocument13 pagesMicrosoft Azure Media ServiceJames WarnerNo ratings yet

- Simatic St80 STPC Complete English 2013Document676 pagesSimatic St80 STPC Complete English 2013Galal Saif KariemNo ratings yet

- Week6Introduction To Advanced MaterialsDocument4 pagesWeek6Introduction To Advanced Materialsmarlon corpuzNo ratings yet

- Isa S95-222Document32 pagesIsa S95-222optisearchNo ratings yet

- Virtual Reality in Sports 1Document6 pagesVirtual Reality in Sports 1api-457303233No ratings yet

- 2.5.18 - MESA White Paper 58 Smart-Mfg-Importance of Standards FINALDocument17 pages2.5.18 - MESA White Paper 58 Smart-Mfg-Importance of Standards FINALMarc OlivéNo ratings yet

- Integrating Requirements of Industry 4.0 Into Maritime Education PDFDocument94 pagesIntegrating Requirements of Industry 4.0 Into Maritime Education PDFMichael Abanilla AmonNo ratings yet

- Industry 4.0 - Chances and Challenges of The Digital TransformationDocument50 pagesIndustry 4.0 - Chances and Challenges of The Digital TransformationShared AxNNo ratings yet

- Business To Manufacturing Markup Language Material Version 6.0 - March 2013 B2MML-MaterialDocument19 pagesBusiness To Manufacturing Markup Language Material Version 6.0 - March 2013 B2MML-MaterialWass GharbiNo ratings yet

- Cloud-Based Industrial Cyber-Physical System For Data-Driven Reasoning. A Review and Use Case On An Industry 4.0 Pilot LineDocument9 pagesCloud-Based Industrial Cyber-Physical System For Data-Driven Reasoning. A Review and Use Case On An Industry 4.0 Pilot LineSrichandan SobhanayakNo ratings yet

- Carwash Management SystemDocument92 pagesCarwash Management SystemAdam ChengulaNo ratings yet

- T061 Isa95-04Document32 pagesT061 Isa95-04Haogoaro ZrNo ratings yet

- World Class EA A Leader's Approach To Establishing and Evolving An EA Capability W160Document112 pagesWorld Class EA A Leader's Approach To Establishing and Evolving An EA Capability W160Faqih ZulfikarNo ratings yet

- An ISA-95-based Manufacturing Intelligence System in Support of Lean InitiativesDocument15 pagesAn ISA-95-based Manufacturing Intelligence System in Support of Lean InitiativesGlauco SantiagoNo ratings yet

- Bridging The Gap Between Operational Technology and Information TechnologyDocument8 pagesBridging The Gap Between Operational Technology and Information TechnologymauriziolapucaNo ratings yet

- Big Data Processing and Analytics Platform Architecture For Process Industry FactoriesDocument15 pagesBig Data Processing and Analytics Platform Architecture For Process Industry FactoriessergioNo ratings yet

- Whitepaper ARC Process Control PCS7+CPASDocument30 pagesWhitepaper ARC Process Control PCS7+CPASCuconnacht BookfacesuckNo ratings yet

- OPC UA Security Advise EN PDFDocument24 pagesOPC UA Security Advise EN PDFDaniel Sánchez De MarcosNo ratings yet

- Digital Transformation - Takeouts 1Document25 pagesDigital Transformation - Takeouts 1ahmad_shishan2584No ratings yet

- Hype CycHype Cycle For Application Development 2007le For Application Development 2007Document47 pagesHype CycHype Cycle For Application Development 2007le For Application Development 2007lacasa3No ratings yet

- Ey Is Your Business Transforming Its Technology or Is Technology Transforming Your BusinessDocument6 pagesEy Is Your Business Transforming Its Technology or Is Technology Transforming Your BusinessakashNo ratings yet

- OPC-UA For ISA95Document15 pagesOPC-UA For ISA95vpascarielloNo ratings yet

- Manufacturing Log Research BookDocument18 pagesManufacturing Log Research BookAjit Kumar SubramanyamNo ratings yet

- Digital Transformation Published ArticleDocument5 pagesDigital Transformation Published ArticleAnjoNo ratings yet

- Reference Architecture and Maturity Levels For Cyber-Physical Systems in The Mechanical Engineering Industry PDFDocument6 pagesReference Architecture and Maturity Levels For Cyber-Physical Systems in The Mechanical Engineering Industry PDFMaleja Camargo VilaNo ratings yet

- Ernest - Adding Value To The It Organization With The CBM - 1Document17 pagesErnest - Adding Value To The It Organization With The CBM - 1tessioyudi2070No ratings yet

- Investigating System RequirementsDocument60 pagesInvestigating System RequirementsKitambulio abdullyNo ratings yet

- WBF Implementing B2MMLDocument9 pagesWBF Implementing B2MMLvpascarielloNo ratings yet

- 1 Intro To SCM Strategy and ValueDocument38 pages1 Intro To SCM Strategy and ValueDerv BreenNo ratings yet

- Wonderware Manufacturing Solutions: Mike LlapitanDocument21 pagesWonderware Manufacturing Solutions: Mike LlapitandhinojahimeshNo ratings yet

- DCOR 1.0 Reference GuideDocument5 pagesDCOR 1.0 Reference GuideJeff SamNo ratings yet

- Manual FestoDocument158 pagesManual FestoEliúh CuecuechaNo ratings yet

- b2mml v0401 CommonDocument35 pagesb2mml v0401 CommonChristopher Jeffry HamiltonNo ratings yet

- Business To Manufacturing Markup Language Batch Production Record Version 6.0 - March 2013 Batchml - Batch Production RecordDocument40 pagesBusiness To Manufacturing Markup Language Batch Production Record Version 6.0 - March 2013 Batchml - Batch Production RecordWass GharbiNo ratings yet

- Product: 44432 Current Date (Do Not Change/delete)Document25 pagesProduct: 44432 Current Date (Do Not Change/delete)Joyce ShiNo ratings yet

- Smart Factory - EricssonDocument14 pagesSmart Factory - EricssonFebby MellianiNo ratings yet

- AEO2020 Full ReportDocument81 pagesAEO2020 Full Reportgiorgis072No ratings yet

- 3.3. TR5 TR 5-20Document1 page3.3. TR5 TR 5-20giorgis072No ratings yet

- AEO2020 Full ReportDocument144 pagesAEO2020 Full Reportgiorgis072No ratings yet

- 3.3. TR5 TR 5-19Document1 page3.3. TR5 TR 5-19giorgis072No ratings yet

- 3.3. TR5 TR 5-18Document1 page3.3. TR5 TR 5-18giorgis072No ratings yet

- 3.3. TR5 TR 5-16Document1 page3.3. TR5 TR 5-16giorgis072No ratings yet

- 3.3. TR5 TR 5-21Document1 page3.3. TR5 TR 5-21giorgis072No ratings yet

- 3.3. TR5 TR 5-15Document1 page3.3. TR5 TR 5-15giorgis072No ratings yet

- 3.3. TR5 TR 5-09Document1 page3.3. TR5 TR 5-09giorgis072No ratings yet

- 3.3. TR5 TR 5-17Document1 page3.3. TR5 TR 5-17giorgis072No ratings yet

- 3.3. TR5 TR 5-10Document1 page3.3. TR5 TR 5-10giorgis072No ratings yet

- 3.3. TR5 TR 5-14Document1 page3.3. TR5 TR 5-14giorgis072No ratings yet

- 3.3. TR5 TR 5-13Document1 page3.3. TR5 TR 5-13giorgis072No ratings yet

- 3.3. TR5 TR 5-12Document1 page3.3. TR5 TR 5-12giorgis072No ratings yet

- 3.3. TR5 TR 5-04Document1 page3.3. TR5 TR 5-04giorgis072No ratings yet

- 3.3. TR5 TR 5-11Document1 page3.3. TR5 TR 5-11giorgis072No ratings yet

- 3.3. TR5 TR 5-07Document1 page3.3. TR5 TR 5-07giorgis072No ratings yet

- 3.3. TR5 TR 5-08Document1 page3.3. TR5 TR 5-08giorgis072No ratings yet

- 3.3. TR5 TR 5-06Document1 page3.3. TR5 TR 5-06giorgis072No ratings yet

- 3.3. TR5 TR 5-03Document1 page3.3. TR5 TR 5-03giorgis072No ratings yet

- 3.3. TR5 TR 5-01Document1 page3.3. TR5 TR 5-01giorgis072No ratings yet

- 3.3. TR5 TR 5-02Document1 page3.3. TR5 TR 5-02giorgis072No ratings yet

- 3.3. TR5 TR 5-05Document1 page3.3. TR5 TR 5-05giorgis072No ratings yet

- 3.3. TR5 TR 5-00-10Document1 page3.3. TR5 TR 5-00-10giorgis072No ratings yet

- U.T.S.: 330kN All Dimensions Are in MM.: Aney No ScaleDocument1 pageU.T.S.: 330kN All Dimensions Are in MM.: Aney No Scalegiorgis072No ratings yet

- 3.3. TR5 TR 5-00-9Document1 page3.3. TR5 TR 5-00-9giorgis072No ratings yet

- U.T.S.: 165kN All Dimensions Are in MM.: Aney No ScaleDocument1 pageU.T.S.: 165kN All Dimensions Are in MM.: Aney No Scalegiorgis072No ratings yet

- 3.3. TR5 TR 5-00-5Document1 page3.3. TR5 TR 5-00-5giorgis072No ratings yet

- 3.3. TR5 TR 5-00-6Document1 page3.3. TR5 TR 5-00-6giorgis072No ratings yet

- Desktop Publishing Final Review Multiple ChoiceDocument24 pagesDesktop Publishing Final Review Multiple ChoiceHasen MediaNo ratings yet

- Aodb EngDocument48 pagesAodb EngZaharNo ratings yet

- 3up S4CLD2308 BPD en XXDocument42 pages3up S4CLD2308 BPD en XXyahya.ayari.06No ratings yet

- Transportation Algorithm: Nova Sepadyati, M.SCDocument34 pagesTransportation Algorithm: Nova Sepadyati, M.SCLivienia SugiartoNo ratings yet

- JDBC Practice ProgramsDocument10 pagesJDBC Practice ProgramsAyisha Sadiq shaikNo ratings yet

- The Complete Guide To Microsoft Access 20211Document5 pagesThe Complete Guide To Microsoft Access 20211Jaime Jr CarlosNo ratings yet

- Assignment 1Document2 pagesAssignment 1janvi patelNo ratings yet

- VW Vento User Manual PDFDocument4 pagesVW Vento User Manual PDFMaiyappan Muniandy100% (2)

- QuadaoDocument5 pagesQuadaotien dangNo ratings yet

- AWMDA Version 6 Part 1 SlidesDocument69 pagesAWMDA Version 6 Part 1 SlidesPc-technicus DendermondeNo ratings yet

- Python Course DQLabDocument18 pagesPython Course DQLabHaikal FikriNo ratings yet

- Utkarsh Agarwal: ObjectiveDocument2 pagesUtkarsh Agarwal: ObjectiveUtkarsh AgarwalNo ratings yet

- Namma Kalvi 10th Tamil Unit 2 Surya GuideDocument42 pagesNamma Kalvi 10th Tamil Unit 2 Surya Guidemadan esv67% (6)

- SignatureDocument25 pagesSignatureTong Kai QianNo ratings yet

- SFAP Report 2023.1 Part CDocument4 pagesSFAP Report 2023.1 Part CSteohanie BritoNo ratings yet

- Bee Movie Script (Binary Code)Document104 pagesBee Movie Script (Binary Code)Joseph Burns96% (26)

- IMPORTANT NOTE: Nearpod Regular Service Is Intended For Use by Teachers and by Educational Institutions, Public orDocument6 pagesIMPORTANT NOTE: Nearpod Regular Service Is Intended For Use by Teachers and by Educational Institutions, Public orNajmuddinNo ratings yet

- SDA UML ModelingDocument13 pagesSDA UML ModelingMudasser HussainNo ratings yet

- Shekhar Somani: Autodesk IncDocument2 pagesShekhar Somani: Autodesk IncShekhar SomaniNo ratings yet

- Blogs Sap Com 2014 10 02 How To Registeractivate Activex Component Mscomm32ocx On Windows 7Document1 pageBlogs Sap Com 2014 10 02 How To Registeractivate Activex Component Mscomm32ocx On Windows 7Nikhil ShahNo ratings yet

- BitcoinAnalysis - Ipynb - ColaboratoryDocument12 pagesBitcoinAnalysis - Ipynb - Colaboratoryramihameed2000No ratings yet

- Time and Work 6Document4 pagesTime and Work 6brittoajaychatNo ratings yet

- Summer Training Report - PDF C++Document20 pagesSummer Training Report - PDF C++Satyam SinghNo ratings yet

- (Assignment Name) : (Type The Document Subtitle)Document2 pages(Assignment Name) : (Type The Document Subtitle)Zeeshan ch 'Hadi'No ratings yet

- BIM QuickStart S101 - Modeling Structural Frames CE07 en - 1Document62 pagesBIM QuickStart S101 - Modeling Structural Frames CE07 en - 1ANGELI NAGI ANAK JARAYEE / UPMNo ratings yet