Professional Documents

Culture Documents

03.0-310 Checking and Tightening Connecting Rod Bolts

Uploaded by

Schmiernippel Oskar0 ratings0% found this document useful (0 votes)

23 views2 pagesThis document provides specifications and tightening instructions for connecting rod bolts on M116 and M117 engines. It lists the bolt dimensions, required torque values, and special tools needed. It notes that expanding bolts should be replaced if the minimum expanding shaft diameter is reached after reuse. Proper oiling and use of torque wrenches or angle gauges are emphasized to prevent damage during tightening.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications and tightening instructions for connecting rod bolts on M116 and M117 engines. It lists the bolt dimensions, required torque values, and special tools needed. It notes that expanding bolts should be replaced if the minimum expanding shaft diameter is reached after reuse. Proper oiling and use of torque wrenches or angle gauges are emphasized to prevent damage during tightening.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views2 pages03.0-310 Checking and Tightening Connecting Rod Bolts

Uploaded by

Schmiernippel OskarThis document provides specifications and tightening instructions for connecting rod bolts on M116 and M117 engines. It lists the bolt dimensions, required torque values, and special tools needed. It notes that expanding bolts should be replaced if the minimum expanding shaft diameter is reached after reuse. Proper oiling and use of torque wrenches or angle gauges are emphasized to prevent damage during tightening.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Ghecking and Tightenins Gonnecting Rod Bolts O3.

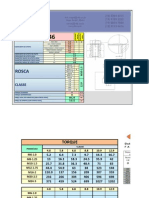

Dimensions of Connecting Rod Bolt

Model M 116, M 117

Part No. 11603801 71

Th reads M 11x 1

Expanding shaft dia. when new 9.0-0. 1

Min. expanding shaft dia. 8.5

Tightening the Expanding Bolts

Model all

I n itial torq ue 4+ 1 kpm

Angle of rotation torque goo + 1oo

Special Tool

115589021300

Angle of rotation tightening tool for all connecting rod

and flywheel bolts

General Note

Each time an expanding bolt is tightened, a lasting

deformation will remain. Prior to reusing an expand-

ing bolt the smallest diameter of the expanding shaft

should be measured with the knife edges of a slide

gauge.

When the expanding shaft is down to the minimum

dia. named in the Table, replace bolts.

Fig. 1

€r Engines ' Volume 1

310/1

03.O Checking and Tightening Connecting Rod Bolts

lnspection Note: lf no angle of rotation tightening tool is avail-

able, the nut can be tightened by means of a standard

1 Measure expanding shaft visible after removing socket spanner and a tommy bar in one step by the

connecting rod bearing cap, since deformation will specified angle. Estimate angle as accurately as possible.

occur at this point only (Fig. 1 ). To prevent angle errors, do not use a yielding torgue

wrench when tightening according to angle of rotation.

Knock connecting rod bolts out of connecting rod

only if they are subsequently replaced.

Tighening

2 Coat threads and contact surface well with oil

prior to screwing on nuts.

Note: Use only perfect socket wrenches for tighten-

ing. Since tightening according to angle of rotation

provides higher torques than with the tightening

method used before, widened or badly applied

wrenches may easily slip.

3 Tighten to specified initial torque (4 + 1 kpm)

with torque wrench.

4 Then tighten to specif ied angle (90o + 10o) with

angle of rotation tightening tool (Fig.2l.

Fig.2

31012

You might also like

- 4620 - Removal and Installation of The Two-Mass Flywheel Engine 104Document4 pages4620 - Removal and Installation of The Two-Mass Flywheel Engine 104Oscar ChohfiNo ratings yet

- Iston With Undulated Piston Crown: Lmbo QFKD Fkpqor'qflkDocument2 pagesIston With Undulated Piston Crown: Lmbo QFKD Fkpqor'qflkRonald Bienemi Paez100% (2)

- Timing Manual Galant ST v6!24!1998 2005 PDFDocument8 pagesTiming Manual Galant ST v6!24!1998 2005 PDFArya RamadhanNo ratings yet

- 4M41Document10 pages4M41Guadalupe GuerreroNo ratings yet

- Mitsubishi 8DC9 Engine Bolt Torque Specs (PRINT) PDFDocument3 pagesMitsubishi 8DC9 Engine Bolt Torque Specs (PRINT) PDFAnsori88% (8)

- 2007-013 Slew Ring Bolt Check Exchange Rev3 01Document4 pages2007-013 Slew Ring Bolt Check Exchange Rev3 01Luis EaNo ratings yet

- 10 - SsangYong-Korando - 2012 - EN - US - Manual - de - Taller - Cardan - E1b09bee1eDocument14 pages10 - SsangYong-Korando - 2012 - EN - US - Manual - de - Taller - Cardan - E1b09bee1eMateus FumuassucaNo ratings yet

- EC480D - Swing Gearbox, Maintenance StandardDocument4 pagesEC480D - Swing Gearbox, Maintenance Standardeck yuwanNo ratings yet

- Euronorm Slewing Rings Manual (ENG)Document8 pagesEuronorm Slewing Rings Manual (ENG)Gladwin JesNo ratings yet

- Desarme Parking Brake Wa600-6Document2 pagesDesarme Parking Brake Wa600-6Oliver ArcosNo ratings yet

- Work Shop Manual - BUKH DV 20 ME PDFDocument306 pagesWork Shop Manual - BUKH DV 20 ME PDFTom KooleNo ratings yet

- TI 07 006 DF AdjustmentDocument12 pagesTI 07 006 DF Adjustmenteko sunaryoNo ratings yet

- 8000231-Metric and Inch (Sae) FastenersDocument11 pages8000231-Metric and Inch (Sae) FastenersFrancisco DiazNo ratings yet

- Nissan Rear SuspensionDocument19 pagesNissan Rear SuspensionFrederikusNo ratings yet

- General InformationDocument7 pagesGeneral InformationRobert SantiagoNo ratings yet

- Service Manual Cat G3416eDocument753 pagesService Manual Cat G3416eUsaha MandiriNo ratings yet

- Direct Tension Indicator: Instruction ManualDocument5 pagesDirect Tension Indicator: Instruction ManualKemal HanogluNo ratings yet

- Taper Grid Coupling: Operating and Maintenace ManualDocument4 pagesTaper Grid Coupling: Operating and Maintenace ManualFlorez Machado GhgustavoNo ratings yet

- Chapter 8Document13 pagesChapter 8igorNo ratings yet

- 7.2 Crusher Erection and Maintenance Data - FlsmidthDocument4 pages7.2 Crusher Erection and Maintenance Data - Flsmidthdannyjoelec99No ratings yet

- 3 Rear Suspension-N900 Series JMCDocument17 pages3 Rear Suspension-N900 Series JMCRusonegroNo ratings yet

- VZH-1820 CatalogDocument5 pagesVZH-1820 CatalogVinhNo ratings yet

- Service Information No. 990209 GBDocument2 pagesService Information No. 990209 GBAndrei 26No ratings yet

- 34 Rear SuspensionDocument5 pages34 Rear SuspensionAbbode HoraniNo ratings yet

- Drill Grinder Instructions 0CECFEC7086BDDocument8 pagesDrill Grinder Instructions 0CECFEC7086BDMIGUEL ANGEL GARCIA BARAJASNo ratings yet

- Front Wheel FittingDocument2 pagesFront Wheel FittingliebherrmanNo ratings yet

- General Properties: Element Tekan Komponen Struktur Menahan LenturDocument5 pagesGeneral Properties: Element Tekan Komponen Struktur Menahan LenturOecoep IteemNo ratings yet

- Pamphlet On Instruction For Axle Mounted Brake Disc in LHB Coach (FTIL Type)Document8 pagesPamphlet On Instruction For Axle Mounted Brake Disc in LHB Coach (FTIL Type)Dasari RamamohanaNo ratings yet

- Bawn 004Document4 pagesBawn 004sike1977No ratings yet

- Installation Procedure - RFN 7012Document3 pagesInstallation Procedure - RFN 7012Barry ChungNo ratings yet

- Ringlok RingfederDocument5 pagesRinglok RingfederHector MaldonadoNo ratings yet

- Einbau Kolbenringsaetze Piston Ring Sets enDocument3 pagesEinbau Kolbenringsaetze Piston Ring Sets enEdimilson RodriguesNo ratings yet

- 1 General Remarks: Original Installation and Maintenance Instructions For Bibby Torque Limiters With ModulesDocument13 pages1 General Remarks: Original Installation and Maintenance Instructions For Bibby Torque Limiters With ModulesAmirmasoudNo ratings yet

- Machinery 11Document32 pagesMachinery 11PT.CAHAYA ANUGERAH SAKTINo ratings yet

- ENG1 FastDocument5 pagesENG1 FastAlexNo ratings yet

- Fastener Torques For Reciprocating Compressors: Engineering ReferenceDocument8 pagesFastener Torques For Reciprocating Compressors: Engineering ReferenceTomy lee youngNo ratings yet

- Dokumen - Tips - Engine Mechanical DaihatsuDocument33 pagesDokumen - Tips - Engine Mechanical DaihatsuJovie GrohlNo ratings yet

- Section 6-2Document80 pagesSection 6-2Raidul WafiNo ratings yet

- Operating Manual: For Lokring Single Ring Tube JoiningDocument11 pagesOperating Manual: For Lokring Single Ring Tube Joininganilp12rNo ratings yet

- CBM820 Service ManualDocument41 pagesCBM820 Service Manualhaithembs2017No ratings yet

- Ringspann GMBH: Operating Instructions ForDocument2 pagesRingspann GMBH: Operating Instructions ForAlaa MaherNo ratings yet

- Calculo de Torque X Forca AxialDocument4 pagesCalculo de Torque X Forca Axialmajonas77No ratings yet

- Bracket 100: If Crack or Fatigue Is Evident, Replace Control Arm, ImmediatelyDocument2 pagesBracket 100: If Crack or Fatigue Is Evident, Replace Control Arm, ImmediatelyHaingNo ratings yet

- MANUAL BOOK DifferentialDocument14 pagesMANUAL BOOK DifferentialHaris100% (2)

- ER-63 Fastener Torques For Reciprocating CompressorsDocument8 pagesER-63 Fastener Torques For Reciprocating CompressorsCarlos A. Mantilla J.No ratings yet

- Pneumatic Actuators: For Power, Motion and ControlDocument162 pagesPneumatic Actuators: For Power, Motion and ControlMahmoud ElsamantyNo ratings yet

- Accessories ESAB Gas Equipment Accessories: Torch Cutting GuidesDocument1 pageAccessories ESAB Gas Equipment Accessories: Torch Cutting GuidesDries VandezandeNo ratings yet

- Cat General Torque Specifications PDFDocument48 pagesCat General Torque Specifications PDFAlaudin Awang Xwijaya0% (1)

- CAT Torque Specifications General InformationDocument2 pagesCAT Torque Specifications General InformationSergeyNo ratings yet

- Fasteners Information: S6RW0C0101004Document2 pagesFasteners Information: S6RW0C0101004Rico MalibiranNo ratings yet

- 04 Table ChartsDocument8 pages04 Table ChartsRIAN NOFENDRINo ratings yet

- Catalogo Foton - Bj3319dmpkc-Abza02Document5 pagesCatalogo Foton - Bj3319dmpkc-Abza02Jhean PhierNo ratings yet

- Carraro 711-19 Axle Workshop ManualDocument34 pagesCarraro 711-19 Axle Workshop ManualautobritaiNo ratings yet

- Tightening ProcedureDocument3 pagesTightening ProceduregabrielNo ratings yet

- Inspection: - Clutch UnitDocument1 pageInspection: - Clutch UnitsalusfrankNo ratings yet

- Slew Ring 20: Lubricating ProcedureDocument2 pagesSlew Ring 20: Lubricating ProcedureM RefaiNo ratings yet

- Ajust EmbreagemDocument1 pageAjust Embreagemzuntoy000No ratings yet

- Improvement of Surface Roughness of Crankshaft Journal: SEN05157-00 90 Repair and Replacement of PartsDocument5 pagesImprovement of Surface Roughness of Crankshaft Journal: SEN05157-00 90 Repair and Replacement of PartsЕгорNo ratings yet

- Bearing Mounting Procedure: (Page 1 of 6)Document6 pagesBearing Mounting Procedure: (Page 1 of 6)JoséMiguelSánchezGNo ratings yet

- Patil Ajinkya MASc MECH May 2020Document143 pagesPatil Ajinkya MASc MECH May 2020Schmiernippel OskarNo ratings yet

- Mitsubishi Electric MSZ-LN-VG Installation Manual EngDocument8 pagesMitsubishi Electric MSZ-LN-VG Installation Manual EngSchmiernippel OskarNo ratings yet

- Black Powder Cheat Sheet-4-BertDocument2 pagesBlack Powder Cheat Sheet-4-BertSchmiernippel OskarNo ratings yet

- Manual Team Magic B8er Wp-8bl100 EscDocument2 pagesManual Team Magic B8er Wp-8bl100 EscSchmiernippel OskarNo ratings yet

- Inot'Cei: Servicing Your Honda Outboard MotorDocument1 pageInot'Cei: Servicing Your Honda Outboard MotorSchmiernippel OskarNo ratings yet

- hv04-07 Parts 2008Document96 pageshv04-07 Parts 2008muppetscrapNo ratings yet

- Honda BF115 PDFDocument486 pagesHonda BF115 PDFPedro Avila100% (1)

- Air-To-Water Heat Pump: Shanghai Hezhong Carrier Air-Conditioning Equipment Co., LTDDocument7 pagesAir-To-Water Heat Pump: Shanghai Hezhong Carrier Air-Conditioning Equipment Co., LTDguy namNo ratings yet

- VP 226 012 SK 001Document2 pagesVP 226 012 SK 001ritoh8657No ratings yet

- CAT-026 Fine GoldDocument302 pagesCAT-026 Fine GoldsimonNo ratings yet

- BBH 1500Document1 pageBBH 1500Cornel MihaiNo ratings yet

- Airman Ax30 Bottom RollerDocument1 pageAirman Ax30 Bottom RollerMichael BochoridisNo ratings yet

- ARK Resource CalculatorDocument97 pagesARK Resource CalculatorAndres KimenezNo ratings yet

- Unit-1 Plane Table SurveyingDocument4 pagesUnit-1 Plane Table SurveyingSaHil ShaRmaNo ratings yet

- MOS For Installation of Alumium CladdingDocument3 pagesMOS For Installation of Alumium CladdingSuban HariNo ratings yet

- Shooting Times - November 2016Document92 pagesShooting Times - November 2016MARCOSNo ratings yet

- Lathe AccessoriesDocument10 pagesLathe AccessoriesJeremiah FernandezNo ratings yet

- Samuk Es10-10cxDocument50 pagesSamuk Es10-10cxihianbissellNo ratings yet

- Appendix E: Load Values, in Water Supply Fixture Units (Wsfu) Type of Supply Fixture Occupancy Control Cold Hot TotalDocument2 pagesAppendix E: Load Values, in Water Supply Fixture Units (Wsfu) Type of Supply Fixture Occupancy Control Cold Hot Totalkarim tarekNo ratings yet

- Manufacturing Technology - Ii Unit 1 Surface Finish ProcessDocument8 pagesManufacturing Technology - Ii Unit 1 Surface Finish ProcessKallol ChakrabortyNo ratings yet

- Rohrbefestigungstechnik: Pipe Clamps, U-Bolts HangersDocument26 pagesRohrbefestigungstechnik: Pipe Clamps, U-Bolts HangersStefaan JacobsNo ratings yet

- Tools and Equipment For The BakeshopDocument13 pagesTools and Equipment For The Bakeshopanthony anggotNo ratings yet

- Project: Kalinga Hospital at Bhubaneswar: Sankalpa Tech BangaloreDocument2 pagesProject: Kalinga Hospital at Bhubaneswar: Sankalpa Tech BangalorejohnnysuneethNo ratings yet

- Steyr AUG 9mmDocument4 pagesSteyr AUG 9mmouraltn2001No ratings yet

- DYNISCO P/N 200100: Transducer Mounting Hole Cleaning Tool KitDocument2 pagesDYNISCO P/N 200100: Transducer Mounting Hole Cleaning Tool KitalexsandrNo ratings yet

- Center LatheDocument33 pagesCenter LathejohnNo ratings yet

- Service Charges For Philips Personal Health Products: Kitchen AppliancesDocument1 pageService Charges For Philips Personal Health Products: Kitchen AppliancesManish GoyalNo ratings yet

- Porta Sanitary Ware Price ListDocument10 pagesPorta Sanitary Ware Price ListImran Aziz80% (5)

- Valves: Rice List ofDocument16 pagesValves: Rice List ofakshatjain3001No ratings yet

- South Bend Taper AttachmentDocument6 pagesSouth Bend Taper AttachmentMikeNo ratings yet

- Target Shooter JuneDocument102 pagesTarget Shooter JuneTarget Shooter100% (1)

- Audi TransmisionDocument202 pagesAudi TransmisionJean GalNo ratings yet

- Equipment For Rural Workshops 1975Document98 pagesEquipment For Rural Workshops 1975yourmothersucksNo ratings yet

- KomatsuDocument8 pagesKomatsuTuluss Kosonq Tiiga100% (1)

- Concealed Flush Valves: A Flush Valve Is ADocument2 pagesConcealed Flush Valves: A Flush Valve Is AdjNo ratings yet

- Virgen Milagrosa University Foundation College of Radiologic Technology Human Anatomy and PhysiologyDocument2 pagesVirgen Milagrosa University Foundation College of Radiologic Technology Human Anatomy and PhysiologyJas-Stephanie MarcoNo ratings yet

- Kreator Power Tool Accessories PDFDocument106 pagesKreator Power Tool Accessories PDFjesus giraldoNo ratings yet