Professional Documents

Culture Documents

Sequence VID Engine Test: (ASTM D7589) Specifications Objective

Uploaded by

Сергій БоженкоOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sequence VID Engine Test: (ASTM D7589) Specifications Objective

Uploaded by

Сергій БоженкоCopyright:

Available Formats

Sequence VID Engine Test

(ASTM D7589)

Specifications

• ILSAC GF-5

• API SN

Objective

• Provide a comparative fuel economy index (FEI) of the fuel-saving capabilities

of automotive engine oils under repeatable laboratory conditions.

Field Service Simulated

• Passenger cars and light-duty trucks.

D018986_8595

Test Fixture

• 2009 3.6 L V6 General Motors gasoline engine with external lubricant

heating/cooling system and “flying flush” system for changing lubricants

without engine shutdown.

Test Parameters

• The test duration is 153 hours.

• Fuel consumption is measured for six speed/load/temperature test conditions compared to an

SAE 20W-30 baseline (BL) lubricant to ensure consistent engine response.

• FEI 1, FEI 2 and FEI Sum (FEI 1 plus FEI 2) are calculated from those comparisons.

• The candidate lubricant is introduced and aged for 16 hours at aging conditions and then fuel

consumption is measured for six test conditions for FEI 1.

• The candidate lubricant is left in the engine and aged for 84 hours at aging conditions for FEI 2.

• Fuel consumption for each of the six test conditions for BL after.

• Operating targets are as follows:.

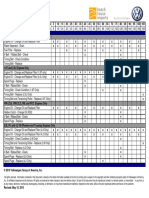

Test Condition Stage 1 Stage 2 Stage 3 Stage 4 Stage 5 Stage 6

Speed, rpm 2000 2000 1500 695 695 695

Torque, Nm 105 105 105 20 20 40

Lubricant temp, °C 115 65 115 115 35 115

Coolant-in temp, °C 109 65 109 109 35 109

Test Parts Evaluation Pass/Fail Criteria

• None. Fuel Efficiency Test Limit

• Test results are expressed as a SAE XW-20 viscosity grade

percent change of fuel consumed for FEI Sum at end of test 2.6% minimum

the candidate lubricant after Aging FEI 2 after 100 hours aging 1.2% minimum

Phase I (FEI 1) and after Aging SAE XW-30 viscosity grade

Phase II (FEI 2) relative to the baseline FEI Sum at end of test 1.9% minimum

lubricant before and after the FEI 2 after 100 hours aging 0.9% minimum

candidate lubricant. SAE 10W-30 and all other viscosity grades not listed above

FEI Sum at end of test 1.5% minimum

Used Lubricant Analysis FEI 2 after 100 hours aging 0.6% minimum

Viscosity @ 40°C & 100°C (ASTM D445)

We welcome your inquiries.

For additional information,

please contact:

Dan Worcester

Principal Engineer

Benefiting government, industry and the public

(210) 522-2405 through innovative science and technology

dan.worcester@swri.org An Equal Opportunity Employer M/F/D/V

Committed to Diversity in the Workplace

Fuels and Lubricants Research Division

Southwest Research Institute

6220 Culebra Road • P.O. Drawer 28510

San Antonio, Texas 78228-0510

swri.org

lubricanttesting.swri.org

Southwest Research Institute is an independent, nonprofit,

applied engineering and physical sciences research and

development organization using multidisciplinary approaches

to problem solving. The Institute occupies 1,200 acres in

San Antonio, Texas, and provides more than 2 million square

feet of laboratories, test facilities, workshops and offices for

nearly 3,000 employees who perform contract work for

industry and government clients.

Benefiting government,

industry and the public through

innovative science and technology

An Equal Employment Opportunity/Affirmative Action Employer • Race/

Find us on

Color/Religion/Sex/Sexual Orientation/Gender Identity/National Origin/

Disabled/Veteran • Committed to Diversity in the Workplace

08-0616 JCN 254508 tp

You might also like

- Delo® Gold MultigradeDocument2 pagesDelo® Gold MultigradeAymanSayedElantableeNo ratings yet

- Total Quartz Ineo Long Life 5W-30: Key DataDocument2 pagesTotal Quartz Ineo Long Life 5W-30: Key DataVelibor KaranovicNo ratings yet

- FM Approvals Firestop Contractor Approval ProgramDocument46 pagesFM Approvals Firestop Contractor Approval Programrty2100% (1)

- Maejo International Journal of Science and TechnologyDocument9 pagesMaejo International Journal of Science and TechnologyOcta RioNo ratings yet

- Wilks InfraCal Analyzers Guide for Oil in Water, Soil and Biofuels TestingDocument45 pagesWilks InfraCal Analyzers Guide for Oil in Water, Soil and Biofuels TestingMiguel RomanNo ratings yet

- Fuel SprayDocument2 pagesFuel SprayVictor ZhicayNo ratings yet

- Mobilube HD 80w-90 85w-140Document2 pagesMobilube HD 80w-90 85w-140ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNo ratings yet

- Everlube 620 CTDSDocument2 pagesEverlube 620 CTDSchristianNo ratings yet

- MC 10231590 0001Document5 pagesMC 10231590 0001m9dx2fx52tNo ratings yet

- HD 80W-90 en FR Motul 35500 20210713Document2 pagesHD 80W-90 en FR Motul 35500 20210713Marcelo Santo AndréNo ratings yet

- Field Testing: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDocument47 pagesField Testing: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia CoralieNo ratings yet

- TOTAL QUARTZ INEO HTC 5W-30 Engine Oil ProtectionDocument2 pagesTOTAL QUARTZ INEO HTC 5W-30 Engine Oil ProtectionVelibor KaranovicNo ratings yet

- Oil Analysis PracticesDocument37 pagesOil Analysis PracticesKasinathan MuniandiNo ratings yet

- MSLA Lab Integration Communication For DistDocument12 pagesMSLA Lab Integration Communication For Distdhavit wijayantoNo ratings yet

- Total Oil DetDocument2 pagesTotal Oil DetAwais A.No ratings yet

- Castrol Girth Gear LubeDocument19 pagesCastrol Girth Gear LubeAnil VermaNo ratings yet

- Improved Friction Tests for Engine MaterialsDocument4 pagesImproved Friction Tests for Engine Materialsslv_prasaadNo ratings yet

- Texamatic 7045EDocument3 pagesTexamatic 7045EIgor MitrovićNo ratings yet

- TOTAL QUARTZ 7000 10W-40: Key DataDocument2 pagesTOTAL QUARTZ 7000 10W-40: Key DataDouimni AyoubNo ratings yet

- Vistalon 6602Document1 pageVistalon 6602ANo ratings yet

- Oil Analysis Guide and Sampling Procedure PDFDocument28 pagesOil Analysis Guide and Sampling Procedure PDFbboyary100% (2)

- HVOF PowderDocument2 pagesHVOF PowderLogeshNo ratings yet

- Schulamid 612 PresentationDocument24 pagesSchulamid 612 PresentationAngel LagrañaNo ratings yet

- Nuclear Maintenance Applications Center - Lubrication Guide - Revision 4 - Formerly 1003085Document194 pagesNuclear Maintenance Applications Center - Lubrication Guide - Revision 4 - Formerly 1003085Alex Pujol100% (1)

- Bucyrus OGL Lubrication SD 4713Document8 pagesBucyrus OGL Lubrication SD 4713dpomahNo ratings yet

- Gpcdoc Gtds Shell Helix Ultra 5w-40 (SN CF A3 b4) (En) TdsDocument2 pagesGpcdoc Gtds Shell Helix Ultra 5w-40 (SN CF A3 b4) (En) TdsDenny WahyudiNo ratings yet

- AGMA Tribology Test Report Provides Insights on Gear Lubrication TestingDocument30 pagesAGMA Tribology Test Report Provides Insights on Gear Lubrication TestingPeter CardenNo ratings yet

- 23rd International Colloquium TribologyDocument26 pages23rd International Colloquium TribologyPriti Suman MishraNo ratings yet

- 2 - SyntheticsDocument57 pages2 - SyntheticsRay Cepeda Mena100% (1)

- Bell 1 Hydraulic Oil Awp (Ua6301)Document2 pagesBell 1 Hydraulic Oil Awp (Ua6301)randiNo ratings yet

- Cat Deo 15w40Document2 pagesCat Deo 15w40Eduardo Saúl Tapia100% (1)

- Testin G Procedure and EquipmentDocument10 pagesTestin G Procedure and EquipmentClint CooperNo ratings yet

- Total Quartz Ineo Mc3 5W-30: Key DataDocument2 pagesTotal Quartz Ineo Mc3 5W-30: Key DataVelibor KaranovicNo ratings yet

- Everslik - 1201 TDSDocument2 pagesEverslik - 1201 TDShvdb72100% (1)

- Assessment of Lubricating Oil Degradation in SmallDocument10 pagesAssessment of Lubricating Oil Degradation in SmallJiYong YookNo ratings yet

- 3 - Syntetic Pocket GuideDocument9 pages3 - Syntetic Pocket GuideRay Cepeda MenaNo ratings yet

- Steps To Optimize Lubricants Use PDFDocument113 pagesSteps To Optimize Lubricants Use PDFPrabhu LohakareNo ratings yet

- Cat DEO: Caterpillar. The Difference CountsDocument2 pagesCat DEO: Caterpillar. The Difference CountsMinaSaeedNo ratings yet

- Shell Rimula Oils: High Ash Level Oils For Diesel EnginesDocument2 pagesShell Rimula Oils: High Ash Level Oils For Diesel EnginesYeesvaran NarayanasamyNo ratings yet

- 300V2 - 4T - Factory - Line 10W-50 DATASHEETDocument2 pages300V2 - 4T - Factory - Line 10W-50 DATASHEETtahsin gürmanNo ratings yet

- 300V2 4T Factory Line 10W-50 (GB)Document2 pages300V2 4T Factory Line 10W-50 (GB)ManoNo ratings yet

- Esso Torque Fluid 62: Product DescriptionDocument2 pagesEsso Torque Fluid 62: Product Descriptionhoussem houssemNo ratings yet

- Inter-Av Equipment: Attention: Important Bocle InformationDocument1 pageInter-Av Equipment: Attention: Important Bocle InformationpersadanusantaraNo ratings yet

- Oil Analysis PDFDocument0 pagesOil Analysis PDFrizaldyjoe100% (1)

- Thermal SprayDocument28 pagesThermal Spraycutefrenzy0% (1)

- MOLYKOTE G-1057 Grease 80-3706A-01Document2 pagesMOLYKOTE G-1057 Grease 80-3706A-01If ChenNo ratings yet

- GL XX Mobil Delvac Synthetic Transmission Fluid 50Document3 pagesGL XX Mobil Delvac Synthetic Transmission Fluid 50Dennis Alexander Oseguera OsegueraNo ratings yet

- Car Lubricant PresentationDocument36 pagesCar Lubricant PresentationGia NicoNo ratings yet

- FLTM BJ 126-01Document3 pagesFLTM BJ 126-01GabrielFalconNo ratings yet

- World Lubricants Brochure-2021-LRDocument18 pagesWorld Lubricants Brochure-2021-LRAung Myat ThuNo ratings yet

- Pilot M-20200049-005Document1 pagePilot M-20200049-005Mayur PattanshettiNo ratings yet

- 08 Used Oil Analysis NaDocument50 pages08 Used Oil Analysis NaІнвент ГрупNo ratings yet

- TDTO 10W Ulei Transmisie CaterpillarDocument2 pagesTDTO 10W Ulei Transmisie CaterpillarCorina Stanculescu0% (1)

- Chevron Delo Gold Ultra SAE 15W-40Document4 pagesChevron Delo Gold Ultra SAE 15W-40German Vladimir Martinez EstradaNo ratings yet

- Pehj0030-03 Cat GoDocument2 pagesPehj0030-03 Cat GoJorge A. Paredes RodriguezNo ratings yet

- Industrial Statistics: Practical Methods and Guidance for Improved PerformanceFrom EverandIndustrial Statistics: Practical Methods and Guidance for Improved PerformanceNo ratings yet

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionFrom EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionRating: 5 out of 5 stars5/5 (3)

- Seat Alhambra 2005 Owners Manual (En)Document272 pagesSeat Alhambra 2005 Owners Manual (En)Сергій БоженкоNo ratings yet

- Cat 325F L Operators ManualDocument4 pagesCat 325F L Operators ManualСергій БоженкоNo ratings yet

- PETRONAS PLI VPO Special Vacuum Pump OilDocument1 pagePETRONAS PLI VPO Special Vacuum Pump OilСергій БоженкоNo ratings yet

- 4165D Motor Grader: Tough World. Tough EquipmentDocument2 pages4165D Motor Grader: Tough World. Tough EquipmentСергій БоженкоNo ratings yet

- Specified Transmission Oils (Commercial Vehicle, Van) - Overview BB00.40-P-0231-02ADocument5 pagesSpecified Transmission Oils (Commercial Vehicle, Van) - Overview BB00.40-P-0231-02AСергій БоженкоNo ratings yet

- File 90035Document253 pagesFile 90035Сергій БоженкоNo ratings yet

- File 97319Document370 pagesFile 97319Сергій БоженкоNo ratings yet

- 304991936-Manual-operator-telescopic - 530 - 532 - 533 - 535 - 537 - 540 - карта смазкиDocument3 pages304991936-Manual-operator-telescopic - 530 - 532 - 533 - 535 - 537 - 540 - карта смазкиСергій БоженкоNo ratings yet

- Specifications and recommended lubricants for a diesel engineDocument3 pagesSpecifications and recommended lubricants for a diesel engineСергій БоженкоNo ratings yet

- Man 8.163Document198 pagesMan 8.163halilagic75% (8)

- VW Lupo Automatic Gearbox 001 EngDocument225 pagesVW Lupo Automatic Gearbox 001 EngСергій БоженкоNo ratings yet

- Seat Alhambra 2005 Owners Manual (en) картаDocument3 pagesSeat Alhambra 2005 Owners Manual (en) картаСергій БоженкоNo ratings yet

- OMH231307Document622 pagesOMH231307Сергій БоженкоNo ratings yet

- Refill Capacities: Note NoteDocument2 pagesRefill Capacities: Note NoteСергій БоженкоNo ratings yet

- Owner's Manual: Volvo V50 Web EditionDocument286 pagesOwner's Manual: Volvo V50 Web EditionСергій БоженкоNo ratings yet

- 2015-mazda6-owners-manual (1) - карта смазкиDocument4 pages2015-mazda6-owners-manual (1) - карта смазкиСергій БоженкоNo ratings yet

- 0371 JCB WPC Lubricants Brochure 23 02 15 PDFDocument36 pages0371 JCB WPC Lubricants Brochure 23 02 15 PDFkotvasilevNo ratings yet

- 308.8515.3.4-4 Serie 9 ENDocument40 pages308.8515.3.4-4 Serie 9 ENСергій БоженкоNo ratings yet

- 2015-Rogue-owner-manual (1) - карта смазкиDocument3 pages2015-Rogue-owner-manual (1) - карта смазкиСергій БоженкоNo ratings yet

- Manual Miniexcavadora Con Orugas 3000kg JCB Mod.8026cts 8030ztsDocument332 pagesManual Miniexcavadora Con Orugas 3000kg JCB Mod.8026cts 8030ztsGeorge Chiorean100% (4)

- 2014 Mazda 6 30305Document576 pages2014 Mazda 6 30305rimshadtpNo ratings yet

- Service Manual: Publication NoDocument6 pagesService Manual: Publication NoСергій Боженко0% (1)

- JCB Lubricants - 2021Document19 pagesJCB Lubricants - 2021Сергій БоженкоNo ratings yet

- Service Manual: ForewordDocument24 pagesService Manual: ForewordСергій Боженко100% (1)

- 4WG 190 210 5872 194 002 PDFDocument53 pages4WG 190 210 5872 194 002 PDFAnonymous g1Uh7kzLvb100% (4)

- JCB 8085 - Operation Manual JCB 8085 PDFDocument195 pagesJCB 8085 - Operation Manual JCB 8085 PDFCristian Antonio0% (1)

- Operator'S Manual: Compact ExcavatorDocument208 pagesOperator'S Manual: Compact ExcavatorSoban Reddy100% (1)

- JCB 456 ZX Wheel Loader Fast FactsDocument8 pagesJCB 456 ZX Wheel Loader Fast FactsСергій БоженкоNo ratings yet

- Midi Excavator: A Product of Hard WorkDocument20 pagesMidi Excavator: A Product of Hard WorkСергій БоженкоNo ratings yet

- Section 3 Section 3: Routine MaintenanceDocument2 pagesSection 3 Section 3: Routine MaintenanceСергій БоженкоNo ratings yet

- Carl Schmitt Land and SeaDocument52 pagesCarl Schmitt Land and SeaAnthony GioffreNo ratings yet

- Case 1Document4 pagesCase 1nisha gauchanNo ratings yet

- Nce 265291Document1 pageNce 265291porcotNo ratings yet

- 2010 Ford FusionDocument176 pages2010 Ford FusionAishah Ayoshah100% (3)

- Directions Winter 2014Document48 pagesDirections Winter 2014angshuman87No ratings yet

- Directions, Listenting and Practice.Document8 pagesDirections, Listenting and Practice.laura martinezNo ratings yet

- Navigation VIIDocument47 pagesNavigation VIINoe Ganir100% (1)

- Tugas 2-Berge StahlDocument4 pagesTugas 2-Berge StahlRizqiNo ratings yet

- Esquema Elétrico Do Módulo Traseiro (HM) Actros.Document11 pagesEsquema Elétrico Do Módulo Traseiro (HM) Actros.Joao Victor Vargas RosaNo ratings yet

- KIỂM TRA 7-1Document3 pagesKIỂM TRA 7-1Uyển Lương0% (1)

- Name of Project: Road Maintenance Location of Project: Section Cassa-Aiasa (A13) /25.1 KM, Ainaro MunicipaltyDocument18 pagesName of Project: Road Maintenance Location of Project: Section Cassa-Aiasa (A13) /25.1 KM, Ainaro MunicipaltyYedid AmqNo ratings yet

- Paris The City of LightsDocument27 pagesParis The City of LightsErn NievaNo ratings yet

- Applications of Machine Learning and Data Analytics Models in Maritime TransportationDocument319 pagesApplications of Machine Learning and Data Analytics Models in Maritime Transportation신영호No ratings yet

- Daftar AccuDocument3 pagesDaftar AccusetyoNo ratings yet

- VW-2004 Schedule ManualDocument3 pagesVW-2004 Schedule Manualanyone331No ratings yet

- How To Program A BMW Key Fob - BMW Digital Key - Rallye BMW PDFDocument6 pagesHow To Program A BMW Key Fob - BMW Digital Key - Rallye BMW PDFtimNo ratings yet

- Technical Catalog II-Installation, Operation and Maintenance InstructionDocument51 pagesTechnical Catalog II-Installation, Operation and Maintenance InstructionpubudunishanthaNo ratings yet

- Alcohol Ignition Interlock Devices I: Position Paper: International Council On Alcohol, Drugs and Traffic Safety (Icadts)Document26 pagesAlcohol Ignition Interlock Devices I: Position Paper: International Council On Alcohol, Drugs and Traffic Safety (Icadts)Ivan VascoNo ratings yet

- ACTIVITY TASK 5 - Passive VoiceDocument4 pagesACTIVITY TASK 5 - Passive Voicesantiago quicenoNo ratings yet

- CRN5594681450Document3 pagesCRN5594681450amitdesai92No ratings yet

- QC Comprehensive Land Use Plan 2011 PDFDocument60 pagesQC Comprehensive Land Use Plan 2011 PDFcrimsonbunnie75% (8)

- Utilization of Flight Simulator in AviationDocument5 pagesUtilization of Flight Simulator in AviationSamuel ANo ratings yet

- Distress SignalsDocument4 pagesDistress SignalsKush UpadhyayNo ratings yet

- Is 13187 - 1991Document9 pagesIs 13187 - 1991vikash kumarNo ratings yet

- Hybris IEPS 2022 GuideDocument63 pagesHybris IEPS 2022 Guideedi2805No ratings yet

- Arrivage Ms Germany (1) 09-07-2023Document21 pagesArrivage Ms Germany (1) 09-07-2023adelNo ratings yet

- A340 Emergency Procedures Quick Reference HandbookDocument196 pagesA340 Emergency Procedures Quick Reference HandbookGraham WaterfieldNo ratings yet

- GongeraPetts ClanviewCivilsIntech 2020 EstablishmentTractorbasedRoadWorksDTU PR3 AfCAP ZAM2059B 200424Document28 pagesGongeraPetts ClanviewCivilsIntech 2020 EstablishmentTractorbasedRoadWorksDTU PR3 AfCAP ZAM2059B 200424Wei LeeNo ratings yet

- Bill of Lading Form - Printable TemplateDocument1 pageBill of Lading Form - Printable TemplateFlorencia B. QuiñonesNo ratings yet

- 2005 Polaris Ranger 500 4x4 Owner's ManualDocument121 pages2005 Polaris Ranger 500 4x4 Owner's Manualdustin hensleyNo ratings yet