Professional Documents

Culture Documents

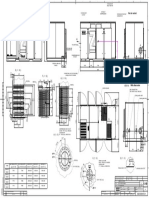

Fire Sprinkler System

Uploaded by

Jaybee MoralesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Sprinkler System

Uploaded by

Jaybee MoralesCopyright:

Available Formats

September 17, 2018

FIRE SPRINKLERS SYSTEM hose streams to the fire. This additional time can result in a much

larger fire, requiring much more water to extinguish.

Is an active fire protection method, consisting of a water supply

system, providing adequate pressure and flow rate to a water

distribution piping system, onto which fire sprinklers are connected.

Fire sprinkler systems are extensively used worldwide, with over

40 million sprinkler heads fitted each year. In buildings completely This chart from the fire safety standards indicates the colour of the

protected by fire sprinkler systems, over 96% of fires were controlled bulb and the respective operating temperature.

by fire sprinklers alone.

Sprinkler systems are intended to either control the fire or

to suppress the fire. Temperature Color of liquid alcohol

°C °F inside bulb

USAGE OF FIRE SPRINKLERS SYSTEM

Sprinklers have been in use in the United States since 1874, and

were used in factory applications where fires at the turn of the century 57 135 Orange

were often catastrophic in terms of both human and property losses.

Sprinklers may be required to be installed by building codes, or 68 155 Red

may be recommended by insurance companies to reduce potential

property losses or business interruption. 79 174 Yellow

SPRINKLER ACTIVATION 93 200 Green

A sprinkler activation will do less water damage than a fire

department hose stream, which provide approximately 900 litres/min. 141 286 Blue

A typical sprinkler used for industrial manufacturing occupancies

discharge about 75-150 litres/min. However, a typical Early 182 360 Purple

Suppression Fast Response (ESFR) sprinkler at a pressure of 50 psi

(340 kPa) will discharge approximately 380 litres per minute. 227 440

Black

In addition, a sprinkler will usually activate within one to four 260 500

minutes of the fire's start, whereas it typically takes at least five

minutes for a fire department to register an alarm and drive to the fire TYPES OF SPRINKLER SYSTEM

site, and an additional ten minutes to set up equipment and apply Wet Pipe Fire Sprinkler System

Dry Pipe Fire Sprinkler System

ARBT5 – ALTERNATIVE BUILDING SYSTEM Page 6

September 17, 2018

Deluge Fire Sprinkler System Disadvantages to using a wet pipe fire sprinkler system include:

Pre-action Fire Sprinkler System Wet pipe systems are not suited for sub-freezing environments.

Foam Water Fire Sprinkler System There may also be a concern where piping is subject to severe

Water Spray Fire Sprinkler System impact damage and could consequently leak

Water Mist Fire Sprinkler System

WET PIPE FIRE SPRINKLER SYSTEM

A dry pipe sprinkler system is one in which pipes are filled with

pressurized air or nitrogen, rather than water. This air holds a remote

valve, known as a dry pipe valve, in a closed position. Located in a

heated space, the dry-pipe valve prevents water from entering the

pipe until a fire causes one or more sprinklers to operate. Once this

happens, the air escapes and the dry pipe valve releases. Water then

enters the pipe, flowing through open sprinklers onto the fire.

Advantages to using a wet pipe fire sprinkler system include:

System simplicity and reliability - Wet pipe sprinkler systems

have the least number of components and therefore, the lowest

number of items to malfunction. This produces unexcelled

reliability which is important since sprinklers may be asked to sit

in waiting for many years before they are needed. This

simplicity aspect also becomes important in facilities where

system maintenance may not be performed with the desired

frequency.

Relative low installation and maintenance expense - Due to their

overall simplicity, wet pipe sprinklers require the least amount

of installation time and capital. Maintenance cost savings are

also realized since less service time is generally required

DRY PIPE FIRE SPRINKLER SYSTEM

compared to other system types. These savings become A dry pipe sprinkler system is one in which pipes are filled with

important when maintenance budgets are shrinking. pressurized air or nitrogen, rather than water. This air holds a remote

valve, known as a dry pipe valve, in a closed position. Located in a

ARBT5 – ALTERNATIVE BUILDING SYSTEM Page 6

September 17, 2018

heated space, the dry-pipe valve prevents water from entering the fire. This will delay fire extinguishing actions, which may

pipe until a fire causes one or more sprinklers to operate. Once this produce increased content damage.

happens, the air escapes and the dry pipe valve releases. Water then Increased corrosion potential - Following operation, dry-pipe

enters the pipe, flowing through open sprinklers onto the fire. sprinkler systems must be completely drained and dried.

In areas where low temperatures could cause a wet pipe system Otherwise remaining water may cause pipe corrosion and

to freeze, a dry pipe system is intended for use. Dry pipe systems are premature failure. This is not a problem with wet pipe systems

pressurized with air in the ambient condition and experience an where water is constantly maintained in piping.

inherent delay in the discharge of water to allow the pressurized air in

the system to escape.

Advantages of using dry pipe fire sprinkler systems include:

Dry pipe sprinkler systems provide automatic protection in

spaces where freezing is possible. Typical dry pipe installations

include unheated warehouses and attics, outside exposed

loading docks and within commercial freezers.

Disadvantages of using dry pipe fire sprinkler systems include:

Increased complexity - Dry pipe systems require additional

control equipment and air pressure supply components which

increases system complexity. Without proper maintenance this

equipment may be less reliable than a comparable wet pipe

system.

Higher installation and maintenance costs - The added

complexity impacts the overall dry-pipe installation cost. This

complexity also increases maintenance expenditure, primarily

due to added service labor costs.

Lower design flexibility - There are strict requirements regarding

the maximum permitted size (typically 750 gallons) of individual

dry-pipe systems. These limitations may impact the ability of an

owner to make system additions.

Increased fire response time - Up to 60 seconds may pass from

the time a sprinkler opens until water is discharged onto the

ARBT5 – ALTERNATIVE BUILDING SYSTEM Page 6

September 17, 2018

DELUGE FIRE SPRINKLER SYSTEM Lower design flexibility - There are strict requirements regarding

A deluge fire sprinkler system is similar to a pre-action system the maximum permitted size (typically 750 gallons) of individual

except the sprinkler heads are open and the pipe is not pressurized dry-pipe systems. These limitations may impact the ability of an

with air. owner to make system additions.

Deluge systems are connected to a water supply through a Increased fire response time - Up to 60 seconds may pass from

deluge valve that is opened by the operation of a smoke or heat the time a sprinkler opens until water is discharged onto the

detection system. The detection system is installed in the same area as fire. This will delay fire extinguishing actions, which may

the sprinklers. When the detection system is activated water produce increased content damage.

discharges through all of the sprinkler heads in the system. Deluge Increased corrosion potential - Following operation, dry-pipe

systems are used in places that are considered high hazard areas such sprinkler systems must be completely drained and dried.

as power plants, aircraft hangars and chemical storage or processing Otherwise remaining water may cause pipe corrosion and

facilities. premature failure. This is not a problem with wet pipe systems

Deluge systems are needed where high velocity suppression is where water is constantly maintained in piping.

necessary to prevent fire spread.

Advantages of using dry pipe fire sprinkler systems include:

Dry pipe sprinkler systems provide automatic protection in

spaces where freezing is possible. Typical dry pipe installations

include unheated warehouses and attics, outside exposed

loading docks and within commercial freezers.

Disadvantages of using dry pipe fire sprinkler systems include:

Increased complexity - Dry pipe systems require additional

control equipment and air pressure supply components which

increases system complexity. Without proper maintenance this

equipment may be less reliable than a comparable wet pipe

system.

Higher installation and maintenance costs - The added

complexity impacts the overall dry-pipe installation cost. This

complexity also increases maintenance expenditure, primarily

due to added service labor costs.

PRE-ACTION FIRE SPRINKLERS SYSTEM

ARBT5 – ALTERNATIVE BUILDING SYSTEM Page 6

September 17, 2018

Pre-action fire sprinkler systems employ the basic concept of a that something may not work when needed. Regular

dry pipe system in that water is not normally contained within the maintenance is essential to ensure reliability.

pipes. The difference, however, is that water is held from piping by an

electrically operated valve, known as a pre-action valve. Valve

operation is controlled by independent flame, heat, or smoke

detection.

Pre-action sprinkler systems are specialized for use in locations

where accidental activation is undesired, such as in museums with rare

art works, manuscripts, or books; and data centers, for protection of

computer equipment from accidental water discharge.

Advantages of using pre-action fire sprinkler systems include:

The dual action required for water release - The pre-action

valve must operate and sprinkler heads must fuse. This feature

provides an added level of protection against inadvertent

discharge. For this reason, pre-action systems are frequently

employed in water sensitive environments such as archival

vaults, fine art storage rooms, rare book libraries and computer

centers.

Disadvantages of using pre-action fire sprinkler systems include:

Higher installation and maintenance costs - Pre-action systems

are more complex with several additional components, notably

a fire detection system. This adds to the overall system cost.

Modification difficulties - As with dry-pipe systems, pre-action

sprinkler systems have specific size limitations which may

impact future system modifications. In addition, system

modifications must incorporate changes to the fire detection

and control system to ensure proper operation.

Potential decreased reliability - The higher level of complexity

associated with pre-action systems creates an increased chance

ARBT5 – ALTERNATIVE BUILDING SYSTEM Page 6

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Types Dry Pipe Fire Sprinkler System: Active Fire Protection Fire SprinklersDocument5 pagesTypes Dry Pipe Fire Sprinkler System: Active Fire Protection Fire SprinklersthundrsNo ratings yet

- Chimneys & Fireplaces: They Contribute to the Health Comfort and Happiness of the Farm Family - How to Build ThemFrom EverandChimneys & Fireplaces: They Contribute to the Health Comfort and Happiness of the Farm Family - How to Build ThemNo ratings yet

- 4 Types of Fire Sprinkler SystemsDocument14 pages4 Types of Fire Sprinkler SystemsFayas100% (1)

- Research Work 4 ME 417L (2P.M-8P.M SATURDAY)Document7 pagesResearch Work 4 ME 417L (2P.M-8P.M SATURDAY)Norman AntonioNo ratings yet

- Firefighting IntroductionDocument116 pagesFirefighting IntroductionEngineer Fasey AhmadNo ratings yet

- Deluge System Definition Working Applications and Advantages With PDFDocument4 pagesDeluge System Definition Working Applications and Advantages With PDFSiwaNo ratings yet

- Wiginton Fire ProtectionDocument20 pagesWiginton Fire Protectionmazu_bzNo ratings yet

- Fire Protection System Risk Control Guide v1 - RCG010 (E)Document7 pagesFire Protection System Risk Control Guide v1 - RCG010 (E)Laxminarayan NayakNo ratings yet

- CSTDocument2 pagesCSTCarlo Santi BayabayNo ratings yet

- Fire Sprinkler Systems ExplainedDocument3 pagesFire Sprinkler Systems ExplainedRomzy KutonNo ratings yet

- Water Mist Fire Suppression: How Less Water Has A Big ImpactDocument6 pagesWater Mist Fire Suppression: How Less Water Has A Big ImpactSI Comércio e ServiçosNo ratings yet

- Fire Sprinkler SystemDocument8 pagesFire Sprinkler SystemMuhammad Zuhairi IINo ratings yet

- Me Reporting ContentDocument10 pagesMe Reporting ContentALLEN MAACNo ratings yet

- Sprinkler System DesignDocument19 pagesSprinkler System DesignRajahi Moahmed100% (1)

- Design of Automatic Fire Sprinkler SystemDocument41 pagesDesign of Automatic Fire Sprinkler SystemISH-QUENo ratings yet

- Steam Trap Integrity 04122021Document1 pageSteam Trap Integrity 04122021Zulhafizan ZulkifliNo ratings yet

- Fire Fighting SystemsDocument11 pagesFire Fighting SystemsMariah Ibrahim100% (1)

- Fire Sprinklers As Fire Prevention SystemsDocument6 pagesFire Sprinklers As Fire Prevention SystemsMuhammad Jamshaid KhanNo ratings yet

- Deluge Sprinkler SystemDocument8 pagesDeluge Sprinkler SystemRaed Al-nomanNo ratings yet

- Body 1 PDFDocument66 pagesBody 1 PDFAnjelyn SaltingNo ratings yet

- Retrofitting The Existing Flare / Burnery For Smoke Less OperationsDocument31 pagesRetrofitting The Existing Flare / Burnery For Smoke Less Operationsmehul10941No ratings yet

- BAFSA View On Water Mist SystemsDocument4 pagesBAFSA View On Water Mist SystemsLarry StanfordNo ratings yet

- Water Mist Firefighting SystemDocument5 pagesWater Mist Firefighting SystemAntony Jebaraj100% (1)

- Fire Sprinkler DesignDocument68 pagesFire Sprinkler DesignJuan Paulo Mayor89% (9)

- Analysis 2 FinalDocument9 pagesAnalysis 2 FinalأبومحمدالزياتNo ratings yet

- Aqua Cooling Adiabatic Cooling SystemDocument4 pagesAqua Cooling Adiabatic Cooling Systemcradha736No ratings yet

- Jeff EleDocument5 pagesJeff Eleclaudialop647No ratings yet

- 3 Fire Protecttion PDFDocument8 pages3 Fire Protecttion PDFJea May CallejoNo ratings yet

- VDS Interaction of Water Extinguishing Systems and Smoke and Heat ExtractorsDocument0 pagesVDS Interaction of Water Extinguishing Systems and Smoke and Heat Extractorsmicaziv4786No ratings yet

- The Building Owners Guide To Fire Sprinkler and Fire Pump SystemsDocument17 pagesThe Building Owners Guide To Fire Sprinkler and Fire Pump SystemsTamouh ZakrtNo ratings yet

- Steam Trap Integrity - v1Document1 pageSteam Trap Integrity - v1Zulhafizan ZulkifliNo ratings yet

- BAFSA BIF09 WaterMistDocument3 pagesBAFSA BIF09 WaterMistdanateo2835No ratings yet

- Task 8Document3 pagesTask 8YNo ratings yet

- Fire Sprinkler Testing 2015Document104 pagesFire Sprinkler Testing 2015Jose R Birmighan S100% (1)

- The Interaction of Sprinklers With Smoke and Heat Vents: InsightDocument3 pagesThe Interaction of Sprinklers With Smoke and Heat Vents: InsightToniHospitalerNo ratings yet

- 1-Fire Fighting ComparisonDocument3 pages1-Fire Fighting ComparisonRamy MahmoudNo ratings yet

- Module 2 - Boilers - Steam SystemDocument29 pagesModule 2 - Boilers - Steam Systemmadan karkiNo ratings yet

- Automatic Sprinkler System GuideDocument4 pagesAutomatic Sprinkler System Guidebugoff700100% (2)

- ÜP 10WAe 04 Sprinkleranlagen Final 20100804Document4 pagesÜP 10WAe 04 Sprinkleranlagen Final 20100804hichtn2009No ratings yet

- Active Fire ProtectionDocument1 pageActive Fire ProtectiondeniseeeeeeNo ratings yet

- Basics of AFSS DesignDocument59 pagesBasics of AFSS DesignJoseph Ryan Manandeg100% (2)

- Fire Fighting ResearchDocument6 pagesFire Fighting ResearchRaymond ZuYang Hng100% (1)

- Stairwell PressurizationDocument23 pagesStairwell PressurizationPrinces Tuguinay100% (1)

- Cause Sprinkler LeakageDocument7 pagesCause Sprinkler LeakageAmalia IstighfarahNo ratings yet

- EsII Fire Suppression IIDocument20 pagesEsII Fire Suppression IIHadiqa ChaudhryNo ratings yet

- Sprinklers BernanteDocument12 pagesSprinklers Bernantechristianrod.bernanteNo ratings yet

- Top 10 Sprinkler TipsDocument2 pagesTop 10 Sprinkler TipsSales DexNo ratings yet

- Steam Tracing TipsDocument2 pagesSteam Tracing TipsRam SudarshanNo ratings yet

- Automatic Sprinkler BasicsDocument4 pagesAutomatic Sprinkler BasicsPrabhakar ReddyNo ratings yet

- Protection For High Voltage TransfromersDocument4 pagesProtection For High Voltage TransfromersMani KumarNo ratings yet

- Design Guide 13: "Use Available Data To Lower System Cost"Document12 pagesDesign Guide 13: "Use Available Data To Lower System Cost"EjubNo ratings yet

- Condenser Vacuum MarEDocument4 pagesCondenser Vacuum MarEMayeiaElenorNo ratings yet

- Fire Sprinkler SystemsDocument9 pagesFire Sprinkler SystemsVin Bds100% (1)

- Steam Solved - Steam Trap OperationDocument17 pagesSteam Solved - Steam Trap Operationvj100% (1)

- STARTLAB2Document7 pagesSTARTLAB2Norman AntonioNo ratings yet

- Preventing Warehouse Total Loss Caused by Excessive VentilationDocument6 pagesPreventing Warehouse Total Loss Caused by Excessive VentilationEngineer TitusNo ratings yet

- Thermal Fluid System Clean OutDocument2 pagesThermal Fluid System Clean OutLord KrsnikNo ratings yet

- FinalDocument45 pagesFinalilya khalvashiNo ratings yet

- NM8 (S) DatasheetDocument53 pagesNM8 (S) Datasheetcalvin gninguiNo ratings yet

- Nex TracDocument2 pagesNex TracZouhair WahbiNo ratings yet

- Hauptkatalog 2017 KAP2 en PDFDocument160 pagesHauptkatalog 2017 KAP2 en PDFTaQuangDucNo ratings yet

- ZA6VSD RysDocument1 pageZA6VSD RysDanielNo ratings yet

- Delcam - PowerMILL 2014 R1 Whats New EN - 2013Document137 pagesDelcam - PowerMILL 2014 R1 Whats New EN - 2013phạm minh hùngNo ratings yet

- Hotel Property Management System: Software Requirements SpecificationDocument17 pagesHotel Property Management System: Software Requirements SpecificationUmair HassanNo ratings yet

- SET General Aptitude SampleDocument11 pagesSET General Aptitude SampleFast FeneNo ratings yet

- Nsec Btech Brochure 2022 ReDocument71 pagesNsec Btech Brochure 2022 ReFood RestorersNo ratings yet

- 560CMR02 DS enDocument4 pages560CMR02 DS enBhageerathi SahuNo ratings yet

- NEOM-NPR-GFR-Management Manual Rev 01Document24 pagesNEOM-NPR-GFR-Management Manual Rev 01MOHD ZEESHAN100% (3)

- The Data Science Design ManualDocument456 pagesThe Data Science Design Manualalbgomez100% (4)

- Backing Up Applications With Networker Modules: Emc Proven Professional Knowledge Sharing 2009Document38 pagesBacking Up Applications With Networker Modules: Emc Proven Professional Knowledge Sharing 2009Hend Ben SaadNo ratings yet

- Vermeer D7x11 SERIES II NavigatorDocument694 pagesVermeer D7x11 SERIES II NavigatorAbraham JohnsonNo ratings yet

- Clients and Firms of The Future: How To CompeteDocument2 pagesClients and Firms of The Future: How To CompeteRoss DawsonNo ratings yet

- My Daily Routine UNIT 3Document5 pagesMy Daily Routine UNIT 3Francisco EricesNo ratings yet

- VRZ Usa Iphone 11 128GBDocument1 pageVRZ Usa Iphone 11 128GBDamien Tucson100% (2)

- 001 Hydraulics IntroDocument22 pages001 Hydraulics IntroShereen SweissNo ratings yet

- 1 ABE 111 FinalDocument94 pages1 ABE 111 FinalMarooning ManNo ratings yet

- DS5300Document4 pagesDS5300kishore kumarNo ratings yet

- Adhesive Bandage: Jump To Navigation Jump To SearchDocument6 pagesAdhesive Bandage: Jump To Navigation Jump To SearchtokagheruNo ratings yet

- Mobile TestingDocument2 pagesMobile Testingvishalsuman4uNo ratings yet

- CV Nicolas Duarte Cifuentes InglesDocument2 pagesCV Nicolas Duarte Cifuentes InglesNicolas Duarte CifuentesNo ratings yet

- Magazine: Mcneel'S FL Ying CircusDocument36 pagesMagazine: Mcneel'S FL Ying CircusNoureddine SemaraNo ratings yet

- Planning Techiniques, Tools and ApplicationsDocument56 pagesPlanning Techiniques, Tools and ApplicationsSharlyn Marie N. BadilloNo ratings yet

- Excavadora Hidraulica 336eDocument15 pagesExcavadora Hidraulica 336eOscar LosadaNo ratings yet

- Handbook of Metal Injection MoldingDocument3 pagesHandbook of Metal Injection MoldingPk Jha0% (2)

- Paulina SlidesCarnivalDocument40 pagesPaulina SlidesCarnivalMestre FranciscoNo ratings yet

- E-Mail Spam Detection Using Machine Lear PDFDocument7 pagesE-Mail Spam Detection Using Machine Lear PDFTrending this yearNo ratings yet

- Lab Exercise 2: Perform The Following TasksDocument2 pagesLab Exercise 2: Perform The Following Tasksdicin94115No ratings yet

- FTTH-ODN - Optical Fiber Networks Fundamentals (Part 3)Document39 pagesFTTH-ODN - Optical Fiber Networks Fundamentals (Part 3)Mohamed ShabanaNo ratings yet

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyFrom EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyRating: 4 out of 5 stars4/5 (277)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterFrom EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterRating: 4 out of 5 stars4/5 (467)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.From EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Rating: 4 out of 5 stars4/5 (17)

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeFrom EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeRating: 5 out of 5 stars5/5 (2)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingFrom EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingRating: 4.5 out of 5 stars4.5/5 (844)

- Kintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritFrom EverandKintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritRating: 4.5 out of 5 stars4.5/5 (3)

- Survival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosFrom EverandSurvival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosRating: 3.5 out of 5 stars3.5/5 (8)

- Martha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesFrom EverandMartha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesRating: 4 out of 5 stars4/5 (11)

- The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingFrom EverandThe Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingRating: 4 out of 5 stars4/5 (2995)

- The Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyFrom EverandThe Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyRating: 4 out of 5 stars4/5 (40)

- Cluttered Mess to Organized Success Workbook: Declutter and Organize your Home and Life with over 100 Checklists and Worksheets (Plus Free Full Downloads) (Home Decorating Journal)From EverandCluttered Mess to Organized Success Workbook: Declutter and Organize your Home and Life with over 100 Checklists and Worksheets (Plus Free Full Downloads) (Home Decorating Journal)Rating: 4.5 out of 5 stars4.5/5 (36)

- Declutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeFrom EverandDeclutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeRating: 4.5 out of 5 stars4.5/5 (164)

- Decluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffFrom EverandDecluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffRating: 4.5 out of 5 stars4.5/5 (578)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeFrom EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNo ratings yet

- Nobody Wants Your Sh*t: The Art of Decluttering Before You DieFrom EverandNobody Wants Your Sh*t: The Art of Decluttering Before You DieRating: 4.5 out of 5 stars4.5/5 (21)

- At Home with Madame Chic: Becoming a Connoisseur of Daily LifeFrom EverandAt Home with Madame Chic: Becoming a Connoisseur of Daily LifeRating: 4 out of 5 stars4/5 (58)

- How to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsFrom EverandHow to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsRating: 5 out of 5 stars5/5 (339)

- Mini Farming: Self-Sufficiency on 1/4 AcreFrom EverandMini Farming: Self-Sufficiency on 1/4 AcreRating: 4.5 out of 5 stars4.5/5 (6)

- Summary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiFrom EverandSummary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiRating: 4.5 out of 5 stars4.5/5 (5)

- Unf*ck Your Habitat: You're Better Than Your MessFrom EverandUnf*ck Your Habitat: You're Better Than Your MessRating: 4 out of 5 stars4/5 (176)

- 52 Prepper Projects: A Project a Week to Help You Prepare for the UnpredictableFrom Everand52 Prepper Projects: A Project a Week to Help You Prepare for the UnpredictableRating: 5 out of 5 stars5/5 (1)

- Dwelling: Simple Ways to Nourish Your Home, Body, and SoulFrom EverandDwelling: Simple Ways to Nourish Your Home, Body, and SoulRating: 4.5 out of 5 stars4.5/5 (9)