Professional Documents

Culture Documents

Dimensions Weldolet® Size On Size STD MSS SP97

Uploaded by

Musslih Yulianto100%(1)100% found this document useful (1 vote)

407 views2 pagesOriginal Title

Dimensions Weldolet

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

407 views2 pagesDimensions Weldolet® Size On Size STD MSS SP97

Uploaded by

Musslih YuliantoCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Dimensions Weldolet® Size on Size STD MSS

SP97

Dimensions NPS 1/2 to 24

NPS A B C D

3/4 1.3/8 15/16 5/8

1/2 19.05 34.93 23.81 15.88

7/8 1.5/8 1.3/16 13/16

3/4 22.23 41.28 30.16 20.64

1.1/16 2 1.7/16 1.1/32

1 26.99 50.80 36.51 26.19

1¼ 2.3/8 1¾ 1.3/8

1¼ 31.75 60.3 44.45 34.93

1.5/16 2.7/8 2 1.5/8

1½ 33.34 73 50.80 41.28

1½ 3½ 2.9/16 2.1/16

2 38.10 88.90 65.09 52.39

1.5/8 4.1/16 3 2.7/16

2½ 41.28 103.19 76.20 61.91

1¾ 4.13/16 3.11/16 3.1/16

3 44.45 122.24 93.66 77.79

2 5.3/8 3.7/8 3.9/16

3½ 50.80 136.53 98.43 90.49

2 6 4¾ 4

4 50.80 152.40 120.65 101.60

2¼ 7.1/8 5.9/16 5.1/16

5 57.15 180.98 141.29 128.59

2.3/8 8½ 6.11/16 6.1/16

6 60.3 215.90 169.86 153.99

2¾ 10.3/8 8.11/16 7.15/16

8 69.85 263.53 220.66 201.61

3.1/16 12.9/16 10.13/16 10

10 77.79 319.09 274.64 254.00

3.3/8 14.7/8 12.13/16 12

12 85.73 377.83 325.44 304.80

3½ 16.1/8 14.1/16 13¼

14 88.90 409.58 357.19 336.55

3.11/16 18¼ 16.1/16 15¼

16 93.66 463.55 407.99 387.35

4.1/16 20¾ 18.5/8 17¼

18 103.19 527.05 473.08 438.15

4.5/8 23.1/16 20.1/16 19¼

20 117.48 585.79 509.59 488.95

5.3/8 27.7/8 25.1/8 23¼

24 136.53 708.03 638.18 590.55

NPS A B C D

General notes:

Dimensions: Top Row in Inches / Bottom Row in millimeters.

Root Gap - X - "Space" for welding the O'let is raised off the run pipe to establish

proper

weld gap by placing spacers, e.g. welding rods, under the fitting. This provides a

uniform

welding gap between the curvature of the run and base of fitting.

L = Dimensions Center Line of Run Pipe + X (Root Gap) + A (height of Weldolet).

Bevelled Ends ASME B16.9 and B16.25.

Source comes from Bonney Forge (except the sizes in millimeters).

Weldolet® is a registered name. Another often used name is Welding Outlet.

You might also like

- WPQ WELDER PERFORMANCE QUALIFICATIONDocument2 pagesWPQ WELDER PERFORMANCE QUALIFICATIONalokbdasNo ratings yet

- LARGE DIAMETER FLANGES & FITTINGS GUIDEDocument38 pagesLARGE DIAMETER FLANGES & FITTINGS GUIDEAshfaq Anwer100% (1)

- Weldolet DimensionDocument4 pagesWeldolet DimensionabhishekNo ratings yet

- ASME PCC-1-2013 Bolt Torque Table for SA-105 Steel FlangesDocument1 pageASME PCC-1-2013 Bolt Torque Table for SA-105 Steel FlangeskhaireddinNo ratings yet

- Recommended Torque Values for CG Spiral Wound GasketsDocument2 pagesRecommended Torque Values for CG Spiral Wound GasketsCarlos Roberto Tamariz100% (1)

- Torque Chart For ASTM A193 Grade B7 StudsDocument3 pagesTorque Chart For ASTM A193 Grade B7 StudsEmmanuel100% (1)

- Torque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....Document1 pageTorque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....Shijumon Kp100% (2)

- Split Tee CatalogoDocument3 pagesSplit Tee Catalogobotella berNo ratings yet

- QT 16Cr PDFDocument1 pageQT 16Cr PDFYaroslav RuizNo ratings yet

- ASME PCC-1 Bolted Flange Joint AssemblyDocument1 pageASME PCC-1 Bolted Flange Joint Assemblykhaireddin75% (4)

- Flanges ASME B 16.47 Serie ADocument2 pagesFlanges ASME B 16.47 Serie Aprabhuarunkumar100% (1)

- AES Type Heat ExchangerDocument8 pagesAES Type Heat ExchangerSudhanshu67100% (1)

- Toriconical Head 87 PsiDocument2 pagesToriconical Head 87 PsiFabio Augusto Hincapie HenaoNo ratings yet

- ASME B16 Welding EndsDocument2 pagesASME B16 Welding Endsf_riseNo ratings yet

- Tabla Limite de Retiro EspesoresDocument4 pagesTabla Limite de Retiro EspesoresVicent RojasNo ratings yet

- Calculo Espesores ASME B31.4Document13 pagesCalculo Espesores ASME B31.4Juan YepesNo ratings yet

- Anvil Fig137 U-Bolt PDFDocument1 pageAnvil Fig137 U-Bolt PDFAin AzmiNo ratings yet

- Table 11 of API 5LDocument1 pageTable 11 of API 5LBilly Kurniawan100% (1)

- Flange Bolt Tightening ProcedureDocument5 pagesFlange Bolt Tightening ProcedureArya100% (1)

- Torque Values B7 Studs PDFDocument1 pageTorque Values B7 Studs PDFipsthethiNo ratings yet

- Pipe Maximum Alowable Pressures For A53 A106 and API 5LDocument8 pagesPipe Maximum Alowable Pressures For A53 A106 and API 5Llinhcdt3100% (1)

- 2.1 WPS - PipingDocument13 pages2.1 WPS - PipingSheri DiĺlNo ratings yet

- Stillwell Pipe ArrangementDocument1 pageStillwell Pipe ArrangementVishalDhiman100% (1)

- Fitting - ASTM A 197Document4 pagesFitting - ASTM A 197yajuNo ratings yet

- Dimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97Document3 pagesDimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97konazoi100% (1)

- Bolt Pocket ChartDocument2 pagesBolt Pocket ChartAlex LaraNo ratings yet

- Blind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGDocument1 pageBlind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGVarun MalhotraNo ratings yet

- API 5L Grade X52 Pipe Chemical Composition and Mechanical PropertiesDocument1 pageAPI 5L Grade X52 Pipe Chemical Composition and Mechanical PropertiesMohamed HassanNo ratings yet

- API Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksDocument12 pagesAPI Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksEC BaloncestoNo ratings yet

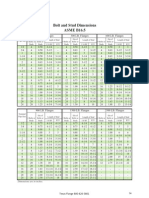

- Bolt and Stud Bolt Dimensions For ANSI / ASME B16.5 Class 150 FlangesDocument1 pageBolt and Stud Bolt Dimensions For ANSI / ASME B16.5 Class 150 Flangesגרבר פליקסNo ratings yet

- Butt Welded Fittings Dimensions ANSI B-16.9 16.28 MSS SP-43Document3 pagesButt Welded Fittings Dimensions ANSI B-16.9 16.28 MSS SP-43Reginaldo Matias NunesNo ratings yet

- Asme b36.10 M 2004 10Document14 pagesAsme b36.10 M 2004 10SICKERESANo ratings yet

- Gasket Installation: DurlonDocument3 pagesGasket Installation: Durlonlorenzo100% (1)

- API 6A Spec Flange Bolt Ring Chart Tap EndDocument1 pageAPI 6A Spec Flange Bolt Ring Chart Tap EndKali AbdennourNo ratings yet

- Flange Bolting Torque Values API 6ADocument1 pageFlange Bolting Torque Values API 6Aparthameister100% (1)

- Pressure-Temp Chart for Materials 4 Spec-GradeDocument5 pagesPressure-Temp Chart for Materials 4 Spec-GradeWilson Ramirez ZuniniNo ratings yet

- ASTM A126 (China Suggested Chemical Composition)Document3 pagesASTM A126 (China Suggested Chemical Composition)EduardoNo ratings yet

- API Valve Trim ChartDocument2 pagesAPI Valve Trim ChartkhaireddinNo ratings yet

- TAYLOR FORGE - Catalog 722 PDFDocument79 pagesTAYLOR FORGE - Catalog 722 PDFMiguel Martinez Guerrero0% (1)

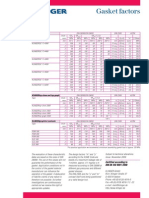

- Klinger - Gasket FactorsDocument4 pagesKlinger - Gasket FactorsFelip PrietoNo ratings yet

- Flange Weight ChartDocument4 pagesFlange Weight ChartDayo IdowuNo ratings yet

- PSV 430066 PDFDocument41 pagesPSV 430066 PDFErikikoNo ratings yet

- ASME RTP-1–2007 Nozzle Flange Dimensions for Class 150 BoltingDocument1 pageASME RTP-1–2007 Nozzle Flange Dimensions for Class 150 BoltingAndres Camilo Galvis Espinel100% (1)

- API E-165 Standard Test Method For Liquid Penetrant Examination PDFDocument20 pagesAPI E-165 Standard Test Method For Liquid Penetrant Examination PDFDaniel GamioNo ratings yet

- API 6A Bolting, API 6ACRA Bolting, API 6A718 Bolting: Minimum Requirement of Closure BoltingDocument10 pagesAPI 6A Bolting, API 6ACRA Bolting, API 6A718 Bolting: Minimum Requirement of Closure BoltingQuality controller0% (1)

- Bolt and Stud DimentionDocument1 pageBolt and Stud DimentionwhngomjNo ratings yet

- Astm E110Document2 pagesAstm E110nandorg27No ratings yet

- ES 22 Color Coding of Piping MaterialsDocument3 pagesES 22 Color Coding of Piping MaterialsjojeecaresNo ratings yet

- American National Standard Stub Acme ThreadsDocument4 pagesAmerican National Standard Stub Acme Threadsjavierpapirico0% (1)

- Torqueo Pikotek PDFDocument4 pagesTorqueo Pikotek PDFjast111100% (1)

- Asme b16.47 Series A (Mss Sp-44) FlangesDocument5 pagesAsme b16.47 Series A (Mss Sp-44) FlangesAlcides Llanque ChoqueNo ratings yet

- Dimensions Reducing - Mss Sp97: Weldolet®Document2 pagesDimensions Reducing - Mss Sp97: Weldolet®Emer Roy Castillo OlivosNo ratings yet

- CHAPAS E BARRAS - Metric Standard GaugeDocument1 pageCHAPAS E BARRAS - Metric Standard GaugeGaston ContrerasNo ratings yet

- LWNRF WeightDocument24 pagesLWNRF WeightAnonymous AyDvqgNo ratings yet

- BSW BSF UNC UNF BSP NPT Metric (MM) : MD MD 7.9 9.7 10.3Document2 pagesBSW BSF UNC UNF BSP NPT Metric (MM) : MD MD 7.9 9.7 10.3navin srivastavaNo ratings yet

- Cable EstructuralDocument2 pagesCable EstructuralSebastián RomaníNo ratings yet

- F C Width Across Corners Basic Max Width Across FlatsDocument8 pagesF C Width Across Corners Basic Max Width Across FlatsJJGM120No ratings yet

- Tabla Roscas Dibujo IndustrialDocument2 pagesTabla Roscas Dibujo Industrialahs00022No ratings yet

- Stock BookDocument66 pagesStock BookAndrew YouNo ratings yet

- API Casing TableDocument1 pageAPI Casing TableChoon BoonNo ratings yet

- Bill of Materials: RDMP Ru V Balikpapan RDMP Balikpapan JoDocument1 pageBill of Materials: RDMP Ru V Balikpapan RDMP Balikpapan JoMusslih YuliantoNo ratings yet

- MIS List Welding TestDocument8 pagesMIS List Welding TestMusslih YuliantoNo ratings yet

- LTCSDocument1 pageLTCSMusslih YuliantoNo ratings yet

- Special Thanks To:: All Hse Team & All Staff MemberDocument1 pageSpecial Thanks To:: All Hse Team & All Staff MemberMusslih YuliantoNo ratings yet

- Status of MIR and MIS Received for PT. Rekayasa Industri & Hyundai ProjectDocument2 pagesStatus of MIR and MIS Received for PT. Rekayasa Industri & Hyundai ProjectMusslih YuliantoNo ratings yet

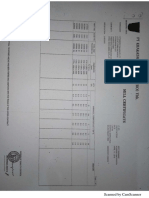

- Dok Baru 2021-09-01 08.32.53Document1 pageDok Baru 2021-09-01 08.32.53Musslih YuliantoNo ratings yet

- F1-3 - Mei'20 (Update 27 Mei' 20)Document13 pagesF1-3 - Mei'20 (Update 27 Mei' 20)Musslih YuliantoNo ratings yet

- Wind direction diagram and ladder platform detailDocument4 pagesWind direction diagram and ladder platform detailMusslih YuliantoNo ratings yet

- Dok Baru 2021-09-01 08.32.53Document1 pageDok Baru 2021-09-01 08.32.53Musslih YuliantoNo ratings yet

- BOQ 56 Deep Well & Flame LinesDocument14 pagesBOQ 56 Deep Well & Flame LinesMusslih YuliantoNo ratings yet

- FabricationDocument27 pagesFabricationMusslih YuliantoNo ratings yet

- FSL 180416 DE01-2102525 Vinfast, Hanoi Vietnam #02 TanksDocument2 pagesFSL 180416 DE01-2102525 Vinfast, Hanoi Vietnam #02 TanksMusslih YuliantoNo ratings yet

- A Study of Storage Tank Accidents InternetDocument10 pagesA Study of Storage Tank Accidents Internetfoamtrailer100% (1)

- API 578 Study MaterialDocument12 pagesAPI 578 Study MaterialVimin Prakash100% (1)

- AECT360 Lecture 33Document13 pagesAECT360 Lecture 33Lakshman Kumar AdusumilliNo ratings yet

- Xsteel - Lesson1 BasicModelingDocument39 pagesXsteel - Lesson1 BasicModelingsaisssms9116100% (5)

- Platelets & Blood Clotting: The Hemostasis ProcessDocument34 pagesPlatelets & Blood Clotting: The Hemostasis ProcesssamayaNo ratings yet

- Alaina W - Food Project ReflectionDocument1 pageAlaina W - Food Project Reflectionapi-438601399No ratings yet

- Dog Cake Recipe For Dozer's Birthday! - RecipeTin EatsDocument36 pagesDog Cake Recipe For Dozer's Birthday! - RecipeTin EatsZyreen Kate CataquisNo ratings yet

- High Pressure Processing For Preservation of FoodsDocument36 pagesHigh Pressure Processing For Preservation of FoodsPravin Zine PatilNo ratings yet

- (New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffDocument1 page(New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffSek PyroNo ratings yet

- Drawing and Reading Structural FormulasDocument12 pagesDrawing and Reading Structural FormulasVy Nguyen100% (1)

- Kraby System 2018Document22 pagesKraby System 2018soga010178No ratings yet

- Booklet English 2016Document17 pagesBooklet English 2016Noranita ZakariaNo ratings yet

- Fundamental aim training routines and benchmarksDocument8 pagesFundamental aim training routines and benchmarksAchilles SeventySevenNo ratings yet

- A Feminist Analysis of Habba Khatoon'S Poetry: Dr. Mir Rifat NabiDocument7 pagesA Feminist Analysis of Habba Khatoon'S Poetry: Dr. Mir Rifat NabiShabir AhmadNo ratings yet

- Transcript Ken Robinson 2010 NewDocument34 pagesTranscript Ken Robinson 2010 NewCarmen Maria FluturaşNo ratings yet

- AAB 075323 EPDM Waterproofing Membrane (For RC Roof Build-Up Inc. Insulation)Document3 pagesAAB 075323 EPDM Waterproofing Membrane (For RC Roof Build-Up Inc. Insulation)tewodrosNo ratings yet

- Image Processing Based Leaf Rot Disease, Detection of Betel Vine (Piper Betlel.)Document7 pagesImage Processing Based Leaf Rot Disease, Detection of Betel Vine (Piper Betlel.)ManiNo ratings yet

- Of Course 1 - Dossier de Revisions ConfinementDocument5 pagesOf Course 1 - Dossier de Revisions ConfinementCamNo ratings yet

- Capacitores Electroliticos SMDDocument8 pagesCapacitores Electroliticos SMDalvaro marrugoNo ratings yet

- Material Safety Data Sheet: Chemtherm 550Document6 pagesMaterial Safety Data Sheet: Chemtherm 550Javier vaca villalbaNo ratings yet

- Effect of Water Immersion On Mechanical Properties of Polyurethane ...Document8 pagesEffect of Water Immersion On Mechanical Properties of Polyurethane ...konshoeNo ratings yet

- Idioms and Phrases MCQs - English Grammar For Competitive ExamsDocument6 pagesIdioms and Phrases MCQs - English Grammar For Competitive ExamsgeologistlakhanNo ratings yet

- Logicroof V-RP enDocument1 pageLogicroof V-RP enCristina DogariNo ratings yet

- Reading Test 7 - PassageDocument12 pagesReading Test 7 - PassageĐinh Quốc LiêmNo ratings yet

- Cefiget-Range-Leaflet-PakistanDocument2 pagesCefiget-Range-Leaflet-PakistanZafran KhanNo ratings yet

- Common Carrier RulingDocument4 pagesCommon Carrier RulingChic PabalanNo ratings yet

- Theoretical Development of The Brooks-Corey CapillDocument7 pagesTheoretical Development of The Brooks-Corey CapillDiana Vanessa PedrazaNo ratings yet

- November 2010 (v1) QP - Paper 3 CIE Biology A-Level PDFDocument12 pagesNovember 2010 (v1) QP - Paper 3 CIE Biology A-Level PDFWiji NingNo ratings yet

- Maersk QuestionnaireDocument43 pagesMaersk QuestionnaireSahil SharmaNo ratings yet

- Assess The Knowledge and Attitude On Prevention of Dengue Among The Patients AttendantsDocument6 pagesAssess The Knowledge and Attitude On Prevention of Dengue Among The Patients AttendantsIJAR JOURNALNo ratings yet

- Analog Layout Design (Industrial Training)Document10 pagesAnalog Layout Design (Industrial Training)Shivaksh SharmaNo ratings yet

- EVS Complete Notes PDFDocument148 pagesEVS Complete Notes PDFrevantrajkpdh2002No ratings yet

- Maximizing Area and Minimizing Costs with CalculusDocument18 pagesMaximizing Area and Minimizing Costs with Calculusanon_218576188No ratings yet

- 6kW V2G EV Charger Module Datasheet (2018)Document2 pages6kW V2G EV Charger Module Datasheet (2018)pysogaNo ratings yet