Professional Documents

Culture Documents

Nastra: Features & Benefits Hamburg, GE

Nastra: Features & Benefits Hamburg, GE

Uploaded by

Ahmed EbhaireOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nastra: Features & Benefits Hamburg, GE

Nastra: Features & Benefits Hamburg, GE

Uploaded by

Ahmed EbhaireCopyright:

Available Formats

NASTRA®

Iron silicate abrasive

Features & Benefits Hamburg , GE

During melting of copper ore concentrates an iron silicate is formed. This is passing a groove and is granulated at a

temperature of approximately 1250 °C, using a temperature-controlled pressurized water jet. After cooling down in a tank with

fresh water, the fine particles are separated from the granulate manufactured in this way. NAstra® is produced in accordance

with DIN EN ISO 11126-3. It is a vitreous amorphous slag, it does not absorb water. During the manufacturing of the abrasive

no crushing or grinding procedures are included. Therefore, the single abrasive particle is not broken up and retains its

extreme hardness and tenacity which is the case for all particle sizes.

Used as blast cleaning abrasive for all applications fields in conventional corrosion protection on almost all surfaces. Suitable

for SA-3, SA-2½, SA-2 and SA-1.

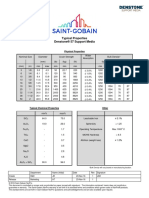

Granulometric Data & Physical Characteristics

Mean values. These do not represent a specification.

Shape : angular

Colour : grey / black v±itreous amorphous slag

Hardness : >7 Mohs

Specific density : 3.7 kg/dm3

Loose bulk density : 1.85 kg/dm3

Conductivity : less than 250 µS/cm

Water-soluble chlorides : less than 0,0025% (m/m)

NA10 0.2 - 1.0 mm NA25 0.2 - 2.5 mm

NA14 0.2 - 1.4 mm NA28 0.2 - 2.8 mm

NA514 0.5 - 1.4 mm NAST 0.5 - 2.5 mm

NA20 0.2 - 2.0 mm NA428 1.4 - 2.8 mm

Chemical Analysis (XRF) %

Mean values. These do not represent a specification.

SiO2 :

FeO :

Al2O3 :

CaO :

K2O :

MgO :

S

The globe mark is a trademark of SCR-Sibelco®, its subsidiaries and affiliates. A list of Sibelco group companies Page 1 of 2

and their registered addresses is available at SCR-Sibelco NV, Plantin en Moretuslei 1A, 2018 Antwerp, Belgium.

Company No: 0404.679.941

www.sibelco.com

You might also like

- CE Board Exam 1997Document17 pagesCE Board Exam 1997AaRichard Manalo100% (1)

- CalculatorDocument19 pagesCalculatorandrew_yeap_2No ratings yet

- Engineering Updated 15 Feb 2013Document1,076 pagesEngineering Updated 15 Feb 2013Boban ThomasNo ratings yet

- TESMEC Surface MiningDocument46 pagesTESMEC Surface MiningA RamasubramanianNo ratings yet

- OpenCV by Example - Sample ChapterDocument25 pagesOpenCV by Example - Sample ChapterPackt PublishingNo ratings yet

- Series: K5V 200 DT H 100 R 9N 01Document1 pageSeries: K5V 200 DT H 100 R 9N 01Stelian Crisan100% (1)

- THP Eng Thermography e PDFDocument72 pagesTHP Eng Thermography e PDFIvana KostićNo ratings yet

- Blastrite Product ID Sheet Rev7Document1 pageBlastrite Product ID Sheet Rev7Mohd YusriNo ratings yet

- Hastelloy C276 / Alloy C276 / UNS N10276 / DIN 2.4819Document3 pagesHastelloy C276 / Alloy C276 / UNS N10276 / DIN 2.4819SamkitNo ratings yet

- Brochure Scorex enDocument5 pagesBrochure Scorex enrafeekhoneyNo ratings yet

- Features and Benefits Dessel, BelgiumDocument2 pagesFeatures and Benefits Dessel, BelgiumPhạm ViệtNo ratings yet

- Grit PDS - Vasilgrit Technical DatasheetDocument1 pageGrit PDS - Vasilgrit Technical DatasheetNelson IzorNo ratings yet

- CatalystCarriers TypicalProperties PFDocument4 pagesCatalystCarriers TypicalProperties PFAdel SukerNo ratings yet

- Technical Data: SilverbondDocument2 pagesTechnical Data: SilverbondI Love MusicNo ratings yet

- Silicate DaluminiumDocument1 pageSilicate DaluminiumrosemaryNo ratings yet

- SZS Bi Nghien Su Ceramic Zs Czs HelicoDocument2 pagesSZS Bi Nghien Su Ceramic Zs Czs HelicoAnonymous Ske1XzNo ratings yet

- Fumed SilicaDocument4 pagesFumed SilicaVishal ThelkarNo ratings yet

- Blastrite Glass Bead - Starbead - Industrial BeadsDocument1 pageBlastrite Glass Bead - Starbead - Industrial BeadsYoutube For EducationNo ratings yet

- TDS Sibelite M3000 M4000 M6000 PDFDocument2 pagesTDS Sibelite M3000 M4000 M6000 PDFLe PhongNo ratings yet

- Material Chemical Composition - Cast Analysis: Brand, Source, Tests Etc. Units RequirementDocument1 pageMaterial Chemical Composition - Cast Analysis: Brand, Source, Tests Etc. Units RequirementNandika MilindaNo ratings yet

- High-Reliability Lead-Free Solder Paste: Senju Metal Industry Co., Ltd. Senju Manufacturing (Europe) LTDDocument3 pagesHigh-Reliability Lead-Free Solder Paste: Senju Metal Industry Co., Ltd. Senju Manufacturing (Europe) LTDzaizamNo ratings yet

- GHCL LABS13-DSA-gammaDocument1 pageGHCL LABS13-DSA-gammaUmar HayatNo ratings yet

- Jetblast™ Copper SlagDocument4 pagesJetblast™ Copper SlaglambtranNo ratings yet

- Hydrochloric Acid HandbookDocument2 pagesHydrochloric Acid HandbookEmre YıldırımNo ratings yet

- Hempel Alloy254SMO14547LongflatproductsHempel PDFDocument1 pageHempel Alloy254SMO14547LongflatproductsHempel PDFqualityNo ratings yet

- Solid Bronze Bearing: Technical DataDocument6 pagesSolid Bronze Bearing: Technical DatadangminhNo ratings yet

- Corrosion Resistance Table PDFDocument20 pagesCorrosion Resistance Table PDFDaniel Puello RodeloNo ratings yet

- National Water Quality Standards For Malaysia Parameter Unit ClassDocument6 pagesNational Water Quality Standards For Malaysia Parameter Unit ClassmaizansofiaNo ratings yet

- National Water Quality Standard For Malaysia PDFDocument6 pagesNational Water Quality Standard For Malaysia PDFMohd Shareen Ezzry Mohd SomNo ratings yet

- National Water Quality Standards For Malaysia Parameter Unit ClassDocument6 pagesNational Water Quality Standards For Malaysia Parameter Unit ClassPrivate SapekNo ratings yet

- National Water Quality Standards For Malaysia Parameter Unit ClassDocument6 pagesNational Water Quality Standards For Malaysia Parameter Unit ClassSyafiq HassanNo ratings yet

- Wqi Standard PDFDocument6 pagesWqi Standard PDFnnsNo ratings yet

- National Water Quality Standards For Malaysia Parameter Unit ClassDocument6 pagesNational Water Quality Standards For Malaysia Parameter Unit ClassNina AzizNo ratings yet

- National Water Quality Standards For Malaysia Parameter Unit ClassDocument6 pagesNational Water Quality Standards For Malaysia Parameter Unit ClassBoos yousufNo ratings yet

- Anti-Seize Compound TdsDocument3 pagesAnti-Seize Compound TdskorayNo ratings yet

- GHCL Labs08 - LsaDocument1 pageGHCL Labs08 - LsaUmar HayatNo ratings yet

- Roughness Conversion Chart RampinelliDocument1 pageRoughness Conversion Chart RampinelliServesh KumarNo ratings yet

- E2SB Series 2.5 2.0 Seam Sealing CrystalDocument1 pageE2SB Series 2.5 2.0 Seam Sealing CrystalMaksimUSNo ratings yet

- GHCL LABS11-DSA-alphaDocument1 pageGHCL LABS11-DSA-alphaUmar HayatNo ratings yet

- Miginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- Blastrite BeadsDocument1 pageBlastrite BeadsAsad AhmedNo ratings yet

- Powders: Technical, Application & Safety DataDocument7 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- TDS 38 White Aluminium OxideDocument2 pagesTDS 38 White Aluminium OxideRashid SaleemNo ratings yet

- Powders: Technical, Application & Safety DataDocument7 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- Material No.: EscriptionDocument2 pagesMaterial No.: EscriptionMd Omar FaruqueNo ratings yet

- Gophin Chemical Co., LTD: DatasheetDocument3 pagesGophin Chemical Co., LTD: DatasheetmadhudNo ratings yet

- 2023 EmaxDocument3 pages2023 EmaxYander Luis Hernández ArmasNo ratings yet

- Zinc Die Casting Alloy-Zamak-2020Document4 pagesZinc Die Casting Alloy-Zamak-2020Metal deptNo ratings yet

- Sand BrochureDocument4 pagesSand BrochureKTSivakumarNo ratings yet

- Nextel Ceramic Fiber Typical Properties: 3M Property Units Nextel™ 312 Nextel™ 440 Nextel™ 550Document2 pagesNextel Ceramic Fiber Typical Properties: 3M Property Units Nextel™ 312 Nextel™ 440 Nextel™ 550ninatenaNo ratings yet

- PosiTector 6000 SeriesDocument4 pagesPosiTector 6000 SeriesJorge GranadosNo ratings yet

- 1 s2.0 S0040609005025459 MainDocument4 pages1 s2.0 S0040609005025459 Mainrautsubhajit89No ratings yet

- 1325 Laser Cutting Machine-Amy-20201230Document12 pages1325 Laser Cutting Machine-Amy-20201230EdgarNo ratings yet

- Denstone® 57 Support Media Typical PropertiesDocument1 pageDenstone® 57 Support Media Typical PropertiesJuan Victor Sulvaran ArellanoNo ratings yet

- How To Get The Most Out of Orbis Micro-Xrf Measurements With Multiple Acquisition ConditionsDocument2 pagesHow To Get The Most Out of Orbis Micro-Xrf Measurements With Multiple Acquisition Conditionstaufiq_hidayat_1982No ratings yet

- NIST 2010 - Engineering - MaterialsDocument8 pagesNIST 2010 - Engineering - MaterialsbonyjuniorNo ratings yet

- Insulating Brick ExampleDocument1 pageInsulating Brick ExamplepsaayoNo ratings yet

- Insulating Brick Example PDFDocument1 pageInsulating Brick Example PDFpsaayoNo ratings yet

- Mineral Slag BlastingDocument2 pagesMineral Slag BlastingtestNo ratings yet

- SCRM BrochureDocument6 pagesSCRM BrochureRizwan TonoyNo ratings yet

- Hilti Anchor CatalogueDocument4 pagesHilti Anchor CatalogueARUN GOYALNo ratings yet

- Nycolube 127 TDSDocument1 pageNycolube 127 TDSpokleNo ratings yet

- ULTRA DIVERSITY-21 - Oct - 2022 - 06 - 03 - 14-100009554Document15 pagesULTRA DIVERSITY-21 - Oct - 2022 - 06 - 03 - 14-100009554Lee Quan DeNo ratings yet

- National Water Quality Standards For Malaysia: Parameter Unit ClassDocument6 pagesNational Water Quality Standards For Malaysia: Parameter Unit ClassvinoNo ratings yet

- 490.399 en Low VITA Mark II PDFDocument4 pages490.399 en Low VITA Mark II PDFsousourimeNo ratings yet

- Introduction To The Space AgeDocument16 pagesIntroduction To The Space AgeAnne MillbrookeNo ratings yet

- Materials Science ProgramDocument45 pagesMaterials Science Programibson045001256No ratings yet

- BJT Ebers Moll RepresentaionDocument3 pagesBJT Ebers Moll RepresentaionRamanaButterflyNo ratings yet

- Definitions, Dimension and Importance of QualityDocument45 pagesDefinitions, Dimension and Importance of Qualitymohammedakbar88100% (1)

- Steel Shape W 18x283Document1 pageSteel Shape W 18x283Alberto Acosta GongoraNo ratings yet

- Datasheet ds26c32Document11 pagesDatasheet ds26c32Mgc ElektronikNo ratings yet

- HP Technik 2017.1 PDFDocument72 pagesHP Technik 2017.1 PDFMilos Kovacevic100% (1)

- KPI OptimizationDocument2 pagesKPI Optimizationbikramaditya_malickNo ratings yet

- 1174rr320801 Mass Transfer Operations IIDocument8 pages1174rr320801 Mass Transfer Operations IIsobichemNo ratings yet

- Driver Wifi Windows7Document2 pagesDriver Wifi Windows7Fauzi WidodoNo ratings yet

- HR 550 FS: Product InformationDocument4 pagesHR 550 FS: Product InformationAgim ZilkicNo ratings yet

- Fibrograph Method PDFDocument4 pagesFibrograph Method PDFMd Amir HossainNo ratings yet

- Dabond Product Information Sheet PDFDocument2 pagesDabond Product Information Sheet PDFKruglikova MariaNo ratings yet

- Repair of Tube-Tubesheet Weld Cracks in A Cracked Gas/Steam Heat ExchangerDocument7 pagesRepair of Tube-Tubesheet Weld Cracks in A Cracked Gas/Steam Heat ExchangerBaher ElsheikhNo ratings yet

- Course Outline: - Chairperson/DeanDocument7 pagesCourse Outline: - Chairperson/DeanmarkuspinkusNo ratings yet

- Schuller Furniture, Mirrors, DecorationDocument186 pagesSchuller Furniture, Mirrors, DecorationLiteHouseNo ratings yet

- E4E - A - ES - GL - FS Interface - INT - GL - 010 - XCFEC04E - v2.0Document25 pagesE4E - A - ES - GL - FS Interface - INT - GL - 010 - XCFEC04E - v2.0JaimeNo ratings yet

- Searching and Sorting 2Document24 pagesSearching and Sorting 2Purushothama ReddyNo ratings yet

- IoT USSD API Developers GuideDocument27 pagesIoT USSD API Developers GuideJamal DeenNo ratings yet

- Question PaperDocument2 pagesQuestion Paperharmankalsi95No ratings yet

- Katalog Za Kancelariski MebelDocument21 pagesKatalog Za Kancelariski MebelbzdravevaNo ratings yet

- BHOPAL Presentation On Energy EfficiencyDocument68 pagesBHOPAL Presentation On Energy Efficiencygayathri12092002No ratings yet