Professional Documents

Culture Documents

CIM Subject Guide for Mechanical Engineering Students

Uploaded by

Keerthe VaasanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CIM Subject Guide for Mechanical Engineering Students

Uploaded by

Keerthe VaasanCopyright:

Available Formats

YEAR III L T P C

COMPUTER INTEGRATED MANUFACTURING

SEMESTER VI 3 0 0 3

(COMMON TO MECH & MECHT)

Aim The aim of the subject is to provide knowledge in computer integrated manufacturing

Scope 1. To understand the importance of CIM and business aspects

2. To gain knowledge about GT and CAPP

3. To enable student to learn about FMS and SFC

4. To understand about architecture and network concepts

5. To learn about automation protocol and database

Outcom The students would be able to understand the various concepts viz. group technology,

e CAPP,FMS.

UNIT I INTRODUCTION TO CAD/CAM 9

The design process Morphology of design, Product cycle Computer Aided Design,

Benefits of CAD. Role of computers - principles of computer graphics - Current trends in

manufacturing engineering - - Design for Manufacturing and Assembly - Sequential and

concurrent engineering,-Rapid prototyping

UNIT II SOLID MODELING 9

Graphic software: coordinate representation- graphic functions, software standards. Graphical

Kernel system (GKS) - Initial graphics exchange system (IGES) - Graphic packages. Geometric

Modeling - Wire frame, Surface and Solid models - Constructive Solid Geometry (CSG) and

Boundary Representation (B-REP) Techniques - Features of Solid Modeling Packages.

UNIT III FUNDAMENTALS OF CNC MACHINES 9

CNC Technology - Functions of CNC Control in Machine Tools - Classification of CNC systems

- Contouring System - Interpolators, open loop and closed loop CNC systems - CNC Controllers,

Direct Numerical Control (DNC Systems). - Work holding devices and tool holding devices

-Automatic Tool changers. Feedback devices - Principles of Operation-Machining Centres -

Tooling for CNC machines

Numerical control codes - Standards - Manual Programming - Canned cycles and subroutines -

Computer Assisted Programming, CAD / CAM approach to NC part programming - APT

language, machining from 3D models.

UNIT IV GROUP TECHNOLOGY AND COMPUTER AIDED PROCESS PLANNING 10

Introduction to CIM and its related activities-History of group technology- role of G.T. in

CAD/CAM integration - part families - classification and coding - DCLASS and MICLASS and

OPITZ coding systems-facility design using G.T. - benefits of G.T. - cellular manufacturing.

Process planning - role of process planning in CAD/CAM integration - approaches to computer

aided process planning - variant approach and generative approaches - CAPP and CMPP process

planning systems.

Checked By Verified By HOD/MECH

UNIT V SHOP FLOOR CONTROL AND INTRODUCTION OF FMS 9

Shop floor control-phases -factory data collection system -automatic identification methods- Bar

code technology-automated data collection system. MS-components of FMS - types -FMS

workstation -material handling and storage systems- FMS layout -computer control systems-

application and benefits.

Total Hours : 45

TEXT BOOKS

1. Mikell.P.Groover “Automation, Production Systems and Computer Integrated

manufacturing”, Pearson Education 2001.

2. Radhakrishnan P, Subramanyan.S. and Raju V., “CAD/CAM/CIM”, 2nd Edition New Age

International (P) Ltd., New Delhi, 2000.

REFERENCES

1. Yorem koren, “Computer Integrated Manufacturing System”, McGraw-Hill, 1983.

2. Ranky, Paul G., “Computer Integrated Manufacturing”, Prentice Hall International, 1986.

3. David D.Bedworth, Mark R.Hendersan, Phillip M.Wolfe “Computer Integrated Design and

Manufacturing”, McGraw-Hill Inc.

4. Roger Hanman “Computer Integrated Manufacturing”, Addison – Wesley, 1997.

5. Mikell.P.Groover and Emory Zimmers Jr., “CAD/CAM”, Prentice Hall of India Pvt. Ltd.,

New Delhi-1, 1998.

6. Kant Vajpayee S, “Principles of Computer Integrated Manufacturing”, Prentice Hall India,

2003.

Checked By Verified By HOD/MECH

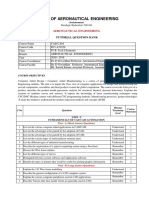

VINAYAKA MISSION’S RESEARCH FOUNDATION

(DEEMED TO BE UNIVERSITY)

AARUPADAI VEEDU INSTITUTE OF TECHNOLOGY, CHENNAI

&

V.M.K.V.ENGINEERING COLLEGE, SALEM

BOARD : MECHANICAL ENGINEERING

PROGRAM : B.E – MECHANICAL ENGINEERING & MECHATRONICS ENGINEERING

SEMESTER : VI

SUBJECT : COMPUTER INTEGRATED MANUFACTURING.

UNIT – I

PART- A

1. List the role of computers in design.

2. Define CAD and mention the areas of application.

3. What is the Design Process?

4. What is meant by conceptual design?

5. Why lead time in sequential product development is more?

6. Write down the phases in Morphology of Design.

7. Write any four benefits of CAD.

8. List the role of computers in Manufacturing.

9. Define CAM.

10. Differentiate sequential and concurrent engineering.

11. List some of the important guide lines to be followed in DFA.

12. Write the objectives of DFM.

13. What are main features of drafting software?

14. Define the term “Rapid prototyping”.

15. List the most common Rapid Prototyping techniques.

16. List the applications of Rapid prototyping.

17. What is meant by Embodiment design?

18. List the benefits of concurrent engineering.

19. Name any two reasons for implementing CAD in design.

20. Define CAE.

PART B

1. With the help of flow diagram explain the Pahl and Beitz model.

2. Explain the various steps for design process as outlined by Shigley.

3. With the help of diagram, explain any two Rapid Prototyping techniques.

4. Explain the general guidelines to be followed in DFM & DFA?

5. List some important DFM guide lines to be followed for moulding and forming

processes.

6. Compare the conventional product cycle with computer aided product cycle.

7. Explain the seven phases of Morphology of design.

8. Explain the function of CAD system and their applications in design process.

9. Discuss and explain the various steps of concurrent engineering.

10. Explain the various stages in Ohsuga model.

Checked By Verified By HOD/MECH

UNIT – II

PART- A

1. Define Geometric modeling.

2. Write down the three types of Geometric models.

3. List few mass properties.

4. List the general features of a solid modeler.

5. Write any four solid primitives.

6. Write any two Boolean operations.

7. What are the primitives of B– REP scheme?

8. List the basic entities used in surface modeling software.

9. State Euler rule for topological checking.

10. What are the types of parametric modeling?

11. Name the two types of feature based modeling technique.

12. Define sculptures surface.

13. What is DXF?

14. Define the term “Feature”.

15. Write down the applications of feature based models.

16. List any four modeling packages.

17. List the basic entities in CSG approach of solid modeling.

18. List any two disadvantages of surface modeling.

19. What is meant by IGES?

20. What is meant by GKS?

PART B

1. With neat sketch, explain in detail about the wire frame modeling.

2. With neat sketch, explain about the entities used in surface modeling.

3. Explain in detail about the CSG technique in 3D solid modeling.

4. Explain in detail about the B-rep technique in 3D solid modeling.

5. Explain briefly about the parametric modeling with examples.

6. Classify the graphics standards. Name some important standards used in plotting and

CAD data exchange.

7. Explain briefly the GKS and IGES system.

8. Explain two techniques followed in feature based modeling.

9. What is meant by topological consistency? Discuss the rules to be followed to get

geometrical valid solid models?

10. List the advantage & disadvantage of Surface & Solid Modeling.

Checked By Verified By HOD/MECH

UNIT – III

PART- A

1. Write down the classification of CNC machines based on feedback control.

2. Write down the classification of CNC machines based on control system features.

3. List the various areas where design changes are required in CNC machine.

4. What are the factors considered while designing the structure of a CNC machine?

5. List the two major type of spindle drives used in CNC machine tools.

6. What are the requirements of a good slideway system?

7. Write down the classification of ATC.

8. Describe shortly about the requirements of spindles for CNC machines.

9. Why is feedback necessary in machine tools?

10. List the broad classification of Feedback devices.

11. Classify the machining centers according to the spindle configuration.

12. What are the various types of DC motors used in a CNC machine tools?

13. Define the term Interpolation.

14. Write down the types of interpolators.

15. What are advantages of digital feedback devices over analog feedback devices?

16. What are the different types of Inductosyns?

17. Write any two advantages of laser interferometer.

18. Describe shortly about DNC.

19. What is meant by qualified tools?

20. What are the special features of work holding devices used in CNC machines?

PART B

1. Explain the functions of CNC control in machine tools?

2. With the help of block diagram, explain the closed loop control system in CNC machines.

3. Explain in detail about motion control system in CNC machines.

4. Discuss the methods used for position and velocity feedback in CNC machines.

5. Explain with neat sketch, the working principle of Recirculating Ball screws.

6. Discuss in detail about DNC.

7. Describe in detail about the work holding and tool holding devices of a CNC.

8. With neat sketch, explain the working principle of double gripper type ATC.

9. Describe the principle of working of Incremental rotary encoders.

10. Discuss in detail about tooling for CNC machines.

Checked By Verified By HOD/MECH

UNIT – IV

PART- A

1. Define the term “Group Technology”.

2. When the GT is applied in manufacturing industry?

3. What is mean by “Part family”?

4. Write any two Design attributes?

5. Write any two Manufacturing attributes?

6. List the methods of grouping the parts into families.

7. Write down the three categories of parts classification systems?

8. What is meant by “Monocode”?

9. Write any two examples of parts classification and coding system.

10. Write short notes on “Production flow analysis”?

11. Describe shortly about “cellular manufacturing”.

12. On what basis GT manufacturing cells are classified.

13. Classify the GT manufacturing cells.

14. What is meant by process planning?

15. Classify CAPP.

16. List any four advantages of process planning.

17. Write short notes on visual inspection methods in grouping of parts.

18. Define Generative approach.

19. Write down the factors considered for machine cell design?

20. What do you mean by CMPP?

PART – B

1. Explain the OPTIZ system of parts classification and coding.

2. Explain the MICLASS system of parts classification and coding.

3. List and explain the steps involved in Production Flow Analysis.

4. Explain in detail the process plan activity.

5. Explain in detail about machine cell design.

6. With the help of flow diagram, explain in detail about Variant type CAPP.

7. Discuss in detail about Generative type CAPP.

8. Discuss the applications and benefits of GT in detail.

9. Explain the concepts of part family with suitable illustration.

10. Explain the role of process planning in CAD/CAM integration.

Checked By Verified By HOD/MECH

UNIT – V

PART- A

1. What is meant by “Shop floor control”?

2. Write down the three phases of SFC.

3. Write down the three principal components of automatic identification technologies?

4. Define the term “FMS”.

5. Write short notes on random ordered FMS?

6. What is meant by in-line layout in FMS?

7. What is meant by loop layout in FMS?

8. What is meant by ladder layout in FMS?

9. What are the types of Bar code?

10. What is meant by Robot centered layout in FMS?

11. What are the ultimate purposes of Factory data collection system?

12. Write short notes on inventory control?

13. List any four automatic identification methods.

14. Write any four Bar code printing technologies.

15. Write any two application of computer control in FMS?

16. List any two benefits of computer control in FMS.

17. State the benefits of FMS.

18. What are the types of flexibility?

19. Name the types of voice recognition system.

20. What are the components of FMS?

PART – B

1. Explain in detail about the phases of shop floor control.

2. What is shop floor control? What are the functions of SFC?

3. What is meant by factory data collection system? Explain the various techniques used for

this purpose

4. Explain Bar-code technology?

5. List and explain the types of FMS layout.

6. Explain the FMS components in detail.

7. Explain in detail about FMS workstation.

8. Discuss in detail about the functions of material handling and storage system in FMS.

9. Write short notes on following

(1) Aggregate production planning (2) Master production planning

(3) MRP (4) Capacity planning

10. Discuss the applications, advantages and disadvantages of a FMS.

Checked By Verified By HOD/MECH

You might also like

- Me8691 Cad&m UpdatedDocument70 pagesMe8691 Cad&m UpdatedkipseyNo ratings yet

- Mechanical - VI. Sem Syllabus GtuDocument115 pagesMechanical - VI. Sem Syllabus GtukishormechNo ratings yet

- CAD/CAM Important QuestionsDocument3 pagesCAD/CAM Important Questionsivs yeswanthNo ratings yet

- Me8691-Computer Aided Design and ManufacturingDocument2 pagesMe8691-Computer Aided Design and ManufacturingGeorge Oliver100% (3)

- Me8691 Computer Aided Design and Manufacturing SyllabusDocument2 pagesMe8691 Computer Aided Design and Manufacturing SyllabusGanapathy TNo ratings yet

- Thirumalai Engineering College Question Bank on Computer Integrated ManufacturingDocument5 pagesThirumalai Engineering College Question Bank on Computer Integrated ManufacturingS A ABDUL SUKKURNo ratings yet

- ME2402-Computer Integrated ManufacturingDocument6 pagesME2402-Computer Integrated ManufacturingLarry SmithNo ratings yet

- Mechanical Engg 19Document115 pagesMechanical Engg 19Harshul BrahmbhattNo ratings yet

- Prist University B.Tech Part Time Mechanical Engineering Question Bank for Computer Integrated ManufacturingDocument5 pagesPrist University B.Tech Part Time Mechanical Engineering Question Bank for Computer Integrated ManufacturingMahalingam NanjappanNo ratings yet

- Computer Integrated Manufacturing One Mark Question & AnswersDocument14 pagesComputer Integrated Manufacturing One Mark Question & AnswersLovely ShalihNo ratings yet

- Cadcam Assignments PartADocument4 pagesCadcam Assignments PartAmkumar_234155No ratings yet

- Andhra Loyola Institute of Engineering and Andhra Technology Subject-Cad/Cam Iv-Mechanical Faculty-T.Subba ReddyDocument1 pageAndhra Loyola Institute of Engineering and Andhra Technology Subject-Cad/Cam Iv-Mechanical Faculty-T.Subba ReddyKarthik ChowdaryNo ratings yet

- ME8691 Syllabus Edubuzz360Document2 pagesME8691 Syllabus Edubuzz360Johnson PaulNo ratings yet

- Ec8791 Erts QBDocument8 pagesEc8791 Erts QBRajarajeswari KannanNo ratings yet

- Me6703 Cim - QBDocument22 pagesMe6703 Cim - QBMukesh SaravananNo ratings yet

- Cad-Cam-Cim Lab Manual Me804Document49 pagesCad-Cam-Cim Lab Manual Me804Vivek Patil100% (1)

- Unit 1 CAD PDFDocument4 pagesUnit 1 CAD PDFChennai RajaNo ratings yet

- CADCAM-minDocument91 pagesCADCAM-minBandi KumarreddyNo ratings yet

- MEL 502: Computer Aided Manufacturing and Computer Integrated ManufacturingDocument2 pagesMEL 502: Computer Aided Manufacturing and Computer Integrated ManufacturingSumer DirbudeNo ratings yet

- 17mecc12-Computer Integrated Manufacturing-Question BankDocument10 pages17mecc12-Computer Integrated Manufacturing-Question BankPrabhaharMuthuswamyNo ratings yet

- ME2402 COMPUTER INTEGRATED MENUFACTURING (Questions & AnswersDocument9 pagesME2402 COMPUTER INTEGRATED MENUFACTURING (Questions & AnswersMartin De Boras Pragash100% (1)

- Department of Mechanical Engineering Me6501Computer Aided Designquestion Bank Unit - I Part ADocument2 pagesDepartment of Mechanical Engineering Me6501Computer Aided Designquestion Bank Unit - I Part AChennai RajaNo ratings yet

- Cad-Cam-Cim Lab Manual Me804Document47 pagesCad-Cam-Cim Lab Manual Me804siddharth100% (1)

- EC8791 Important QuestionsDocument27 pagesEC8791 Important QuestionsSurendar PNo ratings yet

- ME8691 University Important Questions Two MarksDocument1 pageME8691 University Important Questions Two MarksPrakash RNo ratings yet

- Cad/Cam Syllabus: B.Tech IV Year I Semester Examination (Mechanical Engineering)Document23 pagesCad/Cam Syllabus: B.Tech IV Year I Semester Examination (Mechanical Engineering)Mohammed SameerNo ratings yet

- Computer Aided Manufacturing 2 Marks All 5 UnitsDocument18 pagesComputer Aided Manufacturing 2 Marks All 5 UnitsMehul MunshiNo ratings yet

- QB For CAD CAMDocument4 pagesQB For CAD CAMsmg26thmayNo ratings yet

- CIM - Question Bank - StudentsDocument3 pagesCIM - Question Bank - StudentsmandloianujNo ratings yet

- Mech VI Sem Question BankDocument134 pagesMech VI Sem Question BankMr G Kaliraj MECHNo ratings yet

- IPE 443 Advanced Manufacturing System: 1. Write Down CAD & CAM HistoryDocument16 pagesIPE 443 Advanced Manufacturing System: 1. Write Down CAD & CAM HistoryHadi Ahamed LipuNo ratings yet

- 22658-Sample-Question-Paper (Msbte Study Resources)Document4 pages22658-Sample-Question-Paper (Msbte Study Resources)Ganesh GopalNo ratings yet

- Lecture01 - CAD CAM - CAE - Introduction of The CourseDocument21 pagesLecture01 - CAD CAM - CAE - Introduction of The CourseSameer shaikhNo ratings yet

- Computer Aided Design 2 Mark Questions With AnswersDocument18 pagesComputer Aided Design 2 Mark Questions With AnswersM.Thirunavukkarasu100% (4)

- CAD CAM SyllabusDocument2 pagesCAD CAM SyllabusDeepak AwasthiNo ratings yet

- Computer Aided Manufacturing - 2 Marks - All 5 UnitsDocument18 pagesComputer Aided Manufacturing - 2 Marks - All 5 UnitsMohan Prasad.M67% (6)

- Computer Integrated Manufacturing CourseDocument3 pagesComputer Integrated Manufacturing CoursesatheeshNo ratings yet

- 1.cim Text BookDocument18 pages1.cim Text BookVinayakNo ratings yet

- Computer Integrated ManufacturingDocument5 pagesComputer Integrated ManufacturingbalamaddysweetNo ratings yet

- ME2402 Question Bank for Computer Integrated ManufacturingDocument6 pagesME2402 Question Bank for Computer Integrated ManufacturingPrashanth BalaNo ratings yet

- Institute of Aeronautical EngineeringDocument7 pagesInstitute of Aeronautical EngineeringGGRNo ratings yet

- Mee2007 Cad CamDocument2 pagesMee2007 Cad CamSrivathson EswaranNo ratings yet

- ME6703-CIMS Question BankDocument9 pagesME6703-CIMS Question BankKanagarajNo ratings yet

- Final Exam CADCAMFinal 2016FinalAnswersDocument10 pagesFinal Exam CADCAMFinal 2016FinalAnswerskhalil alhatabNo ratings yet

- Software Engineering Question Bank for Units I-IVDocument11 pagesSoftware Engineering Question Bank for Units I-IVHema MaheNo ratings yet

- CAD&MDocument2 pagesCAD&MVarun ANo ratings yet

- Cadcam 2 Marks PDFDocument18 pagesCadcam 2 Marks PDFPct TejNo ratings yet

- Iat 2reDocument1 pageIat 2reSuresh NatarajanNo ratings yet

- 15AE308J - Design Lab Manual New 2020Document43 pages15AE308J - Design Lab Manual New 2020rushan ahmedNo ratings yet

- CADCAMDocument50 pagesCADCAMPrem Chander100% (5)

- Department of Computer Science and Engineering Question BankDocument11 pagesDepartment of Computer Science and Engineering Question BankDevi SriNo ratings yet

- Unit 2Document34 pagesUnit 2sai venkatsharmaNo ratings yet

- CadDocument4 pagesCadpvrbalaNo ratings yet

- Cloud Computing Archives - TIEDocument2 pagesCloud Computing Archives - TIEDeeksha gowdaNo ratings yet

- Cad Cam PDFDocument2 pagesCad Cam PDFRanjit SinghNo ratings yet

- Up and Running with AutoCAD 2012: 2D Drawing and ModelingFrom EverandUp and Running with AutoCAD 2012: 2D Drawing and ModelingRating: 3.5 out of 5 stars3.5/5 (3)

- Complete PCB Design Using OrCAD Capture and PCB EditorFrom EverandComplete PCB Design Using OrCAD Capture and PCB EditorRating: 5 out of 5 stars5/5 (1)

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Unit-1: 1. List and Briefly Describe The General Steps of Finite Element AnalysisDocument45 pagesUnit-1: 1. List and Briefly Describe The General Steps of Finite Element AnalysisKeerthe VaasanNo ratings yet

- Part-B: 1. Determine The Shape Functions N N, and N at The Interior Point P For The Triangular Element Shown in FigDocument44 pagesPart-B: 1. Determine The Shape Functions N N, and N at The Interior Point P For The Triangular Element Shown in FigKeerthe VaasanNo ratings yet

- Microcontrollers & Applications QBDocument7 pagesMicrocontrollers & Applications QBKeerthe VaasanNo ratings yet

- Evaluate by Applying 3 Point Gaussian Quadrature.: X XDXDocument15 pagesEvaluate by Applying 3 Point Gaussian Quadrature.: X XDXKeerthe VaasanNo ratings yet

- Question Bank: Discrete Fourier Transforms & Fast Fourier TransformsDocument10 pagesQuestion Bank: Discrete Fourier Transforms & Fast Fourier TransformsKeerthe VaasanNo ratings yet

- MEMS Elective CourseDocument6 pagesMEMS Elective CourseKeerthe VaasanNo ratings yet

- DMS QB 2015 RDocument8 pagesDMS QB 2015 RKeerthe VaasanNo ratings yet

- Digital Electronics QB 2015-RDocument8 pagesDigital Electronics QB 2015-RKeerthe VaasanNo ratings yet

- OrganizationalBehavior OP PDFDocument703 pagesOrganizationalBehavior OP PDFSamuel Aina100% (3)

- Evaluating E-Commerce Website Content Management System in Assisting Usability IssuesDocument6 pagesEvaluating E-Commerce Website Content Management System in Assisting Usability IssuesWu XiNo ratings yet

- CSC153 Syllabus of MicroprocessorDocument3 pagesCSC153 Syllabus of MicroprocessorPrajowal ManandharNo ratings yet

- Application Areas of ICTDocument12 pagesApplication Areas of ICTowuor PeterNo ratings yet

- Jntuworld: Branch: Computer Science & EngineeringDocument10 pagesJntuworld: Branch: Computer Science & EngineeringventhiiNo ratings yet

- Micropython On ESP8266 Workshop Documentation: Release 1.0Document35 pagesMicropython On ESP8266 Workshop Documentation: Release 1.0Hendri Kus23No ratings yet

- Advisor MASTER Total Security System: Fully IntegratedDocument64 pagesAdvisor MASTER Total Security System: Fully IntegratedcrissdemonNo ratings yet

- 8.2.5.4 Lab - Identifying IPv6 AddressesDocument10 pages8.2.5.4 Lab - Identifying IPv6 AddressesPriscila Maldonado100% (1)

- Online PharmacyDocument114 pagesOnline PharmacyRajesh Salla100% (1)

- Docker Study GuideDocument12 pagesDocker Study GuideDaniel De Los Santos LugoNo ratings yet

- HW 6Document4 pagesHW 6api-479531624No ratings yet

- Class Ix Subject: Information Technology Chapter 2 Introduction To It - Ites IndustryDocument10 pagesClass Ix Subject: Information Technology Chapter 2 Introduction To It - Ites IndustryChinna SamyNo ratings yet

- Dmatrix CDocument4 pagesDmatrix Csk_firdousNo ratings yet

- CM2347 SKF Standard Product Reference GuideDocument12 pagesCM2347 SKF Standard Product Reference GuideAshish KumarNo ratings yet

- ACS800 04 Technical Manual 0 55kW To 160kWDocument136 pagesACS800 04 Technical Manual 0 55kW To 160kWsawarNo ratings yet

- The Engineering Design Revolution - CAD History - Appendix B - BibliographyDocument6 pagesThe Engineering Design Revolution - CAD History - Appendix B - BibliographyphamduyprojectNo ratings yet

- CISSP My - Nots PDFDocument11 pagesCISSP My - Nots PDFMarc Anthony N100% (1)

- Res 40 RMFDocument118 pagesRes 40 RMFGustavo Javier Castañón SelemNo ratings yet

- 5.0 Adobe Acrobat: New Feature HighlightsDocument7 pages5.0 Adobe Acrobat: New Feature Highlights同道文档中心100% (2)

- Free Ebook: Generate Pagination Links in Laravel Like A ProDocument6 pagesFree Ebook: Generate Pagination Links in Laravel Like A ProDinesh SutharNo ratings yet

- 01 Profiling Complex Muliphase PDFDocument10 pages01 Profiling Complex Muliphase PDFJorge Miguel Sandoval HernandezNo ratings yet

- CS6503 Theory of Computations Unit 2Document47 pagesCS6503 Theory of Computations Unit 2dgk84_id67% (3)

- Office Communications Server 2007 and 2007 R2 Visio StencilsDocument3 pagesOffice Communications Server 2007 and 2007 R2 Visio StencilsElizabeth RamosNo ratings yet

- Lateral Thinking PuzzlesDocument259 pagesLateral Thinking PuzzlesShobana JayarajNo ratings yet

- Raspberry Pi Internet Radio: Bob Rathbone Computer ConsultancyDocument256 pagesRaspberry Pi Internet Radio: Bob Rathbone Computer ConsultancyCristian SeguelNo ratings yet

- Streaming ParameterDocument3 pagesStreaming ParameterRiski Ahmad TaufiqNo ratings yet

- MoogAnimatics 2016 ProductCatalogDocument52 pagesMoogAnimatics 2016 ProductCatalogChaly KhoaNo ratings yet

- Statistical Computing by Using RDocument11 pagesStatistical Computing by Using RChen-Pan Liao100% (1)

- MTG Teeth AdapterDocument2 pagesMTG Teeth AdapterMaimun maimunNo ratings yet

- How To Create Tree Structure in Excel SpreadsheetDocument11 pagesHow To Create Tree Structure in Excel Spreadsheetnagushankar8840No ratings yet

- XP-K7VM333 1002Document22 pagesXP-K7VM333 1002Claudio RomNo ratings yet