Professional Documents

Culture Documents

4A, 21V 500Khz Synchronous Step-Down Converter: General Description Features

Uploaded by

Rakesh SutharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4A, 21V 500Khz Synchronous Step-Down Converter: General Description Features

Uploaded by

Rakesh SutharCopyright:

Available Formats

®

RT8288A

4A, 21V 500kHz Synchronous Step-Down Converter

General Description Features

The RT8288A is a synchronous step-down regulator with z 4A Output Current

an internal power MOSFET. It achieves 4A of continuous z Internal Soft-Start

output current over a wide input supply range with excellent z 120mΩ Ω/40mΩΩ Internal Power MOSFET Switch

load and line regulation. Current mode operation provides z Internal Compensation Minimizes External Parts

fast transient response and eases loop stabilization. Count

z Fixed 500kHz Frequency

Fault condition protection includes cycle-by-cycle current

z Thermal Shutdown Protection

limiting and thermal shutdown. An internal soft-start

z Cycle-by-Cycle Over Current Protection

minimizes external parts count and internal compensation

z Wide 4.5V to 21V Operating Input Range

circuitry.

z Adjustable Output from 0.808V to 15V

The RT8288A requires a minimal number of readily z Available in an SOP-8 (Exposed Pad) Package

available external components, providing a compact z RoHS Compliant and Halogen Free

solution.

Applications

Ordering Information z Distributive Power Systems

RT8288A

z Battery Charger

Package Type

z DSL Modems

SP : SOP-8 (Exposed Pad-Option 2)

z Pre-Regulator for Linear Regulators

Lead Plating System

Z : ECO (Ecological Element with

Halogen Free and Pb free) Pin Configurations

Note : (TOP VIEW)

Richtek products are :

` RoHS compliant and compatible with the current require- VIN 8 GND

ments of IPC/JEDEC J-STD-020. SW 2 7 VCC

GND

SW 3 6 FB

` Suitable for use in SnPb or Pb-free soldering processes. 9

BOOT 4 5 EN

SOP-8 (Exposed Pad)

Marking Information

RT8288AZSP : Product Number

RT8288A YMDNN : Date Code

ZSPYMDNN

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8288A-03 June 2012 www.richtek.com

1

RT8288A

Typical Application Circuit

1 4

VIN VIN BOOT

CIN CBOOT

RT8288A L

22µF 2, 3 100nF VOUT

SW

Chip Enable 5 EN 6

FB RT R1 COUT

R2

8, 9 (Exposed Pad) VCC 7

GND CC

0.1µF

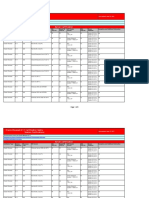

Table 1. Recommended Components Selection

VOUT (V) R1 (kΩ) R2 (kΩ) RT (kΩ) L (μH) COUT (μF)

5 75 14.46 0 4.7 22 x 2

3.3 75 24.32 0 3.6 22 x 2

2.5 75 35.82 0 3.6 22 x 2

1.8 5 4.07 30 2 22 x 2

1.5 5 5.84 39 2 22 x 2

1.2 5 10.31 47 2 22 x 2

1.05 5 16.69 47 1.5 22 x 2

Function Pin Description

Pin No. Pin Name Pin Function

Supply Input. VIN supplies the power to the IC, as well as the step-down converter

1 VIN switches. Drive VIN with a 4.5V to 21V power source. Bypass VIN to GND with a

suitably large capacitor to eliminate noise on the input to the IC.

Switch Node. SW is the switching node that supplies power to the output. Connect

2, 3 SW the output LC filter from SW to the output load. Note that a capacitor is required

from SW to BOOT to power the high side switch.

High Side Gate Drive Boost Input. BOOT supplies the drive for the high side

4 BOOT N-MOSFET switch. Connect a 100nF or greater capacitor from SW to BOOT to

power the high side switch.

Chip Enable (Active High). For automatic start-up, connect the EN pin to VIN with a

5 EN

100kΩ resistor.

Feedback Input. FB senses the output voltage to regulate said voltage. Drive FB

6 FB with a resistive voltage divider from the output voltage. The feedback threshold is

0.808V.

Bias Supply. Decouple with 0.1μF to 0.22μF capacitor. The capacitance should be

7 VCC

no more than 0.22μF.

8, Ground. The exposed pad must be soldered to a large PCB and connected to

GND

9 (Exposed Pad) GND for maximum power dissipation.

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS8288A-03 June 2012

2

RT8288A

Function Block Diagram

VIN

Shutdown Current Sense

Comparator Ramp Amplifier -

1.2V + Generator +

- Regulator

BOOT

5k

EN - Oscillator

1µA S

+ 500kHz

Lockout Q Driver

3V Comparator +

1.7V R

-

PWM SW

Comparator

VCC

Reference Error

+ Amplifier GND

FB -

30pF

400k

1pF

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8288A-03 June 2012 www.richtek.com

3

RT8288A

Absolute Maximum Ratings (Note 1)

z Supply Input Voltage, VIN ---------------------------------------------------------------------------------- −0.3V to 26V

z Switch Voltage, SW ----------------------------------------------------------------------------------------- −0.3V to (VIN + 0.3V)

z Boot Voltage, BOOT ----------------------------------------------------------------------------------------- (SW − 0.3V) to (SW + 6V)

z Other Pins ------------------------------------------------------------------------------------------------------ −0.3V to 6V

z Power Dissipation, PD @ TA = 25°C

SOP-8 (Exposed Pad) -------------------------------------------------------------------------------------- 1.333W

z Package Thermal Resistance (Note 2)

SOP-8 (Exposed Pad), θJA --------------------------------------------------------------------------------- 75°C/W

SOP-8 (Exposed Pad), θJC -------------------------------------------------------------------------------- 15°C/W

z Junction Temperature ---------------------------------------------------------------------------------------- 150°C

z Lead Temperature (Soldering, 10 sec.) ------------------------------------------------------------------ 260°C

z Storage Temperature Range ------------------------------------------------------------------------------- −65°C to 150°C

z ESD Susceptibility (Note 3)

HBM (Human Body Model) --------------------------------------------------------------------------------- 2kV

Recommended Operating Conditions (Note 4)

z Supply Input Voltage, VIN ---------------------------------------------------------------------------------- 4.5V to 21V

z Junction Temperature Range ------------------------------------------------------------------------------- −40°C to 125°C

z Ambient Temperature Range ------------------------------------------------------------------------------- −40°C to 85°C

Electrical Characteristics

(VIN = 12V, TA = 25°C unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Unit

Shutdown Current ISHDN VEN = 0 -- 0 1 μA

Quiescent Current IQ VEN = 2V, VFB = 1V -- 0.7 -- mA

Upper Switch On Resistance RDS(ON)1 -- 120 -- mΩ

Lower Switch On Resistance RDS(ON)2 -- 40 -- mΩ

Switch Leakage ILEAK VEN = 0V, VSW = 0V or 12V -- 0 10 μA

Current Limit ILIMIT VBOOT − VSW = 4.8V 5.9 7 -- A

Oscillator Frequency fSW VFB = 0.75V 425 500 575 kHz

Short Circuit Frequency VFB = 0V -- 150 -- kHz

Maximum Duty Cycle DMAX VFB = 0.8V -- 90 -- %

Minimum On Time tON -- 100 -- ns

Feedback Voltage VFB 4.5V ≤ V IN ≤ 21V 0.796 0.808 0.82 V

Feedback Current IFB -- 10 50 nA

EN Input Threshold Logic-High VIH 2 -- 5.5

V

Voltage Logic-Low VIL -- -- 0.4

VEN = 2V -- 1 --

Enable Current μA

VEN = 0V -- 0 --

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS8288A-03 June 2012

4

RT8288A

Parameter Symbol Test Conditions Min Typ Max Unit

Under Voltage Lockout

VUVLO VIN Rising 3.8 4 4.2 V

Threshold

Under Voltage Lockout

ΔVUVLO -- 400 -- mV

Threshold Hysteresis

VCC Regulator -- 5 -- V

VCC Load Regulation ICC = 5mA -- 5 -- %

Soft-Start Period tSS -- 2 -- ms

Thermal Shutdown TSD -- 150 -- °C

Thermal Shutdown Hysteresis ΔTSD -- 30 -- °C

Note 1. Stresses beyond those listed “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in

the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions may

affect device reliability.bsolute maximum rating conditions for extended periods may remain possibility to affect device

reliability.

Note 2. θJA is measured at TA = 25°C on a high effective thermal conductivity four-layer test board per JEDEC 51-7. θJC is

measured at the exposed pad of the package.

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8288A-03 June 2012 www.richtek.com

5

RT8288A

Typical Operating Characteristics

Efficiency vs. Output Current Reference Voltage vs. Input Voltage

100 0.830

90 VIN = 12V 0.825

80

Reference Voltage (V)

VIN = 21V 0.820

70

Efficiency (%)

0.815

60

50 0.810

40 0.805

30

0.800

20

0.795

10

VOUT = 1.22V, IOUT = 0A to 4A

0 0.790

0 0.5 1 1.5 2 2.5 3 3.5 4 4 6 8 10 12 14 16 18 20 22

Output Current (A) Input Voltage (V)

Reference Voltage vs. Temperature Output Voltage vs. Output Current

0.84 1.240

0.83 1.235

Reference Voltage (V)

0.82 1.230

Output Voltage (V)

0.81 1.225

0.80 1.220

0.79 1.215

0.78 1.210

0.77 1.205

VIN = 12V, VOUT = 1.22V, IOUT = 0A to 4A

0.76 1.200

-50 -25 0 25 50 75 100 125 0 0.5 1 1.5 2 2.5 3 3.5 4

Temperature (°C) Output Current (A)

Switching Frequency vs. Input Voltage Switching Frequency vs. Temperature

550 550

525 525

Switching Frequency (kHz)1

Switching Frequency (kHz)1

500 500

475 475

450 450

425 425

400 400

375 375

VOUT = 1.22V, IOUT = 0.8A VIN = 12V, VOUT = 1.22V, IOUT = 1A

350 350

4 6 8 10 12 14 16 18 20 22 -50 -25 0 25 50 75 100 125

Input Voltage (V) Temperature (°C)

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS8288A-03 June 2012

6

RT8288A

Current Limit vs. Input Voltage Current Limit vs. Temperature

12 11

10

10

9

Current Limit (A)

Current Limit (A)

8

8

6 7

6

4

5

2

4

VIN = 12V, VOUT = 1.22V

0 3

4 6 8 10 12 14 16 18 20 22 -50 -25 0 25 50 75 100 125

Input Voltage (V) Temperature (°C)

Load Transient Response Load Transient Response

VOUT VOUT

(200mV/Div) (200mV/Div)

IOUT IOUT

(2A/Div) (2A/Div)

VIN = 12V, VOUT = 1.22V, IOUT = 0A to 4A VIN = 12V, VOUT = 1.22V, IOUT = 1A to 4A

Time (100μs/Div) Time (100μs/Div)

Output Voltage Ripple Output Voltage Ripple

VOUT VOUT

(50mV/Div) (50mV/Div)

VSW VSW

(10V/Div) (10V/Div)

IL IL

(2A/Div) (2A/Div)

VIN = 12V, IOUT = 1A VIN = 12V, IOUT = 4A

Time (1μs/Div) Time (1μs/Div)

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8288A-03 June 2012 www.richtek.com

7

RT8288A

Power On from VIN Power Off from VIN

VIN VIN

(10V/Div) (10V/Div)

VOUT VOUT

(1V/Div) (1V/Div)

IL IL

(5A/Div) (5A/Div)

VIN = 12V, VOUT = 1.22V, IOUT = 4A VIN = 12V, VOUT = 1.22V, IOUT = 4A

Time (5ms/Div) Time (50ms/Div)

Power On from EN Power Off from EN

VEN VEN

(5V/Div) (5V/Div)

IL IL

(5A/Div) (5A/Div)

VSW VSW

(10V/Div) (10V/Div)

VOUT VOUT

(1V/Div) (1V/Div)

VIN = 12V, VOUT = 1.22V, IOUT = 4A VIN = 12V, VOUT = 1.22V, IOUT = 4A

Time (2.5ms/Div) Time (50μs/Div)

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS8288A-03 June 2012

8

RT8288A

Application Information

the converter starts up. Soft-Start automatically begins

The IC is a synchronous high voltage buck converter that

once the chip is enabled. During soft-start, the internal

can support the input voltage range from 4.5V to 21V and

soft-start capacitor becomes charged and generates a

the output current can be up to 4A.

linear ramping up voltage across the capacitor. This voltage

Output Voltage Setting clamps the voltage at the internal reference, causing the

duty pulse width to increase slowly and in turn reduce the

The output voltage is set by an external resistive divider

output surge current. Finally, the internal 1V reference

according to the following equation :

takes over the loop control once the internal ramping-up

VOUT = VFB ⎛⎜ 1+ R1 ⎞⎟

⎝ R2 ⎠ voltage becomes higher than 1V. The typical soft-start

where VFB is the feedback reference voltage 0.808V time for this IC is set at 2ms.

(typical).

Under Voltage Lockout Threshold

The resistive divider allows the FB pin to sense a fraction

The IC includes an input Under Voltage Lockout Protection

of the output voltage as shown in Figure 1.

VOUT

(UVLO). If the input voltage exceeds the UVLO rising

threshold voltage (4.2V), the converter resets and prepares

R1 the PWM for operation. If the input voltage falls below the

FB UVLO falling threshold voltage (3.8V) during normal

RT8288A R2 operation, the device stops switching. The UVLO rising

GND and falling threshold voltage includes a hysteresis to

prevent noise caused reset.

Figure 1. Output Voltage Setting

Chip Enable Operation

External Bootstrap Diode The EN pin is the chip enable input. Pulling the EN pin

Connect a 100nF low ESR ceramic capacitor between low (<0.4V) will shut down the device. During shutdown

the BOOT pin and SW pin as shown in Figure 2. This mode, the IC quiescent current drops to lower than 1μA.

capacitor provides the gate driver voltage for the high side Driving the EN pin high (>2V, <5.5V) will turn on the device

MOSFET. It is recommended to add an external bootstrap again. For external timing control (e.g.RC), the EN pin

diode between an external 5V and BOOT pin for efficiency can also be externally pulled high by adding a REN* resistor

improvement when input voltage is lower than 5.5V or duty and CEN* capacitor from the VIN pin, as can be seen from

ratio is higher than 65% .The bootstrap diode can be a the Figure 5.

low cost one such as IN4148 or BAT54. The external 5V An external MOSFET can be added to implement digital

can be a 5V fixed input from system or a 5V output of the control on the EN pin when front age system voltage below

IC. Note that the external boot voltage must be lower than 2.5V is available, as shown in Figure 3. In this case, a

5.5V. 5V 100kΩ pull-up resistor, REN, is connected between VIN

and the EN pin. MOSFET Q1 will be under logic control to

BOOT pull down the EN pin.

RT8288A 100nF To prevent enabling circuit when VIN is smaller than the

SW VOUT target value, a resistive voltage divider can be placed

Figure 2. External Bootstrap Diode between the input voltage and ground and connected to

the EN pin to adjust IC lockout threshold, as shown in

Soft-Start

Figure 4. For example, if an 8V output voltage is regulated

The IC contains an internal soft-start function to prevent from a 12V input voltage, the resistor REN2 can be selected

large inrush current and output voltage overshoot when to set input lockout threshold larger than 8V.

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8288A-03 June 2012 www.richtek.com

9

RT8288A

1 4

VIN VIN BOOT CBOOT

REN CIN RT8288A

100k 2, 3 L

5 EN SW VOUT

Chip Enable

Q1 COUT

R1

7 RT

VCC FB 6

CC R2

8, 9 (Exposed Pad)

GND

Figure 3. Enable Control Circuit for Logic Control with Low Voltage

1 4

VIN VIN BOOT

CBOOT

REN CIN RT8288A

100k 2, 3 L

5 EN SW VOUT

COUT

REN2 R1

RT

7 FB 6

VCC

8, 9 (Exposed Pad) R2

CC GND

Figure 4. The Resistors can be Selected to Set IC Lockout Threshold

Under Output Voltage Protection-Hiccup Mode ⎡ VOUT ⎤ ⎡ VOUT ⎤

L =⎢

f × Δ I ⎥ × ⎢1 − VIN(MAX) ⎥

For the IC, Hiccup Mode of Under Voltage Protection (UVP) ⎣ L(MAX) ⎦ ⎣ ⎦

is provided. When the FB voltage drops below half of the The inductor's current rating (caused a 40°C temperature

feedback reference voltage, VFB, the UVP function will be rising from 25°C ambient) should be greater than the

triggered and the IC will shut down for a period of time and maximum load current and its saturation current should

then recover automatically. The Hiccup Mode of UVP can be greater than the short circuit peak current limit. Please

reduce input current in short circuit conditions. see Table 2 for the inductor selection reference and it is

highly recommended to keep inductor value as close as

Inductor Selection

possible to the recommended inductor values for each

For a given input and output voltage, the inductor value VOUT as shown in Table 1.

and operating frequency determine the ripple current. The

Table 2. Suggested Inductors for Typical

ripple current ΔIL increases with higher VIN and decreases

Application Circuit

with higher inductance.

Component Supplier Series Dimensions (mm)

ΔIL = ⎡⎢ OUT ⎤⎥ × ⎡⎢1− OUT ⎤⎥

V V

⎣ f × L ⎦ ⎣ VIN ⎦ TDK VLF10045 10 x 9.7 x 4.5

Having a lower ripple current reduces not only the ESR TDK SLF12565 12.5 x 12.5 x 6.5

losses in the output capacitors but also the output voltage TAIYO YUDEN NR8040 8x8x4

ripple. Highest efficiency operation is achieved by reducing

Input and Output Capacitors Selection

ripple current at low frequency, but it requires a large

inductor to attain this goal. The input capacitance, C IN, is needed to filter the

trapezoidal current at the source of the high side MOSFET.

For the ripple current selection, the value of ΔIL = 0.24

To prevent large ripple current, a low ESR input capacitor

(IMAX) will be a reasonable starting point. The largest ripple

sized for the maximum RMS current should be used. The

current occurs at the highest VIN. To guarantee that the

RMS current is given by :

ripple current stays below a specified maximum, the

V VIN

inductor value should be chosen according to the following IRMS = IOUT(MAX) OUT −1

VIN VOUT

equation :

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS8288A-03 June 2012

10

RT8288A

This formula has a maximum at VIN = 2VOUT, where IRMS = Choose a capacitor rated at a higher temperature than

IOUT / 2. This simple worst case condition is commonly required. Several capacitors may also be paralleled to

used for design because even significant deviations do meet size or height requirements in the design.

not offer much relief. For the input capacitor, one 22μF low ESR ceramic

capacitors are recommended. For the recommended

capacitor, please refer to Table 3 for more detail.

Table 3. Suggested Capacitors for CIN and COUT

Location Component Supplier Part No. Capacitance (μF) Case Size

CIN MURATA GRM32ER71C226M 22 1210

CIN TDK C3225X5R1C226M 22 1210

COUT MURATA GRM31CR60J476M 47 1206

COUT TDK C3225X5R0J476M 47 1210

COUT MURATA GRM32ER71C226M 22 1210

COUT TDK C3225X5R1C226M 22 1210

The selection of COUT is determined by the required ESR Thermal Shutdown

to minimize voltage ripple. Thermal shutdown is implemented to prevent the chip from

Moreover, the amount of bulk capacitance is also a key operating at excessively high temperatures. When the

for COUT selection to ensure that the control loop is stable. junction temperature is higher than 150°C, the chip will

Loop stability can be checked by viewing the load transient shut down the switching operation. The chip will

response. automatically resume switching, once the junction

temperature cools down by approximately 30°C.

The output ripple, ΔVOUT, is determined by :

ΔVOUT ≤ ΔIL ⎡⎢ESR + 1 ⎤ EMI Consideration

⎣ 8fC OUT ⎥⎦

Since parasitic inductance and capacitance effects in PCB

Higher values, lower cost ceramic capacitors are now

circuitry would cause a spike voltage on SW pin when

becoming available in smaller case sizes. Their high ripple

high side MOSFET is turned-on/off, this spike voltage on

current, high voltage rating and low ESR make them ideal

SW may impact on EMI performance in the system. In

for switching regulator applications. However, care must

order to enhance EMI performance, there are two methods

be taken when these capacitors are used at input and

to suppress the spike voltage. One way is by placing an

output. When a ceramic capacitor is used at the input

R-C snubber (RS*, CS*) between SW and GND and locating

and the power is supplied by a wall adapter through long

them as close as possible to the SW pin, as shown in

wires, a load step at the output can induce ringing at the

Figure 5. Another method is by adding a resistor in series

input, VIN. At best, this ringing can couple to the output

with the bootstrap capacitor, CBOOT, but this method will

and be mistaken as loop instability. At worst, a sudden

decrease the driving capability to the high side MOSFET.

inrush of current through the long wires can potentially

It is strongly recommended to reserve the R-C snubber

cause a voltage spike at VIN large enough to damage the

during PCB layout for EMI improvement. Moreover,

part.

reducing the SW trace area and keeping the main power

in a small loop will be helpful on EMI performance. For

detailed PCB layout guide, please refer to the section

Layout Considerations.

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8288A-03 June 2012 www.richtek.com

11

RT8288A

1 4

VIN VIN BOOT

CBOOT

REN* CIN RT8288A L

2, 3

5 EN SW VOUT

CS*

CEN* COUT

RS* R1

7 RT

VCC FB 6

CC 8, 9 (Exposed Pad) R2

* : Optional GND

Figure 5. Reference Circuit with Snubber and Enable Timing Control

Thermal Considerations 1.4

Four-Layer PCB

Maximum Power Dissipation (W)1

For continuous operation, do not exceed absolute 1.2

maximum junction temperature. The maximum power

1.0

dissipation depends on the thermal resistance of the IC

package, PCB layout, rate of surrounding airflow, and 0.8

difference between junction and ambient temperature. The

0.6

maximum power dissipation can be calculated by the

following formula : 0.4

PD(MAX) = (TJ(MAX) − TA) / θJA 0.2

where TJ(MAX) is the maximum junction temperature, TA is 0.0

the ambient temperature, and θJA is the junction to ambient 0 25 50 75 100 125

Ambient Temperature (°C)

thermal resistance.

Figure 6. Derating Curve of Maximum Power Dissipation

For recommended operating condition specifications, the

maximum junction temperature is 125°C. The junction to

Layout Considerations

ambient thermal resistance, θJA, is layout dependent. For

Follow the PCB layout guidelines for optimal performance

SOP-8 (Exposed Pad) package, the thermal resistance,

of the IC.

θJA, is 75°C/W on a standard JEDEC 51-7 four-layer

thermal test board. The maximum power dissipation at TA ` Keep the traces of the main current paths as short and

= 25°C can be calculated by the following formula : wide as possible.

PD(MAX) = (125°C − 25°C) / (75°C/W) = 1.333W for ` Put the input capacitor as close as possible to the device

pins (VIN and GND).

SOP-8 (Exposed Pad) package

` SW node is with high frequency voltage swing and

The maximum power dissipation depends on the operating

should be kept at small area. Keep analog components

ambient temperature for fixed T J(MAX) and thermal

away from the SW node to prevent stray capacitive noise

resistance, θJA. The derating curve in Figure 6 allows the

pickup.

designer to see the effect of rising ambient temperature

on the maximum power dissipation. ` Connect feedback network behind the output capacitors.

Keep the loop area small. Place the feedback

components near the IC.

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS8288A-03 June 2012

12

RT8288A

` Connect all analog grounds to a common node and then

connect the common node to the power ground behind

the output capacitors.

` An example of PCB layout guide is shown in Figure 7

for reference.

Place the input and

output capacitors

as close to the IC

as possible.

GND

CIN

SW should be connected VIN 8 GND

to inductor by wide and

SW 2 7 VCC R2 Place the feedback

short trace and keep GND RT

sensitive components SW 3 6 FB as close to the IC as

9

away from this trace. BOOT possible.

4 5 EN R1

CBOOT VOUT

L

COUT

VOUT GND

Figure 7. PCB Layout Guide

Copyright © 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8288A-03 June 2012 www.richtek.com

13

RT8288A

Outline Dimension

H

A

EXPOSED THERMAL PAD Y

(Bottom of Package)

J X B

C

I

D

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

A 4.801 5.004 0.189 0.197

B 3.810 4.000 0.150 0.157

C 1.346 1.753 0.053 0.069

D 0.330 0.510 0.013 0.020

F 1.194 1.346 0.047 0.053

H 0.170 0.254 0.007 0.010

I 0.000 0.152 0.000 0.006

J 5.791 6.200 0.228 0.244

M 0.406 1.270 0.016 0.050

X 2.000 2.300 0.079 0.091

Option 1

Y 2.000 2.300 0.079 0.091

X 2.100 2.500 0.083 0.098

Option 2

Y 3.000 3.500 0.118 0.138

8-Lead SOP (Exposed Pad) Plastic Package

Richtek Technology Corporation

5F, No. 20, Taiyuen Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789

Richtek products are sold by description only. Richtek reserves the right to change the circuitry and/or specifications without notice at any time. Customers should

obtain the latest relevant information and data sheets before placing orders and should verify that such information is current and complete. Richtek cannot

assume responsibility for use of any circuitry other than circuitry entirely embodied in a Richtek product. Information furnished by Richtek is believed to be

accurate and reliable. However, no responsibility is assumed by Richtek or its subsidiaries for its use; nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Richtek or its subsidiaries.

www.richtek.com DS8288A-03 June 2012

14

You might also like

- Corporate Business CardDocument2 pagesCorporate Business CardRakesh SutharNo ratings yet

- BIAB - Wheat Beer Recipe - Arishtam IndiaDocument3 pagesBIAB - Wheat Beer Recipe - Arishtam IndiaRakesh SutharNo ratings yet

- Energies: A High-Performance Adaptive Incremental Conductance MPPT Algorithm For Photovoltaic SystemsDocument17 pagesEnergies: A High-Performance Adaptive Incremental Conductance MPPT Algorithm For Photovoltaic SystemsRakesh SutharNo ratings yet

- INA350 Cost and Size Optimized, Low Power, 1.8-V To 5.5-V Selectable Gain Instrumentation AmplifierDocument45 pagesINA350 Cost and Size Optimized, Low Power, 1.8-V To 5.5-V Selectable Gain Instrumentation AmplifierRakesh SutharNo ratings yet

- 1.9 Flyback Converter in DCM: Output PowerDocument4 pages1.9 Flyback Converter in DCM: Output PowerRakesh SutharNo ratings yet

- Open Loop Vector Control of Induction Motor With Space Vector Pulse Width Modulation TechniqueDocument7 pagesOpen Loop Vector Control of Induction Motor With Space Vector Pulse Width Modulation TechniqueRakesh SutharNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideRakesh SutharNo ratings yet

- Texas InstrumentsDocument24 pagesTexas Instrumentsjack bengunNo ratings yet

- DRV8243-Q1 Automotive H-Bridge Driver With Integrated Current Sense and DiagnosticsDocument78 pagesDRV8243-Q1 Automotive H-Bridge Driver With Integrated Current Sense and DiagnosticsRakesh SutharNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideRakesh SutharNo ratings yet

- Automatic Rescue Device ArdDocument2 pagesAutomatic Rescue Device ArdMohammed SajidNo ratings yet

- Liftmedia User Manual v10Document24 pagesLiftmedia User Manual v10هشام الشماليNo ratings yet

- Park Transformation and Clarke Transformation in DetailDocument20 pagesPark Transformation and Clarke Transformation in DetailKevin Dito GrandhikaNo ratings yet

- Plx-Daq HelpDocument25 pagesPlx-Daq HelpAnonymous C05BLcNo ratings yet

- Sls (SRC/LLC+SR) Controller With 1 Fm+2 PWMS: General Description FeaturesDocument16 pagesSls (SRC/LLC+SR) Controller With 1 Fm+2 PWMS: General Description FeaturesPhenom PhonemeNo ratings yet

- AOZ3018PIDocument14 pagesAOZ3018PIpravin jadavNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sperry BM E S Band Scanner Tech SpecDocument2 pagesSperry BM E S Band Scanner Tech SpecBeto GallardoNo ratings yet

- SM ATF400G-6 - EN - Intern Use OnlyDocument1,767 pagesSM ATF400G-6 - EN - Intern Use OnlyReinaldo Zorrilla88% (8)

- 2020 - Roadroid University Registration FormDocument2 pages2020 - Roadroid University Registration FormAiidil SuwandiNo ratings yet

- M580 HSBY System Planning GuideDocument217 pagesM580 HSBY System Planning GuideISLAMIC LECTURESNo ratings yet

- PesisirDocument1 pagePesisirMohammad Hafiz MahadzirNo ratings yet

- ECIL Technical Officer Recruitment 2023 NotificationDocument3 pagesECIL Technical Officer Recruitment 2023 NotificationLucasNo ratings yet

- Master Trip Relay PDFDocument2 pagesMaster Trip Relay PDFEr Suraj KumarNo ratings yet

- Svit - Module 4Document30 pagesSvit - Module 4gjtuyNo ratings yet

- Fujifilm GFX100S Medium Format Camera SpecificationsDocument5 pagesFujifilm GFX100S Medium Format Camera SpecificationsNikonRumorsNo ratings yet

- DL067AA - Delcos 1000 PDFDocument2 pagesDL067AA - Delcos 1000 PDFmak67% (3)

- Getting Started With PIC Microcontroller - CCS C Compiler PDFDocument19 pagesGetting Started With PIC Microcontroller - CCS C Compiler PDFNithya100% (2)

- Lesson 2Document10 pagesLesson 2Anore James IvanNo ratings yet

- Rotary InformationDocument14 pagesRotary InformationMohammad UsmanNo ratings yet

- Construction Planning and SchedulingDocument70 pagesConstruction Planning and SchedulingDessalegn AyenewNo ratings yet

- Rodavigo Acoplamientos 02 Acoplamientos de BielasDocument20 pagesRodavigo Acoplamientos 02 Acoplamientos de BielasArturo J. Londono MNo ratings yet

- No. 304 (171) 2021/PA Admn 111!: To, Centre ExcellenceDocument9 pagesNo. 304 (171) 2021/PA Admn 111!: To, Centre ExcellenceSanjeev kumarNo ratings yet

- Java DL 2023Document16 pagesJava DL 2023Sktr BhanuNo ratings yet

- Decision Support For Blockchain PlatformDocument20 pagesDecision Support For Blockchain PlatformgianniNo ratings yet

- Tuguegarao Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceDocument7 pagesTuguegarao Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceNenbon NatividadNo ratings yet

- Lecture-13 Indexing and Its Types: Subject: DBMS Subject Code: BCA-S301T Faculty: Saurabh JhaDocument16 pagesLecture-13 Indexing and Its Types: Subject: DBMS Subject Code: BCA-S301T Faculty: Saurabh JhaShivam KushwahaNo ratings yet

- 5-Day Self-Love Challenge - Big Life JournalDocument16 pages5-Day Self-Love Challenge - Big Life Journalmatias apecenaNo ratings yet

- First Order Logic: Artificial Intelligence COSC-3112 Ms. Humaira AnwerDocument24 pagesFirst Order Logic: Artificial Intelligence COSC-3112 Ms. Humaira AnwerKhizrah RafiqueNo ratings yet

- Medium-Low Speed AD LiDAR Perception Solution Brochure EN 20200312Document2 pagesMedium-Low Speed AD LiDAR Perception Solution Brochure EN 20200312nazi1945No ratings yet

- Grade 9: Tle - Ict Computer Systems Servicing Quarter 2 - Module 1 Install Network CablesDocument6 pagesGrade 9: Tle - Ict Computer Systems Servicing Quarter 2 - Module 1 Install Network CablesSharmaine Paragas FaustinoNo ratings yet

- Neeraj BitcellDocument2 pagesNeeraj BitcellPRANJAL RAJANNo ratings yet

- Biochips: Submitted byDocument17 pagesBiochips: Submitted byCharina Marie CaduaNo ratings yet

- Oracle Ow811 Certification Matrix 161594Document8 pagesOracle Ow811 Certification Matrix 161594ps.calado5870No ratings yet

- ITC LAB 4 - FlowchartsDocument7 pagesITC LAB 4 - FlowchartspathwayNo ratings yet

- Satellite TTC Module 4Document21 pagesSatellite TTC Module 4AmitNo ratings yet

- Edukasyon Sa Pagpapakatao 6 q1w4Document26 pagesEdukasyon Sa Pagpapakatao 6 q1w4Juliet Del RosarioNo ratings yet