Professional Documents

Culture Documents

Automotive Power Relay: Technical Data For Contact Side

Uploaded by

Rakesh SutharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automotive Power Relay: Technical Data For Contact Side

Uploaded by

Rakesh SutharCopyright:

Available Formats

3572

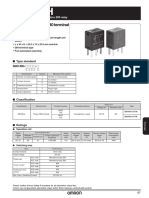

AUTOMOTIVE POWER RELAY

FEATURES APPLICATION

l Direct PCB Mountable l Direction Indicators

l Air-Conditioning Systems

l High Performance

l Boby Controllers

l Suitable for various loads l Head Lamp Control

l Heav y Duty l Ventilation Motors

l Immersion Cleanable Version available l Security Systems

TECHNICAL DATA FOR CONTACT SIDE

AREAS OF APPLICATION RESISTIVE / INDUCTIVE LOADS INDICATOR LAMP LOADS**

Contact Configuration : 1A/1C 1A

Contact Material : Silver Nickel Palladium Copper* / Silver Nickel

0

Contact Rating at 23 C - 12 VDC : 45 / 30 A 12 A

24 VDC : 20 / 10 A

Electrical Life Operations Min. : 2 x 105 5 x 105

Mechanical Life Operations Min. : 1 x 107 1 x 107

Contact Voltage Drop at 10 A (Min) : 30mV 50mV

Ma ximum Switching Current

@ 12.8 VDC For 3 Sec. : 100A 100A

*The moving contact (Pdcu) must be connected to positive potential **Under in troduction

GENERAL DATA FOR COIL SIDE CIRCUIT DIAGRAM

Nominal Coil Power : 1.6W (Approx)

Operating Power : 0.9W (Approx)

Operate Time** : 5 milli Seconds COM NO

Release Time** : 3 milli Seconds

** At nominal voltage without coil suppression (excluding bounce) COIL

OPERATING CONDITIONS

1Form A

Ambient Temperature : -400C to +850C

Ma ximum Temperature : 1550C COM NO NC

Dielectric Strength : 500VRMS

Insulation Resistance : 100 MS Min. At 500 VDC, 250C COIL

RH 50

Vibration Resistance without change : 10-200Hz, 20-40g

in the switching state>10µS 1Form C

Shock Resistance without change : 30g, 11mS

in the switching state>10µS

HOW TO ORDER COIL DATA

3572 - 1A - 12 - X - 01 - XX

Nominal Voltage

Drop-out Voltage

*Pick-up Voltage

Coil Resistance

Ohms ± 10%

VDC (Max)

VDC (Min)

VDC

E-lmmersion Cleanable

E5-Open

250g Release spring &

1.7mm wide contact Terminal

Product 06 3.3 0.6 19

Series

Plating

P- Nickel Plated Body

E-Copper Plated Body 12 6.8 1.2 90

Contact Form

1A - 1 Form A

Nominal Coil Voltage

1C - 1 Form C

(Refer coil data)

24 13.9 2.4 362

*Lower pick-up voltages available on request

DRILLING PATTERN DIMENSIONS

SEALED TYPE

2.5 min

26.5 max

12.1 3.30

2.15

0.3 min 21.5 ma x

22.5 ma x

3.5 ma x

11.0

7.15

* Vent hole to be opened af ter PCB soldering and cleaning

2.95

OPEN TYPE

2.75

19.0 ma x 24.0 ma x

14.25

AVAILABLE ON REQUEST

l High Temperature winding wire

l Special coil resistance & pick-up

l Resistor / Diode across coil

l For other custom solutions consult factory

DATA ON VARIOUS TESTS CONDUCTED FOR OPERATING CONDITIONS *

TEST TEST CONDITION RESULT

0

Relay kept at 100 C

Coil Voltage : 14 VDC

Load given : 30 A @ 12 VDC

Continuous Energisation test at Relays successfully completed

Ex treme temperature Conditions Duration : 5 Sec. On, 5 Sec. OFF 100000 operations at given load

No. of operation : 50000

0

The above test repeated at - 30 C for 50000

operations

Relay subjected to :-

0 0

-30 C to + 100 C in 2 Hrs. with coil ON

0

+100 C for 2 Hrs. with coil ON

Thermal cycling All operating parameters within

0 0

+100 C to - 30 C in 2 Hrs. with 1 Hrs. Coil ON & the specifications af ter test

1 Hrs. Coil OFF

0

-30 C for two Hrs. with Coil ON

No. of Cycles : 3

Relay is subjected to :-

Ma x. Voltage : 100VDC

Shock Wave : Exponential Damping vibration

Shock Voltage Af ter the test, all operating parameters

Time : 500 micro Sec. of the relay are within specification.

Period : 30 Sec.

Test Time : 10 Hrs.

Dropping Impact No change in operating

Relays dropped from a height of 1 Meter to a

parameters of the relay.

concrete floor

Jump Start 24 VDC for 1 minute conducting nominal current Withstood successfully

0

at 23 C

Corrosion Resistance 5% Sodium Chloride solution No damage to relay parts

applied to relay for 48 Hrs.

Water Resistance test IP 67 (For Sealed Version)

*Typical values for relays with 12 VDC coil. For higher severity please consult factory

You might also like

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideRakesh SutharNo ratings yet

- Automotive Power Relay Features and ApplicationsDocument3 pagesAutomotive Power Relay Features and ApplicationsJesus HernadezNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideStuxnetNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideStuxnetNo ratings yet

- G8V-RH: High Current Micro 280 Terminal LayoutDocument3 pagesG8V-RH: High Current Micro 280 Terminal Layoutchrdue1No ratings yet

- JQC 16FDocument2 pagesJQC 16FLIN TIMOFEI100% (1)

- Technical specifications and ratings of glass silicon zener diodesDocument3 pagesTechnical specifications and ratings of glass silicon zener diodesLangllyNo ratings yet

- OEB 45 IN Relay DatasheetDocument2 pagesOEB 45 IN Relay DatasheetVISHNU RAVINDRANATHNo ratings yet

- 8567 RelayDocument3 pages8567 RelayAmandaNo ratings yet

- Datasheet - HK p9nc60 41128 PDFDocument9 pagesDatasheet - HK p9nc60 41128 PDFJacson FagundesNo ratings yet

- sk13 DiodeDocument3 pagessk13 DiodeДрагиша Небитни ТрифуновићNo ratings yet

- Relafy 30 Amps T Typfe RelfayDocument2 pagesRelafy 30 Amps T Typfe RelfayMarudhasalamMarudhaNo ratings yet

- Bas Bs SC SeriesDocument2 pagesBas Bs SC SeriesElectronNo ratings yet

- HJR-21FF TboDocument3 pagesHJR-21FF Tboalisalar1No ratings yet

- Relé Tianbo 5V PDFDocument3 pagesRelé Tianbo 5V PDFjhonny gonzalezNo ratings yet

- DRC.4720 Bridge Sensor Setup GuideDocument3 pagesDRC.4720 Bridge Sensor Setup GuidetedysuNo ratings yet

- RBV1000 - RBV1010: Silicon Bridge Rectifiers PRV: 50 - 1000 Volts Io: 10 AmperesDocument2 pagesRBV1000 - RBV1010: Silicon Bridge Rectifiers PRV: 50 - 1000 Volts Io: 10 AmperesmaheseeeNo ratings yet

- PCB Relay: NRP - 17 - C - 12DDocument2 pagesPCB Relay: NRP - 17 - C - 12DZaman SahibNo ratings yet

- Technical specifications of glass silicon zener diodesDocument2 pagesTechnical specifications of glass silicon zener diodesRizky AnandaNo ratings yet

- EV500 Series DC ContactorDocument8 pagesEV500 Series DC ContactorDIEGO VICENTE SANCHEZNo ratings yet

- Compact Power Relay FBR51, 52 Series: 1 POLE - 25/30A (For Automotive Applications)Document11 pagesCompact Power Relay FBR51, 52 Series: 1 POLE - 25/30A (For Automotive Applications)Maxi De los SantosNo ratings yet

- Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)Document9 pagesObsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)GermánNo ratings yet

- IRF530stmicroelectronics cd00000699-1204277 PDFDocument9 pagesIRF530stmicroelectronics cd00000699-1204277 PDFGermánNo ratings yet

- LM120 THRU LM1100: Surface Mount Schottky Barrier Rectifier Reverse Voltage - 20 To 100 V Forward Current - 1 ADocument2 pagesLM120 THRU LM1100: Surface Mount Schottky Barrier Rectifier Reverse Voltage - 20 To 100 V Forward Current - 1 AAndres VillaltaNo ratings yet

- High-Wattage General Purpose Relay: Small PCB Relay For Automobile UseDocument3 pagesHigh-Wattage General Purpose Relay: Small PCB Relay For Automobile Usesuan kwang TanNo ratings yet

- Low voltage silicon rectifiers specificationsDocument1 pageLow voltage silicon rectifiers specificationsprajwal shivaiahNo ratings yet

- By127, By133Document1 pageBy127, By133Jesus RubiaNo ratings yet

- TZDocument21 pagesTZDicky Nurul IlhamNo ratings yet

- Diodes - Inc. ZXMP6A17GTA DatasheetDocument7 pagesDiodes - Inc. ZXMP6A17GTA DatasheetEduardo PaisNo ratings yet

- Datasheet ReleDocument2 pagesDatasheet ReleGuillermo Pocovi L.No ratings yet

- High power & low cost HJQ-15F relay with 30A switchingDocument3 pagesHigh power & low cost HJQ-15F relay with 30A switchingDaniel MolinosNo ratings yet

- 1N4148WTDocument3 pages1N4148WT鄭建銘(小銘)No ratings yet

- Surface Mount Schottky Barrier Rectifier SpecificationsDocument2 pagesSurface Mount Schottky Barrier Rectifier Specificationsserrano.flia.coNo ratings yet

- Skai 90 A2 Gd06-Wci 14282034Document12 pagesSkai 90 A2 Gd06-Wci 14282034nishant_dreamviewerNo ratings yet

- YL303H S 12VDC 1Z Datasheet RelayDocument3 pagesYL303H S 12VDC 1Z Datasheet RelayAndres CamachoiNo ratings yet

- Sima Electronics Automotive Relays: Ordering InformationDocument2 pagesSima Electronics Automotive Relays: Ordering InformationJHelfNo ratings yet

- General Purpose Relay: TA, TR Series Part Number DescriptionDocument17 pagesGeneral Purpose Relay: TA, TR Series Part Number DescriptionMIKENo ratings yet

- High voltage glass rectifier datasheetDocument2 pagesHigh voltage glass rectifier datasheetabthakurNo ratings yet

- Fast Switching Diode: Lead Free Finish, Rohs Compliant (Note 2)Document2 pagesFast Switching Diode: Lead Free Finish, Rohs Compliant (Note 2)zileNo ratings yet

- Ev 200 HaanaDocument3 pagesEv 200 HaanaGiovani De Oliveira DiasNo ratings yet

- General Purpose RU Series RelaysDocument4 pagesGeneral Purpose RU Series Relaysthu hangNo ratings yet

- High Voltage Rectifier: DO-41 Plastic Dim Min Max A B C D All Dimensions in MMDocument2 pagesHigh Voltage Rectifier: DO-41 Plastic Dim Min Max A B C D All Dimensions in MMNadeem YounusNo ratings yet

- SB160 Schottky Diode 60V 1a PDFDocument3 pagesSB160 Schottky Diode 60V 1a PDFdemostenessNo ratings yet

- BA823Document7 pagesBA823BanyugeaNo ratings yet

- Ponte de Diodo RBV3510Document3 pagesPonte de Diodo RBV3510Allyfranhy Nunes AlvesNo ratings yet

- CV & SV OLTC Operating InstructionDocument34 pagesCV & SV OLTC Operating InstructionAlvinNo ratings yet

- N - Channel Enhancement Mode " Single Feature Size " Power MosfetDocument9 pagesN - Channel Enhancement Mode " Single Feature Size " Power MosfetGiancarloRichardRivadeneyraMirandaNo ratings yet

- Model Number Structure: Relays With Forcibly Guided ContactsDocument22 pagesModel Number Structure: Relays With Forcibly Guided Contactselkin mezaNo ratings yet

- Power Mosfet Irf640aDocument7 pagesPower Mosfet Irf640aOlegNo ratings yet

- PCRB Rerlay For Stablrizer TTTDocument2 pagesPCRB Rerlay For Stablrizer TTTMarudhasalamMarudhaNo ratings yet

- 18Document3 pages18Ilyas PaghdiwalaNo ratings yet

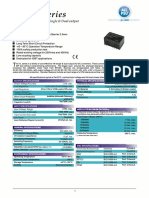

- Vl-1 W Series: Lwunregulated SingleDocument4 pagesVl-1 W Series: Lwunregulated SingleMr.K chNo ratings yet

- NingBo Songle Relay Co.,LTD. Product SpecificationDocument3 pagesNingBo Songle Relay Co.,LTD. Product Specificationatlas tajhizNo ratings yet

- User Manual 1374484Document12 pagesUser Manual 1374484gutierkNo ratings yet

- LM4001 THRU LM4007: FeaturesDocument2 pagesLM4001 THRU LM4007: FeaturesSetyo RiniNo ratings yet

- Eng DS KCS03X 885Document8 pagesEng DS KCS03X 885clipclapNo ratings yet

- O e N 3R32320 Relay Datasheet PDFDocument1 pageO e N 3R32320 Relay Datasheet PDFSukhirthan SenthilkumarNo ratings yet

- LEV200Document2 pagesLEV200clipclapNo ratings yet

- BIAB - Wheat Beer Recipe - Arishtam IndiaDocument3 pagesBIAB - Wheat Beer Recipe - Arishtam IndiaRakesh SutharNo ratings yet

- Energies: A High-Performance Adaptive Incremental Conductance MPPT Algorithm For Photovoltaic SystemsDocument17 pagesEnergies: A High-Performance Adaptive Incremental Conductance MPPT Algorithm For Photovoltaic SystemsRakesh SutharNo ratings yet

- INA350 Cost and Size Optimized, Low Power, 1.8-V To 5.5-V Selectable Gain Instrumentation AmplifierDocument45 pagesINA350 Cost and Size Optimized, Low Power, 1.8-V To 5.5-V Selectable Gain Instrumentation AmplifierRakesh SutharNo ratings yet

- Corporate Business CardDocument2 pagesCorporate Business CardRakesh SutharNo ratings yet

- Open-Loop Vector Control of Induction Motor with Space Vector Pulse Width ModulationDocument7 pagesOpen-Loop Vector Control of Induction Motor with Space Vector Pulse Width ModulationRakesh SutharNo ratings yet

- 1.9 Flyback Converter in DCM: Output PowerDocument4 pages1.9 Flyback Converter in DCM: Output PowerRakesh SutharNo ratings yet

- Texas InstrumentsDocument24 pagesTexas Instrumentsjack bengunNo ratings yet

- DRV8243-Q1 Automotive H-Bridge Driver With Integrated Current Sense and DiagnosticsDocument78 pagesDRV8243-Q1 Automotive H-Bridge Driver With Integrated Current Sense and DiagnosticsRakesh SutharNo ratings yet

- AOZ3018PIDocument14 pagesAOZ3018PIpravin jadavNo ratings yet

- ARD Automatic Rescue Device for LiftsDocument2 pagesARD Automatic Rescue Device for LiftsMohammed SajidNo ratings yet

- Park Transformation and Clarke Transformation in DetailDocument20 pagesPark Transformation and Clarke Transformation in DetailKevin Dito GrandhikaNo ratings yet

- Liftmedia User Manual v10Document24 pagesLiftmedia User Manual v10هشام الشماليNo ratings yet

- Plx-Daq HelpDocument25 pagesPlx-Daq HelpAnonymous C05BLcNo ratings yet

- 4A, 21V 500Khz Synchronous Step-Down Converter: General Description FeaturesDocument14 pages4A, 21V 500Khz Synchronous Step-Down Converter: General Description FeaturesRakesh SutharNo ratings yet

- Sls (SRC/LLC+SR) Controller With 1 Fm+2 PWMS: General Description FeaturesDocument16 pagesSls (SRC/LLC+SR) Controller With 1 Fm+2 PWMS: General Description FeaturesPhenom PhonemeNo ratings yet

- Ashpasol SupremeDocument2 pagesAshpasol SupremeAlex K.No ratings yet

- Proposed Revisions To MORTH Specifications For Roads (Fifth Edition Dated 2013) by Prof. KandhalDocument14 pagesProposed Revisions To MORTH Specifications For Roads (Fifth Edition Dated 2013) by Prof. KandhalProf. Prithvi Singh KandhalNo ratings yet

- EED 5 Unit 8Document45 pagesEED 5 Unit 8Reinaliza FerraroNo ratings yet

- AGE Site Core Cutting DataDocument1 pageAGE Site Core Cutting Dataaashish patidarNo ratings yet

- Touch screen wheelchair controlDocument3 pagesTouch screen wheelchair controlKhatriZabirNo ratings yet

- Nidia Mindiyarti: Projects Big Data and Machine LearningDocument1 pageNidia Mindiyarti: Projects Big Data and Machine Learningnidia mindiyartiNo ratings yet

- Jurnal Row Cropping PK GoshDocument12 pagesJurnal Row Cropping PK GoshAdek AbangNo ratings yet

- Introduction Programming C EngineersDocument648 pagesIntroduction Programming C EngineersClaudio Di LivioNo ratings yet

- Dissolving Cellulose from Different Sources in NaOH/UreaDocument11 pagesDissolving Cellulose from Different Sources in NaOH/Ureajitendra kumarNo ratings yet

- Chemistry Investigatory Project: Name: Mengulhounuo Keretsu Class: 12 (Science) School: Maple Tree SchoolDocument23 pagesChemistry Investigatory Project: Name: Mengulhounuo Keretsu Class: 12 (Science) School: Maple Tree SchoolmengulhounuoNo ratings yet

- Red Soil and Bentonite As LinerDocument8 pagesRed Soil and Bentonite As LinerGKNo ratings yet

- VB Toolbar Tutorial: Create a Toolbar in Visual BasicDocument25 pagesVB Toolbar Tutorial: Create a Toolbar in Visual BasicRizemmaNo ratings yet

- Mathcad - Drilled Shaft PDFDocument14 pagesMathcad - Drilled Shaft PDFHeak HorNo ratings yet

- SC-9790AV SX-9790: Service ManualDocument80 pagesSC-9790AV SX-9790: Service ManualBRAULIO GARCIA SANTIAGONo ratings yet

- XML Quiz with AnswersDocument17 pagesXML Quiz with AnswersManoj GuptaNo ratings yet

- Arraystorm Consolidated Product CatalogueDocument44 pagesArraystorm Consolidated Product Cataloguesuhasacharya117No ratings yet

- SE1Document5 pagesSE1AlexisNo ratings yet

- Introduction To Operations ResearchDocument37 pagesIntroduction To Operations ResearchSiegfred Laborte100% (1)

- Marine Engine Application and Installation Guide: - Boat PerformanceDocument13 pagesMarine Engine Application and Installation Guide: - Boat Performancefernando hutnikNo ratings yet

- Can / Am Emtp News: Sorted According To Rule Book ChaptersDocument25 pagesCan / Am Emtp News: Sorted According To Rule Book ChaptersAnonymous YynGVcqdBMNo ratings yet

- MPD 500 User Manual PDFDocument72 pagesMPD 500 User Manual PDFpdrich8100% (1)

- Annexure IV - ET-P26-G1 Guidelines For Protection Energy Meter Requirements For Power Supply To B PDFDocument72 pagesAnnexure IV - ET-P26-G1 Guidelines For Protection Energy Meter Requirements For Power Supply To B PDFannuvyas0% (1)

- Control Valve Packing Guide - PTFE, Graphite, & EPA Compliant Options in 40 CharactersDocument2 pagesControl Valve Packing Guide - PTFE, Graphite, & EPA Compliant Options in 40 Charactersmilton1987No ratings yet

- Phys 1111 SygsuDocument4 pagesPhys 1111 SygsuLeporeNo ratings yet

- Bally 5500 SetUpandOperationDocument34 pagesBally 5500 SetUpandOperationFreder AngelNo ratings yet

- Cable 4 PDFDocument46 pagesCable 4 PDFmuhammadshafiq69No ratings yet

- Rate of Reaction Part 1Document19 pagesRate of Reaction Part 1danielphilip68No ratings yet

- Nuclear Physics QuestionsDocument29 pagesNuclear Physics Questionsjorsen93No ratings yet

- Drainage DesignDocument21 pagesDrainage Designronaldnyirenda2230100% (1)

- 13/15/19-Wire Installation Guide: D2proDocument1 page13/15/19-Wire Installation Guide: D2proerickNo ratings yet