Professional Documents

Culture Documents

Meter ®: Dual Chamber Orifice Fitting

Uploaded by

Enamul KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Meter ®: Dual Chamber Orifice Fitting

Uploaded by

Enamul KhanCopyright:

Available Formats

meter2 ® www.epsltd-uk.

com

Dual Chamber Orifice Fitting

Energy Project Solutions meter2 TM Dual Chamber Orifice fittings are manufactured to meet stringent

industry standards and safety guidelines and are designed to meet the end users expectations.

All our products are designed using DFM (Design For Manufacture) and DFA (Design For Assembly)

techniques. This has resulted in products differentiated by their simplicity, reduced level of complex

parts, and consequently provide the end user with a product that is remarkably simple to use, and is

virtually maintenance free.

The “meter2” product range has been rationalised to the extent that we can offer significantly reduced

lead times on this range.

Benefits

• High Accuracy, precision machined orifice

fitting.

• Minimal maintenance required.

• Plate0 ® - Quick release plate system that is

impossible to install backwards

• Modular design - a meter1 TM can be

upgraded to a meter2 TM whilst installed in

the pipeline.

• Use of modern seals and simplest designs

• Field-repairable

Options

• Exotic Materials for demanding service –

Duplex, Inconel.

• High Pressure solutions (10,000PSI).

• Wide Temperature ranges.

• Stainless Internals as standard

• Meter Runs and accessories

• Bespoke design service available

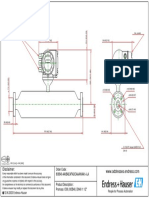

8” 900 meter2 TM Dual Chamber orifice • ‘Double Isolation’ option

The meter2 TM dual chamber orifice fitting can be installed into horizontal or vertical lines. Each

product has been fully FEA (Finite Element Analysis) tested at design stage ensuring maximum

safety to the user and the system. Upon product assembly, each product is fully pressure tested

to satisfy industry safety, European pressure guidelines and product expectations.

innovation for energy

1

EPS-M2-001 Rev/Iss. 003 Date 27.02.2012 Page 1

meter2 ® www.epsltd-uk.com

Dual Chamber Orifice Fitting

Size and Pressure Rating Body Configurations

Size (mm) ANSI Pressure Class

Flange x Flange, Flange x Weld or Weld x Weld

2" (50) 150, 300, 600, 900 #

FF (Flat Face), RF (Raised Face), RTJ (Ring Type

3" (75) 150, 300, 600, 900 #

Joint)

4" (100) 150, 300, 600, 900 #

6" (150) 150, 300, 600, 900 #

Flanges available in the following formats;

8" (200) 150, 300, 600, 900 # • ANSI 16.5, 16.47

10" (250) 150, 300, 600, 900 # • Techlok & SPO

12" (300) 150, 300, 600, 900 # • Graylok

14" (350) 150, 300, 600, 900 # • API 6A

16" (400) 150, 300, 600, 900 #

18" (450) 150, 300, 600, 900 #

20" (500) 150, 300, 600, 900 #

Maximising the meter2 ®

24" (600) 150, 300, 600, 900 # To ensure absolute metering accuracy, it is

recommended that meter tubes are purchased

2" (50) 1500, 2500 # and manufactured to complement the orifice

3" (75) 1500, 2500 # fitting. This ensures concentricity between the

4" (100) 1500, 2500 # pipe and the fitting, and eliminates

6" (150) 1500, 2500 # uncertainties associated with misalignment.

8" (200) 1500, 2500 # EPS can supply the following items for a

10" (250) 1500, 2500 # complete metering solution;

12" (300) 1500, 2500 #

14" (350) 1500 # • Orifice fitting with Meter Tube including

16" (400) 1500 # straightening vane/profiler

Notes: For sizes not listed, contact sales@epsltd-uk.com • DP transmitters and Process Transmitters

• Flow Computer and Enclosure

Design Codes

Standard Materials of Construction

• ASME B31.8 Gas Transmission and

Distribution Piping • Body Casting – ASTM A352 LCC

• NACE MR-01-75 • Pressure Caps/Covers – ASTM A516 Gr.70

• ASME B31.1 Power Piping • Internal components – Stainless Steel 316

• ASME B31.3 Liquid Petroleum Transportation • Seals – Selected per application

Piping Systems • External Bolting – ASTM A194 L7 (HDG)

• PED 97/23/EC – Pressure Equipment Directive • Other materials are available upon request

• HSG253 – The safe isolation of plant and

equipment Orifice Plates

Measurement Standards The meter1 and meter2 orifice fittings use

industry standard orifice plate thicknesses as

• ISO 5167 per the guidelines set out within ISO 5167 and

• API MPMS 14.3.2 (AGA Report No.3) API 14.3.

innovation for energy

2

EPS-M2-001 Rev/Iss. 003 Date 27.02.2012 Page 2

You might also like

- CUT - 200 300 400 MS SP - ENDocument24 pagesCUT - 200 300 400 MS SP - ENMoustaffaNo ratings yet

- RBSS 7ML19985GX62Document35 pagesRBSS 7ML19985GX62Humberto Valentim MenegazNo ratings yet

- MultiCam 2000-Series CNC LaserDocument14 pagesMultiCam 2000-Series CNC LaserDaniel Austin0% (1)

- 05a - MSM 86 - e PDFDocument2 pages05a - MSM 86 - e PDFMuhammad Nur CahyadiNo ratings yet

- VARGUS - Gear Milling New - InchDocument6 pagesVARGUS - Gear Milling New - InchGilberto ManhattanNo ratings yet

- KAM Oid™ Optical Interface Detector: User ManualDocument21 pagesKAM Oid™ Optical Interface Detector: User ManualLITO BABUNo ratings yet

- Omsco Drillpipe CatalogueDocument24 pagesOmsco Drillpipe Cataloguerwinmill100% (3)

- 138CurvedThicknessBlocks797 PDFDocument3 pages138CurvedThicknessBlocks797 PDFCastoriadisNo ratings yet

- C955 09Document4 pagesC955 09jacr27No ratings yet

- 64edbd0626e2d797acaf5791 - Posalux Brochure ULTRASPEED DUODocument4 pages64edbd0626e2d797acaf5791 - Posalux Brochure ULTRASPEED DUOGunaNo ratings yet

- SAF Welding Cutting GuideDocument165 pagesSAF Welding Cutting GuideSelvem0% (1)

- Timex Group Precision Engineering Limited (TGPEL)Document24 pagesTimex Group Precision Engineering Limited (TGPEL)sanjeevbatra0% (1)

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetsarkaftNo ratings yet

- Allen-Bradley 30.5mm 3-Hole EnclosureDocument2 pagesAllen-Bradley 30.5mm 3-Hole EnclosureCARLOS COANo ratings yet

- Brosura Busbar EatonDocument8 pagesBrosura Busbar EatonTibor DanielNo ratings yet

- Esab Welding AutomationDocument40 pagesEsab Welding AutomationRoryLudwigNo ratings yet

- Product Data Sheet Rosemount CMB Chamber en 6236194Document16 pagesProduct Data Sheet Rosemount CMB Chamber en 6236194shaharlaleNo ratings yet

- Ps 001222Document16 pagesPs 001222Lassané KINDONo ratings yet

- 17 262 Specimen Blanking Machines For Specimen Preparation of Metals PI enDocument5 pages17 262 Specimen Blanking Machines For Specimen Preparation of Metals PI enDanan GentleNo ratings yet

- Flat Palm Scanner - GEDocument4 pagesFlat Palm Scanner - GEpokeboy19No ratings yet

- Expert 1000 Series Servo Hydraulic Test System BrochureDocument4 pagesExpert 1000 Series Servo Hydraulic Test System BrochureAde DjatnikaNo ratings yet

- Am ItDocument27 pagesAm Itakalbhor90No ratings yet

- ABB Dual ChamberDocument4 pagesABB Dual Chambermatteo2009No ratings yet

- Cilindros e Servo CilindrosDocument16 pagesCilindros e Servo CilindrosluisbottonNo ratings yet

- VIETZ Pipe Bending Machines GuideDocument16 pagesVIETZ Pipe Bending Machines GuideBoopathi RajuNo ratings yet

- BB3 Catalogue 2015Document8 pagesBB3 Catalogue 2015nima hasanzadehNo ratings yet

- BMD Plug Gauges Technical GuideDocument52 pagesBMD Plug Gauges Technical Guidekunalkp88No ratings yet

- Mstube BrochureDocument8 pagesMstube Brochuresatish3682No ratings yet

- Ultrasonic Inspection-Test BlocksDocument0 pagesUltrasonic Inspection-Test BlocksSreeji ChittamveeduNo ratings yet

- 1533724968DLA Corrosion Probe EN 201608Document2 pages1533724968DLA Corrosion Probe EN 201608baurzhannNo ratings yet

- Copper Press Fittings: CatalogDocument28 pagesCopper Press Fittings: CatalogSiddiqui Muhammad AshfaqueNo ratings yet

- Brochure_SCDocument4 pagesBrochure_SCJerNo ratings yet

- Pipe Bender MachineDocument3 pagesPipe Bender MachineNaman PrajapatiNo ratings yet

- Torque Systems Bmr2000 SpecsheetDocument4 pagesTorque Systems Bmr2000 SpecsheetElectromateNo ratings yet

- Brochure Flujo Magnetico FoxboroDocument4 pagesBrochure Flujo Magnetico FoxboroJuan Carlos Calderón UribeNo ratings yet

- Manufacturing Machines and ToolsDocument5 pagesManufacturing Machines and Tools2K18/ME/237 UJJWAL BHARTINo ratings yet

- Oripac-5300 SS316 Orifice Plate Flow MeteringDocument8 pagesOripac-5300 SS316 Orifice Plate Flow MeteringkicsnerNo ratings yet

- Namson - PCU - ECU - Version 2019 - Final - English Only - Part 2Document10 pagesNamson - PCU - ECU - Version 2019 - Final - English Only - Part 2Danny DoanNo ratings yet

- HT Barrelsscrews e PDFDocument2 pagesHT Barrelsscrews e PDFsantu_23No ratings yet

- Low Speed Subsonic Wind TunnelsDocument8 pagesLow Speed Subsonic Wind TunnelscparamesNo ratings yet

- ISI Marked Rigid Steel Conduits and Fittings Product CatalogueDocument20 pagesISI Marked Rigid Steel Conduits and Fittings Product CatalogueSaptarshi RoyNo ratings yet

- Modular Rack and Pinion System CatalogDocument39 pagesModular Rack and Pinion System Catalogmeendismurat100% (1)

- E005 - SBQ 280422 - Special Bar Quality MillsDocument2 pagesE005 - SBQ 280422 - Special Bar Quality MillssustainsailNo ratings yet

- DLA Corrosion Probe en 201608 WebDocument2 pagesDLA Corrosion Probe en 201608 WebDennis ChaiNo ratings yet

- APEX Adhesive Slot Die ApplicatorDocument2 pagesAPEX Adhesive Slot Die ApplicatorITWDynatecNo ratings yet

- Belvel Jumbo enDocument2 pagesBelvel Jumbo enGicuNo ratings yet

- Oss Subsea Connectors BR PDFDocument12 pagesOss Subsea Connectors BR PDFDheeraj Chowdary DhanekulaNo ratings yet

- Oss Subsea Connectors BRDocument12 pagesOss Subsea Connectors BRVISHNU GAIDHANINo ratings yet

- Trunnion Mounted Ball Valve Technical Specs & DimensionsDocument28 pagesTrunnion Mounted Ball Valve Technical Specs & DimensionsAnonymous UArnIExNo ratings yet

- LineTrapsAir Core, Dry TypeDocument8 pagesLineTrapsAir Core, Dry TypeSINU0607IITEEENo ratings yet

- Eml 3160 NTDocument6 pagesEml 3160 NTVenkatesh BantwalNo ratings yet

- Summer Tranning-Evaluation: Indian Telephone Industry Santosh PatelDocument28 pagesSummer Tranning-Evaluation: Indian Telephone Industry Santosh PatelVishal Singh MallNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Dimensioning Best Practices - NewDocument61 pagesDimensioning Best Practices - NewEnamul KhanNo ratings yet

- Rex Pipe & Cable Locators: User GuideDocument32 pagesRex Pipe & Cable Locators: User GuideEnamul KhanNo ratings yet

- Installation and Service Instructions for Heat-Flo Indirect-Fired Water HeatersDocument28 pagesInstallation and Service Instructions for Heat-Flo Indirect-Fired Water HeatersEnamul KhanNo ratings yet

- Ariel KBK KBT compressor features and specsDocument2 pagesAriel KBK KBT compressor features and specsEnamul KhanNo ratings yet

- Water Bath Heater Writeup PDFDocument2 pagesWater Bath Heater Writeup PDFJayesh SanganiNo ratings yet

- Canalta DCOF Product ManualDocument13 pagesCanalta DCOF Product ManualWilmar EstepaNo ratings yet

- Indirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhDocument6 pagesIndirect Fired Water Bath Heater Indirect Fired Water Bath Heater Flash Point - IfwbhMuhammad AhsanNo ratings yet

- Manual Serviço Boggi VL89 TM21591-1Document58 pagesManual Serviço Boggi VL89 TM21591-1Ivo Silva100% (1)

- Yokogawa Eja110e PDFDocument17 pagesYokogawa Eja110e PDFAdrian MendozaNo ratings yet

- Aurora Model 481 Pumps: Single-Stage Fire ServiceDocument20 pagesAurora Model 481 Pumps: Single-Stage Fire ServicenhacotungNo ratings yet

- DNG - en - PDF 04.02.2010 10 20 09Document29 pagesDNG - en - PDF 04.02.2010 10 20 09Hoàng ThắngNo ratings yet

- Specification For Control ValveDocument5 pagesSpecification For Control ValveamilasriNo ratings yet

- Fisher GX3 - Way Control Valve and Actuator SystemDocument20 pagesFisher GX3 - Way Control Valve and Actuator SystemAlberto GuillenNo ratings yet

- EIL - Formats - PMI PDFDocument53 pagesEIL - Formats - PMI PDFABHISHEK SINGHNo ratings yet

- Thaletec Reactors AE ENGDocument6 pagesThaletec Reactors AE ENGNaveen KumarNo ratings yet

- Parts Catalog-Honda Navi110Document45 pagesParts Catalog-Honda Navi110Josue Sosa SosaNo ratings yet

- PCCFL001Document16 pagesPCCFL001Hermann KlierNo ratings yet

- Piping Engineering: Marathon Petroleum Co. Project Specific AddendumDocument17 pagesPiping Engineering: Marathon Petroleum Co. Project Specific AddendumChirag ShahNo ratings yet

- Pratt Sugg Specs Ballcentric Plug ValvesDocument1 pagePratt Sugg Specs Ballcentric Plug Valvesivanfr259No ratings yet

- Ductile Iron Flanged Fittings: SpecificationsDocument20 pagesDuctile Iron Flanged Fittings: SpecificationsTarun ChakrabortyNo ratings yet

- 06 Technical SpecificationDocument67 pages06 Technical SpecificationAgnel StanleyNo ratings yet

- BIW - Products and ServicesDocument13 pagesBIW - Products and ServicesCarlos Alberto Aguilera MendezNo ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- Chapter 04 - MM-FR-CT005-BE-2251-50-2004-00-CDocument64 pagesChapter 04 - MM-FR-CT005-BE-2251-50-2004-00-CRonaldo LamarhNo ratings yet

- DIN Reactors AE 63 - 6300 Litres: Thale EmailDocument6 pagesDIN Reactors AE 63 - 6300 Litres: Thale EmailNaveen Suresh KumarNo ratings yet

- Waterwork Product Catalog PDFDocument23 pagesWaterwork Product Catalog PDFpasal muarifNo ratings yet

- Safety Valve Technical DetailsDocument5 pagesSafety Valve Technical DetailsvineethvskkdNo ratings yet

- U of I Facilities Standards - Control ValvesDocument25 pagesU of I Facilities Standards - Control Valvesforevertay2000No ratings yet

- MetalisEnergy TechnicalBrochureDocument60 pagesMetalisEnergy TechnicalBrochureAshok SureshNo ratings yet

- Child parts and kits for scooter componentsDocument54 pagesChild parts and kits for scooter componentsGoulam RezaNo ratings yet

- Static Equipment Awarness Session - 02Document156 pagesStatic Equipment Awarness Session - 02Baher Elsheikh100% (2)

- Horizontal & Vertical end suction & in-line centrifugal pumps guideDocument19 pagesHorizontal & Vertical end suction & in-line centrifugal pumps guideRizal Falevy100% (2)

- Rectangular Tank 4 July 2015Document27 pagesRectangular Tank 4 July 2015Asep DarojatNo ratings yet

- 8i3b40-Aaibaeafadcaaawaa1 LaDocument1 page8i3b40-Aaibaeafadcaaawaa1 Lafile26No ratings yet

- Aramco Exam QusDocument23 pagesAramco Exam Qussarath100% (3)

- Ddokpukpuokopedhiwuluunuobodo Project EkpeyeDocument7 pagesDdokpukpuokopedhiwuluunuobodo Project EkpeyeAllswell ElleNo ratings yet

- Datasheet H Thermostatic Valve 0812 Rev4Document11 pagesDatasheet H Thermostatic Valve 0812 Rev4Paul MathewNo ratings yet