Professional Documents

Culture Documents

Hygiene Gradeslate For Plastic N Resin en

Uploaded by

velan lanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hygiene Gradeslate For Plastic N Resin en

Uploaded by

velan lanCopyright:

Available Formats

Vistamaxx™ ExxonMobil™ PP Achieve™ Advanced PP

Exceed™ XP Exceed™ Enable™ Escorez™

Innovate new levels of comfort, fit and barrier

performance with our hygiene solutions

Not all hygiene solutions are created equal. ExxonMobil’s comprehensive range of hygiene products

allows you to innovate new levels of softness, strength, fit and barrier performance. Our hygiene

portfolio includes Vistamaxx™ performance polymers, ExxonMobil™ PP, Achieve™ Advanced PP,

Exceed™ XP, Exceed™ and Enable™ performance PE polymers and Escorez™ tackifiers.

■ Nonwoven fabrics

In spunbond or meltblown nonwoven production, Vistamaxx performance polymers, Achieve Advanced PP and ExxonMobil PP offer

ease of processing, softness, loft capabilities, strength, and improved barrier performance.

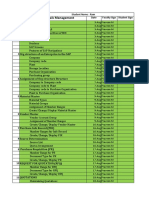

Typical values Availability

Middle

Conversion East

Grade process MFR* Attributes Americas Asia Europe & Africa

Vistamaxx 7020BF Spunbond 20 Enables ability to tailor softness, drapability and

extensibility of fabric when used in a blend with PP.

Good color stability.

Vistamaxx 7050BF Spunbond 45 Enables ability to tailor elasticity, softness and

Meltblown drapability of fabrics when used in a blend with PP.

Good color stability.

Achieve Advanced PP3854 Spunbond 24 Outstanding uniformity for high-strength and

fine denier.

ExxonMobil PP3155E5 Spunbond 36 Excellent spinnability for consistent, high-quality *** ***

fabrics at maximum throughputs.

ExxonMobil PP3684HL Spunbond 13.5 Enable high-loft, ultra-soft nonwovens through

bi-component (BiCo) spunbond process.

Achieve Advanced PP6035G1 Meltblown 500 Enhanced strength with broad processing window.

Achieve Advanced PP6945G1 Meltblown 925 Excellent balance between softness, barrier and

strength, wide processing window.

Achieve Advanced PP6936G2 Meltblown 1550 Superior barrier and softness.

Vistamaxx 8880 Meltblown 1200** Improved barrier properties and tunable softness.

* MFR 230°C/2.16kg based on ExxonMobil method g/10min.

** Viscosity at 190˚C (374˚F) based on ExxonMobil method mPa•s.

*** Please check with your local sales contact for grade availability.

■ Backsheet film

Exceed™ XP, Exceed™ and Enable™ performance PE polymers based-solutions offer thinner breathable and non-breathable backsheet

films while maintaining excellent mechanical properties for high-quality products. Value creation is possible through improved

extrusion line speeds, higher throughput and downgauging.

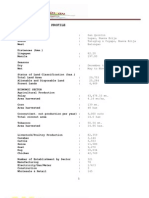

Typical values

Blown Cast

Grade Melt index* Density** film film Attributes

Exceed XP 8318 1.0 0.918 Superior toughness and sealing properties.

High film integrity.

Easy processing on blown film lines.

Downgauge opportunity.

Exceed XP 8358 0.5 0.918 High flex-crack resistance and increased output.

Robust operations on blown film lines.

Exceed 1018 1.0 0.918 Toughness and sealing properties.

High film integrity.

Downgauge opportunity.

Exceed 1327 1.3 0.927 Toughness, sealing and optical properties.

Stiffness and breathability.

Robust operations on blown film lines.

Downgauge opportunity.

Exceed 2018 2.0 0.918 Extrudability, tensile, impact strength and puncture.

Exceed 3518 3.5 0.918 Toughness properties.

Robust operations on cast film lines.

Exceed 3527 3.5 0.927 Toughness and sealing properties.

Stiffness and breathability.

Robust operations on cast film lines.

Exceed 4518 4.5 0.918 Toughness and sealing properties.

Easy processing on high-speed cast film lines.

Exceed 4536 4.5 0.936 Stiffness and toughness balance.

Breathability.

Easy processing on high-speed cast film lines.

Enable 2005 0.5 0.920 Easy processing on blown film lines with enhanced yield strength.

Bubble stability.

High film integrity.

Downgauge opportunity.

Enable 2010 1.0 0.920 Easy processing on film lines with enhanced yield strength.

Neck-in improvement in cast lines.

High film integrity.

Enable 4009 0.9 0.940 Easy processing on blown film lines: bubble stability and extrudability.

Stiffness and toughness balance.

Downgauge opportunity.

* Melt index 190°C/2.16kg based on ExxonMobil method g/10min.

** Density based on ExxonMobil method g/cm3.

■ Elastic laminates using elastic film

Vistamaxx™ performance polymer allows manufacturers to tailor the level of elasticity for improved fit, comfort and discretion,

while maintaining low odor.

Typical values

Grade Conversion process MFR* Attributes

Vistamaxx 6102FL** Film 3.0 Provides excellent elasticity in films.

Vistamaxx 6202FL** Film 20 Provides excellent elasticity in films and enables coating or lamination of elastic

Extrusion lamination layers to nonwoven substrates.

Good compatibility with polyolefin nonwoven facing layers in laminates.

Vistamaxx 7810** Film 4.8 Offers softer stretch without sacrificing elasticity in films.

* MFR 230°C/2.16kg based on ExxonMobil method g/10min.

**FL grades pass ExxonMobil’s test for film appearance with regard to gels, as needed for performance film applications (‘A’ rating).

Please check with your local sales contact for Vistamaxx 7810 availability.

■ Hygiene construction and elastic attachment adhesives

Vistamaxx performance polymers and the Escorez™ 5000 family of high-performance tackifiers are compatible with a wide range

of polymers used in nonwoven applications. Used in adhesive formulations, they are low in odor, light in color and remain thermally

stable from manufacturing to product use.

Typical values

Grade Viscosity (mPa•s) Attributes

Vistamaxx 8380 7000* Enables high polymer load adhesive formulations with low odor, improved

mileage, thermally stable viscosity, and low application temperatures.

Vistamaxx 8780 4550* Enables high polymer load adhesive formulations with low odor, improved

mileage, thermally stable viscosity, and low application temperatures.

Escorez 5000 series 200 - 4000** Offer excellent color performance with outstanding shelf-life stability.

They also offer low odor, outstanding thermal and UV stability, compatibility with a wide

range of polymers and an excellent balance of adhesion and cohesion properties.

* Viscosity at 190°C (374°F) ExxonMobil method mPa•s.

** Viscosity at 160°C (320°F) based on ExxonMobil method mPa•s. Please refer to Escorez Product Data Sheet by grade for individual melt viscosity and other

parameters for your adhesive formulation design.

High performing solutions for every diaper part

Elastic stretch ears Elastic waistbands

Film laminates or nonwoven fabrics using Film laminates or nonwoven fabrics using

Vistamaxx™ performance polymers Vistamaxx performance polymers

Top sheets

Fabrics using ExxonMobil™ PP, Achieve™ Advanced PP,

Vistamaxx performance polymers

Hot-melt adhesives Core wrap

HMA using Vistamaxx performance polymers/ Fabrics using ExxonMobil PP

Escorez™ tackifiers throughout

Leg cuffs

Fabrics using ExxonMobil PP, Achieve Advanced PP,

Vistamaxx performance polymers

Backsheet

Fabrics using ExxonMobil PP/

Vistamaxx performance polymers

Breathable and non-breathable films using Exceed™ XP, Soft-stretch elastic

Exceed™ and Enable™ performance PE polymers

Soft PP nonwovens

PP nonwovens

Backsheet films

Hot-melt adhesives

©2020 ExxonMobil. ExxonMobil, the ExxonMobil logo, the interlocking “X” device and other product or service names used herein are trademarks of ExxonMobil, unless indicated otherwise. This document may

not be distributed, displayed, copied or altered without ExxonMobil’s prior written authorization. To the extent ExxonMobil authorizes distributing, displaying and/or copying of this document, the user may do

so only if the document is unaltered and complete, including all of its headers, footers, disclaimers and other information. You may not copy this document to or reproduce it in whole or in part on a website.

ExxonMobil does not guarantee the typical (or other) values. Any data included herein is based upon analysis of representative samples and not the actual product shipped. The information in this document

relates only to the named product or materials when not in combination with any other product or materials. We based the information on data believed to be reliable on the date compiled, but we do not

represent, warrant, or otherwise guarantee, expressly or impliedly, the merchantability, fitness for a particular purpose, freedom from patent infringement, suitability, accuracy, reliability, or completeness of

this information or the products, materials or processes described. The user is solely responsible for all determinations regarding any use of material or product and any process in its territories of interest. We

expressly disclaim liability for any loss, damage or injury directly or indirectly suffered or incurred as a result of or related to anyone using or relying on any of the information in this document. This document is not

an endorsement of any non-ExxonMobil product or process, and we expressly disclaim any contrary implication. The terms “we,” “our,” “ExxonMobil Chemical” and “ExxonMobil” are each used for convenience,

and may include any one or more of ExxonMobil Chemical Company, Exxon Mobil Corporation, or any affiliate either directly or indirectly stewarded.

Contact us for more information:

exxonmobilchemical.com

V0520-413E49

You might also like

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Exceed XP 8784 Factsheet EnpdfDocument2 pagesExceed XP 8784 Factsheet EnpdfHafiani HichamNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- EnableThinner Stronger Collation Shrink Films Help Brand Owners Deliver Bundled Products Securely enDocument2 pagesEnableThinner Stronger Collation Shrink Films Help Brand Owners Deliver Bundled Products Securely enSajib BhattacharyaNo ratings yet

- Food Packaging Exceed XP Factsheet en 2pdfDocument2 pagesFood Packaging Exceed XP Factsheet en 2pdfSabbir AhmedNo ratings yet

- LLDPE Product Catalouge - RevisedDocument1 pageLLDPE Product Catalouge - RevisedupinderpalsinghNo ratings yet

- StrongGlass E900Document2 pagesStrongGlass E900Radja NurNo ratings yet

- 109 - 20A Hydraulic CemMortars Engineer0 - 4Document1 page109 - 20A Hydraulic CemMortars Engineer0 - 4HighwayNo ratings yet

- TDS Nitowrap FRC Saudi ArabiaDocument3 pagesTDS Nitowrap FRC Saudi ArabiarayNo ratings yet

- CemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalDocument2 pagesCemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalvliegenkristofNo ratings yet

- Nitowrap CFP: High Performance, High Strength, Corrosion Resistant Pultruded Carbon Fi Bre PlatesDocument2 pagesNitowrap CFP: High Performance, High Strength, Corrosion Resistant Pultruded Carbon Fi Bre PlatesbinodNo ratings yet

- Sikawrap - 430 G/25: Woven Glass Fiber Fabric For Structural StrengtheningDocument4 pagesSikawrap - 430 G/25: Woven Glass Fiber Fabric For Structural StrengtheningCretu Cezar CatalinNo ratings yet

- Lucent Matched CladDocument6 pagesLucent Matched CladPatrickJesusCordovaGarateNo ratings yet

- SikaWrap 231 C PDS PDFDocument4 pagesSikaWrap 231 C PDS PDFMohit KohliNo ratings yet

- Qualify Tech CFRP WrapDocument2 pagesQualify Tech CFRP Wrapabolfazlmp9No ratings yet

- Seal-Guard+ECF TDS EnglishDocument1 pageSeal-Guard+ECF TDS Englishabbas ansariNo ratings yet

- Bituthene 8000HCDocument4 pagesBituthene 8000HCa73806780No ratings yet

- Tekasil Neutral Profi enDocument2 pagesTekasil Neutral Profi enEzeval GráficaNo ratings yet

- MKT Apac Tds Fleximesh Feb 2022 enDocument2 pagesMKT Apac Tds Fleximesh Feb 2022 enIvanRomanovićNo ratings yet

- E-CR Glass: CFM For Reinforced Polyurethane FoamsDocument2 pagesE-CR Glass: CFM For Reinforced Polyurethane FoamsANo ratings yet

- 3M 865X Lapping Film Sheet 8 5X8 5 200 Sheets DatasheetDocument4 pages3M 865X Lapping Film Sheet 8 5X8 5 200 Sheets Datasheetfelixnord19No ratings yet

- Durable, Long-Lasting Punches & Punch Blanks: Heads-Above-The-Rest PerformanceDocument12 pagesDurable, Long-Lasting Punches & Punch Blanks: Heads-Above-The-Rest PerformancealexNo ratings yet

- TDS Nitowrap EPCF India PDFDocument3 pagesTDS Nitowrap EPCF India PDFEngr SaifuddinNo ratings yet

- 2800PLT14M PlatimunDocument3 pages2800PLT14M PlatimunSergio RamirezNo ratings yet

- General Properties Viscosity Aging: PVC Paste Resin (Homopolymer)Document2 pagesGeneral Properties Viscosity Aging: PVC Paste Resin (Homopolymer)AminulIslamNo ratings yet

- B-Uhb-M: Outstanding Barrier Metallized BOPP FilmDocument2 pagesB-Uhb-M: Outstanding Barrier Metallized BOPP FilmSayed FathyNo ratings yet

- SikaWrap 600C PDSDocument4 pagesSikaWrap 600C PDSFranco VasquezNo ratings yet

- Sikawrap®-900 C: Product Data SheetDocument4 pagesSikawrap®-900 C: Product Data SheetnovitaapriyaniNo ratings yet

- Hexene LLDPE film, moulding and extrusion overviewDocument4 pagesHexene LLDPE film, moulding and extrusion overviewYayan RnsNo ratings yet

- XP1000 en LR 22Document12 pagesXP1000 en LR 22michael KetselaNo ratings yet

- Sikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningDocument2 pagesSikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningRoberto Jimenez PerezNo ratings yet

- TDS Nitowrap CW Saudi ArabiaDocument3 pagesTDS Nitowrap CW Saudi ArabiaSHAIK ASIMUDDINNo ratings yet

- Sikawrap - 230 C/45: Woven Carbon Fiber Fabric For Structural StrengtheningDocument3 pagesSikawrap - 230 C/45: Woven Carbon Fiber Fabric For Structural StrengtheningBudhi KurniawanNo ratings yet

- Forest: MasterDocument8 pagesForest: MasterPawan ChaturvediNo ratings yet

- Low exotherm epoxy grout for heavy loadsDocument4 pagesLow exotherm epoxy grout for heavy loadsSAJEED MOHAMMADNo ratings yet

- Elephant Moistbloc Gypsum Board Product SpecificationDocument1 pageElephant Moistbloc Gypsum Board Product SpecificationDilon Fernando0% (1)

- Fosroc Nitomortar PEDocument5 pagesFosroc Nitomortar PEShahril ZainulNo ratings yet

- EC TDS High Density Polyurethane Foam BlockDocument2 pagesEC TDS High Density Polyurethane Foam BlockDiego OrtegaNo ratings yet

- TDS-Conbextra-EP10-India6Document3 pagesTDS-Conbextra-EP10-India6jasonNo ratings yet

- Power Design: Exxtraaa Smoothh.Document2 pagesPower Design: Exxtraaa Smoothh.John GonzalezNo ratings yet

- Sikawrap - 300 CDocument4 pagesSikawrap - 300 CJhune UrabaNo ratings yet

- F13 - Carboguard 893-Zn PDS 10-09Document2 pagesF13 - Carboguard 893-Zn PDS 10-09naveenbaskaran1989No ratings yet

- Product Data Sheet: 24K Carbon TowDocument1 pageProduct Data Sheet: 24K Carbon TowsaadnaumanNo ratings yet

- ESTOP-TDS-Estowrap 300 & 600Document5 pagesESTOP-TDS-Estowrap 300 & 600Dona Dwi SaputroNo ratings yet

- FP Fusion Salessheet FNL-webDocument2 pagesFP Fusion Salessheet FNL-webuğur alparslanNo ratings yet

- VHB Acrylic Foam Tape 4950: Product Data SheetDocument3 pagesVHB Acrylic Foam Tape 4950: Product Data SheetAfzal ImamNo ratings yet

- Carboxane 2000: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarboxane 2000: Selection & Specification Data Substrates & Surface PreparationPurwanto ritzaNo ratings yet

- Chopped Strand Mat Powder BinderDocument2 pagesChopped Strand Mat Powder Binderbasanth babuNo ratings yet

- Rotary metallurgical materialsDocument4 pagesRotary metallurgical materialsNabeel MohammedNo ratings yet

- SikaWrap®-900 CDocument4 pagesSikaWrap®-900 CN.J. PatelNo ratings yet

- Conbextra Ep300 PDFDocument4 pagesConbextra Ep300 PDFUa AnyanhunNo ratings yet

- Nitowrap UW: High Performance Glass Fibre System For Under-Water Strengthening & RetrofittingDocument4 pagesNitowrap UW: High Performance Glass Fibre System For Under-Water Strengthening & RetrofittingKareem SaberNo ratings yet

- Certoplast 514 TD EnglischDocument1 pageCertoplast 514 TD Englischgutman98No ratings yet

- Dow Corning 794 Silicone Sealant: Glazing and Construction (Previously DC 916)Document2 pagesDow Corning 794 Silicone Sealant: Glazing and Construction (Previously DC 916)engramir07No ratings yet

- Fosroc Nitomortar FC (FS) : Constructive SolutionsDocument2 pagesFosroc Nitomortar FC (FS) : Constructive SolutionsVincent JavateNo ratings yet

- Mci - 2241/mci - 2242 Watertight Coat: Typical Applications and FeaturesDocument2 pagesMci - 2241/mci - 2242 Watertight Coat: Typical Applications and FeaturesAdrian EspinosaNo ratings yet

- Final Acrylic Brochure LRDocument7 pagesFinal Acrylic Brochure LRThuy NguyenNo ratings yet

- 29 - Application of Adhesives and Bonded Joint Design in Improving Vehicle Structure PerformanceDocument18 pages29 - Application of Adhesives and Bonded Joint Design in Improving Vehicle Structure Performancemohamed mourad Lafifi100% (1)

- Hetron 922 Infusion Resin 45 en A4Document1 pageHetron 922 Infusion Resin 45 en A4uzzy2No ratings yet

- Nitowrap FRCDocument2 pagesNitowrap FRCMansoor AliNo ratings yet

- 2D IconsDocument8 pages2D IconsJacky ManNo ratings yet

- What Is A Human Resources Strategy?Document8 pagesWhat Is A Human Resources Strategy?abdallah abdNo ratings yet

- Systemverilog Interview QuestionsDocument31 pagesSystemverilog Interview QuestionsDivya Dm100% (1)

- W3. The Relational ModelDocument21 pagesW3. The Relational ModelSABOOR UR RAHMANNo ratings yet

- HACCP Plan With Flow Chart-1Document23 pagesHACCP Plan With Flow Chart-1Anonymous aZA07k8TXfNo ratings yet

- Triumph Spitfire MK4 - 1500Document108 pagesTriumph Spitfire MK4 - 1500Ricardo100% (1)

- Spirax-Sarco - Boiler Controls and SystemsDocument8 pagesSpirax-Sarco - Boiler Controls and SystemstpqnhatNo ratings yet

- 229 PGTRB Commerce Study Material Unit 15 and 16Document16 pages229 PGTRB Commerce Study Material Unit 15 and 16shareena ppNo ratings yet

- Piano Sonata No. 17 Tempest 1. Largo - AllegroDocument10 pagesPiano Sonata No. 17 Tempest 1. Largo - AllegroOtrebor ImlesNo ratings yet

- Em8 1session2.2Document25 pagesEm8 1session2.2DreamCodmNo ratings yet

- NY B17 ATF FDR - 7-24-03 ATF Email and 10-25-01 ATF After Action Report 092Document20 pagesNY B17 ATF FDR - 7-24-03 ATF Email and 10-25-01 ATF After Action Report 0929/11 Document Archive100% (2)

- DES-3611.prepaway - Premium.exam.65q: Number: DES-3611 Passing Score: 800 Time Limit: 120 Min File Version: 1.1Document22 pagesDES-3611.prepaway - Premium.exam.65q: Number: DES-3611 Passing Score: 800 Time Limit: 120 Min File Version: 1.1Emre Halit POLATNo ratings yet

- OT Lawsuit CPDDocument20 pagesOT Lawsuit CPDDan LehrNo ratings yet

- Kalokal Barangay Highway HillsDocument35 pagesKalokal Barangay Highway HillsDixie MirandaNo ratings yet

- Philips LCD Monitor 220EW9FB Service ManualDocument10 pagesPhilips LCD Monitor 220EW9FB Service Manualpagy snvNo ratings yet

- Table 141: India'S Overall Balance of Payments - RupeesDocument2 pagesTable 141: India'S Overall Balance of Payments - Rupeesmahbobullah rahmaniNo ratings yet

- TUTO 4 PU Sol PDFDocument21 pagesTUTO 4 PU Sol PDFVievie Le BluewberrietrufflesNo ratings yet

- C-TECC Principles Guide TECC EducationDocument4 pagesC-TECC Principles Guide TECC EducationDavid Sepulveda MirandaNo ratings yet

- High-Energy Fuels For Cruise MissilesDocument4 pagesHigh-Energy Fuels For Cruise Missilesgrindormh53No ratings yet

- TD2Document4 pagesTD2Terry ChoiNo ratings yet

- Ram SAP MM Class StatuscssDocument15 pagesRam SAP MM Class StatuscssAll rounderzNo ratings yet

- Written Report Maneco FinalDocument31 pagesWritten Report Maneco FinalKymicah DesiertoNo ratings yet

- Company Law PPT on Types of CompaniesDocument8 pagesCompany Law PPT on Types of CompaniesAbid CoolNo ratings yet

- Innova 2100-IQ, 3100/3100-IQ, 4100/4100-IQ Cardiovascular Imaging System SM DVDDocument1 pageInnova 2100-IQ, 3100/3100-IQ, 4100/4100-IQ Cardiovascular Imaging System SM DVDSwami Meera100% (1)

- Parent DC Promo Ui LogDocument193 pagesParent DC Promo Ui LogRachell SmithNo ratings yet

- Municipal Profile of Umingan, PangasinanDocument51 pagesMunicipal Profile of Umingan, PangasinanGina Lee Mingrajal Santos100% (1)

- Terex-CC8800 1 Twin B1 200808Document8 pagesTerex-CC8800 1 Twin B1 200808pvs12684No ratings yet

- Year Overview 2012 FinalDocument65 pagesYear Overview 2012 FinalArjenvanLinNo ratings yet

- Sap AbapDocument7 pagesSap Abapidrees aliNo ratings yet

- Consultants DirectoryDocument36 pagesConsultants DirectoryAnonymous yjLUF9gDTSNo ratings yet

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (57)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationFrom EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationRating: 4.5 out of 5 stars4.5/5 (46)

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The End of Craving: Recovering the Lost Wisdom of Eating WellFrom EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellRating: 4.5 out of 5 stars4.5/5 (80)

- The Weather Machine: A Journey Inside the ForecastFrom EverandThe Weather Machine: A Journey Inside the ForecastRating: 3.5 out of 5 stars3.5/5 (31)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- Reality+: Virtual Worlds and the Problems of PhilosophyFrom EverandReality+: Virtual Worlds and the Problems of PhilosophyRating: 4 out of 5 stars4/5 (24)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseFrom EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseRating: 3.5 out of 5 stars3.5/5 (12)

- Packing for Mars: The Curious Science of Life in the VoidFrom EverandPacking for Mars: The Curious Science of Life in the VoidRating: 4 out of 5 stars4/5 (1395)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Designing Data-Intensive Applications: The Big Ideas Behind Reliable, Scalable, and Maintainable SystemsFrom EverandDesigning Data-Intensive Applications: The Big Ideas Behind Reliable, Scalable, and Maintainable SystemsRating: 5 out of 5 stars5/5 (6)

- Pale Blue Dot: A Vision of the Human Future in SpaceFrom EverandPale Blue Dot: A Vision of the Human Future in SpaceRating: 4.5 out of 5 stars4.5/5 (587)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980From Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Rating: 4 out of 5 stars4/5 (21)

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4.5 out of 5 stars4.5/5 (4)