Professional Documents

Culture Documents

B-Uhb-M: Outstanding Barrier Metallized BOPP Film

Uploaded by

Sayed FathyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B-Uhb-M: Outstanding Barrier Metallized BOPP Film

Uploaded by

Sayed FathyCopyright:

Available Formats

FLEXMETPROTECT TM B-UHB-M

TECHNICAL DATA SHEET

B-UHB-M

Outstanding Barrier Metallized BOPP Film

B-UHB-M is an outstanding barrier metallized BOPP film, having ultra high surface energy on one side and the other side heat

sealable. The film has exceptional barrier to oxygen, moisture, aroma and mineral oil. Sustainable & recyclable solutions to

replace AL foil.

Vacuum Deposited

Aluminium Layer

Ultra High Surface

Energy Layer

Inter Layer

FILM STRUCTURE

OPP Core Layer

Inter Layer

Heat Sealable Layer

(SIT 1050 C)

THE BIG DIFFERENTIATORS

Ultra High Barrier

Improves shelf life of chips/snacks Excellent Metal Bond &

Flex Cracking Resistance

by 50% retaining classical freshness,

Replacement Of Durability & sustainability of barrier

crispness & aroma.

Aluminium Foil under extreme conditions. Much

Sustainable & recyclable stronger extrusion/adhesive bond

solution. Superior Gelbo strengths.

test results.

Good Resistance To Mineral Oil Chlorine Free Solution

Environment friendly & non-carcinogenic.

Absolute protection of oxidation for cattle

chips with significant fat content.

KEY FEATURES: APPLICATIONS:

• Exceptional oxygen & moisture barrier • Dry fruits & beverage packaging

• Exceptional barrier to aroma • Chips & snacks packaging

• Good migration barrier (mineral oil) • Biscuits, cookies & crackers packaging

• Excellent metal adhesion • Confectionery & chocolate packaging

• PVDC coated film replacement chlorine free

• Replacement of AL foil

• Easy processing at high speed

• Sustainable and recyclable solution

FLEXMETPROTECT TM B-UHB-M

TECHNICAL DATA SHEET

PROPERTIES TEST METHOD UNIT TYPICAL VALUES

(ASTM)

Micron 18 20

THICKNESS Internal

(Gauge) 72 80

FILM DENSITY D-1505 gm/cc 0.91

GRAMMAGE Internal gm/m2 16.4 18.2

m2/kg 61.1 54.9

YEILD Internal

in2/lb 42953 38594

TREATMENT LEVEL D-2578 dyne/cm 36

OPTICAL DENSITY

Internal - 2.5

(TOLERANCE: +/- 5%)

MD* 1200

kg/cm2 2500

TENSILE STRENGTH TD*

D-882

AT BREAK

MD* 17.0

(KPsi)

TD* 35.5

MD* 200

ELONGATION AT BREAK D-882 %

TD* 60

LINEAR SHRINKAGE (max) MD* 6.0

D-1204 %

(5 Minutes at 1300 C) TD* 3.0

HEAT SEAL INITIATION

TEMPERATURE Internal 0

C 105

HEAT SEAL STRENGTH (Min) Internal gm/25mm 375 400

WATER VAPOUR TRANSMISSION gm/m2/day 0.1

F-1249

RATE (380 C & 90% RH) (gm/100 in2/day) 0.006

OXYGEN TRANSMISSION RATE cc/m /day

2 0.1

D-3985

(230 C & 0% RH) (cc/100 in /day)2 0.006

Ref no QAD UFLI S/20 – MB 12/1

*MD = MACHINE DIRECTION *TD = TRANSVERSE DIRECTION

STORAGE & HANDLING

FLEXMETPROTECTTM does not require special storage conditions. It is recommended to storage below 30°C in order to avoid any deterioration of the film surface properties. It is

advisable to use the material on FIFO basis. The film should be kept at operating environment for 24 hours before processing. FLEXMETPROTECTTM is best suitable for use within

3 months from date of dispatch.

FOOD CONTACT

FLEXMETPROTECTTM complies with EC and FDA regulations. Specific document and MSDS are available on request.

DISCLAIMER

It is the responsibility of our customers to determine that their use of our products is safe, lawful, and technically suitable in their intended applications. The technical data

sheets are provided for discussion purposes only. The customer may not rely on the data provided for any manufacturing purpose. The values provided in the technical data

sheet represent typical values based on the best of our knowledge as of the date when the data was compiled. The data is offered solely to provide possible suggestions for

your own experimentation and not as a guarantee for the material supplied. The user is solely responsible for the end use of the product and needs to perform their own

tests to confirm the product suitability/compatibility in all respects. Flex provides no warranty and accepts no liability for any loss or fitness of the product for any

specific purpose based on the information contained in the technical data sheets. Flex reserves the right to change the technical data sheet

at any time without prior notice.

FlexFilms

Manufacturing Facilities at

**TDS issued on 01-04-2020. All previous versions of this grade are invalid.

India | UAE | Poland | Egypt | Mexico |

USA | Hungary | Russia | Nigeria

enquiry@flexfilm.com

www.flexfilm.com

You might also like

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- B-TVS-M: Metallized BOPP FilmDocument2 pagesB-TVS-M: Metallized BOPP FilmSayed FathyNo ratings yet

- EC Tech Report High Performance Polyurethanes: PDFFrom EverandEC Tech Report High Performance Polyurethanes: PDFVincentz Network GmbH & Co. KGNo ratings yet

- B-TVL-M: Standard Barrier Metallized BOPP FilmDocument2 pagesB-TVL-M: Standard Barrier Metallized BOPP FilmSayed FathyNo ratings yet

- B-TVB-M: Sandwich Grade Heat Sealable Metallized Bopp FilmDocument2 pagesB-TVB-M: Sandwich Grade Heat Sealable Metallized Bopp FilmSayed FathyNo ratings yet

- B-PVL-M: White Voided Metallized BOPP FilmDocument2 pagesB-PVL-M: White Voided Metallized BOPP FilmSayed FathyNo ratings yet

- CemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalDocument2 pagesCemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalvliegenkristofNo ratings yet

- Amercoat 450HDocument2 pagesAmercoat 450HJairo ArroyoNo ratings yet

- Hexene LLDPE film, moulding and extrusion overviewDocument4 pagesHexene LLDPE film, moulding and extrusion overviewYayan RnsNo ratings yet

- High Build Epoxy Coating for PipelinesDocument3 pagesHigh Build Epoxy Coating for PipelinesAndrea Pamela León AlgarañazNo ratings yet

- Belzona 1121: Product Specification SheetDocument2 pagesBelzona 1121: Product Specification SheetQuy RomNo ratings yet

- TDS E-323Document1 pageTDS E-323APEX SONNo ratings yet

- Cardolite Ultra LITE 2009: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite Ultra LITE 2009: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- Seal-Guard+ECF TDS EnglishDocument1 pageSeal-Guard+ECF TDS Englishabbas ansariNo ratings yet

- High Metal AdhesionDocument9 pagesHigh Metal AdhesionSachin KothariNo ratings yet

- 124826carboset® CR-785Document17 pages124826carboset® CR-785ForeverNo ratings yet

- VHB Acrylic Foam Tape 4950: Product Data SheetDocument3 pagesVHB Acrylic Foam Tape 4950: Product Data SheetAfzal ImamNo ratings yet

- PDS HF09522 Rev0 - EvaleneDocument2 pagesPDS HF09522 Rev0 - EvalenechinchotarngNo ratings yet

- Product Specification Sheet Belzona 1111Document2 pagesProduct Specification Sheet Belzona 1111Quy RomNo ratings yet

- T 200 PDFDocument2 pagesT 200 PDFDhika aryNo ratings yet

- Belzona 1821: Product Specification SheetDocument2 pagesBelzona 1821: Product Specification SheetAlex BravoNo ratings yet

- ASIAN PAINTS SMARTCARE DAMP PROOFING SOLUTIONSDocument6 pagesASIAN PAINTS SMARTCARE DAMP PROOFING SOLUTIONSgowthamNo ratings yet

- Durebild HSE: High Build Two Pack Epoxy CoatingDocument3 pagesDurebild HSE: High Build Two Pack Epoxy CoatinglivefreakNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Marlex D139 Polyethylene: Nominal Resin Properties English SI MethodDocument1 pageMarlex D139 Polyethylene: Nominal Resin Properties English SI MethodGabriela Lopez MunozNo ratings yet

- Higher Performance Not Higher Prices.: OX Engineered ProductsDocument4 pagesHigher Performance Not Higher Prices.: OX Engineered ProductsMyron BrandwineNo ratings yet

- SABIC® LLDPE - 218WM - Global - Technical - Data - SheetDocument1 pageSABIC® LLDPE - 218WM - Global - Technical - Data - SheetKenneth ShiNo ratings yet

- SABIC® LLDPE - 218WM - Global - Technical - Data - Sheet 2Document1 pageSABIC® LLDPE - 218WM - Global - Technical - Data - Sheet 2Kenneth ShiNo ratings yet

- Chevron_Phillips_Marlex_D139Document1 pageChevron_Phillips_Marlex_D139AthonioMourinhoNo ratings yet

- Reinforcekit Beam Fiche TechniqueDocument24 pagesReinforcekit Beam Fiche TechniqueAmel RADJEFNo ratings yet

- Berry Polyken 558ca Spec SheetDocument1 pageBerry Polyken 558ca Spec SheetFajri SaputraNo ratings yet

- Belzona 1321: Product Specification SheetDocument2 pagesBelzona 1321: Product Specification Sheetmehdi kamaliNo ratings yet

- Adsyl and Clyrell Advantage: Boost Performance With Advanced Sealing Resins From Industry Leader LyondellbasellDocument6 pagesAdsyl and Clyrell Advantage: Boost Performance With Advanced Sealing Resins From Industry Leader Lyondellbasellnouman ashrafNo ratings yet

- Film Packaging BrochureDocument6 pagesFilm Packaging BrochuremaheshgupteNo ratings yet

- Vulkem NEM - Data SheetDocument2 pagesVulkem NEM - Data SheetRobertNo ratings yet

- SubseaLV DatasheetDocument1 pageSubseaLV DatasheetPablo TorresNo ratings yet

- GEOMETDocument4 pagesGEOMETdavideNo ratings yet

- BrederoShaw PDS YJ2KDocument2 pagesBrederoShaw PDS YJ2KJayNo ratings yet

- DAG LayerDocument3 pagesDAG LayerSudhansu DashNo ratings yet

- Acetal Copolymer (POM)Document5 pagesAcetal Copolymer (POM)DiegoTierradentroNo ratings yet

- Lexible Ackaging Dhesives: Headquarter 7-10 Chandos StreetDocument2 pagesLexible Ackaging Dhesives: Headquarter 7-10 Chandos StreetAbu Sayed AzadNo ratings yet

- EcoPoly Data Sheet Template EcoSmooth PDFDocument1 pageEcoPoly Data Sheet Template EcoSmooth PDFعبيد أنسNo ratings yet

- PE LL6201 Series DatasheetDocument1 pagePE LL6201 Series DatasheetmaheshgupteNo ratings yet

- B-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmDocument2 pagesB-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmSayed FathyNo ratings yet

- D139FKDocument1 pageD139FKsonhungdoanNo ratings yet

- POLYPLEX ISO NPG SOLID SURFACE RESIN - EN - LetterDocument2 pagesPOLYPLEX ISO NPG SOLID SURFACE RESIN - EN - LetterOXY Composite TechNo ratings yet

- Technical Data Sheet: Epoguard EnamelDocument3 pagesTechnical Data Sheet: Epoguard Enameltrường phạmNo ratings yet

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDocument2 pagesLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakNo ratings yet

- WP - Retail Brochure FINALDocument8 pagesWP - Retail Brochure FINALVikas Singh ChandelNo ratings yet

- Elastomer Solutions For Pharmaceutical Packaging and Medical DevicesDocument27 pagesElastomer Solutions For Pharmaceutical Packaging and Medical DevicesRonaldo CamargoNo ratings yet

- Metal Liquido LoctiteDocument2 pagesMetal Liquido Loctitepablolz712No ratings yet

- KolothermDocument2 pagesKolothermtodotodiNo ratings yet

- Eterset 2967Document2 pagesEterset 2967legivethNo ratings yet

- M06 Alkyd Metal Primer: Features General PropertiesDocument2 pagesM06 Alkyd Metal Primer: Features General Propertiesplj0001No ratings yet

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- Sikafloor - Decor: 5-Part Epoxy Self-Smoothing and Broadcast SystemDocument6 pagesSikafloor - Decor: 5-Part Epoxy Self-Smoothing and Broadcast SystemAmNo ratings yet

- Densolen - System AS39P / R20HT: Product InformationDocument2 pagesDensolen - System AS39P / R20HT: Product InformationCarlos PazNo ratings yet

- Kefloy40 en OdkDocument1 pageKefloy40 en OdkMax SalogniNo ratings yet

- Anti Crak Brochure ScreenDocument7 pagesAnti Crak Brochure ScreenPablo Quinteros PizarroNo ratings yet

- The Ultra Power of Newmax Lead-Acid BatteryDocument3 pagesThe Ultra Power of Newmax Lead-Acid BatteryMuhammad FachrullahNo ratings yet

- B-THL: Standard Transparent Heat Sealable BOPP FilmDocument2 pagesB-THL: Standard Transparent Heat Sealable BOPP FilmSayed FathyNo ratings yet

- 5s Checklist OperationDocument1 page5s Checklist OperationallanbatiancilaNo ratings yet

- Plastics Product Design Engineering Handbook (1984, Springer US) - Sidney Levy, J. Harry DuBois (Auth.)Document373 pagesPlastics Product Design Engineering Handbook (1984, Springer US) - Sidney Levy, J. Harry DuBois (Auth.)ajaikumar ShankarNo ratings yet

- Aramco PP HP30EGDocument2 pagesAramco PP HP30EGSayed FathyNo ratings yet

- Bearing Failure Analysis by Using 8 D ReportDocument7 pagesBearing Failure Analysis by Using 8 D Reportyash prajapatiNo ratings yet

- B-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmDocument2 pagesB-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmSayed FathyNo ratings yet

- 8D Worksheet TemplateDocument3 pages8D Worksheet TemplateBenja GSNo ratings yet

- Silo Feeding LOG Book: Flex P.Films EgyptDocument8 pagesSilo Feeding LOG Book: Flex P.Films EgyptSayed FathyNo ratings yet

- Pareto Chart: Project/problemDocument1 pagePareto Chart: Project/problemSayed FathyNo ratings yet

- Material Check Check Date: Reason: ..: Observer Name: .Document4 pagesMaterial Check Check Date: Reason: ..: Observer Name: .Sayed FathyNo ratings yet

- Failure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleDocument1 pageFailure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleCarolineNo ratings yet

- Failure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleDocument1 pageFailure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleAlper GmNo ratings yet

- To-do list template for multiple projectsDocument1 pageTo-do list template for multiple projectstt123456No ratings yet

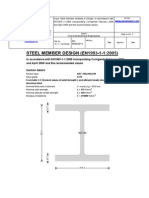

- Sachpazis Steel Member Analysis & Design (EN1993-1!1!2005)Document6 pagesSachpazis Steel Member Analysis & Design (EN1993-1!1!2005)Costas SachpazisNo ratings yet

- What Is Hydrated Silica - (With Pictures)Document6 pagesWhat Is Hydrated Silica - (With Pictures)RankHakrNo ratings yet

- Use of Waste Tyres in Road ConstructionDocument11 pagesUse of Waste Tyres in Road Constructionvotetorecieve 1100% (1)

- B21 5530 EnglishDocument20 pagesB21 5530 EnglishWillianNo ratings yet

- The Marangoni Effect ZulaikhaDocument3 pagesThe Marangoni Effect ZulaikhaZulaikha ZulaikhaNo ratings yet

- Classification of Elements and Periodicity in Properties (@Document20 pagesClassification of Elements and Periodicity in Properties (@LONE WOLFNo ratings yet

- Co-base alloy creep and rupture propertiesDocument4 pagesCo-base alloy creep and rupture propertiesqueno1No ratings yet

- DTD 560Document5 pagesDTD 560kulveer singhNo ratings yet

- Fired Heater DesignDocument36 pagesFired Heater DesignBladimir Soliz PardoNo ratings yet

- PRESTRESSED CONCRETE 03 Rev00Document4 pagesPRESTRESSED CONCRETE 03 Rev00Hussein MuslihNo ratings yet

- Consolidated-Undrained Tri-Axial Test (Cu - Test) : Problem 1Document14 pagesConsolidated-Undrained Tri-Axial Test (Cu - Test) : Problem 1Jemuel FloresNo ratings yet

- Waste ManagementDocument7 pagesWaste Managementwongsc70No ratings yet

- Dokumen - Tips - Wps PQR Er309l MoDocument4 pagesDokumen - Tips - Wps PQR Er309l Moel_sharkawy2011No ratings yet

- Waste Water StoryDocument18 pagesWaste Water StoryAbishek ThiyagarajanNo ratings yet

- Consumer Chemistry: Quarter 1 - Module 2: History of Organic ChemistryDocument25 pagesConsumer Chemistry: Quarter 1 - Module 2: History of Organic ChemistryChianlee Carreon100% (7)

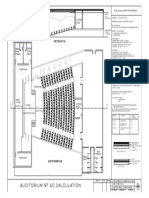

- RT 60 Calculation for AuditoriumDocument1 pageRT 60 Calculation for AuditoriumAniket WayalNo ratings yet

- Blue Bond Bonding 2004 01Document2 pagesBlue Bond Bonding 2004 01crodriguezcolonNo ratings yet

- Antimicrobial and Conductive Nanocellulose-Based Films For Active and Intelligent Food PackagingDocument16 pagesAntimicrobial and Conductive Nanocellulose-Based Films For Active and Intelligent Food PackagingJoão CostaNo ratings yet

- The Comparative Study On Corrosion Behaviour of Steel and Basalt Fibre Reinforced Polymer (BFRP) Rebar in Concrete"Document9 pagesThe Comparative Study On Corrosion Behaviour of Steel and Basalt Fibre Reinforced Polymer (BFRP) Rebar in Concrete"Abhijeet SableNo ratings yet

- Hydra Oil Control Energetic TonerDocument2 pagesHydra Oil Control Energetic TonerAlna TechnicalNo ratings yet

- Bostik Corporate - Presentation - 2013 PDFDocument18 pagesBostik Corporate - Presentation - 2013 PDFAshwathRaghavendranNo ratings yet

- Leaching Spent Batteries Powder Sodium Carbonate CO2Document6 pagesLeaching Spent Batteries Powder Sodium Carbonate CO2Boulos NassarNo ratings yet

- Unit 10 - Week 7: Assignment 7Document5 pagesUnit 10 - Week 7: Assignment 7Umamaheswararao TumatiNo ratings yet

- NSSWM-2019 Second Call for Papers on Sustainable Waste ManagementDocument2 pagesNSSWM-2019 Second Call for Papers on Sustainable Waste ManagementAprizon PutraNo ratings yet

- A 391 - A 391M - 98 Qtm5ms9bmzkxts1sruqDocument6 pagesA 391 - A 391M - 98 Qtm5ms9bmzkxts1sruqClaudia Patricia Magaña RabanalesNo ratings yet

- Butt Joint X Structural Silicon GlazingDocument3 pagesButt Joint X Structural Silicon GlazingfercaetNo ratings yet

- MLS-3750 MLS-3780: Instruction ManualDocument32 pagesMLS-3750 MLS-3780: Instruction Manualfelix bazan100% (1)

- Experiment 2Document6 pagesExperiment 2Rohann James Abrogueña ReañoNo ratings yet

- 6.product Tech Slide PresentationDocument158 pages6.product Tech Slide PresentationHadi MuchlisNo ratings yet

- 9606-Article Text PDF-22911-3-10-20170313Document6 pages9606-Article Text PDF-22911-3-10-20170313kalaiNo ratings yet