Professional Documents

Culture Documents

XH360L-V: Temperature and Humidity Controller For Seasoning-Maturing Cabinets

Uploaded by

Jennifer Eszter SárközyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XH360L-V: Temperature and Humidity Controller For Seasoning-Maturing Cabinets

Uploaded by

Jennifer Eszter SárközyCopyright:

Available Formats

4.

2 DEHUMIDIFYING ACTION WITHOUT DEHUMIDIFIER RELAY, OA1 DIFFERENT FROM DEH

XH360L-V (XH360L TERMINALS 3-4, XH360V TERMINALS. 11-12)

In this case the dehumidifying action is performed by setting the following parameters in this way:

tHu = c-H kind of dehumidifying by means of heating and compressor relays

oA1 different from dEH (XH360L terminals 3-4, XH360V terminals. 11-12):

TEMPERATURE AND HUMIDITY CONTROLLER The heating and compressor outputs are activated together when humidity is higher than SET_RH+dbH

value. Outputs are disabled when humidity comes back to the SET_RH value.

FOR SEASONING-MATURING CABINETS

4.2.1 Relation between cooling, heating and dehumidifying

1. If is simultaneously present a request of cooling (temp>SET_T+dbt) and dehumidifying (RH >

1. GENERAL WARNING SET_RH+dbH): the cooling action has the priority over the dehumidifying action: only the

compressor relay is energised till the SET_T is reached at this point also the heating relay is

enabled.

1.1 PLEASE READ BEFORE USING THIS MANUAL 2. If is simultaneously present a request of heating (temp< SET_T-dbt) and dehumidifying (RH >

This manual is part of the product and should be kept near the instrument for easy and quick SET_RH+dbH): the dehumidifying action has the priority over the heating action: both the

reference. compressor and the heating relays are energised till the humidity set is reached at this point only

The instrument shall not be used for purposes different from those described hereunder. It cannot the heating relay is enabled.

be used as a safety device.

Check the application limits before proceeding.

Dixell Srl reserves the right to change the composition of its products, even without notice, 4.3 DEHUMIDIFYING ACTION WITH DEHUMIDIFIER RELAY, OA1 = DEH – (XH360L

ensuring the same and unchanged functionality. TERMINALS 3-4, XH360V TERMINALS. 11-12)

The configurable relay is used, (XH360L terminals 3-4, XH360V terminals. 11-12) setting the parameter

oA1 =dEH.

NOTE: the LIGHT button is not more available;

1.2 SAFETY PRECAUTIONS

Two kinds of de-humidifying are available:

Check the supply voltage is correct before connecting the instrument.

4.3.1 Dehumidifying action with ONLY de-humidifier relay

Do not expose to water or moisture: use the controller only within the operating limits avoiding

By setting the parameter tHu = db the de-humidifying action is performed by enabling the de-humidifier

sudden temperature changes with high atmospheric humidity to prevent formation of

relay when the humidity is higher than SET_RH + dbH.

condensation

The relay is switch off when humidity comes back to the SET_RH value.

Warning: disconnect all electrical connections before any kind of maintenance.

Fit the probe where it is not accessible by the End User. The instrument must not be opened.

In case of failure or faulty operation send the instrument back to the distributor or to “Dixell s.r.l.” 4.3.2 Dehumidifying action with de-humidifier and compressor relays

(see address) with a detailed description of the fault. By setting the parameter tHu = cHu the de-humidifying action is performed by enabling the de-

Consider the maximum current which can be applied to each relay (see Technical Data). humidifier and compressor relays together. when the humidity is higher than SET_RH + dbH.

Ensure that the wires for probes, loads and the power supply are separated and far enough from The relays are switched off when humidity comes back to the SET_RH value.

each other, without crossing or intertwining.

In case of applications in industrial environments, the use of mains filters (our mod. FT1) in parallel If is simultaneously present a request of cooling (temp>SET_T+dbt) and dehumidifying (RH >

with inductive loads could be useful. SET_RH+dbH): the cooling action has the priority over the dehumidifying action: only the compressor

relay is energised till the SET_T is reached at this point also the de-humidifier is enabled.

2. GENERAL DESCRIPTION

5. FA NS

The XH360L, 38x185 format and the XH360V, 100x64 format, are microprocessor controllers, suitable

for applications on medium or low temperature refrigerating units. They have 6 output relays to control The fan control mode is selected by means of the “FnC” parameter:

compressor, heating elements, defrost/extractor fan, fan, de-humidifier/light and humidifier. They have 2 FnC=C-n fans will switch ON and OFF with the compressor and not run during defrost:;

NTC inputs one for thermostat the other one for defrost. It’s also present a 4÷20mA input for humidity. FnC= O-n fans will run continuously, but not during defrost

There is one digital input (free contact) configurable by parameter. An output allows the user to FnC=C-y fans will switch ON and OFF with the compressor and run during defrost;

programme the parameter list with the “Hot Key”. FnC=O-y fans will run continuously also during defrost

6. EXTRACTOR FAN

3. TEMPERATURE REGULATION

The temperature regulation is performed through neutral zone using compressor and heater output 6.1 EXTRACTOR FAN CYCLES

relays. The second relay (XH360L terminals 9-10-11, XH360V terminals 6-7) is configured as extractor

fan, oA2= ESt, then it is possible to make extraction cycles, both manually and automatically.

ON

Extraction cycle can be activated both manually by pushing the UP key for 3s, and automatically by the

internal time rFi. Cycle duration is set by the rFd parameter. The cycle can be stopped also by key.

OFF If rFI = 0 only manual cycle can be activated.

Set point If rFd = 0 the cycle is stopped only by pushing the key.

• Heating output: CUT IN is “SET_T-dbt”, CUT OUT is when the temperature reaches the set point.

• Compressor output CUT IN is “ SET_T +dbt”, CUT OUT is when the temperature reaches the set

point. 7. MATURING CYCLE WITH DRIPPING, RUNNING AND STOPPING PHASE.

3.1 DEFROST

During defrost the temperature control is disabled.

If the second relay is configured as defrost: oA2=dEF (XH360L terminals 9-10-11, XH360V

terminals 6-7) then two defrost modes are available through the “tdF” parameter: defrost with electrical

heater (tdF=rE) or hot gas (tdF= in). The defrost interval is control by means of parameter “EdF”:

(EdF=in) the defrost is made every “IdF” time, (EdF=Sd) the interval “IdF” is calculate through Smart

Defrost algorithm (only when the compressor is ON). At the end of defrost dripping time is started, set

by “Fdt” parameter.

To disable the defrost set the MdF parameter to zero

If oA2 is different from dEF, defrost is made only by stopping compressor (tdF=rE).

To disable defrosts set MdF=0.

Dripping Running Stopping Running Stopping

Humidity regulation during defrost depends on the Hud parameter.

With Hud=no humidity regulation is disabled. The diagrams displays a typical maturing cycle with the starting dripping phase.

Con Hud=yES humidity regulation is performed also during defrost. DRIPPING PHASE lasts for the “dri” time, without humidity control, temperature set is SETG

RUNNING PHASE lasts for the “on” time, both temperature and humidity are controlled.

4. HUMIDITY REGULATION STOPPING PHASE lasts for the “off” time, without any control of temperature and humidity.

The humidity regulation is performed through neutral zone, by humidifying dehumidifying actions. The end of the stopping phase is signalled by the internal buzzer and by the “End” message on the

Humidity control can be disabled setting the SET_RH to “nu” value. In this case only the temperature display.

control is perform. After the STOPPING PHASE the behaviour of the controller depends on the parameter trc, according

to the following settings:

4.1 HUMIDIFYING ACTION trc = co controller maintains the set points of the running phase

trc = in controller stop the regulation at all.

The humidifying action is done enabling the humidifier relay when the humidity is lower than the trc = cL controller performs the running and stopping phase till is stopped manually.

“SET_RH-dbH” value. trc = cLE as (trc = cL) plus at the end of each cycle the End label is displayed and the buzzer

The relay is switch off when humidity reaches the set values. is switched on.

1592002810 XH360L-V GB r1.0 28.09.12 XH360L – XH360V 1/5

7.1 HOW TO SET THE DURATION OF THE DRIPPING, RUNNING AND STOPPING PHASES In programming mode it browses the parameter codes or increases the displayed value.

1. Push the CLOCK key, the display shows on the bottom display the “dri” message, while the If oA2=ESt hold it pressed for 3s to start a extraction cycle

“hourglass” start flashing. To start a manual defrost: hold it pressed for at least 3s.

2. Push again the CLOCK the duration of the dipping phase is shown, hh:mm. In programming mode it browses the parameter codes or decreases the displayed value.

3. To set the duration push the UP and DOWN keys.

4. Push again the CLOCK to confirm the time and pass to the setting of the running phase: the “on” Switch ON and OFF the light, if present (oA1=lig)

message is displayed.

5. Push the CLOCK key to see its duration and use the UP and DOWN keys to set it.

6. Push again the CLOCK to confirm the time and pass to the setting of the stopping phase: the Start: to start the cycle

“oFF” message is displayed.

7. Push the CLOCK key to see its duration and use the UP and DOWN keys to set it.

8. Confirm the value by pushing again the CLOCK key and pass to the humidity display. Clock: to set the duration of the dripping (dri), running (on) and stopping (off) phases

7.2 HOW TO SET THE TARGET HUMIDITY OF THE RUNNING CYCLE

Switch ON and OFF the instrument.

1. Push the SET_RH key, the display shows on the bottom display the “SH1” message, while the

“set” icon starts flashing.

2. Push again the SET_RH the humidity set point of the running phase is shown. Set it using the UP KEY COMBINATIONS

and DOWN keys. To disable the humidity control during the freezing phase set it to “nu”.

3. Push again the SET_RH to confirm the value and pass to the humidity display.

+ To lock and unlock the keyboard

7.3 HOW TO SET THE TARGET TEMPERATURE OF THE DRIPPING AND RUNNING PHASES

+ To enter the programming mode.

1. Push the SET_T key, the display shows on the upper display the “StG” message, while the “set ”

icon starts flashing.

2. Push again the SET_T the temperature set point of the running phase is shown. Set it using the + To exit the programming mode.

UP and DOWN keys.

3. Push again the SET_T to confirm the value and pass to the setting of the dripping phase: the 8.1 ICONS AND SYMBOLS

“St1” message is displayed.

4. Push the SET_T key to see its value and use the UP and DOWN keys to set it. Each LED function is described in the following table.

7.4 HOW TO START THE CYCLE

LED2 LED3

Push and release START key: the led will be turned ON.

The led flashes during the proving phase Temperature Display

7.5 END OF THE CYCLE

When the timer has expired, the buzzer starts sounding and the bottom display shows the “End”

Humidity Display

message.

To mute the buzzer push a key: The display come back to show the humidity and the LED of the

START key is turned off.

LED4

7.6 HOW TO STOP THE CYCLE MANUALLY LED MODE FUNCTION

Led 4 ON - Instrument in stand by.

To stop the cycle manually push the ON/OFF key . - In “Pr2” indicates that the parameter is also present in “Pr1”.

ON °C

°F ON °C

7.7 HOW TO MODIFY THE SETTING OF THE CURRENT CYCLE WHILE IT’S RUNNING

ON The compressor is running

To modify the setting of the running cycle temperature (SET_T), humidity (SET_RH) or remaining time

(CLOCK):

FLASHING - Anti-short cycle delay enabled

1. Push twice the corespondent key: the setting value of the current phase (dripping or running) will

be displayed. ON The defrost is enabled

2. Modify it using the UP and DOWN keys

3. Confirm the value using the corespondent key: temperature (SET_T), humidity (SET_RH) or LED 3

remaining time (CLOCK). FLASHING Drip time in progress

NOTE: the changes made will be memorised. So the next cycle will start with the new values. LED 3

LED 2 FLASHING Programming Phase (flashing with LED3)

8. THE DISPLAY ON Heating enabled

FLASHING Temperature Set programming phase

(temp)

ON - ALARM signal

ON Fan is running

ON RH%

ON Dehumidifying enabled

ON Humidifying enabled

FLASHING Humidity Set programming phase

(umid)

ON Running phase is in progress

FLASHING Dripping or stopping phase is in progress

FLASHING Setting of the duration of the cycle

8.2 HOW TO SEE AND MODIFY THE SET POINT (TEMPERATURE AND HUMIDITY)

1. Push and immediately release the SET key: the display will show the Set point

valueand the correspondant set icon starts flashing;

2. To change the Set value push the o or n arrows within 10s.

3. To memorise the new set point value push the SET key again or wait 10s.

8.3 TO START A MANUAL DEFROST

1. Push the DEF key for more than 2 seconds and a manual defrost will start.

8.4 TO START A EXTRACTION CYCLE MANUALLY

To display and modify target temperature set point. (SET_T) for the running (St1)and the Hold pushed the UP key for more than 2 sec.

dripping (StG) phase. To stop manually the cycle: when the cycle is running, hold pushed the UP key for more

To display and modify target humidity set point (SET_RH) of the running (SH1) phase; in than 2 sec.

programming mode it selects a parameter or confirm an operation.

1592002810 XH360L-V GB r1.0 28.09.12 XH360L – XH360V 2/5

8.5 TO ENTER IN PARAMETERS LIST “PR1” tdF Defrost type: rE = electrical heater (Compressor OFF)

To enter the parameter list “Pr1” (user accessible parameters) operate as follows: in = hot gas (Compressor and defrost relays ON)

EdF Defrost mode: in = interval mode. The defrost starts when the time “Idf” is expired.

Sd = Smartfrost mode. The time IdF (interval between defrosts) is increased only when the

1. Enter the Programming mode by pressing the SET_RH+ n for few

compressor is running (even non consecutively).

+ seconds. (LED2&3 start flashing)

SdF Set point for SMARTFROST: (-3030 °C/ -22 86 °F) evaporator temperature which allows the

2. The instrument will show the first parameter present in “Pr1”

IdF counting (interval between defrosts) in SMARTFROST mode.

dtE Defrost termination temperature: (-50,0÷110,0°C; -58÷230°F) (Enabled only when the

8.6 TO ENTER IN PARAMETERS LIST “PR2” evaporator probe is present) sets the temperature measured by the evaporator probe which

causes the end of defrost.

To access parameters in “Pr2”:

IdF Interval between defrosts: (1÷120h) Determines the time interval between the beginning of two

1. Enter the “Pr1” level.

defrost cycles.

2. Select “Pr2” parameter and press the “ SET_RH ” key.

MdF Duration of defrost: (0÷255 min) When P2P = n, no evaporator probe, it sets the defrost

3. The “PAS” flashing message is displayed, shortly followed by “0 - -” with a flashing zero.

duration, when P2P = y, defrost end based on temperature, it sets the maximum length for

4. Use o or n to input the security code in the flashing digit; confirm the figure by pressing “

defrost.

SET_RH ”.

dFd Display during defrost:

The security code is “321“. rt = real temperature; it = temperature reading at the defrost start;

5. If the security code is correct the access to “Pr2” is enabled by pressing “ SET_RH ” on the last Set = set point; dEF = “dEF” label; dEG = “dEG” label;

digit. dAd Defrost display time out: (0255 min) Sets the maximum time between the end of defrost and

Another possibility is the following: after switching ON the instrument the user can push SET_RH + the restarting of the real room temperature display.

n keys within 30 seconds. Fdt Drain down time: (0÷60 min.) time interval between reaching defrost termination temperature

and the restoring of the control’s normal operation. This time allows the evaporator to eliminate

NOTE: each parameter in “Pr2” can be removed or put into “Pr1” (user level) by pressing SET_RH + n . water drops that might have formed due to defrost.

When a parameter is present in “Pr1” LED 4 is on. dPO First defrost after start-up: y = Immediately; n = after the IdF time

Hud Humidity control during defrost: no: the humidity control is stopped during the defrost; yES the

8.7 TO CHANGE PARAMETER VALUES humidity control works also during the defrost.

1. Enter the Programming mode. FANS

2. Select the required parameter with o or n . FnC Fan operating mode: C-n = running when a load is on, OFF during the defrost;

3. Press the “ SET_RH ” key to display its value (LED2&3 start blinking). C-y = running when a load is on, ON during the defrost;

4. Use o or n to change its value. O-n = continuous mode, OFF during the defrost; O-y = continuous mode, ON during the defrost;

5. Press “ SET_RH ” to store the new value and move to the following parameter. EXTRACTOR FANS

To exit: Press SET_RH + UP or wait 15s without pressing a key.

rFi Interval between 2 cycles of change of air (0÷120 ore; 0 = only manual starting)

NOTE: the new programming is stored even when the procedure is exited by waiting the time-out.

rFd Duration of change of air cycle (0÷250min; 0 = only manual stopping)

8.8 HOW TO LOCK THE KEYBOARD

TEMPERATURE ALARMS

ALC Temperature alarm configuration: rE = High and Low alarms related to Set Point

1. Keep the o and n keys pressed together for more than 3 s the o and n keys.

Ab = High and low alarms related to the absolute temperature.

2. The “POF” message will be displayed and the keyboard is locked. At this point it is ALL Low temperature alarm setting: ALC = rE , 0 50 °C or 90°F

only possible the viewing of the set point or the MAX o Min temperature stored and ALC = Ab , - 50°C or -58°F ALU

to switch ON and OFF the light, the auxiliary output and the instrument. when this temperature is reached and after the ALd delay time, the LA alarm is enabled,.

ALU High temperature alarm setting: ALC= rE, 0 50°C or 90°F

TO UNLOCK THE KEYBOARD ALC= Ab, ALL 110°C or 230°F

Keep the o and n keys pressed together for more than 3s. when this temperature is reached and after the ALd delay time the HA alarm is enabled.

ALH Temperature alarm recovery differential: (0,1÷25,5°C; 1÷45°F) Intervention differential for

recovery of temperature alarm.

8.9 ON/OFF FUNCTION ALd Temperature alarm delay: (0÷255 min) time interval between the detection of an alarm condition

By pushing the ON/OFF key, the instrument shows “OFF” for 5 sec. and the ON/OFF and the corresponding alarm signalling.

LED is switched ON. dAO Delay of temperature alarm at start-up: (0min÷23h 50min) time interval between the detection of

During the OFF status, all the relays are switched OFF and the regulations are stopped; the temperature alarm condition after the instrument power on and the alarm signalling.

N.B. During the OFF status the LED4 button is lighted. EdA Alarm delay at the end of defrost: (0 255 min) Time interval between the detection of the

temperature alarm condition at the end of defrost and the alarm signalling.

9. PARAMETER LIST dot Delay of temperature alarm after closing the door : (0255 min) Time delay to signal the

temperature alarm condition after closing the door.

REGULATION HUMIDITY ALARMS

dbt half dead band width for temperature: (0,1÷25,5°C; 1÷45°F) this band is place below and AHC Humidity alarm configuration: rE = High and Low alarms related to humidity Set Point

above the temperature set point (SET_T). The compressor is enabled when the temperature Ab = High and low alarms related to the “absolute” humidity.

increases and reaches the SET_T + dbt value. It is turned off when it comes back to the SET_T. AHL Low humidity alarm setting: (with AHC = rE: 0 ÷ 50. With AHC = Ab: Lci ÷ AHu)

The heating output is enabled when temperature is less than SET_T -dbt value and disabled when when this humidity is reached and after the AHd delay time, the HLA alarm is enabled,.

the SET_T is reached. AHu High humidity alarm setting: (with AHC = rE: 0÷50°C. with AHC = Ab: AHL ÷ uci

dbH half dead band width for humidity: (0,5÷25,5RH) this band is place below and above the when this humidity is reached and after the AHd delay time the HHA alarm is enabled.

humidity set point (SET_RH). The dehumidifying action is enabled when the humidity increases AHH Humidity alarm recovery differential: (0.5÷20.0) Intervention differential for recovery of humidity

and reaches the SET_RH + dbH value. It is stopped when it comes back to the SET_RH. The alarm.

humidifying output is enabled when humidity is less than SET_RH -dbH value and disabled when AHd Humidity alarm delay: (0÷255 min) time interval between the detection of an alarm condition and

the SET_RH is reached. the corresponding alarm signalling.

LS Minimum temperature set point limit: (-50,0°C SET; -58°F÷SET) Sets the minimum dHo Delay of humidity alarm at start-up: (0min÷23h 50min) time interval between the detection of the

acceptable value for the set point. humidity alarm condition after the instrument power on and the alarm signalling.

US Maximum temperature set point limit: (SET 110°C; SET÷230°F) Set the maximum acceptable doH Alarm delay at the end of defrost: (0255 min) Time interval between the detection of the

value for set point. humidity alarm condition at the end of defrost and the alarm signalling.

OdS Outputs activation delay at start up: (0÷255 min) This function is enabled at the initial start up doA Open door alarm delay:(0÷255 min) delay between the detection of the open door condition and

of the instrument and inhibits any output activation for the period of time set in the parameter. its alarm signalling: the flashing message “dA” is displayed.

(Light can work) tbA Alarm relay status after pushing a key: on= the relay remains on; off= the relay is switched off.

AC Anti-short cycle delay: (0÷30 min) interval between the compressor stop and the following nPS Pressure switch number: (0 15) Number of activation of the pressure switch, during the “did”

restart. interval, before signalling the alarm event (I1F= PAL).

tHu Kind of de-humidifying: db: only with de-humidifier relay (oA1= dEH) If the nPS activation in the “did” time is reached, switch off and on the instrument to

cHu with de-humidifier and compressor relay (oA1= dEH) restart normal regulation.

c-H: without de-humidifier relay, by means of compressor and heating relays (oA1 dEH).

LSH Minimum humidity set point limit: (Lci ÷ Set H) Sets the minimum acceptable value for the PROBE INPUTS

humidity set point. Ot Thermostat probe calibration: (-12.0 12.0°C/ -21 21°F) allows to adjust possible offset of the

uSH Maximum humidity set point limit: (Set H ÷ uci) Set the maximum acceptable value for thermostat probe.

humidity set point. OE Evaporator probe calibration: (-12.0 12.0°C/ -21 21°F) allows to adjust possible offsets of the

evaporator probe.

DISPLAY AND KIND OF REGULATION O3 Humidity probe calibration: (-1010 RH) allows to adjust possible offsets of the humidity probe.

P2P Evaporator probe presence: n= not present: the defrost stops only by time; y= present: the

CF Measurement unit: °C= Celsius; °F= Fahrenheit defrost stops by temperature and time.

rES Resolution (for °C): allows decimal point display. dE = 0,1°C; in = 1 °C P3P Humidity probe presence: n= not present; y= present.

rEH Resolution for RH%: in = integer; Hd= half digit. LCI Readout with 4 mA : (-999 ÷ 999). Adjustment of read out corresponding to 4mA signal.

trC Kind of behaviour after the end of the cycle UCI Readout with 20 mA : (-999 ÷ 999). Adjustment of read out corresponding to 20mA signal.

trC=co the controller goes on working, and maintains the temperature and humidity of the running

phase, till the controller is stopped.

trC=in at the end of the stopping phase the controller gives the “End” message, the buzzer is DIGITAL INPUTS

turned on, and the regulation is stopped. i1P Digital input polarity: CL : the digital input is activated by closing the contact; OP : the

trC=cL at the end of the stopping phase the controller gives the “End” message, the buzzer is digital input is activated by opening the contact

turned on, and the regulation restarts from the running phase i1F Digital input operating mode: configure the digital input function: EAL = generic alarm;

trC=cLE at the end of the stopping phase the regulation restarts from the running phase. bAL = serious alarm mode; PAL = Pressure switch; Ht = heating relay safety; dor = door switch

odc Outputs status when open door: on = normal; Fan = Fan OFF; oFF = all the loads off

DEFROST

1592002810 XH360L-V GB r1.0 28.09.12 XH360L – XH360V 3/5

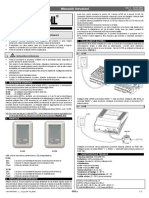

rrd Outputs restarting after doA alarm: no = outputs not affected by the doA alarm; yES = outputs 11.2 XH360V: CUT OUT

restart with the doA alarm;

did Time interval/delay for digital input alarm:(0 255 min.) Time interval to calculate the number of

the pressure switch activation when I1F=PAL. If I1F=EAL or bAL (external alarms), “did” parameter

defines the time delay between the detection and the successive signalling of alarms.

OTHER 56

oA1 Light relay configuration (XH360L terminals 3-4, XH360V terminals. 11-12): ALr = alarm;

72

83,5

dEH = dehumidifier; onF = on/off relay: close with instrument on, open with instrument off; Lig =

light, ESt, dEF not select

oA2 Configuration of the defrost / extractor fans relay (XH360L terminals 9-10-11, XH360V

terminals 6-7) dEH = not select; onF = on/off relay: close with instrument on; open with

instrument on; Lig =Light , ESt = extractor fan; dEF = defrost relay.

Adt RS485 serial address for temperature loads (0÷247) identifies the instrument within a control or

supervising system.

AdH RS485 serial address for humidity loads (0÷247) identifies the instrument within a control or

supervising system.

Ptb Parameter table: (read only) it shows the original code of the dIXEL parameter map. 40

rEL Software release: (read only) Software version of the microprocessor.

Prd Probes display: (read only) display the temperature values of the evaporator probe Pb2. 12. ELECTRICAL CONNECTIONS

Pr2 Access to the protected parameter list (read only).

The instruments are provided with screw terminal block to connect cables with a cross section up to 2,5

mm2 for the digital and analogue inputs. Relays and power supply have a Faston connection (6,3mm).

10. DIGITAL INPUT Heat-resistant cables have to be used. Before connecting cables make sure the power supply complies

with the instrument’s requirements. Separate the probe cables from the power supply cables, from the

One digital input is present configurable by user by means of the i1F parameter according to the outputs and the power connections. Do not exceed the maximum current allowed on each relay, in case

following descriptions. of heavier loads use a suitable external relay.

N.B. Maximum current allowed for all the loads is 20A.

10.1 DOOR SWITCH (I1F = dor)

It signals the door status and the corresponding relay output status through the “odc” parameter: no = 12.1 PROBE CONNECTIONS

normal (any change); Fan = Fan OFF; oFF = all the loads are switched off. The probes shall be mounted with the bulb upwards to prevent damages due to casual liquid infiltration.

Since the door is opened, after the delay time set through parameter “dOA”, the alarm output is enabled It is recommended to place the thermostat probe away from air streams to correctly measure the

and the display shows the message “dA”. average room temperature.

The status of loads depends on the “rrd” parameter:

with rrd=no outputs are not affected by the doA alarm;

13. HOW TO USE THE HOT KEY

with rrd=yES = outputs restart with the doA alarm;

The alarm stops as soon as the external digital input is disabled again. During this time and then for the 13.1 HOW TO PROGRAM A HOT KEY FROM THE INSTRUMENT (UPLOAD)

delay “dot” and “doH” after closing the door, the temperature and humidity alarms are disabled. 1. Program one controller with the front keypad.

2. When the controller is ON, insert the “Hot key” and push o key; the "uPL" message appears

10.2 GENERIC ALARM (I1F = EAL) followed a by flashing “End”

As soon as the digital input is activated the unit will wait for “did” time delay before signalling the “EAL” 3. Push “SET” key and the End will stop flashing.

alarm message. The outputs status don’t change. The alarm stops just after the digital input is de- 4. Turn OFF the instrument remove the “Hot Key”, then turn it ON again.

activated.

NOTE: the “Err” message is displayed for failed programming. In this case push again o key if you

10.3 SERIOUS ALARM MODE (I1F = BAL) want to restart the upload again or remove the “Hot key” to abort the operation.

When the digital input is activated, the unit will wait for “did” delay before signalling the “bAL” alarm

message. The relay outputs are switched OFF. The alarm will stop as soon as the digital input is de- 13.2 HOW TO PROGRAM AN INSTRUMENT USING A HOT KEY (DOWNLOAD)

activated. 1. Turn OFF the instrument.

2. Insert a programmed “Hot Key” into the 5 PIN receptacle and then turn the Controller ON.

10.4 PRESSURE SWITCH (I1F = PAL) 3. Automatically the parameter list of the “Hot Key” is downloaded into the Controller memory, the

If during the interval time set by “did” parameter, the pressure switch has reached the number of “doL” message is blinking followed a by flashing “End”.

activation of the “nPS” parameter, the “PAL” pressure alarm message will be displayed. The 4. After 10 seconds the instrument will restart working with the new parameters.

compressor and the regulation are stopped. When the digital input is ON the compressor is always OFF. 5. Remove the “Hot Key”..

If the nPS activation in the did time is reached, switch off and on the instrument to restart

normal regulation. NOTE the message “Err” is displayed for failed programming. In this case turn the unit off and then on if

you want to restart the download again or remove the “Hot key” to abort the operation.

10.5 HEATING RELAY SAFETY (i1F=Ht)

14. ALARM SIGNALLING

With i1F=Ht as soon as the digital input is activated for “did” time heating relay is disabled.

The alarm will stop as soon as the digital input is de-activated. Message Cause Outputs

“P1” Thermostat probe failure Compressor and heating outputs off

10.6 DIGITAL INPUTS POLARITY “P2” Evaporator probe failure Defrost and by time

The digital input polarity depends on the “i1P” parameters. “P3” Humidity probe failure Humidity regulation off

CL : the digital input is activated by closing the contact. “HA” High temperature alarm Outputs unchanged

OP : the digital input is activated by opening the contact “LA” Low temperature alarm Outputs unchanged

“HHA” High humidity alarm Outputs unchanged

11. INSTALLATION AND MOUNTING “HLA” Low humidity alarm Outputs unchanged

Instruments XW360L shall be mounted on vertical panel, in a 150x31 mm hole, and fixed using two “dA” Door switch alarm Outputs depending on the odC parameter

screws 3 x 2mm. To obtain an IP65 protection grade use the front panel rubber gasket (mod. RG-L). “EAL” External alarm Other outputs unchanged

Instrument XH360V shall be mounted on vertical panel, in a 72x56 mm hole, and fixed using screws 3 “BAL” Serious external alarm Outputs OFF

x 2mm. To obtain an IP65 protection grade use the front panel rubber gasket (mod. RG-V).

“PAL” Pressure switch alarm Outputs OFF

The temperature range allowed for correct operation is 0 - 60 °C. Avoid places subject to strong

vibrations, corrosive gases, excessive dirt or humidity. The same recommendations apply to probes. Let

the air circulate by the cooling holes. The alarm message is displayed until the alarm condition recoveries.

All the alarm messages are showed alternating with the room temperature except for the “P1” which is

11.1 XH360L: CUT OUT flashing. To reset the “EE” alarm and restart the normal functioning press any key, the “rSt” message is

+1 displayed for about 3s.

165 -1

+0.5

150 -0 14.1 SILENCING BUZZER

Once the alarm signal is detected the buzzer, if present, can be silenced by pressing any key.

+0.5

-0

14.2 ALARM RECOVERY

31

Probe alarms : “P1” (probe1 faulty), “P2”, “P3”; they automatically stop 10s after the probe restarts

normal operation. Check connections before replacing the probe.

Temperature alarms “HA” and “LA” automatically stop as soon as the thermostat temperature returns

Ø3 x2 to normal values or when the defrost starts.

Humidity alarms “HHA” and “LHA” automatically stop as soon as the humidity returns to normal values.

Door switch alarm “dA” stop as soon as the door is closed.

External alarms “EAL”, “BAL” stop as soon as the external digital input is disabled

Pressure switch alarm “PAL” alarm is recovered by switching OFF the instrument.

1592002810 XH360L-V GB r1.0 28.09.12 XH360L – XH360V 4/5

Label Value Menu Description Range

dtE 8.0 Pr2 Defrost termination temperature -50,0÷110°C/ -58÷230°F

15. TECHNICAL DATA idF 6 Pr1 Interval between defrosts 1 ÷ 120 h

Housing: self extinguishing ABS. MdF 20 Pr1 Duration of defrost 0 ÷ 250 min

Case: XH360L: facia 38x185 mm; depth 76mm; XH360V: facia 100x64 mm; depth 76mm dFd it Pr2 Display during defrost rt / it / SEt / dEF / dEG

Mounting: XH360L: panel mounting in a 150x31 mm panel cut-out with two screws. 3 x 2mm.

dAd 30 Pr2 Defrost display time out 0 ÷ 250 min

Distance between the holes 165mm

XH360L: panel mounting in a 56x72 mm panel cut-out with two screws. 3x2mm. Distance Fdt 0 Pr2 Draining time 0÷60 min.

between the holes 40mm dPo no Pr2 First defrost after start up n÷y

Protection: IP20. Hud no Pr2 Humidity control during defrost no; yES

Frontal protection: IP65 with optional frontal gasket mod. RG-L (XH360L); RGW-V (XH360V).. Fnc c-n Pr2 Fan operating mode c-n / c-Y / o-n / o-Y

Connections: Screw terminal block 2,5 mm2 heat-resistant wiring and 6,3mm Faston rFi 0 Pr2 Interval between 2 cycles of change of air 1 ÷ 120 h (0 = manual start)

Power supply: 230Vac or 110Vac 10%; Power absorption: 7VA max. rFd 0 Pr2 Duration of cycle of change of air 1 ÷ 250 min (0 = manual stop)

Display: double display + icons. ALc Ab Pr2 Temperature alarm configuration rE = relative / Ab = absolute

Inputs: 1 NTC probe + 4÷20mA probe ALL Low temperature alarm setting 0°C ÷ 50.0°C / -50.0°C ÷ ALu

-40.0 Pr1

Digital input: 1 free voltage

ALu 110 Pr1 High temperature alarm setting 0°C ÷ 50.0°C / ALL ÷ 110°C

Relay outputs: compressor: XH360L: relay SPST 20(8) A, 250Vac;

XH360V: relay SPST 8(3) A, 250Vac; ALH 1.0 Pr2 Temperature alarm recovery differential 0.1°C o 1°F ÷ 25°C o 77°F

heather: relay SPST 8(3) A, 250Vac; defrost/extractor: relay SPST 8(3) A, 250Vac ALd 15 Pr2 Temperature alarm delay 0 ÷ 250 min

fans: relay SPST 8(3) A, 250Vac; humidifier: relay SPST 8(3) A, 250Vac dAo 1.3 Pr2 Delay of temperature alarm at start-up 0.0 ÷ 23.5 h

de-humidifier/light: relay SPST 8(3) A, 250Vac EdA 20 Pr2 Alarm delay at the end of defrost 0 ÷ 250 min

Other output : alarm buzzer (optional) dot 20 Pr2 Delay of temperature alarm after closing the 0 ÷ 250 min

Data storing: on the non-volatile memory (EEPROM). door

Kind of action: 1B.; Pollution grade: normal; Software class: A. AHc Ab Pr2 Humidity alarm configuration rE = relative / Ab = absolute

Operating temperature: 0÷60 °C.; Storage temperature: -25÷60 °C. AHL 0.0 Pr1 Low humidity alarm setting 0 ÷ 50 / Lci ÷ AHu

Relative humidity: 2085% (no condensing)

AHu 100 Pr1 High humidity alarm setting 0 ÷ 50 / AHL ÷ uci

Measuring and regulation range:

NTC probe: -40÷110°C (-58÷230°F) AHH 2.0 Pr2 Humidity alarm recovery differential 0.5 ÷ 25

Resolution: 0,1 °C or 1°C or 1 °F (selectable). AHd 15 Pr2 Humidity alarm delay 0 ÷ 250 min

Accuracy (ambient temp. 25°C): ±0,5 °C ±1 digit dHo 1.3 Pr2 Delay of humidity alarm at start-up 0.0 ÷ 23.5 h

Housing: self extinguishing ABS. doH 20 Pr2 Alarm delay at the end of defrost 0 ÷ 250 min

doA 20 Pr2 Open door alarm delay 0 ÷ 250 min ( 250 = nu )

16. WIRING CONNECTIONS tbA oFF Pr2 Relay status after pushing a key on÷oFF

nPS 15 Pr2 Pressure switch number 0÷15

16.1 XH360L ot 0.0 Pr1 Thermostat probe calibration -12.0 ÷ 12.0

oE 0.0 Pr2 Evaporator probe calibration -12.0 ÷ 12.0

8(3)A 8(3)A 8(3)A 8(3)A 8(3)A 20(8)A 8(3)A o3 0.0 Pr1 Humidity probe calibration -10 ÷ 10

250V~ 250V~ 250V~ 250V~ 250V~ 250V~ 250V~

P2P YES Pr2 Evaporator probe presence no = absent / YES = present

P3P YES Pr2 Humidity probe presence no = absent / YES = present

Lci 0.0 Pr2 Readout with 4 mA -999 ÷ 999

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 13 14 15 16 17 18 19 20 uci 100 Pr2 Readout with 20 mA -999 ÷ 999

N L

De-Hum Def N.C. i1P cL Pr2 Digital input polarity cL =open / oP = close

Room

Def

Heater Hum Fan Comp Digital

Light Extractor Input i1F dor Pr2 Digital input configuration dor / PAL / EAL / bAL / Ht

Supply 115Vac: 14-15 terminals odc FAn Pr2 Outputs status when open door on / Fan / oFF

rrd YES Pr2 Outputs restarting after doA alarm no = no / YES = yes

16.2 XH360V did 0 Pr2 Digital input alarm delay 0÷255 min.

oA1 LiG Pr2 Light relay configuration (XH360L ALr = alarm; dEH =

C terminals 3-4, XH360V terminals. 11-12) dehumidifier; onF = on/off;

Hum Fan Def N.C. Comp Lig = light, ESt, dEF not

select

oA2 ESt Pr2 Light relay configuration (XH360L ALr = alarm; dEH = not use;

8(3)A

8(3)A

8(3)A

8(3)A

8(3)A

MAX

20A 8(3)A250V~ terminals 9-10-11, XH360V terminals 6-7) onF = on/off; Lig = light, ESt=

extractor, dEF =defrost

Adt 1 Pr2 Serial address for temperature 0÷247 num

AdH 1 Pr2 Serial address for humidity 0÷247 num

Room

Def.

Ptb --- Pr2 Parameter table ---

Heater rEL --- Pr2 Software release ---

Prd --- Pr2 Probes display Pb1÷Pb3

Supply 115Vac: 2-3 terminals Pr2 --- Pr1 Access to the protected parameter list ---

17. DEFAULT SETTING VALUES

Set temperature Set humidity Duration

Dripping Phase 5.0 °C -- 5.00 h

Running Phase 5.0 °C 50.0 RH% 5.00 h

Stopping Phase - - 5.00 h

Label Value Menu Description Range

dbt 2.0 Pr1 Half dead band width for temperature 0.1°C o 1°F ÷ 25°C o 77°F

dbH 5.0 Pr1 Half dead band width for humidity 0.5 ÷ 50

LS -40.0 Pr2 Minimum temperature set point limit -50.0°C o –58°F ÷ Set T

uS 110 Pr2 Maximum temperature set point limit Set T ÷ 110°C o 230°F

odS 1 Pr2 Outputs activation delay at start up 0 ÷ 250 min

Ac 1 Pr1 Anti-short cycle delay 0 ÷ 30 min

tHu c-H Pr2 Humidity regulation db = dehumidifier relay.; cHu

= dehum+ compr.; c-H=

without dehum. relay

LSH 0.0 Pr2 Minimum humidity set point limit Lci ÷ Set H

uSH 100 Pr2 Maximum humidity set point limit Set H ÷ uci

cF °C Pr2 Measurement unit °C ÷°F

rES dE Pr2 Resolution (for °C): in = integer / dE = decimal

rEH Hd Pr2 Resolution for RH%: in = integer / Hd = half digit

trC co Pr2 Instrument behaviour at the end of the cycle co=start holding, in=stop

regulation, cL=restart the first

phase+End message; cLE =

restart the first phase

tdF rE Pr2 Defrost type rE, rT, in

EdF in Pr2 Defrost mode In, Sd

SdF 0.0 Pr2 Set point for SMART DEFROST -30 ÷ +30°C / -22÷+86°F

1592002810 XH360L-V GB r1.0 28.09.12 XH360L – XH360V 5/5

You might also like

- XH260L - XH260V: Dixell Operating InstructionsDocument4 pagesXH260L - XH260V: Dixell Operating InstructionsJennifer Eszter SárközyNo ratings yet

- Dixell Operating Instructions: Temperature and Humidity Controller For Freezing - Proving CabinetsDocument5 pagesDixell Operating Instructions: Temperature and Humidity Controller For Freezing - Proving CabinetsJennifer Eszter SárközyNo ratings yet

- XH260L-V GB r1.0 29.02.2007Document4 pagesXH260L-V GB r1.0 29.02.2007Jennifer Eszter SárközyNo ratings yet

- XH240L-V GB r1.0 12.01.2004Document4 pagesXH240L-V GB r1.0 12.01.2004Jennifer Eszter SárközyNo ratings yet

- XH360L VDocument5 pagesXH360L VJorge CantanteNo ratings yet

- Dixell XH240K - GBDocument4 pagesDixell XH240K - GBionut ciobanuNo ratings yet

- 2shudwlqjlqvwuxfwlrqv: 1. General WarningDocument5 pages2shudwlqjlqvwuxfwlrqv: 1. General WarningIov IftodeNo ratings yet

- xlh260 en GB 3723144Document15 pagesxlh260 en GB 3723144tictoknormanNo ratings yet

- XR70C - XR70D - XR72C: Digital Controller With Defrost and Fans ManagementDocument4 pagesXR70C - XR70D - XR72C: Digital Controller With Defrost and Fans ManagementJennifer Eszter SárközyNo ratings yet

- XR70C-D XR72C GB r1.0 18.11.2015Document4 pagesXR70C-D XR72C GB r1.0 18.11.2015Jennifer Eszter SárközyNo ratings yet

- XW360K XW370K: Installing and Operating InstructionsDocument6 pagesXW360K XW370K: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- Hướng dẫn sử dụng bộ điều khiển nhiệt độ Dixell-XR72CXDocument4 pagesHướng dẫn sử dụng bộ điều khiển nhiệt độ Dixell-XR72CXVĩnhNo ratings yet

- XR10C - XR10D: Digital Controller With Cooling or Heating ActionDocument4 pagesXR10C - XR10D: Digital Controller With Cooling or Heating ActionJennifer Eszter SárközyNo ratings yet

- XR30C - XR30D: Digital Controller With Off Cycle DefrostDocument4 pagesXR30C - XR30D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- XR30C - XR30D: Installing and Operating InstructionsDocument4 pagesXR30C - XR30D: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- 100% Outdoor Air Dehumidifier Control Strategies: Technical Bulletin 20Document4 pages100% Outdoor Air Dehumidifier Control Strategies: Technical Bulletin 20Việt Đặng XuânNo ratings yet

- XR30C - XR30D: Digital Controller With Off Cycle DefrostDocument4 pagesXR30C - XR30D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- XR60C - XR60D: Digital Controller With Defrost and Fans ManagementDocument4 pagesXR60C - XR60D: Digital Controller With Defrost and Fans ManagementHaiam BordaNo ratings yet

- XR20C - XR20D: Digital Controller With Off Cycle DefrostDocument4 pagesXR20C - XR20D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- XR70C - XR70D - XR72C: Installing and Operating InstructionsDocument4 pagesXR70C - XR70D - XR72C: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- XR10C - XR10D: Digital Controller With Cooling or Heating ActionDocument4 pagesXR10C - XR10D: Digital Controller With Cooling or Heating ActionJennifer Eszter SárközyNo ratings yet

- XR20C - XR20D: Installing and Operating InstructionsDocument4 pagesXR20C - XR20D: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- Xr70ch Installing Operating Instructions en GB 3843022Document5 pagesXr70ch Installing Operating Instructions en GB 3843022Hadi OktriantoNo ratings yet

- Company Directive: Standard Technique: Sp1NDocument9 pagesCompany Directive: Standard Technique: Sp1Nmir intequabNo ratings yet

- XR77CX: Installing and Operating InstructionsDocument5 pagesXR77CX: Installing and Operating InstructionsVũ Hằng PhươngNo ratings yet

- Digital Controler - Pizza de VerdadDocument5 pagesDigital Controler - Pizza de VerdadEdison EspinalNo ratings yet

- Xr70cx RTC GB DixellDocument4 pagesXr70cx RTC GB DixellTeknik1 sultengNo ratings yet

- EWPC 974: Freezer ControlDocument3 pagesEWPC 974: Freezer ControlFlávio MatosNo ratings yet

- Dixell xw260lDocument4 pagesDixell xw260lMiftakhul KhoirNo ratings yet

- DEI107J AU ManualDocument2 pagesDEI107J AU ManualAddy Born100% (1)

- XR40CX GBDocument4 pagesXR40CX GBmoosaNo ratings yet

- XR75CX GBDocument5 pagesXR75CX GBNelson JesusNo ratings yet

- ManualsLib - Makes It Easy To Find Manuals Online!Document4 pagesManualsLib - Makes It Easy To Find Manuals Online!Sheila Rose Bacerra-VillafloresNo ratings yet

- XR20C - XR20D: Digital Controller With Off Cycle DefrostDocument4 pagesXR20C - XR20D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- XR70CX: Digital Controller With Defrost and Fan ManagementDocument5 pagesXR70CX: Digital Controller With Defrost and Fan ManagementZackyExlipzNo ratings yet

- Tu Eng Guidelines2018-2Document23 pagesTu Eng Guidelines2018-2Island SkorpiosNo ratings yet

- XR06CX: 1. Contents 7. Front Panel CommandsDocument3 pagesXR06CX: 1. Contents 7. Front Panel Commandsjicutu100% (1)

- Dixell XV105D PDFDocument2 pagesDixell XV105D PDFdbricchiNo ratings yet

- PosDocument2 pagesPosJuanluis SernaqueNo ratings yet

- EKC 315A Danfoss Rs8cS302Document16 pagesEKC 315A Danfoss Rs8cS302davebigelow42No ratings yet

- XW20LR XW20LRH ManualDocument5 pagesXW20LR XW20LRH Manualshram444aaNo ratings yet

- XR06CXDocument3 pagesXR06CXRidwan PramudyaNo ratings yet

- Hoffman AC SizingDocument4 pagesHoffman AC SizingRichard YentumiNo ratings yet

- Dixell XR60CDocument4 pagesDixell XR60CCarlos0% (1)

- Psychrometric Data EngDocument1 pagePsychrometric Data EngMc Jason LaureteNo ratings yet

- XW263LDocument4 pagesXW263L270cdi aaNo ratings yet

- Rcf-230td Inst en SV de FRDocument19 pagesRcf-230td Inst en SV de FRkuatifansyahNo ratings yet

- 100% Outdoor Air Dehumidification Methods: Technical Bulletin 16Document6 pages100% Outdoor Air Dehumidification Methods: Technical Bulletin 16Fatiga jrNo ratings yet

- Econo Miz orDocument7 pagesEcono Miz orCantir DumitruNo ratings yet

- XR60CDocument4 pagesXR60CbrandboyvivekNo ratings yet

- Thermal Work Limits Conversion Booklet: Vane AnemometerDocument24 pagesThermal Work Limits Conversion Booklet: Vane AnemometerCommando crawlerNo ratings yet

- Antoine'sDocument3 pagesAntoine'sGarcia RaphNo ratings yet

- Controller For DHW Heat Pump Heaters: EN EnglishDocument4 pagesController For DHW Heat Pump Heaters: EN EnglishToussaintNo ratings yet

- XW60LR-XW60LRH RTC GB r2.0 14.02.2014Document6 pagesXW60LR-XW60LRH RTC GB r2.0 14.02.2014shram444aaNo ratings yet

- Medium Explanation of Eco-BOOST (TM), November 21, 2022Document4 pagesMedium Explanation of Eco-BOOST (TM), November 21, 2022Bechara ASSOUADNo ratings yet

- xr60ch en GB 3843020Document4 pagesxr60ch en GB 3843020Ra CubikNo ratings yet

- Manual AURATON 2030 2030RTH en PDFDocument32 pagesManual AURATON 2030 2030RTH en PDFradomir46No ratings yet

- XW60K GBDocument6 pagesXW60K GBsdsdNo ratings yet

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- XR20C - XR20D: Digital Controller With Off Cycle DefrostDocument4 pagesXR20C - XR20D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- Installing and Operating Instructions: DixelDocument4 pagesInstalling and Operating Instructions: DixelJennifer Eszter SárközyNo ratings yet

- Installing and Operating Instructions: DixelDocument4 pagesInstalling and Operating Instructions: Dixeldorin stoicuNo ratings yet

- XR70C - XR70D - XR72C: Installing and Operating InstructionsDocument4 pagesXR70C - XR70D - XR72C: Installing and Operating InstructionsJennifer Eszter SárközyNo ratings yet

- XEC GB Rel.1.0 17.02.2014Document16 pagesXEC GB Rel.1.0 17.02.2014Jennifer Eszter SárközyNo ratings yet

- XW60LS GB Rel.1.0 27.10.06Document4 pagesXW60LS GB Rel.1.0 27.10.06Jennifer Eszter SárközyNo ratings yet

- iCOOLL v1.1 26.04.2004Document2 pagesiCOOLL v1.1 26.04.2004Jennifer Eszter SárközyNo ratings yet

- XR70C-D XR72C GB r1.0 18.11.2015Document4 pagesXR70C-D XR72C GB r1.0 18.11.2015Jennifer Eszter SárközyNo ratings yet

- XR70C - XR70D - XR72C: Digital Controller With Defrost and Fans ManagementDocument4 pagesXR70C - XR70D - XR72C: Digital Controller With Defrost and Fans ManagementJennifer Eszter SárközyNo ratings yet

- XT11S IT GB r1.0 18.06.2004Document1 pageXT11S IT GB r1.0 18.06.2004Jennifer Eszter SárközyNo ratings yet

- XT110C - XT111C - XT110D - XT111D: Single Stage Digital Controller With Multi Probe InputDocument4 pagesXT110C - XT111C - XT110D - XT111D: Single Stage Digital Controller With Multi Probe InputJennifer Eszter SárközyNo ratings yet

- XT130C - XT131C - XT130D - XT131D: Dead Band Digital Controllers With Multi Probe InputDocument4 pagesXT130C - XT131C - XT130D - XT131D: Dead Band Digital Controllers With Multi Probe InputJennifer Eszter SárközyNo ratings yet

- DixellDocument2 pagesDixellHoàngViệtAnhNo ratings yet

- XC440C XC440D 04Document27 pagesXC440C XC440D 04novato1328No ratings yet

- XR100C GB r3.0 10.10.2001Document1 pageXR100C GB r3.0 10.10.2001Jennifer Eszter SárközyNo ratings yet

- XR20C - XR20D: Digital Controller With Off Cycle DefrostDocument4 pagesXR20C - XR20D: Digital Controller With Off Cycle DefrostJennifer Eszter SárközyNo ratings yet

- Dixell 121C ControllerDocument4 pagesDixell 121C ControllerDorin50% (2)

- XJM60D EN r1.1 29.11.2013Document6 pagesXJM60D EN r1.1 29.11.2013Jennifer Eszter SárközyNo ratings yet

- XT110-115 GB r4.0 20.11.00Document2 pagesXT110-115 GB r4.0 20.11.00Jennifer Eszter SárközyNo ratings yet

- XC460D GB r2.1 08.01.2010Document25 pagesXC460D GB r2.1 08.01.2010Jennifer Eszter SárközyNo ratings yet

- XT141C SSR GB r1.0 30.07.04Document4 pagesXT141C SSR GB r1.0 30.07.04Jennifer Eszter SárközyNo ratings yet

- XW230K GB r1.0 04.08.2015Document2 pagesXW230K GB r1.0 04.08.2015Jennifer Eszter SárközyNo ratings yet

- XT210C - XT211C: Single Stage Digital Controller With Multi Probe InputDocument3 pagesXT210C - XT211C: Single Stage Digital Controller With Multi Probe InputJennifer Eszter Sárközy100% (1)

- XT141C-D GB r1.0 06.03.2007Document4 pagesXT141C-D GB r1.0 06.03.2007Jennifer Eszter SárközyNo ratings yet

- Dixell XR60CDocument4 pagesDixell XR60CCarlos0% (1)

- Dixel: Monitoring UnitDocument47 pagesDixel: Monitoring UnitJennifer Eszter SárközyNo ratings yet

- XC10CX and XC30CX: Digital Controller For CDU ManagementDocument4 pagesXC10CX and XC30CX: Digital Controller For CDU ManagementJennifer Eszter SárközyNo ratings yet

- 6rshudwlqjlqvwuxfwlrqv: Multifunction Digital Controller For RefrigerationDocument4 pages6rshudwlqjlqvwuxfwlrqv: Multifunction Digital Controller For RefrigerationJennifer Eszter SárközyNo ratings yet

- XR10C - XR10D: Digital Controller With Cooling or Heating ActionDocument4 pagesXR10C - XR10D: Digital Controller With Cooling or Heating ActionJennifer Eszter SárközyNo ratings yet

- F Series Handpunch Modem: Installation InstructionsDocument8 pagesF Series Handpunch Modem: Installation Instructionsmartin_jaitmanNo ratings yet

- CPICHPSCPThre EDCH2 MSDocument17 pagesCPICHPSCPThre EDCH2 MSSieh Weeze100% (1)

- FocalDocument48 pagesFocalKing Bangayan100% (2)

- MB Manual Ga-z97x-Gaming3 eDocument116 pagesMB Manual Ga-z97x-Gaming3 eMihai PopaNo ratings yet

- Brand Worcester Digistat Optimiser 87161144620 ENDocument36 pagesBrand Worcester Digistat Optimiser 87161144620 ENJohn WalesNo ratings yet

- Catalog Materiale Electrice FlukeDocument140 pagesCatalog Materiale Electrice FlukeFlorinNo ratings yet

- HSUPA Interference Cancellation ReceiverDocument10 pagesHSUPA Interference Cancellation Receivershailendra pathakNo ratings yet

- MGate 5105 MB EIP SeriesDocument2 pagesMGate 5105 MB EIP SeriesDian Muhammad AdamNo ratings yet

- Power Cable LIOADocument28 pagesPower Cable LIOAHùng NguyễnNo ratings yet

- Monitor Huntleigh SC1000 Service ManualDocument66 pagesMonitor Huntleigh SC1000 Service ManualHomeroLeon100% (3)

- The Visual Language of Electrical Engineering: Edsa Technical 2000Document7 pagesThe Visual Language of Electrical Engineering: Edsa Technical 2000Luis FebresNo ratings yet

- RG6 S60 CCSDocument1 pageRG6 S60 CCSTiên TiênNo ratings yet

- MMG 1070/. TS: Eddy Current Displacement SensorDocument2 pagesMMG 1070/. TS: Eddy Current Displacement Sensorimant197812gmail.comNo ratings yet

- ModiconM218 CatalogueDocument84 pagesModiconM218 CatalogueSagar JadhavNo ratings yet

- 5.syllabus - Deb1053 - Electronic WorkshopDocument8 pages5.syllabus - Deb1053 - Electronic WorkshopadibNo ratings yet

- CCTV and Acs Single Line DiagramDocument2 pagesCCTV and Acs Single Line DiagramCode JonNo ratings yet

- Powerlogic™ Ion7550 / Ion7650: Energy and Power Quality MeterDocument16 pagesPowerlogic™ Ion7550 / Ion7650: Energy and Power Quality MeterFlavio Tonello TavaresNo ratings yet

- App Arm JtagDocument33 pagesApp Arm Jtagcarver_uaNo ratings yet

- MX-6070V, MX-5050N, MX-5070N, MX-6050N, MX-6070N Service ManualDocument457 pagesMX-6070V, MX-5050N, MX-5070N, MX-6050N, MX-6070N Service Manualkenny2021No ratings yet

- Jee & Neet-Current Electricity Question BankDocument257 pagesJee & Neet-Current Electricity Question BankYash100% (2)

- ARGOS CB CE ConformityDocument2 pagesARGOS CB CE ConformityANDRES GUTIERREZNo ratings yet

- Practical Electronics - SWG - Wikibooks, Open Books For An Open WorldDocument5 pagesPractical Electronics - SWG - Wikibooks, Open Books For An Open WorldSandeep Kumar SinghNo ratings yet

- Led Display PDFDocument12 pagesLed Display PDFIrwin DarmansyahNo ratings yet

- SEMICONDUCTOR THEORY Questions and Answers PDF:-: A. Covalent B. Electrovalent C. Co-Ordinate D. None of The AboveDocument5 pagesSEMICONDUCTOR THEORY Questions and Answers PDF:-: A. Covalent B. Electrovalent C. Co-Ordinate D. None of The AboveAbhishek KushwahaNo ratings yet

- OptiX PTN 900 Products BrochureDocument5 pagesOptiX PTN 900 Products BrochureMirza Ghulam SarwarNo ratings yet

- Drive KDL16 Parametros Kone 972483D01 Parameter ListDocument10 pagesDrive KDL16 Parametros Kone 972483D01 Parameter Listmohammedalathwary100% (1)

- Relé Falta de Fase CM-PFEDocument7 pagesRelé Falta de Fase CM-PFEJoao Andre MarquesNo ratings yet

- Huawei eRAN6.0 MIMO Feature Introduction: Node B Products of HuaweiDocument36 pagesHuawei eRAN6.0 MIMO Feature Introduction: Node B Products of HuaweiSaghir TahirNo ratings yet

- C InstrumentationDocument12 pagesC Instrumentation@@ngNo ratings yet

- Green-Mode PWM Controller With Frequency Swapping and Integrated ProtectionsDocument17 pagesGreen-Mode PWM Controller With Frequency Swapping and Integrated ProtectionsAlex GerasimenkoNo ratings yet