Professional Documents

Culture Documents

Detalles Tipicos de Viga Aashto

Uploaded by

Carlos SaldanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detalles Tipicos de Viga Aashto

Uploaded by

Carlos SaldanaCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/257812347

Performance of AASHTO-type bridge model prestressed with carbon fiber-

reinforced polymer reinforcement

Article in Aci Structural Journal · May 2013

CITATIONS READS

30 6,404

4 authors, including:

Nabil F Grace Vasant Matsagar

Lawrence Technological University Indian Institute of Technology Delhi

87 PUBLICATIONS 1,465 CITATIONS 216 PUBLICATIONS 2,527 CITATIONS

SEE PROFILE SEE PROFILE

Chenglin Wu

Missouri University of Science and Technology

59 PUBLICATIONS 487 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Mathematics Applications in Renewable Energy Resources Engineering and Sustainable Systems Engineering View project

ANNs (Artificial Neural Networks) View project

All content following this page was uploaded by Vasant Matsagar on 17 September 2014.

The user has requested enhancement of the downloaded file.

ACI STRUCTURAL JOURNAL TECHNICAL PAPER

Title no. 110-S39

Performance of AASHTO-Type Bridge Model Prestressed

with Carbon Fiber-Reinforced Polymer Reinforcement

by Nabil Grace, Kenichi Ushijima, Vasant Matsagar, and Chenglin Wu

Carbon fiber-reinforced polymer (CFRP) composite material has and reinforced with steel with the same geometry and span.

been widely studied and applied in bridge engineering as an alter- In this study, it states that the flexural behavior of the beams

native solution to the corrosion-related problems posed by steel prestressed with CFRP strands exhibited stiffness similar to

reinforcement. Nevertheless, adoption of CFRP reinforcement

to replace conventional steel reinforcement in highway bridges

the beam prestressed with steel strands. Also, the variation

has not been fully realized yet in the field. Therefore, large-scale of the web reinforcement ratio did not significantly influ-

experimental investigations on bridges with CFRP reinforcement ence the flexural behavior of the beams, and the failures

are essential to encourage its widespread application in highway were controlled by bending capacity. Further, the shape of

bridges. This paper presents an experimental investigation conducted the stirrups did affect the shear failure of the beam.

on a one-third-scale AASHTO-type bridge model prestressed with To further investigate the load-deflection relationship of

carbon fiber composite cable (CFCC) strands. The bridge model concrete beams fully prestressed with CFRP, Abdelrahman

was designed, constructed, instrumented, and tested to thoroughly

investigate its flexural behavior, strain response, and ultimate load

and Rizkalla4 conducted an experimental study that included

failure. A separate one-third-scale single AASHTO-type I-beam four prestressed concrete T-beams with a total length of

was also constructed and tested to study its flexural and shear 6.3 m (21 ft) and a depth of 330 mm (13 in.). The results of

behavior as a control beam. In general, both the control beam and the study show that the load-deflection relationship of these

the bridge model experienced compression-controlled failure as beams was bilinear up to failure, and negligible residual

anticipated. Significant cracking and deflection were experienced deformations were experienced during the tests.

prior to failure. The ultimate strength of the control beam and the To provide guidelines in the design and construction of the

bridge model were in close agreement with the values estimated

using the Unified Design Approach. Bridge Street Bridge—the first concrete bridge prestressed

with CFRP materials in the United States—Grace et

Keywords: AASHTO; carbon fiber composite cable; carbon fiber-reinforced al.5 conducted a full-scale test on a CFRP prestressed double-

polymer; ductility; fiber-reinforced polymer; flexure; prestress; reinforcement. tee beam. It was concluded that the anticipated prestressing

levels were maintained during the test. The strain-compat-

INTRODUCTION ibility-based Unified Design Approach was proposed by

Corrosion of steel strands and reinforcement is one of the Grace and Singh,6 which was validated by experimental

major reasons the structural integrity of prestressed concrete results conducted on a double-tee beam bridge model

bridges is compromised before the bridges reach their full reinforced and prestressed using carbon fiber composite cable

life span. The viable solution to eliminate the corrosion-

(CFCC) strands. Furthermore, a compression-controlled

related problems associated with conventional prestressed

failure mode was recommended as the design failure mode

and reinforced concrete bridges is the application of fiber-

reinforced polymer (FRP) materials. The high strength-to- for CFRP prestressed concrete beams.7 This recommenda-

weight ratio, superior fatigue resistance, ease of handling, tion was based on the better ductility characteristics of over-

low thermal expansion, and low relaxations are some of reinforced sections. Also, an ultimate concrete compressive

the advantages of the FRP materials over conventional strain of 0.0025 was reported, as experienced in the experi-

steel reinforcement. These excellent characteristics made mental work.

carbon fiber-reinforced polymers (CFRPs) a potential future In typical designs of concrete highway bridges prestressed

construction material in the bridge construction industry. with conventional reinforcement, tension-controlled failure

The various types of I-beam cross sections specified in mode dominates, as higher ductility is exhibited by yielding

AASHTO1 have been extensively used in the recent construc- of the steel reinforcement. CFRP, however, is a brittle mate-

tion of prestressed concrete bridges.2 Features such as a rial exhibiting a linear stress-strain relationship up to rupture.

simpler cross section, higher flexural capacities, and reduced Because a compression-controlled failure mode provides

manufacturing costs make the AASHTO beam a modest better ductility than a tension-controlled failure mode in

choice for constructing long-span bridges. In addition, FRP terms of extensive deflections, ACI 440.1R-068 recom-

materials can help sustain a longer life span with minimal mends a compression-controlled design failure mode for the

maintenance costs. To adopt the innovative CFRP materials concrete bridges reinforced and prestressed with the CFRP

in the bridge construction industry, thorough investigations

are essential; however, an extensive review of the literature

reveals that limited research is available on the application of ACI Structural Journal, V. 110, No. 3, May-June 2013.

CFRP materials in AASHTO-type beams. MS No. S-2011-204.R1 received July 11, 2011, and reviewed under Institute

publication policies. Copyright © 2013, American Concrete Institute. All rights

In 1997, Fam et al.3 tested five I-beams prestressed reserved, including the making of copies unless permission is obtained from the

and reinforced with CFRP materials with a span of 9.5 m copyright proprietors. Pertinent discussion including author’s closure, if any, will be

published in the March-April 2014 ACI Structural Journal if the discussion is received

(30.5 ft) and one conventionally reinforced beam prestressed by November 1, 2013.

ACI Structural Journal/May-June 2013 1

ACI member Nabil Grace is the Dean of the College of Engineering, University Materials Research (CIMR) at Lawrence Technological

Distinguished Professor, and Director of the Center for Innovative Materials Research University (LTU). The AASHTO Type IV I-beams9 were

(CIMR) at Lawrence Technological University (LTU), Southfield, MI. designed as over-reinforced sections as per the flexural

Kenichi Ushijima is a Senior Engineer at Cable Technologies North America, Inc.

design philosophy8 to be used in the experimental inves-

He received his bachelor’s degree in engineering from Yamaguchi National University, tigation. The one-third-scale (1:3.6) control beam consisted

Yamaguchi, Japan. of a single precast prestressed AASHTO I-beam with a span

of 12,141 mm (39 ft 10 in.) and a 64 mm (2.5 in.) thick

ACI member Vasant Matsagar is a Visiting Professor at the Center for Innovative CFCC-reinforced composite deck slab. The cross section of

Materials Research (CIMR) at LTU.

the AASHTO I-beams used in this investigation was 502 mm

Chenglin Wu is a former Research Assistant at the Department of Civil Engineering (19.75 in.) deep with top and bottom flange widths of 203 mm

at LTU. (8 in.) and a web thickness of 95 mm (3.75 in.), as shown in

Fig. 1. The one-third-scale (1:3.6) bridge model consisted of

five AASHTO I-beams placed at a center-to-center distance

materials. In this experimental investigation, therefore, the of 502 mm (19.75 in.), joined with five equally spaced 64 mm

compression-controlled design failure mode was adopted. (2.5 in.) thick transverse diaphragms (404 mm [15.875 in.]

in depth below the deck slab soffit), and topped with a 2.5 m

RESEARCH SIGNIFICANCE (98.75 in.) wide and 64 mm (2.5 in.) thick deck slab,9 as

The experimental study presented in this paper explains shown in Fig. 2. The structural integrity of the bridge model

the design philosophy, construction techniques employed, was ensured by extending transverse reinforcement of the

and flexural performance of AASHTO I-beam and bridge diaphragms into the beams and tying protruded vertical

model reinforced and prestressed with CFCC strands. reinforcement of the diaphragms and protruded stirrups of

Experimental results of this investigation were validated the beams to transverse reinforcement of the deck slab.10

with the Unified Design Approach.6 This investigation also Each precast prestressed AASHTO I-beam consisted of

compliments the ongoing research on merits gained by using three longitudinal CFCC prestressed strands and seven longi-

the CFRP reinforcement for the construction of highway tudinal non-prestressed CFCC strands—all with a diameter

bridges. Further, the results presented in this paper should of 15.2 mm (0.6 in.)—as flexural reinforcement distributed

allow engineers and designers to take full advantage of this vertically along the depth of the beam. The CFCC stir-

potential, emerging technology to overcome the corrosion- rups, measuring 7.5 mm (0.3 in.) in diameter and spaced at

related problems in the current practice of AASHTO-type a center-to-center distance of 102 mm (4 in.), were used

beam bridges. as shear reinforcement and protruded in the deck slab

by 38 mm (1.5 in.). The details of the CFCC reinforcement

CONSTRUCTION DETAILS in the I-beam are presented in Fig. 1 and 3. Each beam was

The control beam and bridge model was constructed, subjected to a total prestressing force of 266.89 kN (60 kip)

instrumented, and tested at the Center for Innovative equally distributed among the three longitudinal CFCC

Fig. 1—Cross-sectional details of I-beam.

2 ACI Structural Journal/May-June 2013

Fig. 2—Dimensions of bridge model.

Fig. 3—Cross-sectional details of control beam.

prestressed strands. A rectangular end block 533 mm (21 in.) the CFCC strands and stirrups are shown in Tables 1 and

long, 203 mm (8 in.) wide, and 502 mm (19.75 in.) deep 2, respectively. Because the CFCC stirrups were bent at

was provided on each side of the beams to resist bursting two ends by 90 and 180 degrees, tensile strength tests were

stresses generated during the transfer of the pretensioning conducted on different portions of the CFCC stirrups to

forces. Moreover, confinement in the end-block regions was determine the actual strength. The minimum strength was

provided with rectangular stirrups spaced at a center-to- selected as the design strength of the CFCC stirrups.

center distance of 51 mm (2 in.), as shown in Fig. 3.

The deck slab of the bridge model was reinforced Construction of AASHTO I-beams

by 20 longitudinal non-prestressed CFCC strands 15.2 mm Upon completion of constructing the formwork for the

(0.6 in.) in diameter and 62 transverse non-prestressed CFCC AASHTO I-beams, CFCC reinforcement cages were assem-

strands 7.5 mm (0.3 in.) in diameter spaced at a center-to- bled and placed inside the formwork. The required concrete

center distance of 203 mm (8 in.). CFCC strands 7.5 mm cover (38 mm [1.5 in.]) at the bottom of the beams was

(0.3 in.) in diameter were passed through transverse holes provided by attaching 76 mm (3 in.) diameter plastic circular

provided at the web of the I-beams as diaphragm reinforce- chairs under the cages. The CFCC prestressing strands were

ment for the bridge model. The mechanical properties of passed through the reinforcement cages at designated layers

ACI Structural Journal/May-June 2013 3

Table 1—Mechanical properties of tested CFCC prestressing and non-prestressing strands

Types Transverse non-prestressing strands Longitudinal prestressing strands Longitudinal non-prestressing strands

Diameter, mm (in.) 1 x 7, 7.5 (0.3) 1 x 7, 15.2 (0.6) 1 x 7, 15.2 (0.6)

2 2

Effective area, mm (in. ) 30.97 (0.048) 115.48 (0.179) 115.48 (0.179)

Maximum, kN (kip) 95.01 (21.36) 305.99 (68.79) 305.99 (68.79)

Breaking

Minimum, kN (kip) 91.02 (20.46) 274.99 (61.82) 274.99 (61.82)

load

Average*, kN (kip) 91.99 (20.68) 295.98 (66.54) 295.98 (66.54)

Tensile strength, MPa (ksi) 2972 (431) 2558 (371) 2558 (371)

Modulus of elasticity, MPa (ksi) 164,000 (23,786) 157,000 (22,771) 157,000 (22,771)

*

Five specimens were tested.

Table 2—Mechanical properties of tested CFCC stirrups

Types CFCC rod at straight portion CFCC rod at 180-degree bent end CFCC rod at 90-degree bent end

Diameter, mm (in.) 7 (0.28) 7 (0.28) 7 (0.28)

Effective area, mm2 (in.2) 30.97 (0.048) 30.97 (0.048) 30.97 (0.048)

Maximum, kN (kip) 72.02 (16.19) 37.2 (8.36) 40.5 (9.10)

Breaking

Minimum, kN (kip) 60.00 (13.49) 30.4 (6.83) 25.6 (5.76)

load

*

Average , kN (kip) 64.99 (14.61) 34.0 (7.64) 38.6 (8.68)

Tensile strength, MPa (ksi) 2096 (304) 1098 (159) 1246 (181)

Modulus of elasticity, MPa (ksi) 145,000 (21,030) 145,000 (21,030) 145,000 (21,030)

*

Five specimens were tested.

and positioned between two bulkheads. Calibrated load cells (30 in.) tall, measuring 356 x 1372 mm (14 x 54 in.). Elas-

were mounted on the prestressing strands at the dead end tomeric bearing pads 25.4 mm (1 in.) thick were placed

and connected to a data acquisition system to monitor and between the beams and steel supports at each end to simulate

record the level of pretensioning forces applied. In addition, the field conditions. Upon placing the control beam under

the strain gauges mounted on the prestressing strands and the loading frame, a CFCC-reinforced 64 mm (2.5 in.) thick

the pressure gauge installed on the hydraulic jack were used and 502 mm (19.75 in.) wide deck slab was cast. The average

to monitor the applied pretensioning forces. compressive strength of the concrete for the deck slab was

The pretensioning force was applied through a 305 mm 44.82 MPa (6500 psi). After the concrete in the deck slab

(12 in.) center hole hydraulic jack positioned at the live end. gained adequate strength, the control beam consisting of the

A custom-made steel chair was attached to the hydraulic single AASHTO I-beam and the cast-in-place deck slab was

jack and supported on the bulkhead to transfer the reactions instrumented and tested for flexure.

generated during the application of the pretensioning forces. The other five AASHTO I-beams were moved to another

Moreover, to verify the pretensioning force applied, elon- testing area underneath a loading frame, and the beams

gations experienced in the CFCC prestressing strands were were positioned on steel supports to allow the construction

measured during the prestressing operation by measuring of the deck slab and transverse diaphragms for the bridge

ram displacement of the hydraulic jack. Each prestressing model. The five beams were maintained at a center-to-center

strand was stressed to an average jacking force of 88.96 kN

distance of 502 mm (19.75 in.). Non-prestressing CFCC

(20 kip) to achieve a total pretensioning force of 266.89 kN

strands 7.5 mm (0.3 in.) in diameter were passed through the

(60 kip) on each beam. The applied pretensioning force of

holes kept in the beams and epoxied to brace the beams in

88.96 kN (20 kip) in each CFCC prestressing strand was

approximately 30% of the average breaking load (Table 1). the transverse direction. Vertical reinforcement of the trans-

After the prestressing operation, the concrete was placed verse diaphragm was attached to its transverse reinforcement

in the formwork and proper uniform compaction was and formwork was provided around the reinforcement. Prior

achieved using three electrical pencil vibrators. The average to the deck slab reinforcement placement, formwork for the

28-day compressive strength of the concrete was 44.82 MPa deck slab was attached to the beams and diaphragm form-

(6500 psi). After placing the concrete, the beams were wet- work and supported on the ground as typically practiced in

cured by covering them with soaked burlap for 7 days. When shored construction. The deck slab reinforcement consisted

the concrete attained the required compressive strength, of 20 No. CFCC 1 × 7 φ 15.2 mm (0.6 in.) strands in the

pretensioning forces were released by saw-cutting the longitudinal direction and CFCC 1 × 7 φ 7.5 mm (0.3 in.)

CFCC prestressed strands simultaneously from both ends of strands at 203 mm (8 in.) in the transverse direction. The

the beams. concrete was placed in the diaphragms and the deck slab, and

compacted properly with pencil vibrators and metallic rods.

Construction of control beam and bridge model After finishing the top surface of deck slab the bridge model

One of the six AASHTO I-beams was selected as the was covered with soaked burlap for 7 days. Upon hardening

control beam and was moved to the testing area underneath a of the concrete for 7 days, supports of the formwork were

loading frame and was positioned on steel supports 762 mm removed. The average 28-day compressive strength of the

4 ACI Structural Journal/May-June 2013

Fig. 4—Test setup for control beam.

Fig. 5—Flexural load test of control beam.

concrete in the deck slab and the transverse diaphragms was The control beam was subjected to several loading and

27.58 MPa (4000 psi). unloading cycles to separate the elastic and inelastic ener-

gies. These loading cycles were 13.34, 31.14, 35.59, 53.38,

Instrumentation and test setup 66.72, 88.96, and 111.21 kN (3, 7, 8, 12, 15, 20, 25 kip) and

Prior to the casting of the AASHTO I-beams, electrical ultimate load cycle. Figure 5 shows the control beam during

strain gauges were attached to the CFCC prestressing the flexural load test.

strands to measure the strain responses. After the concrete Different sensors were installed and used to analyze the

in the deck slab gained adequate strength, two linear motion behavior of the bridge model according to the test program.

transducers were installed at the quarter-span and midspan, The test program for the bridge model consisted of the flex-

respectively, to measure the deflections of the control beam ural performance, decompression and cracking load, and

during the flexural load test. Two strain gauges were mounted ultimate load tests.

on the top surface of the deck slab at midspan to record the In the flexural performance test, each beam of the bridge

strain response of the extreme compressive concrete fiber of model was loaded at quarter-span and midspan with a single

the control beam. Meanwhile, to observe the strain response point load of 66.72 kN (15 kip). Linear motion transducers

of the CFCC stirrups, five DEMEC stations (Rosette type) were installed at both quarter-span and midspan to measure

were also installed at the shear-critical sections. A steel the deflections of the beams under different loading cases.

loading frame—that is, a spreader with two loading points In the decompression load test, a 1.22 m (48 in.) long

spaced at a distance of 965 mm (38 in.)—was placed on the spreader was used to load the bridge model at midspan.

deck slab at midspan. An actuator with a maximum loading Linear motion transducers were installed at the midspan of

capacity of 889.64 kN (200 kip) was used to apply load at the bridge model to monitor and record the deflection. Strain

the center of the spreader. A load cell with a capacity of gauges were attached at the bottom surface of the center

889.64 kN (200 kip) was connected to the actuator to record beam at midspan to determine the decompression load.

the applied load. To prevent the possible twist that might In the ultimate load test, the bridge model was loaded

be caused during the loading process, custom-made steel using a steel square tube with a length of 1.22 m (48 in.)

guides were installed around the beam at both quarter-span mounted at the midspan covering the center beam and its

points and beam ends. The test setup for the control beam is two adjacent beams, as shown in Fig. 6. The strain gauges

shown in Fig. 4. installed on the CFCC strands, linear motion transducers

ACI Structural Journal/May-June 2013 5

Fig. 6—Test setup for ultimate load test of bridge model.

Fig. 7—Load-deflection behavior of control beam.

installed at midspan, and strain gauges installed on the top reinforcement ratio of 0.0046 (the balanced reinforce-

surface of the deck slab at midspan were used to analyze the ment ratio for the section was calculated as 0.00196), a

behavior of the bridge model. Similar to the flexural load compression-controlled flexural failure initiated by the

test conducted on the control beam, the bridge model was concrete crushing at the midspan was observed. The load-

subjected to several loading and unloading cycles before deflection behavior of the control beam experienced a

failure to separate the elastic and inelastic energies. These bilinear response, as shown in Fig. 7, with cracking load of

cycles were conducted at 311.38, 355.86, 422.58, 444.82, 28.91 kN (6.5 kip). The load-strain responses of the top and

489.30, 533.79, and 578.27 kN (70, 80, 95, 100, 110, 120, bottom layers of the CFCC prestressing strands also experi-

and 130 kip) and at ultimate load. enced a bilinear response, as shown in Fig. 8. However, the

strain gauges on the strands stopped functioning at a load

RESULTS AND DISCUSSION of 62.28 kN (14 kip). The CFCC prestressing strands were

The control beam failed with an ultimate load-carrying further examined after the beam failure and no damage was

capacity of 162.05 kN (36.43 kip) and a corresponding experienced. Meanwhile, the load-strain response of the

deflection of 292 mm (11.5 in.). The ultimate load-carrying extreme compressive concrete fiber was also recorded, as

capacity of the control beam is in close agreement with the shown in Fig. 9. The maximum strain experienced by the

designed value of 164.58 kN (37 kip) using the Unified

extreme compressive concrete fiber was 2000 με at failure.

Design Approach proposed by Grace and Singh6 (important

The ductility of the control beam was evaluated by the

steps in the design procedure are shown in the Appendix*).

energy ratio, which was calculated using the energy-based

Because the control beam was over-reinforced with a

approach.11 Accordingly, the failure of a structure is defined

as brittle failure if the energy ratio is lower than 70%.

Therefore, the failure of the control beam was defined as a

*

The Appendix is available at www.concrete.org in PDF format as an addendum to

the published paper. It is also available in hard copy from ACI headquarters for a fee

brittle failure with an energy ratio of 46.88%, as shown in

equal to the cost of reproduction plus handling at the time of the request. Fig. 10. However, a sufficient warning prior to the failure

6 ACI Structural Journal/May-June 2013

Fig. 8—Strain experienced by CFCC prestressing strands in control beam.

Fig. 9—Compressive strain of top concrete fiber at midspan of control beam.

Fig. 10—Ductility of control beam.

ACI Structural Journal/May-June 2013 7

Fig. 11—Cracks developed in control beam.

Fig. 12—Strain experienced by CFCC stirrup at DEMEC Station 2.

was provided by the excessive deflection and extensive (25 kip). Thus, the CFCC stirrups provided in the AASHTO

cracks of the control beam before reaching the ultimate load I-beams in the desired bent shapes served the intended

of 162.05 kN (36.43 kip). purpose satisfactorily.

A significant number of diagonal cracks were observed in The strain responses of the CFCC stirrups at DEMEC

the shear zone (between the loading points and beam ends) Station 2 were recorded and compared to the estimated

of the control beam. Details of the cracks mapped at different values using ACI 440.4R-047 and ACI 318-0512 approaches,

load levels are shown in Fig. 11. As the control beam was as shown in Fig. 12. It can be seen that both the shear

designed to have a flexural failure, adequate CFCC stir- design approaches proposed by ACI 440.4R-047 and

rups were provided to avoid any premature shear failure. ACI 318-0512 conservatively predicted the strains of the

Therefore, the widths of the cracks were insignificant and CFCC stirrups at a load of 111.21 kN (25 kip). However, the

the maximum width of the shear cracks was approximately estimated strain responses of the CFCC stirrups using the

0.2 mm (0.009 in.) at a corresponding load of 111.21 kN approach proposed by ACI 440.4R-047 were closer to the

8 ACI Structural Journal/May-June 2013

Fig. 13—Strain experienced at bottom concrete fiber in bridge model.

actual strains experienced as compared to those estimated The ultimate load test was conducted by applying

using ACI 318-05.12 Furthermore, the maximum strain of the a uniformly distributed load on a 1.22 m (48 in.) long

CFCC stirrups measured at DEMEC Station 2 was 500 με, and 152 mm (6 in.) wide steel square tube placed across

which was less than the ultimate strain of the CFCC stirrups the bridge model at the midspan. After several loading

(756 με). This fact signifies adequate strength of the CFCC and unloading cycles, the bridge model failed at a load

stirrups during the flexural load test. The shear failure load of 689.47 kN (155 kip) with the corresponding deflection

for the control beam, predicted based on the strains experi- of 240 mm (9.45 in.) at center beam, B-3. This ultimate load-

enced, was 178 kN (40 kip). carrying capacity of the bridge model was in close agree-

As mentioned previously, the test program conducted on ment with the designed6 value of 733.96 kN (165 kip). The

the bridge model included the flexural performance test, failure was initiated by concrete crushing at top compres-

decompression and cracking load test, and ultimate load sion fibers at the midspan of the bridge model, and the

test. In addition, the flexural performance test was repeated CFCC prestressing strands were still intact after the bridge

after the decompression and cracking load test to examine model failed. The load-deflection behavior of the bridge

the behavior of the bridge model at the cracked stage. model, as shown in Fig. 14, showed bilinear response due

The decompression and cracking load test was conducted to the concrete cracking, similar to what was observed in

to determine the effective prestress and the cracking load the control beam. The load-strain response of the extreme

of the bridge model. During the test, the bridge model was compressive concrete fiber for the bridge model was also

subjected to a single point load positioned on a 1.22 m recorded, as shown in Fig. 15. The maximum concrete strain

(48 in.) long spreader located on the center beam (B-3) at reached by the extreme fiber was 2520 με in compression.

midspan. The first flexural crack was observed at the bottom The strain responses of the CFCC strands in the bridge

of Beam B-3 at the midspan with the corresponding load of model were monitored throughout the test. The load-strain

104.53 kN (23.5 kip). The bridge model was then unloaded responses of different layers of the CFCC strands and the

to allow installing a set of four strain gauges at both sides extreme compressive concrete fiber during the ultimate load

of the initial flexural cracks. Upon completing the installa- cycle are shown in Fig. 16. The maximum strain reached

tion, the bridge model was reloaded. The strain of the bottom by the bottom prestressing strands was 10,000 με, which

concrete fiber increased proportionally to the applied load was 66.7% of the ultimate strain for the CFCC strands

immediately after the reloading started. When the stress of the (15,000 με). This fact suggests that perhaps a higher preten-

bottom concrete fiber approached zero, however, the strain sioning force can be applied to increase the cracking load.

stopped increasing and remained constant as the load applied The energy ratio of the bridge model was 26.67%, which

on the bridge model was still increasing, as shown in Fig. 13. was calculated using the energy-based approach,11 as shown

The decompression load determined through the load-strain in Fig. 17. Although the ductility of the bridge model was

response of the bottom concrete fiber was 57.83 kN (13 kip). low in the terms of the energy ratio and the excessive deflec-

The overall prestress loss was subsequently calculated as 11% tion and extensive cracks experienced, the bridge model

based on the decompression load, which is less than the typical provided significant warning before failure.

15% prestress loss, as usually reported for beams prestressed

using steel strands.13 At the end of the test, the bridge model CONCLUSIONS AND RECOMMENDATIONS

was loaded up to 266.89 kN (60 kip) to allow the development This paper presents an experimental investigation

of the flexural cracks. The flexural performance test was then addressing the application of CFRP strands in prestressed

repeated after the bridge model was extensively cracked. AASHTO I-beams and bridges. The ACI 440.4R-047 design

ACI Structural Journal/May-June 2013 9

Fig. 14—Load-deflection behavior of bridge model.

Fig. 15—Compressive strain experienced by extreme concrete fiber of

bridge model.

guidelines and the Unified Design Approach proposed by the experimental value experienced at the load of 111.21 kN

Grace and Singh6 were used in the flexural and shear design (25 kip). This fact further indicates that ACI 440.4R-047 shear

of the control beam and bridge model. The test results were design approach can be adequately used in the design of the

analyzed and compared with the estimated values, and AASHTO I-beams using CFCC stirrups.

several conclusions are drawn as follows. 4. An 11% prestress loss was calculated through the

1. Both the control beam and the bridge model experienced decompression test conducted on the bridge model, which

a compression-controlled failure as expected. The calcu- is less than the typical 15% prestress loss, as traditionally

lated ultimate load-carrying capacities for both the control reported for beams prestressed using steel strands. This

beam and the bridge model were 164.58 and 733.96 kN further demonstrates the excellent performance of the CFCC

(37 and 165 kip), respectively. These values are in close agree- strands in prestressed concrete AASHTO I-beams.

ment with the experimental values (162.05 kN [36.43 kip] 5. The CFCC strands were not damaged after the failure of

for the control beam and 689.47 kN [155 kip] for the bridge the control beam and the bridge model. The maximum strain

model). This verified that the Unified Design Approach6 is experienced by the prestressing CFCC strands was 66.7%

suitable in designing the AASHTO I-beams and bridges. of the ultimate strain. Therefore, a higher pretensioning

2. The maximum strain of the CFCC stirrups measured at force may be recommended to be applied on the CFCC

the shear-critical sections was 500 με, which was less than prestressing strands.

the ultimate strain of 756 με. This demonstrates the excellent 6. The energy ratios of the control beam and bridge model

performance of the CFCC stirrups in resisting the shear load were 46.88% and 26.67%, respectively. These values clas-

experienced by the AASHTO I-beams. sified the failures of both the control beam and bridge

3. The calculated strain of the CFCC stirrup using model as brittle failure.11 However, the excessive deflec-

ACI 440.4R-047 approach was conservative as compared to tions and the extensive cracks provided sufficient warning

10 ACI Structural Journal/May-June 2013

Fig. 16—Strain experienced by CFCC strands at ultimate load of bridge model.

Fig. 17—Ductility of bridge model.

prior to the failure for this type of AASHTO I-beam bridge 5. Grace, N. F.; Enomoto, T.; Abdel-Sayed, G.; Yagi, K.; and Colla-

with CFCC strands. vino, L., “Experimental Study and Analysis of a Full-Scale CFRP/

CFCC Double-Tee Bridge Beam,” PCI Journal, V. 48, No. 4, July 2003,

pp. 120-139.

ACKNOWLEDGMENTS 6. Grace, N. F., and Singh, S. B., “Design Approach for Carbon Fiber-

This investigation was supported by the U.S. Department of Transpor- Reinforced Polymer Prestressed Concrete Bridge Beams,” ACI Structural

tation (US-DOT) (Contract No. DTOS 59-06-G-0030) and MDOT-LTU Journal, V. 100, No. 3, May-June 2003, pp. 365-376.

Center of Excellence. The support and guidance of B. Jacob, Senior Policy 7. ACI Committee 440, “Prestressing Concrete Structures with FRP

Analyst, US-DOT; and L. N. Triandafilou, Senior Structural Engineer, Tendons (ACI 440.4R-04),” American Concrete Institute, Farmington

FHWA, are truly appreciated. Moreover, the Tokyo Rope Manufacturing Hills, MI, 2004, 35 pp.

Company Limited, Japan, supplied the CFCC reinforcement. 8. ACI Committee 440, “Guide for the Design and Construction of

Concrete Reinforced with FRP Bars (ACI 440.1R-06),” American Concrete

Institute, Farmington Hills, MI, 2006, 44 pp.

REFERENCES 9. MDOT, “Bridge Design Guides,” Bureau of Highway Development,

1. AASHTO, “AASHTO Load and Resistance Factor Design (LRFD) MI, 2001, p. 6.60.01.

Bridge Design Specifications,” third edition, American Association of State 10. MDOT, “Bridge Design Manual,” Bureau of Highway Development,

Highway and Transportation Officials, Washington DC, 2004. MI, 2006, 466 pp.

2. Martin, R. D.; Kang, T. H.-K.; and Pei, J.-S., “Experimental and Code 11. Grace, N. F.; Soliman, A. K.; Abdel-Sayed, G.; and Saleh, K. R.,

Analyses for Shear Design of AASHTO Prestressed Concrete Girders,” “Behavior and Ductility of Simple and Continuous FRP Reinforced Beams,”

PCI Journal, V. 56, No. 1, Dec. 2011, pp. 54-74. Journal of Composites for Construction, ASCE, V. 2, No. 4, Nov. 1998,

3. Fam, A. Z.; Rizkalla, S. H.; and Tadros, G., “Behavior of CFRP for pp. 186-194.

Prestressing and Shear Reinforcements of Concrete Highway Bridges,” 12. ACI Committee 318, “Building Code Requirements for Reinforced

ACI Structural Journal, V. 94, No. 1, Jan.-Feb. 1997, pp. 77-86. Concrete (ACI 318-05),” American Concrete Institute, Farmington Hills,

4. Abdelrahman, A. A., and Rizkalla, S. H., “Deflection Control of MI, 2005, 430 pp.

Concrete Beams Pretensioned by CFRP Reinforcements,” Journal of 13. Nawy, E. G., Prestressed Concrete: Fundamental Approach, fourth

Composites for Construction, ASCE, V. 3, No. 2, May 1999, pp. 55-62. edition, Prentice Hall, Saddle River, NJ, 2003, 960 pp.

ACI Structural Journal/May-June 2013 11

NOTES:

12 ACI Structural Journal/May-June 2013

View publication stats

You might also like

- Flexural Strengthening of RC Continuous T Beam Using CFRP Laminate: A ReviewDocument8 pagesFlexural Strengthening of RC Continuous T Beam Using CFRP Laminate: A ReviewDinesh Kumar JNo ratings yet

- Infrastructures: Feasibility of Reusing Damaged Steel Beams in Temporary StructuresDocument24 pagesInfrastructures: Feasibility of Reusing Damaged Steel Beams in Temporary Structureslouis donyNo ratings yet

- Behavior of Prestressed Concrete Box-Beam Bridges Using CFRP TendonsDocument16 pagesBehavior of Prestressed Concrete Box-Beam Bridges Using CFRP TendonsBatisxuta MichaelNo ratings yet

- Strengthening of Beams Using Carbon Fibre Reinforced PolymerDocument7 pagesStrengthening of Beams Using Carbon Fibre Reinforced PolymerAkhilesh B.MNo ratings yet

- CFRP-steel Hybrid Retrofitting of Steel-Concrete Composite StructuresDocument9 pagesCFRP-steel Hybrid Retrofitting of Steel-Concrete Composite StructuresUsha EngineeringNo ratings yet

- Article1380733714 - Jumaat Et Al PDFDocument7 pagesArticle1380733714 - Jumaat Et Al PDFJob NantawatNo ratings yet

- Repair of Corroded and Buckled Short Steel Columns Using Concrete-Filled GFRP JacketsDocument9 pagesRepair of Corroded and Buckled Short Steel Columns Using Concrete-Filled GFRP JacketsclarkgaguiNo ratings yet

- Polymers 13 02997Document25 pagesPolymers 13 02997adnan-651358No ratings yet

- Retrofit of Square Concrete Columns With Carbon Fiber Reinforced Polymer For Seismic ResistanceDocument11 pagesRetrofit of Square Concrete Columns With Carbon Fiber Reinforced Polymer For Seismic Resistanceanne marieNo ratings yet

- Strengthening Reinforced Concrete Beams Using FibeDocument12 pagesStrengthening Reinforced Concrete Beams Using Fibesyahmi azharNo ratings yet

- Composite Structures: SciencedirectDocument14 pagesComposite Structures: SciencedirectJos PereNo ratings yet

- 1 s2.0 S0264127515307747 MainDocument12 pages1 s2.0 S0264127515307747 Mainj.riquelme16No ratings yet

- flexuralstrengtheningofcolumnsusinganchorsDocument9 pagesflexuralstrengtheningofcolumnsusinganchorsMarwan AlferjaniNo ratings yet

- Performance of RFP Wrapped RC Column Under Combined Axial Flexural LoadingDocument10 pagesPerformance of RFP Wrapped RC Column Under Combined Axial Flexural LoadingCu ToànNo ratings yet

- Flexural Behavior of Ultra-High-Performance Fiber-Reinforced Concrete Beams Reinforced With GFRP and Steel RebarsDocument17 pagesFlexural Behavior of Ultra-High-Performance Fiber-Reinforced Concrete Beams Reinforced With GFRP and Steel Rebarsmohamed ellithyNo ratings yet

- Strengthening Steel Beams Using CFRP Subjected To Impact LoadsDocument6 pagesStrengthening Steel Beams Using CFRP Subjected To Impact Loadssurajitkundu2002No ratings yet

- Shear Behaviour For Deep BeamsDocument17 pagesShear Behaviour For Deep BeamsMuhammad Hamza QadriNo ratings yet

- Jase 202112 24 6 0009Document9 pagesJase 202112 24 6 0009sarathNo ratings yet

- Compressive Behaviour of RC Column With Fibre Reinforced Concrete Confined by CFRP StripsDocument12 pagesCompressive Behaviour of RC Column With Fibre Reinforced Concrete Confined by CFRP Stripsmalek malekNo ratings yet

- Finite Element Analysis of Concrete Bridge Decks Reinforced With Fiber Reinforced Polymer BarsDocument15 pagesFinite Element Analysis of Concrete Bridge Decks Reinforced With Fiber Reinforced Polymer BarsHuda AlrikabiNo ratings yet

- Design of Concrete Beams Reinforced and Unbonded Prestressed With FRP Bars Based On Serviceability RequirementsDocument11 pagesDesign of Concrete Beams Reinforced and Unbonded Prestressed With FRP Bars Based On Serviceability RequirementsPratik MuthaNo ratings yet

- Aq04605306316 PDFDocument11 pagesAq04605306316 PDFDinesh Kumar JNo ratings yet

- Cyclic Behavior of Concrete Columns Reinforced With Partially UnbondedDocument13 pagesCyclic Behavior of Concrete Columns Reinforced With Partially UnbondedAnonymous bnfIOcoMuaNo ratings yet

- Research Article: Flexural and Shear Behavior of FRP Strengthened AASHTO Type Concrete Bridge GirdersDocument11 pagesResearch Article: Flexural and Shear Behavior of FRP Strengthened AASHTO Type Concrete Bridge GirderssanjusamsonNo ratings yet

- A state of the art review on reinforced concrete beams with openings retrofitted with FRPDocument15 pagesA state of the art review on reinforced concrete beams with openings retrofitted with FRPenghrc.2208No ratings yet

- A Comparative Study of Steel Girder Bridge With FRP Using ANSYSDocument6 pagesA Comparative Study of Steel Girder Bridge With FRP Using ANSYSSuraj ApexNo ratings yet

- 612 - ACI STRUCTURAL JOURNAL by Wiryanto Dewobroto PDFDocument168 pages612 - ACI STRUCTURAL JOURNAL by Wiryanto Dewobroto PDFchaval01No ratings yet

- ShearstrengthofsteelfibrereinforcedconcretebeamswithstirrupsDocument2 pagesShearstrengthofsteelfibrereinforcedconcretebeamswithstirrupsmanel.boudiaf.cyNo ratings yet

- Experimental and Numerical Studies On The Flexural Behavior of Fibre Reinforced Concrete Beams With Innovative Hybrid FRP Wrapped Steel BarsDocument14 pagesExperimental and Numerical Studies On The Flexural Behavior of Fibre Reinforced Concrete Beams With Innovative Hybrid FRP Wrapped Steel BarsMatheus AlmeidaNo ratings yet

- Ductility of Concrete Beams Reinforced With Hybrid FRP RebarsDocument13 pagesDuctility of Concrete Beams Reinforced With Hybrid FRP RebarsMuhammad YounisNo ratings yet

- 2011-Ductility of GFRPDocument10 pages2011-Ductility of GFRPGetish TesfayeNo ratings yet

- Ductility Characteristics of Fiber-Reinforced-Concrete Beams ReinforcedDocument11 pagesDuctility Characteristics of Fiber-Reinforced-Concrete Beams ReinforcedNorhafizah Bt SallehNo ratings yet

- Shear Strengthening of Reinforced Concrete Beams Using Epoxy-Bonded FRP CompositesDocument10 pagesShear Strengthening of Reinforced Concrete Beams Using Epoxy-Bonded FRP CompositesVansala GanesanNo ratings yet

- Finite Element Modelling of Strengthened Simple Beams Using FRP Techniques: A Parametric StudyDocument13 pagesFinite Element Modelling of Strengthened Simple Beams Using FRP Techniques: A Parametric StudyRizki Nuursirullah MahibNo ratings yet

- Flexural Strengthening of Reinforced Concrete Beam-Column Joints Using Innovative Anchorage SystemDocument12 pagesFlexural Strengthening of Reinforced Concrete Beam-Column Joints Using Innovative Anchorage SystemmekidesNo ratings yet

- Retrofitting of Reinforced Concrete Slabs Using FRP: July 2021Document6 pagesRetrofitting of Reinforced Concrete Slabs Using FRP: July 2021AminNo ratings yet

- Flexural Behavior and Serviceability of Normal-And High-Strength Concrete Beams Reinforced With Glass Fiber-Reinfor...Document13 pagesFlexural Behavior and Serviceability of Normal-And High-Strength Concrete Beams Reinforced With Glass Fiber-Reinfor...padashtNo ratings yet

- Materials Today: Proceedings: Ata El-Kareim Shoeib, Awad M. EL-Hashmy, Ahmed N. Arafa, Ahmed S. SedawyDocument11 pagesMaterials Today: Proceedings: Ata El-Kareim Shoeib, Awad M. EL-Hashmy, Ahmed N. Arafa, Ahmed S. SedawyYoü Neś Beh NeśNo ratings yet

- Hou 2016Document12 pagesHou 2016Evonne LeeNo ratings yet

- Tests of Continuous Concrete Slabs ReinforcedDocument47 pagesTests of Continuous Concrete Slabs ReinforcedAya SalahNo ratings yet

- International Journal of Research and Innovation : Strengthening of RC Beams Using FRP Sheet 1401-1402Document13 pagesInternational Journal of Research and Innovation : Strengthening of RC Beams Using FRP Sheet 1401-1402ijripublishersNo ratings yet

- FRC BEAMS Rafi-Nadjai-ACI440Document11 pagesFRC BEAMS Rafi-Nadjai-ACI440Jancarlo Mendoza MartínezNo ratings yet

- 612 - Aci Structural Journal by Wiryanto DewobrotoDocument168 pages612 - Aci Structural Journal by Wiryanto Dewobrotomavane25No ratings yet

- Flexural Strength and Deflection Characteristics of High-Strength Concrete Beams With Hybrid FRP and Steel Bar ReinforcementDocument23 pagesFlexural Strength and Deflection Characteristics of High-Strength Concrete Beams With Hybrid FRP and Steel Bar ReinforcementCu ToànNo ratings yet

- Effect of Fiber Material and Loading History On Shear Behavior of Fiber-Reinforced ConcreteDocument24 pagesEffect of Fiber Material and Loading History On Shear Behavior of Fiber-Reinforced ConcreteNot DevalliNo ratings yet

- Development Length of Glass Fiber-Reinforced Polymer Bars in ConcreteDocument1 pageDevelopment Length of Glass Fiber-Reinforced Polymer Bars in ConcreteNiyazuddinNo ratings yet

- Strengthening On RC SlabsDocument16 pagesStrengthening On RC SlabsHarshNo ratings yet

- Use of Carbon Fiber Laminates For StrengtheningDocument19 pagesUse of Carbon Fiber Laminates For StrengtheningLakshmi PrabhaNo ratings yet

- A Ataei M Bradford 10thconferencepaperDocument9 pagesA Ataei M Bradford 10thconferencepapermdkmlNo ratings yet

- A. Dalalbashi 2'12Document7 pagesA. Dalalbashi 2'12Qurrain MirNo ratings yet

- Pstruct 2020 112609Document27 pagesPstruct 2020 112609hudasaadNo ratings yet

- Behaviour of Rectangular Hollow Section Steel Beams Externally Strengthened by Carbon FRP SheetsDocument14 pagesBehaviour of Rectangular Hollow Section Steel Beams Externally Strengthened by Carbon FRP Sheetsnada khaledNo ratings yet

- Review of Strengthening Reinforced Concrete Beams Using CFRP LaminateDocument3 pagesReview of Strengthening Reinforced Concrete Beams Using CFRP LaminateBastian Artanto AmpangalloNo ratings yet

- Compressive Characteristics of Damaged Circular Hollow Section (CHS) Steel Columns Repaired by CFRP or Grout JacketingDocument11 pagesCompressive Characteristics of Damaged Circular Hollow Section (CHS) Steel Columns Repaired by CFRP or Grout Jacketingnomigamer99No ratings yet

- RetrofitOfSteelStructuresUsing FiberwReinforcedPloymers Shaat Schnerch Amir TRB-Nov-03-Revised-PaperDocument15 pagesRetrofitOfSteelStructuresUsing FiberwReinforcedPloymers Shaat Schnerch Amir TRB-Nov-03-Revised-Paperisha patelNo ratings yet

- Probabilistic Assessment of FRP-confined ReinforceDocument60 pagesProbabilistic Assessment of FRP-confined ReinforceRaphael CabanaNo ratings yet

- Simulation of The Behavior of Corrosion Damaged Reinforced Concrete Beams With/without CFRP RetrofitDocument14 pagesSimulation of The Behavior of Corrosion Damaged Reinforced Concrete Beams With/without CFRP RetrofitkarthikNo ratings yet

- Bond CFRPDocument10 pagesBond CFRPyuva_86No ratings yet

- An Experimental Study On Shear Strengthening of RC Lightweight Deep Beams Using CFRPDocument11 pagesAn Experimental Study On Shear Strengthening of RC Lightweight Deep Beams Using CFRPHussein AljoboryNo ratings yet

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)From EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Rating: 4 out of 5 stars4/5 (10)

- CIE626-Chapter-6-Viscous-Viscoeleastic Dampers-Fall 2013Document117 pagesCIE626-Chapter-6-Viscous-Viscoeleastic Dampers-Fall 2013Noor MohdNo ratings yet

- KAT - Ege - ENGDocument84 pagesKAT - Ege - ENGCsaba VargaNo ratings yet

- Leads Institute of Technology & EngineeringDocument22 pagesLeads Institute of Technology & EngineeringAladdin Narzo100% (2)

- Friction Loss, Properties & Standard PipesDocument12 pagesFriction Loss, Properties & Standard PipesAyaEzzNo ratings yet

- Phase Equilibria 200 SoftwareDocument29 pagesPhase Equilibria 200 SoftwareSuraj NairNo ratings yet

- NORMAL SHOCK WAVE PROPERTIESDocument49 pagesNORMAL SHOCK WAVE PROPERTIESIqrar RazaNo ratings yet

- Lecture 2a: Determination of The Concentration and The Acid Dissociation Constants of An Unknown Amino Acid (Part II)Document7 pagesLecture 2a: Determination of The Concentration and The Acid Dissociation Constants of An Unknown Amino Acid (Part II)Steve LiNo ratings yet

- Lashing SystemDocument3 pagesLashing SystemAekJay100% (1)

- Case Studies in Construction MaterialsDocument11 pagesCase Studies in Construction MaterialsAmin ZuraiqiNo ratings yet

- Advancements in Nonoelectric SONOS NVMDocument23 pagesAdvancements in Nonoelectric SONOS NVMeskimo_binNo ratings yet

- GATE 2016 2018 Petroleum Engineering Question Paper and Answer Key PDFDocument61 pagesGATE 2016 2018 Petroleum Engineering Question Paper and Answer Key PDFBramhendra Mude100% (2)

- Facile Synthesis of ZnCo2O4 Nanowire Cluster Arrays On Ni Foam For High-Performance Asymmetric SupercapacitorsDocument8 pagesFacile Synthesis of ZnCo2O4 Nanowire Cluster Arrays On Ni Foam For High-Performance Asymmetric SupercapacitorsCB Dong SuwonNo ratings yet

- Microbiology A Laboratory Manual 10th Edition Cappuccino Solutions ManualDocument3 pagesMicrobiology A Laboratory Manual 10th Edition Cappuccino Solutions Manualzeldaguinevereiur100% (28)

- Trial Number ZeroDocument12 pagesTrial Number ZeroLeandro DijonNo ratings yet

- Arsenic Removal From WastewaterDocument14 pagesArsenic Removal From WastewatersubhoNo ratings yet

- MSDS XW15Document8 pagesMSDS XW15mk7718No ratings yet

- Physico-Chemical Parameters of Residual Water From Different Scouring Treatments of Hemp/Cotton FabricDocument7 pagesPhysico-Chemical Parameters of Residual Water From Different Scouring Treatments of Hemp/Cotton FabricHenry Pelayo RemacheNo ratings yet

- Two Phase Flow, Rheology and Powder Flow: Chapters 6, 9 & 10 in FundamentalsDocument44 pagesTwo Phase Flow, Rheology and Powder Flow: Chapters 6, 9 & 10 in FundamentalsUmesh PatelNo ratings yet

- Junction Diode Characteristics ReviewDocument55 pagesJunction Diode Characteristics ReviewSanthosh DheerajNo ratings yet

- Granular MatterDocument23 pagesGranular MatterfreeroamNo ratings yet

- Saudi Aramco Inspection Checklist: Plumb Drainage System Lay-Out SAIC-S-4040 30-Apr-13Document13 pagesSaudi Aramco Inspection Checklist: Plumb Drainage System Lay-Out SAIC-S-4040 30-Apr-13khurram ijazNo ratings yet

- Water Quality AnalysisDocument100 pagesWater Quality AnalysisSuhil IrshadNo ratings yet

- Product List For Coatings ManualDocument3 pagesProduct List For Coatings ManualMasood TariqNo ratings yet

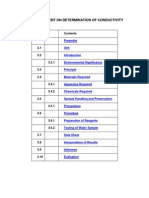

- Determination of Conductivity Exp3 - PDFDocument12 pagesDetermination of Conductivity Exp3 - PDFSusheel TalrejaNo ratings yet

- Example 5.1Document6 pagesExample 5.1Aisyah JamalNo ratings yet

- Dissertation Vinh 2010Document245 pagesDissertation Vinh 2010casanovavnNo ratings yet

- Ion ChromatographyDocument7 pagesIon Chromatographyopenid_mUOZbS9iNo ratings yet

- Dispersed SystemsDocument112 pagesDispersed SystemsDawn WRein LegaspiNo ratings yet

- June 2017 1C Que IGCSE Edexcel ChemistryDocument36 pagesJune 2017 1C Que IGCSE Edexcel ChemistryMichael EllisNo ratings yet

- Equivalent Grades of Gray Iron, Ductile Iron, SG Iron, Nodular Graphite IronDocument2 pagesEquivalent Grades of Gray Iron, Ductile Iron, SG Iron, Nodular Graphite IronNagarjun ReddyNo ratings yet