Professional Documents

Culture Documents

Steag O&M Business in Gas & Coal Based Power Plants

Uploaded by

8103 Anshu PatilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steag O&M Business in Gas & Coal Based Power Plants

Uploaded by

8103 Anshu PatilCopyright:

Available Formats

Steag O&M Business in Gas & Coal Based Power Plants

About us

STEAG Energy Services (India) Pvt. Ltd. (SESI) is a wholly owned

subsidiary of the STEAG GmbH based in Essen, Germany.

STEAG GmbH is Germany’s fifth-largest IPP has an installed capacity of

about 11,000 MW mostly coal fired up to unit size of 800 MW

Supercritical. Based on over 80 years of experience of the mother

Company in operating its own power plants, STEAG Energy Ser vices

GmbH has provided Engineering for more than 100,000 MW of installed

capacity in a whole variety of technologies and is currently providing

O&M Services to several clients for over 7,300 MW. In addition, they

provide O&M management support for further 3,600 MW worldwide.

STEAG Energy Services GmbH also installed and commissioned over

700 IT systems for plant planning and performance optimisation.

STEAG GmbH has planned, constructed and operated its own power

plants for 80 years now. We are among the be st in the industry, thanks

to the expertise we have gained over 40 years in providing third parties

with energy services. The triad of operational expertise, highly-

qualified engineering and innovative software solutions makes us

Unique.

STEAG Capabilities as an O&M Operator of Power Plants

STEAG Energy Services (India) Pvt. Ltd. (hereinafter referred as “SESI”)

an ISO 9001:2008 certified company. SESI is associated in formulation

of policy by Government agencies (CEA, CERC) and Ministry of Power.

Govt. of India has recognized the Training Center equipped with

simulator, library and other state of art training facilities with well

qualified trainers.

Since 2001, SESI has operated a combined -cycle power plant in Hazira

in the north-west of India for our customer Gujarat State Energy

Generation Ltd. The customer also continues to trust in the expertise of

our experienced specialists following expansion of the plant to a total

capacity of 507 MW. Steag do not only operate the plant but Steag also

provide engineering consultancy services, applying our IT solutions to

optimize plant operations are as much a part of our work as the training

of skilled personnel both locally and internationally.

The economic upturn and infrastructure investments planned by the

government make this country one of the most important markets of the

future. STEAG Energy Services employs over a 1500 + people in India.

Among others, we operate Gas based Combined Cycle Power Plants in

GSEG 507 MW CCPP Hazira Gujarat , HMEL CPP 165.1 MW with CFBC

Bathinda, GIPL 225 MW CCPP Kashipur, Uttarakhand and Coal based

power plant in Sterlite Energy Ltd.(Vedanta Group) 4 x 600 MW

Jharsuguda, Hinduja National Power Corporation Ltd 2 x 520 MW,

Vishakhapattanam, Coastal Energen Pvt. Ltd 2x600 MW Tuticorin and

many more.

SESI to provide cost-effective consultancy services of international

standards by integrating resources of the parent company and those of

SESI in India. SESI combines the best of the technology and

professionalism of its German principals and a thorough knowledge and

understanding of conditions in the power sector in India. It is thus able to

synergize its Indian experience with the technological and professional

back up of European standards and provide the best possible solutions

and services to clients in India and elsewhere.

Currently SESI operates such plants at 9 locations in India and has

adapted the best German system and methods to provide the highest

international standards of service. SESI has over 1500 full time

employees mostly in the category of engineers who have, over the years

acquired the requisite experience through mentorship by German

engineers to manage and operate Gas and Coal based power plants.

These plants are based on several different technologies including

660MW size plants supplied from China. The company has establ ished

state of art laboratories and testing facilities to provide comprehensive

O&M services under one roof.

The activities of STEAG Energy Services cover a wide spectrum as detailed below:

Operation and Maintenance - Operation & Maintenance market has

grown around emerging countries, attracting others and becoming a

blue ocean opportunity. Especially Steag has the world’s best

operating technology in the field of operation and maintenance of

multi-machine combined cycle power plants.

Site management including supervision of erection, pre -

commissioning & commissioning of complete Combined Cycle Power

Plants as well as coal based thermal power plants.

Performance Testing, RLA/R&M Studies, Diagnostic & Auditing

Services.

Advisory & Training Services

Project Development, Lender’s Engineering including assistance to

Owner during financial closure. (Thermal Projects & Renewable

Energies)

Owner’s Engineering for civil, structural, mechanical, electrical, C& I

system and Equipments. (Green Field Thermal Projects, R&M

Thermal Projects and Renewable Energies)

Project management & Consultancy.

Factory and Field Inspection.

Development of online and offline software tools: Performance

analysis, diagnostics and optimization (PADO), Operator training

simulators, process and electrical simulation models.

Performance analysis, diagnostics and optimization (PADO) features;

Remotely monitoring whole performance of every power plant

Checking and analyzing all the relevant data for high efficiency

Consisting of Early Warning System, Performance Monitoring

System, Plant Information System, etc

Please visit our website www.steag.in and

www.steag-energyservices.com for more details about our Company.

STEAG Approach & Methodology

The methodologies we follow keeps in view the overall objectives

outlined by our valued client and STEAG’s own philosophy which has

been developed over the last several decades of operating as an IPP in

a competitive environment. Our experience with O&M of Gas and Coal

fired power plants across the world for the third parties has

demonstrated the best approach with highly satisfactory results and can

be also adopted there.

Having come from the background of owning 11,000 MW of Power

Plants, STEAG’s approach is to operate the plant as if we were the

Owners with the sense of responsibility that goes with it.

To Operate, maintain and repair the plant on behalf of th e Owner by

benchmarking against the best Power Plants in terms of cost,

performance, reliability and as well as plant staffing.

To generate uninterrupted electricity and steam from the plant.

To staff and train O&M engineers in the best O & M procedures a nd

practices, so that they become fully equipped to operate / maintain

and continually improve the plant at.

To establish systems, standard operating procedures, standard

maintenance practices / procedures and other technical plant

documentation.

To schedule and co-ordinate deliveries and to perform all duties and

responsibilities.

Operation

Monitoring Maintenance

Procurement

O&M Documentation

Practices

Resource

Training

Management

MIS

STEAG USP

Back office Engineering Support: STEAG has a strong engineering set

up at back office to support the O&M for engineering documents review,

modifications and technical support.

Operation Services Group: Group of experts from each field

(Mechanical, Electrical, I&C, Water chemistry) are the core people of

Operation services group who will support site for routine O&M

functions, including RCA, Outage analysis, Ov erhaul planning and

execution support, performance monitoring.

Testing Services: STEAG has a complete set up of equipment

performance test facilities at Noida. Any testing requirement which is

required will be supported by this group. NABL Accredited Trans former

Oil testing facility is also available.

Training and Simulator facility is available for providing class room and

simulator training to O&M personnel, including field O&M. This Training

centre is CEA certified.

System technologies: Digital tools for online performance monitoring

and predictive maintenance software tools are developed for power

plants using STEAG’s patented software.

Strong resources: STEAG Energy Services India operates 6500 MW of

O&M for thermal power that includes, Coal fired, gas fired CFBC boilers,

both IPP and CPP. STEAG has more than 1,500 O&M personnel at

various sites who can on a short notice can reach out to any support to

support the site operations in case of overhauls and other emergency

scenarios.

Modifications: With a strong background of Engineering, commissioning

and Operations of Thermal power plants supporting O&M team, STEAG

has done more than 100 modifications at each of its operational sites to

stabilize the plant operations in a short span of time.

You might also like

- An Active Integrated Ultra-Wideband MIMO Antenna: Ieee Transactions On Antennas and Propagation 1Document6 pagesAn Active Integrated Ultra-Wideband MIMO Antenna: Ieee Transactions On Antennas and Propagation 1Asad RahmanNo ratings yet

- STOK OPNAME 21 FebruariDocument62 pagesSTOK OPNAME 21 FebruariIhdaAkbarNo ratings yet

- CFA Institute Research Challenge: CFA Society India (IAIP) Team Code - ArtumeDocument31 pagesCFA Institute Research Challenge: CFA Society India (IAIP) Team Code - Artumeshreyansh naharNo ratings yet

- Resilience in Higher Education Students: A Scoping ReviewDocument17 pagesResilience in Higher Education Students: A Scoping ReviewFlorian BodnariuNo ratings yet

- OM Commands Manual (MML)Document344 pagesOM Commands Manual (MML)Rudi WijayaNo ratings yet

- Cs230exam Spr18 Soln PDFDocument45 pagesCs230exam Spr18 Soln PDFMOHAMMAD100% (1)

- WAH Consent and NDA Form - June 2021rev2Document3 pagesWAH Consent and NDA Form - June 2021rev2Bamby Ng CebuuNo ratings yet

- Gwalior Military Air SpaceDocument1 pageGwalior Military Air SpacegauravNo ratings yet

- Catalog CarPakDocument684 pagesCatalog CarPakBillNo ratings yet

- QF ProjectDocument27 pagesQF Projectmhod omranNo ratings yet

- ASIC V Dixon Advisory Superannuation ServicesDocument30 pagesASIC V Dixon Advisory Superannuation ServicesToby VueNo ratings yet

- Final Research Paper For Commerce CorrectedDocument72 pagesFinal Research Paper For Commerce Correctedshetahun waleNo ratings yet

- Virginia Parole Board ReportDocument36 pagesVirginia Parole Board ReportCaitlyn FroloNo ratings yet

- As 129959 Iv3-G500ca Iv3-G500ma Iv3-G600ca Im 96M17460 WW GB 2102 1Document2 pagesAs 129959 Iv3-G500ca Iv3-G500ma Iv3-G600ca Im 96M17460 WW GB 2102 1AfifNasirNo ratings yet

- STAT147 Assessment 5Document4 pagesSTAT147 Assessment 5JOHN ANDREW HITOSISNo ratings yet

- IoB for Improving Customer ServicesDocument4 pagesIoB for Improving Customer ServicesHannan GharadeNo ratings yet

- Syed Zahidul Hassan ResumeDocument5 pagesSyed Zahidul Hassan ResumejewelmirNo ratings yet

- Review of Laser Doping and Its Applications in Silicon Solar CellsDocument12 pagesReview of Laser Doping and Its Applications in Silicon Solar CellsJIJIN KNo ratings yet

- JSW Steel IR 22-23Document308 pagesJSW Steel IR 22-23manishkhemka999No ratings yet

- 900 0 900 1,800 2,700 450 Meter: MC SonipatDocument1 page900 0 900 1,800 2,700 450 Meter: MC SonipatDeepak DahiyaNo ratings yet

- First Last: EducationDocument3 pagesFirst Last: EducationBellaNo ratings yet

- Havells LED Price List Mar 2016Document24 pagesHavells LED Price List Mar 2016Dhanashekar CNo ratings yet

- Module For PECDocument27 pagesModule For PECFrancis Al Maghanoy GabisonNo ratings yet

- W20271-PDF-EnG Asha Handicrafts Association - Redefining The Value Proposition StrategyDocument14 pagesW20271-PDF-EnG Asha Handicrafts Association - Redefining The Value Proposition StrategyRishab AgarwalNo ratings yet

- Case Study Nov Dec 18Document16 pagesCase Study Nov Dec 18Shahid MahmudNo ratings yet

- IIT Patna MTech Cloud Computing ProgramDocument15 pagesIIT Patna MTech Cloud Computing ProgramMANISH KUMARNo ratings yet

- Data Sheet: Scale Out For Performance, Scale Up For CapacityDocument2 pagesData Sheet: Scale Out For Performance, Scale Up For CapacityRufat IbragimovNo ratings yet

- Oriflame CSDocument2 pagesOriflame CSGulnar SayyadNo ratings yet

- 'Retail Revolution in China' - Transformation Processes in The World's Largest Grocery Retailing MarketDocument12 pages'Retail Revolution in China' - Transformation Processes in The World's Largest Grocery Retailing MarketMuhammad SulemanNo ratings yet

- Fdocuments - in - Hero-Motocorp-Ltd-55844bb02b8ee (Repaired)Document66 pagesFdocuments - in - Hero-Motocorp-Ltd-55844bb02b8ee (Repaired)HIMANSHU KUMAR TIWARINo ratings yet

- 2023-04-10 OFR Preliminary ReportDocument10 pages2023-04-10 OFR Preliminary ReportMicah AllenNo ratings yet

- 2022 Year in Review - PowerPoint - January192022Document81 pages2022 Year in Review - PowerPoint - January192022Ben SchachtmanNo ratings yet

- SABMiller 2004 Annual ReportDocument134 pagesSABMiller 2004 Annual ReportBernardo MirandaNo ratings yet

- MHC Panel Listing July 2021 - AIA SMU (Staff)Document35 pagesMHC Panel Listing July 2021 - AIA SMU (Staff)Nicky LimNo ratings yet

- Next Short-Term Lows For StocksDocument2 pagesNext Short-Term Lows For StocksSSmithNo ratings yet

- School Form 5 (SF 5) Report On Promotion and Level of Proficiency & AchievementDocument3 pagesSchool Form 5 (SF 5) Report On Promotion and Level of Proficiency & AchievementArvee Dave GipaNo ratings yet

- Computer Science Paper 2 MSDocument16 pagesComputer Science Paper 2 MSFarhan HossainNo ratings yet

- Lab Front Sheet - MergedDocument112 pagesLab Front Sheet - MergedBennetNo ratings yet

- Expert Banking Professional with 15+ Years ExperienceDocument5 pagesExpert Banking Professional with 15+ Years ExperienceJyoti Sanjay KalraNo ratings yet

- IFU Fuji Triage Capsules WDocument2 pagesIFU Fuji Triage Capsules WFernando LavandeiraNo ratings yet

- XO Wholesale Price List 20211007Document60 pagesXO Wholesale Price List 20211007Samith Madushanka100% (1)

- Sales Report 2020 Vs 2021Document114 pagesSales Report 2020 Vs 2021Hongyi KaltimNo ratings yet

- MERKLE Tig - 254 - AcdcDocument41 pagesMERKLE Tig - 254 - AcdcJosé Carlos de Alencar DiasNo ratings yet

- 17 Paper SR Synchronisation Grid Tech 2015 FinalDocument11 pages17 Paper SR Synchronisation Grid Tech 2015 FinalManash Protim GogoiNo ratings yet

- Univ317 Pset 2Document5 pagesUniv317 Pset 2Bagas KaraNo ratings yet

- Arab Health 14-01-20Document96 pagesArab Health 14-01-20Alaa AljghamiNo ratings yet

- KCBS-KCAL EEO Public File Report 8-1-21 To 7-22!22!1Document8 pagesKCBS-KCAL EEO Public File Report 8-1-21 To 7-22!22!1TatyanaNo ratings yet

- WCM of BLDocument83 pagesWCM of BLVipul TandonNo ratings yet

- FINAL PROJECT - of SharekhanDocument30 pagesFINAL PROJECT - of SharekhanRAGHU M SNo ratings yet

- Intern Final Draft AshishDocument40 pagesIntern Final Draft AshishMadhav RajbanshiNo ratings yet

- BCAC-301 - Lecture 1Document18 pagesBCAC-301 - Lecture 101ABHIGYAN MAJINo ratings yet

- The Complete Guide To Building A Remote Global Tea Me BookDocument20 pagesThe Complete Guide To Building A Remote Global Tea Me BookOrnela RigottiNo ratings yet

- Maritime cabotage overviewDocument12 pagesMaritime cabotage overviewToriqul ChowdhuryNo ratings yet

- Business License Revocation Letter. Naomi I. Halter.1Document3 pagesBusiness License Revocation Letter. Naomi I. Halter.1T RNo ratings yet

- Prosiding IGSC 2021 Full PaperDocument859 pagesProsiding IGSC 2021 Full PaperErsarsit GeaNo ratings yet

- Economic Survey 2020-21 Eng Final RDocument765 pagesEconomic Survey 2020-21 Eng Final RNischith GowdaNo ratings yet

- BreezeACCESS Family Country Codes 090602Document79 pagesBreezeACCESS Family Country Codes 090602Roberto GarridoNo ratings yet

- EG Actuator Tester Models 8909-041 and 8909-059: Product Manual 55021 (Revision F, 10/2021)Document28 pagesEG Actuator Tester Models 8909-041 and 8909-059: Product Manual 55021 (Revision F, 10/2021)MussardNo ratings yet

- Tci 903SDocument8 pagesTci 903SomarhanandehNo ratings yet

- Training Calendar 2023-24Document36 pagesTraining Calendar 2023-24Mantu RajNo ratings yet

- SHT 00 M DOP NA 201 B Project Technical DocumentsDocument29 pagesSHT 00 M DOP NA 201 B Project Technical Documents8103 Anshu PatilNo ratings yet

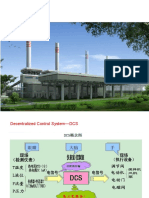

- DCS overview: functions and componentsDocument55 pagesDCS overview: functions and components8103 Anshu PatilNo ratings yet

- Hazira Site - Control Valve Calibration SheetDocument3 pagesHazira Site - Control Valve Calibration Sheet8103 Anshu Patil100% (1)

- Rotan OM ApproachDocument173 pagesRotan OM Approach8103 Anshu PatilNo ratings yet

- Basic RatesDocument110 pagesBasic Rates8103 Anshu PatilNo ratings yet

- Partlist Battery ChargerDocument49 pagesPartlist Battery Charger8103 Anshu PatilNo ratings yet

- 3 Horizons PDFDocument12 pages3 Horizons PDFAaron BareNo ratings yet

- Part List - MCCDocument172 pagesPart List - MCC8103 Anshu PatilNo ratings yet

- ONGC CPP MALLAWARAM Scope of WorkDocument35 pagesONGC CPP MALLAWARAM Scope of Work8103 Anshu PatilNo ratings yet

- Spare Parts ManagementDocument21 pagesSpare Parts Managementdajit1100% (1)

- Anokye 2022Document12 pagesAnokye 2022siti zakhannaNo ratings yet

- Lecture Notes On Software Testing PDFDocument14 pagesLecture Notes On Software Testing PDFJayavanth MarshieeNo ratings yet

- Project ReportDocument72 pagesProject Reportbca21066No ratings yet

- 17CMBF91 - Enterprise Resource PlanningDocument20 pages17CMBF91 - Enterprise Resource PlanningShanthiNo ratings yet

- Bug Busting - A GuideDocument94 pagesBug Busting - A GuidernbhushannNo ratings yet

- MPN Coiled Tubing Services ITT Part 2-Attachment 3-Technical Eval Spec Q2 Gap Analysis Template1 - DoneDocument11 pagesMPN Coiled Tubing Services ITT Part 2-Attachment 3-Technical Eval Spec Q2 Gap Analysis Template1 - Donegodsdoing4979No ratings yet

- Huawei Unified Communications Product PortfolioDocument4 pagesHuawei Unified Communications Product Portfoliosultan aaNo ratings yet

- Cybersecurity For BuildingsDocument13 pagesCybersecurity For Buildings叶宸(Jason)No ratings yet

- Angular Certification Training20220401180227Document14 pagesAngular Certification Training20220401180227Akshay RahaneNo ratings yet

- FloCon 21 - GHOSTS in The MachineDocument31 pagesFloCon 21 - GHOSTS in The MachinegreycompanionNo ratings yet

- Company ProfileDocument21 pagesCompany ProfileQiniso MkhwanaziNo ratings yet

- Grady Booch Software Architecture and The Uml 120427275169679 5Document91 pagesGrady Booch Software Architecture and The Uml 120427275169679 5aksinha4No ratings yet

- MIS ch-3 - MIS and DSSDocument44 pagesMIS ch-3 - MIS and DSSkebede desalegnNo ratings yet

- Expert Answer: Question: Computing Reorder Points (Rop) For Iphones With andDocument1 pageExpert Answer: Question: Computing Reorder Points (Rop) For Iphones With andIshikaNo ratings yet

- May AIX and PowerSW Monthly MeetingDocument36 pagesMay AIX and PowerSW Monthly MeetingsunNo ratings yet

- Configuring and Extending BenefitsDocument54 pagesConfiguring and Extending BenefitsmohamedNo ratings yet

- Hitachi Managed Cloud Operations ChecklistDocument3 pagesHitachi Managed Cloud Operations ChecklistRalph LobatoNo ratings yet

- 04 Sampel Resume 2020 (Traditional Design)Document2 pages04 Sampel Resume 2020 (Traditional Design)kalai arasanNo ratings yet

- SAP S4HANA Webcast Series - EN - 09 - Session - Transformation - Choices - PE - Scenarios - HandoutDocument26 pagesSAP S4HANA Webcast Series - EN - 09 - Session - Transformation - Choices - PE - Scenarios - HandouttelegenicsNo ratings yet

- Getting Started with Google AdsDocument56 pagesGetting Started with Google AdsElijah BalinNo ratings yet

- Atm Treasure Data CDP Use CasesDocument1 pageAtm Treasure Data CDP Use Cases韩勇No ratings yet

- External Equipment Maintenance ProcessDocument3 pagesExternal Equipment Maintenance ProcessMohammed alsalahiNo ratings yet

- Total Cost of Ownership ExerciseDocument3 pagesTotal Cost of Ownership ExerciseAnkit MehtaNo ratings yet

- Chart InkDocument2 pagesChart Inkcoinslots00No ratings yet

- Playful Laundry A Gamified Laundry Booking SystemDocument5 pagesPlayful Laundry A Gamified Laundry Booking SystemFaiza ZainNo ratings yet

- Application of CGDocument23 pagesApplication of CGSanam MaharjanNo ratings yet

- Business Intelligence Masters Training PDFDocument14 pagesBusiness Intelligence Masters Training PDFSanju KumarNo ratings yet

- Purchase-to-Pay Example Using Sap Erp: Product Motivation PrerequisitesDocument26 pagesPurchase-to-Pay Example Using Sap Erp: Product Motivation PrerequisitesShashank MallepulaNo ratings yet

- Professional Summary: Sr. Business AnalystDocument3 pagesProfessional Summary: Sr. Business AnalystCharu IndoriaNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsFrom EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsRating: 5 out of 5 stars5/5 (1)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Corrosion Control in the Oil and Gas IndustryFrom EverandCorrosion Control in the Oil and Gas IndustryRating: 4 out of 5 stars4/5 (12)

- Mooring System Engineering for Offshore StructuresFrom EverandMooring System Engineering for Offshore StructuresRating: 5 out of 5 stars5/5 (1)