Professional Documents

Culture Documents

Fixamin CP T1: - Ready-To-Use Base Paste For Double Dot Coating

Uploaded by

rabiulfOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fixamin CP T1: - Ready-To-Use Base Paste For Double Dot Coating

Uploaded by

rabiulfCopyright:

Available Formats

Fixamin® CP T1 - Ready-to-use base paste for Double Dot Coating

Technical solutions for a better life

With a wide range of products Bozzetto has solutions to satisfy the specific requirements of

the technical textiles industries. In collaboration with our customer we are always looking for

new and environmental friendly solutions, customized products and innovative processes.

• Hotmelt adhesive, lamination and coating products.

Fixamin CP T1 for Double Dot technology

The Double Dot technology is a combination of paste dot and scatter coating.

This kind of coating has been developed for relatively “open” substrates whereas the threat

of backstroke of the hotmelt powder dot shall be eliminated. In this case a combined paste-

scatter dot is been applied, while the paste is printed onto the substrate and may not be

reactivated after drying. The upper dot, usually a Copolyamide powder, is used for the

bonding of the interlining with the shell fabric.

Figure 1: principle of Double Dot

Requirements of Double Dot Paste systems

• Good processing properties (no sticking, long open time)

• High production speed

• Easy to prepare

• Environmental friendly

• Good adhesion to upper dot

• Resistance to wash and dry cleaning

• No strike back

• No high price level

Figure 2: Double Dot Figure 3: displayed at regular dot coating

FIXAMIN CP T1

• Is an aqueous paste based on polyurethane

• Generates a very good dot shape due to it‘s reological behaviour

• Provides a good adhesion to polyamide and polyester powder

• Has an excellent dry cleaning and wash resistance up to 60°C

• Can be used with CC and CP printing screens

• Allows line speed up to 80 m/min and above

• Has a very long open time to prevent a blocking of the surface of the screen

Application

FIXAMIN CP T1 can be applied with rotary printing screens by double dot coating

technology. Very good results can be achieved with CP printing screens. If the viscosity

needs to be increased, MIROX VD 65 can be added.

As scattering powder for the top dot we recommend thermoplastic powder (copolyamides or

copolyesters) in a particle size between 80 - 160 µm.

Figure 4 : Double Dot coating

BONDING TEST

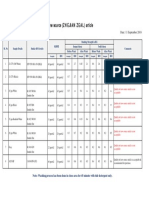

Double Dot trials with Fixamin CP T 1

Fabric:: Warp-knitted fabric 25 g/m²

Screen: CP 76

Speed: 30 m/min

Drying: 140°C / 150°C / 160°C

Lamination: 150°C / 15 sec. / 4N

Washing: 3 times domestic laundry

18

16

14

12

10

CO/PES [N]

8

Cotton [N]

6

4

2

0

Original 40°C 60°C 90°C DC

Figure 5 : Bonding Test with Fixamin CP T1

APPLICATION RANGE

• Interlining for women’s outer garments

• Interlining for Men’s wear

• Interlining on woven

• Interlining on nonwoven

• Interlining on warp-knitted fabric

Figure 6: Women’s outer wear Figure 7: Men’s wear

Figure 8: Interlining on nonwoven Figure 9: Interlining on woven

YOUR PARTNER IN COATING TECHNOLOGY

Contact us for further information or to arrange a testrun on our Coating pilot plant.

BOZZETTO GmbH - Technical Coating & Laminating -

Bäkerpfad 25

47805 Krefeld, Germany

TEL +49 2151 38 34 21

FAX +49 2151 38 10 05

www.bozzetto.de

E-mail: tcl@bozzetto.de

Trials will be arranged according to your needs and specifications.

You might also like

- Optimising Quality and Cost of Bed Sheeting Finishing: 1. SummaryDocument5 pagesOptimising Quality and Cost of Bed Sheeting Finishing: 1. SummarySachin PatelNo ratings yet

- PolyCast PIS EN V1-20230823Document16 pagesPolyCast PIS EN V1-20230823JohnNo ratings yet

- 3D Printer Troubleshooting Handbook: The Ultimate Guide To Fix all Common and Uncommon FDM 3D Printing Issues!From Everand3D Printer Troubleshooting Handbook: The Ultimate Guide To Fix all Common and Uncommon FDM 3D Printing Issues!No ratings yet

- HP CataloqueDocument116 pagesHP CataloquefiliperosaNo ratings yet

- Bottles, Preforms and Closures: A Design Guide for PET PackagingFrom EverandBottles, Preforms and Closures: A Design Guide for PET PackagingRating: 4.5 out of 5 stars4.5/5 (3)

- Ceramic Coating Application On Car Paintings and RimsDocument5 pagesCeramic Coating Application On Car Paintings and RimsRaybert ParedesNo ratings yet

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsFrom EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsRating: 4.5 out of 5 stars4.5/5 (17)

- Specificatie Tehnica BOPPDocument2 pagesSpecificatie Tehnica BOPPkrys780% (1)

- 5 Year Calendered Digital Vinyl With Metascape' SystemDocument1 page5 Year Calendered Digital Vinyl With Metascape' Systemjonjonjon0No ratings yet

- 3M Double Sided TapeDocument2 pages3M Double Sided TapeDennis ChenNo ratings yet

- Product DescriptionDocument1 pageProduct Descriptionjonjonjon0No ratings yet

- Md3a 2Document1 pageMd3a 2jonjonjon0No ratings yet

- Hand Lay UpDocument29 pagesHand Lay UpRavendran Krishnan100% (2)

- Rheo FibreDocument2 pagesRheo FibreBinoy Sankar SarkerNo ratings yet

- Internship Report of A Textile MillDocument29 pagesInternship Report of A Textile MillMUHAMMAD SAGHEER100% (1)

- Cement Mill FDN4-Strengthening-1Document3 pagesCement Mill FDN4-Strengthening-1Devinder Chawla100% (1)

- Technical Data Sheet-Cut Back Bitumen MC30Document2 pagesTechnical Data Sheet-Cut Back Bitumen MC30benzeneinternational100% (1)

- Cidacomfy MMT HCDocument10 pagesCidacomfy MMT HCUtpalNo ratings yet

- Application Instructions Denso Butyl Tape System1Document4 pagesApplication Instructions Denso Butyl Tape System1Khoh Kai ShengNo ratings yet

- Gazechim Brochure Nov 2012 PDFDocument13 pagesGazechim Brochure Nov 2012 PDFByron BrownNo ratings yet

- Study of Nylon Material For Additive Manufacturing: Materials Used in AMDocument8 pagesStudy of Nylon Material For Additive Manufacturing: Materials Used in AMAbhishek PatilNo ratings yet

- Fendolite Proofing PDFDocument4 pagesFendolite Proofing PDFShaji MathewNo ratings yet

- Textile Internship at VardhmanDocument60 pagesTextile Internship at VardhmanNeetek SahayNo ratings yet

- Tez-Flyer 2015 enDocument2 pagesTez-Flyer 2015 enhuman0123No ratings yet

- 3M - EU - Tech Bulletin - 480 - 2017 - 2Document7 pages3M - EU - Tech Bulletin - 480 - 2017 - 2ajmalakramNo ratings yet

- Composite Manufacturing ProcessesDocument4 pagesComposite Manufacturing ProcessesUmesh KsNo ratings yet

- Eco Application GuideDocument8 pagesEco Application GuidemsbaupartnerNo ratings yet

- Specification GlassFiberDocument6 pagesSpecification GlassFiberMukesh MaharjanNo ratings yet

- Cmci Cmci: High Performance Epoxy Grout SystemDocument2 pagesCmci Cmci: High Performance Epoxy Grout Systempravi3434No ratings yet

- The Background of Thermoforming The Advantages of ThermoformingDocument7 pagesThe Background of Thermoforming The Advantages of ThermoformingA MahmoodNo ratings yet

- Berger Coating StandardsDocument9 pagesBerger Coating StandardsHariHaranNo ratings yet

- Ideas Take ShapeDocument28 pagesIdeas Take ShapewjirawichNo ratings yet

- Penguard MidcoatDocument4 pagesPenguard MidcoatfirmanNo ratings yet

- Injection MoldingDocument17 pagesInjection MoldingAnoj pahathkumburaNo ratings yet

- A Solvent-Free Non-Staining Acrylic-Adhesive in Water DispersionDocument4 pagesA Solvent-Free Non-Staining Acrylic-Adhesive in Water DispersionFloorkitNo ratings yet

- REL Group 71Document12 pagesREL Group 71Yuvraj TyagiNo ratings yet

- Application Instructions Petrolatum Tape SystemDocument4 pagesApplication Instructions Petrolatum Tape Systemnikita6969No ratings yet

- DigitalprintingDocument9 pagesDigitalprintingtbagnathNo ratings yet

- Internship Report On HanDocument26 pagesInternship Report On Hanabdulber kedirNo ratings yet

- Phoenix Water Based PrimerDocument5 pagesPhoenix Water Based PrimerbooklandNo ratings yet

- pm002 4446Document2 pagespm002 4446Dhanush Kumar RamanNo ratings yet

- Crea - Lign Freestyle Manual: Natural AestheticsDocument16 pagesCrea - Lign Freestyle Manual: Natural AestheticsAurelia CrismariNo ratings yet

- Triblock Finish GBDocument4 pagesTriblock Finish GBdraganugNo ratings yet

- Strain Gauge InstallationDocument4 pagesStrain Gauge InstallationChetan B ArkasaliNo ratings yet

- An Overview of Polyester and Polyester Dyeing Part-4: ..... Previous Part Next Part....Document5 pagesAn Overview of Polyester and Polyester Dyeing Part-4: ..... Previous Part Next Part....Ronak JoshiNo ratings yet

- PDS Hempaprime Multi 500 Winter en-GBDocument2 pagesPDS Hempaprime Multi 500 Winter en-GBFreddyNo ratings yet

- 3 - PC 7049 - Apcodur MioDocument3 pages3 - PC 7049 - Apcodur Miosujay AvatiNo ratings yet

- Composite Manufacturing 101Document84 pagesComposite Manufacturing 101veljko100% (1)

- Date: Aprile 16 Process: Velvet Effect Customer: Plant: Lab Mill: Denim Total Pounds: Prod. Code: 10630 Sample N°: 2093Document2 pagesDate: Aprile 16 Process: Velvet Effect Customer: Plant: Lab Mill: Denim Total Pounds: Prod. Code: 10630 Sample N°: 2093viathungNo ratings yet

- TDS Wet On Wet Primer - GBDocument3 pagesTDS Wet On Wet Primer - GBชัชชัย พรายมีNo ratings yet

- Ko-17 Liquido para Alta TemperaturaDocument2 pagesKo-17 Liquido para Alta TemperaturaDaniel san martinNo ratings yet

- Mastertop 1230i M 12-04Document3 pagesMastertop 1230i M 12-04djrote4No ratings yet

- DD-DOC 0111 - General Guidelines For Screen Printing On Flat GlassDocument18 pagesDD-DOC 0111 - General Guidelines For Screen Printing On Flat GlassIrina AureliaNo ratings yet

- PE CoatingDocument8 pagesPE CoatingHotnCrispy CrispyNo ratings yet

- Santoprene Blow Molding Guide EnpdfDocument23 pagesSantoprene Blow Molding Guide EnpdfNikhil AherNo ratings yet

- Santoprene Blow Molding Guide enDocument23 pagesSantoprene Blow Molding Guide enasddsaNo ratings yet

- Graphit 33Document2 pagesGraphit 33Manuel Armindo RibeiroNo ratings yet

- New Development in Winch Dyeing-Dyeing High Efficiency & Low Energy Consumption High Temperature Dyeing MachineDocument4 pagesNew Development in Winch Dyeing-Dyeing High Efficiency & Low Energy Consumption High Temperature Dyeing MachineRezaul Karim Tutul100% (1)

- Heat Transfer PrintingDocument2 pagesHeat Transfer PrintingrabiulfNo ratings yet

- Test Report: Overall RatingDocument3 pagesTest Report: Overall RatingrabiulfNo ratings yet

- PrintingDocument2 pagesPrintingrabiulfNo ratings yet

- Dyeing MethodsDocument3 pagesDyeing MethodsrabiulfNo ratings yet

- Pigment DyesDocument2 pagesPigment DyesrabiulfNo ratings yet

- Test Report: Overall RatingDocument3 pagesTest Report: Overall RatingrabiulfNo ratings yet

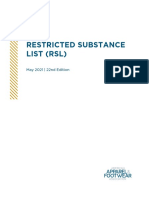

- Restricted Substance List (RSL) : May 2021 - 22nd EditionDocument49 pagesRestricted Substance List (RSL) : May 2021 - 22nd EditionrabiulfNo ratings yet

- Comparison Report Between Newly Developed and Previous Article of QFDocument2 pagesComparison Report Between Newly Developed and Previous Article of QFrabiulfNo ratings yet

- 150 Sample-Chapter PDFDocument25 pages150 Sample-Chapter PDFMochammad Waris SNo ratings yet

- GRAY FABRIC ANALYSIS REPORT-MD Sir 20 MAy 2013Document1 pageGRAY FABRIC ANALYSIS REPORT-MD Sir 20 MAy 2013rabiulfNo ratings yet

- Short Communication Quantitative Determination of Formaldehyde by Spectrophotometry Utilizing Multivariate Curve Resolution Alternating Least SquaresDocument6 pagesShort Communication Quantitative Determination of Formaldehyde by Spectrophotometry Utilizing Multivariate Curve Resolution Alternating Least SquaresrabiulfNo ratings yet

- Comparison ReportDocument1 pageComparison ReportrabiulfNo ratings yet

- Acrylic EsterDocument27 pagesAcrylic EsterrabiulfNo ratings yet

- Coating, Laminating and Testing CapabilitiesDocument28 pagesCoating, Laminating and Testing CapabilitiesrabiulfNo ratings yet

- Fabric Study - (Textbook + Practical Manual) XIIDocument90 pagesFabric Study - (Textbook + Practical Manual) XIIAn Bn50% (2)

- Short Communication Quantitative Determination of Formaldehyde by Spectrophotometry Utilizing Multivariate Curve Resolution Alternating Least SquaresDocument6 pagesShort Communication Quantitative Determination of Formaldehyde by Spectrophotometry Utilizing Multivariate Curve Resolution Alternating Least SquaresrabiulfNo ratings yet

- Dyeing Booklet PDFDocument51 pagesDyeing Booklet PDFKevin WoodNo ratings yet

- Tranexamic AcidDocument5 pagesTranexamic Acidiabureid7460No ratings yet

- Plasticizer SDocument28 pagesPlasticizer SM Arslan AshrafNo ratings yet

- Technical Data Sheet-AL MUSLIM GROUPDocument4 pagesTechnical Data Sheet-AL MUSLIM GROUPrabiulfNo ratings yet

- BlazerDocument1 pageBlazerrabiulfNo ratings yet

- Acrylic EsterDocument27 pagesAcrylic EsterrabiulfNo ratings yet

- Stretch Recovery Test of Denim PantDocument1 pageStretch Recovery Test of Denim PantrabiulfNo ratings yet

- Interlining Manufacturing - Generic Flow ChartDocument1 pageInterlining Manufacturing - Generic Flow ChartrabiulfNo ratings yet

- Pioneer CKDocument1 pagePioneer CKrabiulfNo ratings yet

- Product Certificate: (Additional Info/ Limitation of Product According To Care Instruction of Product& Process)Document2 pagesProduct Certificate: (Additional Info/ Limitation of Product According To Care Instruction of Product& Process)rabiulfNo ratings yet

- Omron Group Sustainable Conduct PoliciesDocument12 pagesOmron Group Sustainable Conduct PoliciesrabiulfNo ratings yet

- Prohibited Sourcing Regions PolicyDocument1 pageProhibited Sourcing Regions PolicyrabiulfNo ratings yet

- Policy For The Management of Hazardous Materials: Environmental Health and Safety Policy (Document13 pagesPolicy For The Management of Hazardous Materials: Environmental Health and Safety Policy (rabiulfNo ratings yet

- Fuji Electric's Offer To Renew Your Power Distribution EquipmentDocument32 pagesFuji Electric's Offer To Renew Your Power Distribution Equipmentfajria saputraNo ratings yet

- Fick's Law of DiffusionDocument6 pagesFick's Law of DiffusionWilson Ling Kuok HungNo ratings yet

- Unnoticed Uses and Making of 100K ResistorDocument7 pagesUnnoticed Uses and Making of 100K ResistorjackNo ratings yet

- Pds Stopaq Paste CZH v5 enDocument2 pagesPds Stopaq Paste CZH v5 enAndyNo ratings yet

- NDS - ASD 2012: Architecture 544 Wood StructuresDocument6 pagesNDS - ASD 2012: Architecture 544 Wood StructuresDow JonesNo ratings yet

- 10 PhyDocument4 pages10 PhyTapas BanerjeeNo ratings yet

- Byk Chemie Rheology Additive PortfolioDocument64 pagesByk Chemie Rheology Additive PortfolioCereliaNo ratings yet

- An Experimental Analysis of The Transport of Drilled ParticlesDocument10 pagesAn Experimental Analysis of The Transport of Drilled ParticlesAlvian IacoccaNo ratings yet

- J N ReddyDocument10 pagesJ N ReddypvmoorthiNo ratings yet

- Problem 2.49 PDFDocument2 pagesProblem 2.49 PDFKauê BrittoNo ratings yet

- 2015thermal PDFDocument26 pages2015thermal PDFBenAmmareImed0% (1)

- Physics at Nanoscale CH 1Document87 pagesPhysics at Nanoscale CH 1ParmodDhandaNo ratings yet

- EEI CV3 IMEP TESt 2Document3 pagesEEI CV3 IMEP TESt 2tyshaNo ratings yet

- Heat Generation in Plastic Deformation Using ANSYS® Mechanical APDL and Workbench v14.5: Application of The New ACT Module - FEA - Tips and Tricks - NewslettersDocument11 pagesHeat Generation in Plastic Deformation Using ANSYS® Mechanical APDL and Workbench v14.5: Application of The New ACT Module - FEA - Tips and Tricks - NewslettersGanesh R NavadNo ratings yet

- 2.properties & Testing MethodsDocument87 pages2.properties & Testing MethodsSamuel EsparteroNo ratings yet

- C Si MN Thickness (MM) Yield Point (Mpa) Tensile Strength (Mpa) Elongation (%) Bend Test (In Radius) F S Applicable Thickness (MM) SpecDocument1 pageC Si MN Thickness (MM) Yield Point (Mpa) Tensile Strength (Mpa) Elongation (%) Bend Test (In Radius) F S Applicable Thickness (MM) SpecEri Dya FadliNo ratings yet

- Nanotechnology in Chemical IndustryDocument3 pagesNanotechnology in Chemical IndustryjournalNo ratings yet

- FEModels of GFRP and CFRP StrengtheningDocument14 pagesFEModels of GFRP and CFRP StrengtheningCrystal SuriyaNo ratings yet

- Astm 112Document45 pagesAstm 112Vajid Madathil100% (1)

- Shear Rate CalculationDocument8 pagesShear Rate CalculationMdAliRazuNo ratings yet

- HT Work Instruction Chart 23.03.2010 RevisedDocument5 pagesHT Work Instruction Chart 23.03.2010 RevisedkvmoorthiNo ratings yet

- Exact Solution of Von Karman EqDocument5 pagesExact Solution of Von Karman EqsyedmuhammadtariqueNo ratings yet

- Tawanda Munemo (H150148M)Document3 pagesTawanda Munemo (H150148M)Keith Tanaka MagakaNo ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- ENGINEERING PHYSICS by DK BHATTACARJEE and POONAM TANDONDocument59 pagesENGINEERING PHYSICS by DK BHATTACARJEE and POONAM TANDONSujata Sarkar56% (9)

- (Kakiuchi) Novel Zeolite Adsorbents and Their Application For AHP and Desiccant SystemDocument6 pages(Kakiuchi) Novel Zeolite Adsorbents and Their Application For AHP and Desiccant SystemAnoop AiyappaNo ratings yet

- Polymers: Electrical and Electrochemical Properties of Conducting PolymersDocument32 pagesPolymers: Electrical and Electrochemical Properties of Conducting PolymersDuc Anh NguyenNo ratings yet

- Delayed PWHTDocument4 pagesDelayed PWHThasan_676489616No ratings yet

- Lab 5 Combined LoadingDocument13 pagesLab 5 Combined Loadingapi-3730129100% (1)