Professional Documents

Culture Documents

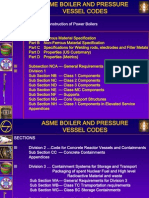

Wps/Pqr Wps/Pqr 153 Slides: 30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by SCB

Wps/Pqr Wps/Pqr 153 Slides: 30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by SCB

Uploaded by

Saptarshi Mandal0 ratings0% found this document useful (0 votes)

11 views35 pagesOriginal Title

Asme Ix Slides (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views35 pagesWps/Pqr Wps/Pqr 153 Slides: 30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by SCB

Wps/Pqr Wps/Pqr 153 Slides: 30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by SCB

Uploaded by

Saptarshi MandalCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 35

WPS/PQR

153 Slides

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 1

SCB

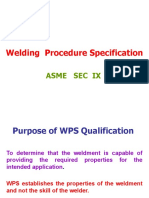

A Welding Procedure is a recipe of variable welding

parameters, which will produce the same results of certain

quality & properties of weld if carried out in the same way

eachh time

ti

Or a procedure which has been welded and tested to a

specification such as ASME IX.

Welding procedure qualification established the properties of

weldment NOT the skill of the welder.

It is a document of a qualified welding procedure

used to give a welder the information which he

needs in order to carry out the work.

It has been issued

iss ed as a res

result

lt of a ssuccessful

ccessf l

Welding Procedure test (WP test).

Additional

ddi i l WPS’s can be b issued

i d on a successful

f l

WP test as long as they remain within the Extent

off Approval.

l

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 3

SCB

Drawing Draft WPS

Construction Code From all range of Welding of a

welding variables test coupon

Materials

9Essential; f

from th

the

Design

9 Nonessential; Range of

Impact testing variables

ABC 9 Supplementary

PWHT etc (if applicable).

applicable)

ABC WPS ABC PQR

W ldi

Welding Record of Record of welding variables

variables actual variable

9 Essential; and test results

9 Nonessential; certification

9 Supplementary 9Specimen preparation

(if applicable). Date

9Mechanical test

sign

9Documentation

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 4

SCB

Once the welding of test coupon has been completed under

some welding variables , No Radiography or any

examination required

The test coupons shall be Mechanically tested to ensure that

the desired level of mechanical pproperties

p have been met

If all the desired properties have been met, then a procedure

qualification record (PQR) is completed with all the test

results reviewed, and the draft WPS then becomes qualified

From thi

F this data,

d t a workable

k bl document

d t for

f production

d ti weldingldi is

i

prepared and called a Welding Procedure Specification. (WPS)

and the welding work may proceed.

QW-200.1 Each manufacturer and contractor shall

prepare written Welding Procedure Specifications which

are defined as follows.

(a) Welding Procedure Specification (WPS). A WPS

i a written

is i qualified

lifi d welding

ldi procedure

d preparedd to

provide direction for making production welds to Code

requirements The WPS or other documents may be

requirements.

used to provide direction to the welder or welding

operator

p to assure compliance

p with the,Code require-

q

ments.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 6

SCB

QW-200.2 Each manufacturer or contractor shall be

required to prepare a procedure qualification record

which is defined as follows.

QW-200(a) Procedure Qualification Record (PQR). A

PQR iis a recordd off the

h welding

ldi data

d usedd to weld ld a test

coupon. The PQR is a record of variables recorded

during the welding of the test coupons.

coupons It also contains

the test results of the tested specimens. Recorded vari-

ables normallyy fall within a small range

g of the actual

variables that will be used in production welding.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 7

SCB

The terms “manufacturer” or “contractor” are:

9 Own the certificate of authorization,, can be a

conventional or a nuclear stamp(s), where required

9 Responsible for the welding

9 Can be an installer, assembler or fabricator

9 Can be an organization effective operational control of

welding qualification for TWO or more companies of

different name, see QW 201.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 8

SCB

Question (1): If Company A reviews and approves

Section IX qualified WPS’s submitted by Companies B

and C for a given project, may Company A use Company

B and C‘s WPS’s?

Reply

R l (1):

(1) No.

N

Question (2): If Company A reviews and approves

S ti IX qualified

Section lifi d WPS’s

WPS’ submitted

b itt d Companies

C i B andd

C for a given project, may Company A authorize

company B to use Company C C‘ss WPS’s

WPS s on that project?

Reply (2): No.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 9

SCB

Question: May a contractor provide his qualified

welding

we d g procedure

p ocedu e spec

specifications,

ca o s, for

o use by hiss

subcontractors, to perform welding in accordance

with the requirements

q of ASME BPV Code

Section IX?

Reply: No.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 10

SCB

Question: In a contract involving piping construction work,

our company subcontracted the piping prefabrication work to a

subcontractor. This subcontractor is managedg by y our company

p y

but has a different name. The subcontractor proceeded to

qualify welding procedures which were conducted in the

presence and with the approval of our company’s welding

engineer

i who

h monitored

i d the

h welding

ldi off the

h test coupons andd

signed approval on the PQRs. The Quality Control System of

the subcontractor and our company fully described the

operational

e ti l controlt l off procedure

ed e qualifications.

lifi ti W our client

Was lie t

right in rejecting the use by our company of the subcontractor

qualified welding procedures for the erection work of the

prefabricated piping?

Reply: This is a contractual issue, which ASME does not

address.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 11

SCB

Three construction companies have participated in a

nuclear power plant construction project as a consortium

contractor. They have a unified Quality Assurance

Program, but the consortium does not hold a Certificate

of Authorization.

Authorization Each of the construction companies

holds its own Certificate of Authorization.

Question: Does “two

two or more companies of different

names in an organization” in QW-201 apply to the

consortium described in the Background?

g

Reply: No

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 12

SCB

Background Two companies are contracted by a client

company to undertake pipe work installation on its facility. All

stages

g of the Welding g Procedure QQualification Processes for

the two contracted companies are witnessed by the client

companies representative and the documentation duly stamped

and signed as accepted by the client.

Question (1): May these procedures be used by the client

company?

Reply

p y ((1):

) No.

Question (2): Does the client company have to re-qualify these

procedures in order to perform in-house maintenance a t a later

date using all the same essential and nonessential variables

with its own qualified welders?

Reply (2): Yes.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 13

SCB

WPSs may be used by the new owner(s) without

requalification, provided all of the following are met:

(a) the new owner(s) takes responsibility for the WPSs and

PQRs

(b) the WPSs reflect the name of the new owner(s)

(c) the Quality Control System/Quality Assurance Program

reflects the source of the PQRs as being from the former

manufacturer or contractor

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 14

SCB

Background: Company A and Company B merge

divisions to form a new Company, C.

Question (1):May the new Company C , use PQRs and

WPSs developed previously by Company A and

Company B?

Reply (1): Yes, provided operational control is in

accordance with QW-201.

Question (2): May the new Company, C, use the central

materials laboratory of Company A to develop WPSs and

PQRs?

Reply (2): Yes, provided operational control is in

accordance with QW-201.

Q

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 15

SCB

Background: When one of a company' s plants is sold, it

is not clear if the new owner can use the Welding

Procedure Specifications (WPS) and Procedure

Qualification Records (PQR) qualified by the original

company when the original company wishes to continue

company.

using those WPS/PQR.

Question: Company A sells one of its plants to Company

B. May both Company A and Company B use the

WPSs/PQRsQ ppreviously y qqualified by

y Company

p yA

Reply: Yes. provided the requirements of QW-201.1 are

addressed by Company B.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 16

SCB

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 17

SCB

(b)Contents

(b)C t t off the

th WPS.

WPS The

Th completedl t d WPS shall

h ll

describe all of the essential, nonessential, and, when

required, supplementary essential variables for each

welding process used in the WPS. These variables are

listed in QW-250 through QW-280 and are defined in

Article IV, Welding Data.

The WPS shall reference the supporting Procedure

Qualification

lifi i Record(s)

d( ) (PQR)

( ) described

d ib d in

i QW-200.2.

The manufacturer or contractor may include any other

information in the WPS that may be helpful in making

a Code weldment.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 18

SCB

QW-401.1 Essential Variable

(Procedure) A change in a welding

(Procedure).

condition which will affect the mechanical

properties

ti (other

( th than

th notcht h toughness)

t h ) off

the weldment (for example, change in P-

Number, weld- ing process, filler metal,

electrode,, ppreheat or p

postweld beat

treatment, etc.).

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 19

SCB

QW-401.3 Supplemental Essential Variable (Procedure). A change in

a welding condition which will affect the notch-toughness properties of a

weldment (for example, change in welding process, uphill or down vertical

welding heat input,

welding, input preheat or PWHT,

PWHT etc.).etc )

When a procedure has been previously qualified to satisfy all

requirements other than notch toughness, it is then necessary only to prepare

an additional test coupon using the same procedure with the same essential

variables,

i bl butb t additionally

dditi ll with ith all

ll off the

th required

i d supplementary

l t essential

ti l

variables, with the coupon long enough to provide the necessary notch-

toughness specimens.

When a pprocedure has been ppreviously y qqualified to satisfy

y all

requirements including notch toughness, but one or more supplementary

essential variable is changed, then it is only necessary to prepare an

additional test coupon using the same welding procedure and the new

supplementary essential variable(s), with the coupon long enough to

provide the necessary notch-toughness specimens. If a previously qualified

weld procedure has satisfactory notch-toughness values in the weld

metal, then it is necessary only to test notch-toughness specimens from the

heat affected zone when such are required.

required

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 20

SCB

QW-401.4 Nonessential Variable (Procedure). A

change in a welding condition which will not affect

the mechanical properties of a weldment (such as joint

design, method of back gouging or cleaning, etc.)

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 21

SCB

((c)) Ch

Changes to

t the

th WPS.

WPS Changes

Ch may be

b made d ini the

th

nonessential variables of a WPS to suit production

requirements without requalification provided such

changes are documented with respect to the essential,

nonessential, and, when required, supplementary essen-

tial variables for each process. This may be by amend-

ment to the WPS or by use of a new WPS.

Changes

h i essential

in i l or supplementary

l essential

i l (when

( h

required) variables require requalification of the WPS

(new or additional PQRs to support the change in

essential or supplementary essential variables).

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 22

SCB

Question: Does QW-200.l(c) require that there be a history

of changes such as margin notes or other record

documenting what specific changes were made in the

essential, nonessential, or supplemental variables each time

a WPS is revised?

Reply: No.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 23

SCB

(d) Format of the WPS. The information required to be in the

WPS may be in any format, written or tabular, to fit the needs of each

manufacturer or contractor,

contractor as long as every essential

essential, nonessential,

nonessential

and, when required, supplementary essential variables outlined in

QW-250 through QW-280 is included or referenced.

Form QW-482 (see Nonmandatory Appendix B) has been

provided as a guide for the WPS. This Form includes the required

data for the SMAW, SAW, GMAW, and GTAW p processesIt is onlyy

a guide and does not list all required data for other processes. It also

lists some variables that do not apply to all processes (e.g., listing

shielding gas which is not required for SAW). The guide does not

easily lend itself to multiple process procedure specification (e.g.,

GTAW root with SMAW fill).

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 24

SCB

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 25

SCB

Each manufacturer or contractor shall maintain a record of

the results obtained in welding procedure and welder and

welding operator performance qualifications. These

records shall be certified by a signature or other means as

described in the manufacturer’s

manufacturer s or contractor’s

contractor s Quality

Control System and shall be accessible to the Authorized

Inspector. Refer to recommended Forms in Non

mandatory Appendix B.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 26

SCB

Question: Is it acceptable to satisfy the requirements of QW-

103.2 for record maintenance, certification, and

accessibility by means of an electronic storage medium, e

.g., computer database?

Reply: Section IX does not address the media in which

records

d are required

i d to

t be

b maintained.

i t i d

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 27

SCB

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 28

SCB

OFW Oxyfuel Gas Welding

SMAW Shield Metal-Arc Welding

SAW Submerged-Arc Welding

GMAW Gas Metal

Metal-Arc

Arc Welding

&FCAW & Flux-Core-Arc Welding

GTAW Gas Tungsten-Arc Welding

PAW Plasma-Arc

Plasma Arc Welding

ESW Electroslag Welding

EGW Electrogas Welding

EBW Electron Beam Weldingg

Stud & Inertia and Continuous Drive Friction Welding

Resistance Welding

LBW Laser Beam Weldingg

Flash Welding

Each welding process has its own welding variables (table QW-252 to 265)

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 29

SCB

QW-250 WELDING VARIABLES

QW-251 General

QW-251.1 Types of Variables for Welding

Procedure Specifications (WPS). These variables

(listed for each welding

elding process in tables QW-

QW

252 through QW-265) are subdivided into

essential variables,, supplementary

pp y essential

variables, and nonessential variables (QW-401).

The "Brief of Variables" listed in the Tables are

for reference only.

only See the complete variable in

Welding Data of Article IV.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 30

SCB

Question (1): Is it required that all of the essential and nonessential

variables listed in QW

QW-250

250 through QWQW-280280 for each welding process be

addressed in the WPS, even though some of these variables are not

applicable?

li bl ?

Reply (1): Yes.

Yes

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 31

SCB

QW-250 WELDING VARIABLES

QW-251.4 Special Processes

(a) The special process essential variables for corrosion

corrosion- resistant

and hard-surfacing weld metal overlays are as indicated in the

following tables for the specified process. Only the variables

specified, for special processes shall apply. A change in the

corrosion-resistant

i i t t or hardsurfacing

h d f i welding ldi process shall

h ll require

i

requalification.

QW-218 Applied Linings

QW 218 1 WPSs

QW-218.1 WPS forf attaching

tt hi applied

li d linings

li i shall

h ll be

b qualified

lifi d

in accordance with QW-202.2(a), (b), or (c).

QW-219 Flash Welding

Fl h welding

Flash ldi shall

h ll be

b limited

li it d to

t automatic

t ti electrical

l t i l resistance

it

flash welding of tubular cross-sections. Procedure qualification tests

shall be conducted in accordance with QW-199.1.

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 32

SCB

QW-252 OFW QW-258 ESW

QW-252.1 OFW (special process) QW-258.1 ESW (special process)

QW-253 SMAW QW-259 EGW

QW 253 1

QW-253.1 SMAW (special

( i l QW 259 1

QW-259.1 EGW (special

( i l process))

process) QW-260 EBW

QW-254 SAW QW-261 Stud Welding

QW-254.1 SAW (special process) QW-262

Q Inertia and Continuous

QW-255 GMAW and FCAW Drive Friction Welding

QW-255.1 GMAW and FCAW QW-263 Resistance Welding

(special process) QW-264 LBW

QW 256

QW-256 GTAW QW-264 1

QW-264.1 LBW (special process)

QW-255.1 GTAW (special QW-265 Flash Welding

process) QW-290.4 Temper Bead

QW-257 PAW

QW 257 1

QW-257.1 PAW (special process)

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 33

SCB

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 34

SCB

30 เมษายน 53 ASME Section IX, WPS/PQR Prepared by 35

SCB

You might also like

- (EW-512-5) - Destructive Testing Methods - Training Workbook-Hobart Institute of Welding Technology (Yasser Tawfik)Document48 pages(EW-512-5) - Destructive Testing Methods - Training Workbook-Hobart Institute of Welding Technology (Yasser Tawfik)kirubha_karan2000100% (2)

- Duplex Stainless WPSDocument10 pagesDuplex Stainless WPSMohammed KamalNo ratings yet

- General Exercise Questions API 1104Document14 pagesGeneral Exercise Questions API 1104Menad SalahNo ratings yet

- 0.1 Duties of The Senior Welding InspectorDocument37 pages0.1 Duties of The Senior Welding InspectorAhmed GomaaNo ratings yet

- API 570 Chapter10 Asme Ix RevDocument50 pagesAPI 570 Chapter10 Asme Ix RevFabio MiguelNo ratings yet

- Section IX of The ASME Boiler and Pressure Vessel CodeDocument6 pagesSection IX of The ASME Boiler and Pressure Vessel CodeMR FIKRINo ratings yet

- WpsDocument39 pagesWpsAkhilesh Kumar100% (1)

- Selected Questions From General MechanicalDocument5 pagesSelected Questions From General MechanicalEhab Harb100% (1)

- Module 4 Weld Geometry and Welding Symbols-1Document87 pagesModule 4 Weld Geometry and Welding Symbols-1Miki Jaksic100% (1)

- AWS CWI SyllabusDocument1 pageAWS CWI SyllabusMayank GuptaNo ratings yet

- Welding Procedure Specification: Asme Sec IxDocument22 pagesWelding Procedure Specification: Asme Sec IxMd Anamul HoqueNo ratings yet

- Gas Transmission and Distribution Piping Systems ASME B31.12 Hydrogen Piping and PipelinesDocument5 pagesGas Transmission and Distribution Piping Systems ASME B31.12 Hydrogen Piping and PipelinesnasrNo ratings yet

- Nickel and Nickel Alloys: Weldability and Joining of MaterialsDocument4 pagesNickel and Nickel Alloys: Weldability and Joining of MaterialsMehmet SoysalNo ratings yet

- Sbtis Model Question Part 1Document48 pagesSbtis Model Question Part 1ganeshNo ratings yet

- Answers Drawing B: BS 499 Part 2. Course Reference WIS 10Document10 pagesAnswers Drawing B: BS 499 Part 2. Course Reference WIS 10Harkynollar Harkyntehye100% (1)

- Welding InspectionDocument43 pagesWelding Inspectionzubairsarwar912No ratings yet

- Technology: Answers Drawing CDocument6 pagesTechnology: Answers Drawing Culsan busanNo ratings yet

- Cswip Questions and AnswerDocument4 pagesCswip Questions and Answerenels770% (2)

- Drawing B BS 499 Part. 2Document10 pagesDrawing B BS 499 Part. 2محمد اظهرNo ratings yet

- Module 1 Welding Inspection and CertificationDocument16 pagesModule 1 Welding Inspection and CertificationMiki JaksicNo ratings yet

- AWS Education - Certification 9-22-15Document21 pagesAWS Education - Certification 9-22-15Carlos PadillaNo ratings yet

- CSWIPDocument3 pagesCSWIPBox Empty100% (2)

- Welding Seminar - Terminology, Symbol & MetallurgyDocument108 pagesWelding Seminar - Terminology, Symbol & Metallurgyarland_limNo ratings yet

- Api - 1104 - 1Document2 pagesApi - 1104 - 1aditya bhideNo ratings yet

- Sections: I Rules For Construction of Power BoilersDocument68 pagesSections: I Rules For Construction of Power BoilersAnonymous VohpMtUSN100% (1)

- 6.0 Weld Procedure Qualifications Specification and Welder QualificationDocument37 pages6.0 Weld Procedure Qualifications Specification and Welder QualificationfinhayNo ratings yet

- Module 8 Welding Metallurgy For The WIDocument39 pagesModule 8 Welding Metallurgy For The WIMiki Jaksic100% (1)

- CSWIP 3.1 Study NotesDocument11 pagesCSWIP 3.1 Study Notesmuhammadazhar50% (2)

- International Welding Inspector (IWI) : M1.1.4. Tungsten Inert Gas WeldingDocument60 pagesInternational Welding Inspector (IWI) : M1.1.4. Tungsten Inert Gas Weldingresky marantinanNo ratings yet

- Module 9.qualification 1.welding PerformanceDocument6 pagesModule 9.qualification 1.welding PerformanceMohd NizamNo ratings yet

- Steel FachaDocument59 pagesSteel FachaviyfNo ratings yet

- WPS Vs PQRDocument3 pagesWPS Vs PQRIbrahim BashaNo ratings yet

- Acceptance Criteria Asme B31.3 PDFDocument1 pageAcceptance Criteria Asme B31.3 PDFAhmad Rizki100% (1)

- General 2Document4 pagesGeneral 2Sobia KalsoomNo ratings yet

- Asme Sec 2 QuizDocument4 pagesAsme Sec 2 QuizBalaji NarasimhanNo ratings yet

- ASME P-Numbers 1Document2 pagesASME P-Numbers 1SH1961No ratings yet

- Cswip3.2 Content ONLYDocument3 pagesCswip3.2 Content ONLYSathishkumar. KNo ratings yet

- CWI TEST Flashcards PDFDocument30 pagesCWI TEST Flashcards PDFGary Oporto cabasNo ratings yet

- Welding Inspector QuestionsDocument4 pagesWelding Inspector QuestionsMateen Khan100% (1)

- Welding Inspection: Weld ProceduresDocument22 pagesWelding Inspection: Weld Proceduresanon_90890103No ratings yet

- WeldingDocument68 pagesWeldingRajneesh Patel100% (1)

- CWB Acboa April 2008Document29 pagesCWB Acboa April 2008bountymaniNo ratings yet

- Acceptable Grade of Plate Material (API 650)Document1 pageAcceptable Grade of Plate Material (API 650)juantamad02No ratings yet

- Welding Metallurgy and Weldability of MetalsDocument134 pagesWelding Metallurgy and Weldability of MetalsAkash Kumar DevNo ratings yet

- Mockup CBDocument18 pagesMockup CBabet_singkong8930100% (1)

- IIW World OverrviewDocument4 pagesIIW World OverrviewAnonymous hBBam1nNo ratings yet

- AWS C5.7 (2000) - 2006r - Recommended Practices For Electrogas WeldingDocument65 pagesAWS C5.7 (2000) - 2006r - Recommended Practices For Electrogas WeldingPubcrawlNo ratings yet

- Question 1 of 25Document7 pagesQuestion 1 of 25antonio larotta100% (1)

- 4 - ASME IX Exam (61 Q&A)Document10 pages4 - ASME IX Exam (61 Q&A)Dada KhalandarNo ratings yet

- Welder and Procedure QualificationDocument26 pagesWelder and Procedure Qualification'Izzad AfifNo ratings yet

- Welder and Procedure QualificationDocument25 pagesWelder and Procedure QualificationRamón G. Pacheco100% (3)

- WPS& WQRDocument132 pagesWPS& WQRAby Jacob Mathews100% (3)

- Asme IxDocument132 pagesAsme IxAhmed Shaban Kotb100% (1)

- Section IX Self StudyDocument325 pagesSection IX Self StudyMohamad Rezazade100% (19)

- PSP1Document171 pagesPSP1Klich77No ratings yet

- General Welding Fabrication and TestingDocument24 pagesGeneral Welding Fabrication and TestingAhmed FathyNo ratings yet

- Asme Sec - IxDocument132 pagesAsme Sec - IxBoran YelkenciogluNo ratings yet

- Asme Section IxDocument260 pagesAsme Section IxHassan Aziz100% (3)

- TWI - FAQ - Can One Company Use Welding Procedures Qualified by Another CompanyDocument3 pagesTWI - FAQ - Can One Company Use Welding Procedures Qualified by Another CompanytuanNo ratings yet

- Excerpt From ASME B31.3Document2 pagesExcerpt From ASME B31.3hanz bermejoNo ratings yet

- Welding SymbolDocument26 pagesWelding SymboldhasdjNo ratings yet

- P No QaDocument11 pagesP No QadhasdjNo ratings yet

- QW-253 Welding Variables Procedure Specifications (WPS) Shielded Metal-Arc Welding (SMAW)Document1 pageQW-253 Welding Variables Procedure Specifications (WPS) Shielded Metal-Arc Welding (SMAW)dhasdjNo ratings yet

- QW-452.3 Groove-Weld Diameter Limits: 2011A Section IxDocument1 pageQW-452.3 Groove-Weld Diameter Limits: 2011A Section IxdhasdjNo ratings yet

- RT FormulaDocument2 pagesRT FormuladhasdjNo ratings yet

- EPOCH LT Training Presentation: Introduction and Basic OperationDocument58 pagesEPOCH LT Training Presentation: Introduction and Basic Operationdhasdj100% (1)

- Structural Inspector Job DescriptionDocument2 pagesStructural Inspector Job DescriptiondhasdjNo ratings yet

- AWS - CWI Model Question Foundamental - Part 2Document17 pagesAWS - CWI Model Question Foundamental - Part 2dhasdj100% (6)

- Specification No: LMB-COI-TRG-001 Rev No. R0 Page ofDocument16 pagesSpecification No: LMB-COI-TRG-001 Rev No. R0 Page ofApoorv MathurNo ratings yet

- AWS - CWI Model Question Foundamental - Part 1Document16 pagesAWS - CWI Model Question Foundamental - Part 1dhasdj75% (4)

- Welding Process and DefetcDocument26 pagesWelding Process and DefetcdhasdjNo ratings yet

- Ein II DGS ManualDocument24 pagesEin II DGS Manualdhasdj100% (1)

- Zhongyi Portable X-Ray EquipmentDocument6 pagesZhongyi Portable X-Ray EquipmentdhasdjNo ratings yet

- Instruction To Vendor Certificates ManagementDocument11 pagesInstruction To Vendor Certificates ManagementdhasdjNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesdhasdjNo ratings yet

- ASTM Material Comparison TableDocument1 pageASTM Material Comparison Tabledhasdj100% (1)

- Quality Control Plan Static EquipmentDocument1 pageQuality Control Plan Static EquipmentdhasdjNo ratings yet

- ME 328.3 E5 - Welding MetallurgyDocument41 pagesME 328.3 E5 - Welding Metallurgytbmari100% (1)

- ITP 63113 XX Stockpile ITP (Working)Document6 pagesITP 63113 XX Stockpile ITP (Working)soni10483No ratings yet

- API 510-Kuwait Petroleum QuestionsDocument160 pagesAPI 510-Kuwait Petroleum QuestionsKamal Niazi Khan100% (21)

- PT-MT Kurs NotuDocument300 pagesPT-MT Kurs NotuBahadir TekinNo ratings yet

- Vision Card ReadDocument1 pageVision Card ReaddhasdjNo ratings yet