Professional Documents

Culture Documents

Design and Fabrication of Automatic Bending and Bend Removal Machine

Design and Fabrication of Automatic Bending and Bend Removal Machine

Uploaded by

viahulCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Fabrication of Automatic Bending and Bend Removal Machine

Design and Fabrication of Automatic Bending and Bend Removal Machine

Uploaded by

viahulCopyright:

Available Formats

Design and Fabrication of Automatic Bending

And Bend Removal Machine

Abstract

Nowadays the world is focusing into automation. Each and every work of human is

reduced by a machine. In order to remove the bend of pipes, rods and bars hydraulic bend

removing machine is the most suitable equipment. To remove bends from pipe or rod to be

supported between the die holders and jack is actuated on pipe. It exerts force on the pipe and

bends it to the suitable angle depending on the dies used.

In industries, Hydraulic bending and bend removing machine is portable, it is a flexible

and less expensive. Hence it is better to replace conventional machines by hydraulic bending and

bend remove machine automatic operated bending machine requires no maintenance and power

utilization. During mass production it can be converted into automated or electrically operated so

that the rate of production can be increased.

The main objective of the devices used for bend the hollow pipe, rod or bar of any

material and similarly removing the bend of already existing bends efficiently with less cost

compared to the existing bending machines and increasing the productivity. Automated bending

and bend removal machine consist of Double acting cylinder, P-40 Direction control valve,

Hoses, Motor, Pump, Rack and Pinion, Free wheel, Fixture. The rod is bent by the hydraulic

cylinder piston with holding the rod in the fixture. Applications of bending machines are found

to be in production industries, workshop automobile etc. now a day focusing into automation

KEYWORDS: Automated Bending Machine, Hydraulic Operation,

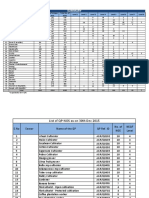

Typical fabrication model

Fixture design might be vary as per requirements

You might also like

- 360 Degree Fire Fighting Protection SystemDocument20 pages360 Degree Fire Fighting Protection Systempramo_dass100% (5)

- Crank Shaft Operated Multi Blade HacksawDocument15 pagesCrank Shaft Operated Multi Blade HacksawTanvi Khurana100% (2)

- Cbe-241rev Quad Processing MachineDocument12 pagesCbe-241rev Quad Processing MachineVigneshMurugesh ANo ratings yet

- Fabrication of Heavy Hydraulic Puller SynopsisDocument3 pagesFabrication of Heavy Hydraulic Puller SynopsisAnonymous j0aO95fgNo ratings yet

- Fabrication of Radial Bending MachineDocument3 pagesFabrication of Radial Bending Machinesantha kumarNo ratings yet

- Report Fabrication of Pipe Bending MachineDocument38 pagesReport Fabrication of Pipe Bending MachineJilly Arasu82% (11)

- Fabrication of Hydraulic Pipe Bending Machine PDFDocument2 pagesFabrication of Hydraulic Pipe Bending Machine PDFAndrew100% (1)

- Research Paper On Hydraulic Pipe Bending MachineDocument7 pagesResearch Paper On Hydraulic Pipe Bending Machinegw0q12dxNo ratings yet

- Automatic Hydro Pneumatic Jack: AbstractDocument3 pagesAutomatic Hydro Pneumatic Jack: AbstractRushikesh BadgujarNo ratings yet

- DCP181 Fabrication of Hydrulic Puller ForDocument3 pagesDCP181 Fabrication of Hydrulic Puller ForANAND KRISHNANNo ratings yet

- Hydrolic Pipe Bending MachineDocument59 pagesHydrolic Pipe Bending MachineNilesh Maheshwari67% (3)

- Metal Bending Machine Project ReportDocument2 pagesMetal Bending Machine Project ReportRahul RathodNo ratings yet

- Hydraulic Rod Bending MachineDocument14 pagesHydraulic Rod Bending Machinek.santhosh kumar50% (2)

- Double Acting Shapper Too LDocument22 pagesDouble Acting Shapper Too LGopuNo ratings yet

- Hydrolic Pipe Bending MachineDocument54 pagesHydrolic Pipe Bending MachineSanketDhande0% (1)

- Motorised Hammer Project ReportDocument35 pagesMotorised Hammer Project ReportRaja ManeNo ratings yet

- Design & Fabrication of Mini Hydraulic Press MachineDocument10 pagesDesign & Fabrication of Mini Hydraulic Press Machinesundar_subash2589% (9)

- Hydraulic Bearing PullerDocument28 pagesHydraulic Bearing PullerBoopathi KalaiNo ratings yet

- 68 PDFDocument6 pages68 PDFVicky SuryawanshiNo ratings yet

- Pof Internship Report Visit To Shop D20Document4 pagesPof Internship Report Visit To Shop D20awais jadoonNo ratings yet

- (Good) Parts of DC Generator - Working, Types and Advantages - LinquipDocument25 pages(Good) Parts of DC Generator - Working, Types and Advantages - LinquipDickson NkongoNo ratings yet

- Final PPT CapstoneDocument22 pagesFinal PPT Capstonekshitu gargNo ratings yet

- Tread Hammer RahulDocument36 pagesTread Hammer RahulHemant MaheshwariNo ratings yet

- Automated Portable Hammering Machine: ComponentsDocument2 pagesAutomated Portable Hammering Machine: ComponentsDheerajyadav YadavNo ratings yet

- Presentation On Design and Development of Pipe Bending MachineDocument45 pagesPresentation On Design and Development of Pipe Bending MachineAdarsh GowdaNo ratings yet

- Hydraulic Pipe Bending MachineDocument19 pagesHydraulic Pipe Bending MachineViraj Phalke75% (8)

- Automatic Drain CleanerDocument19 pagesAutomatic Drain Cleanerkshitu gargNo ratings yet

- Introduction To SectionsDocument10 pagesIntroduction To Sectionssuresh100% (1)

- Justifying, Selecting and Implementing Tube Bending Methods: AuthorDocument30 pagesJustifying, Selecting and Implementing Tube Bending Methods: Authorsarge18No ratings yet

- Automatic Bar Feeding Mechanism For Pipe Cutting Machine: 1.1 Full Automation 1.2 Semi AutomationDocument12 pagesAutomatic Bar Feeding Mechanism For Pipe Cutting Machine: 1.1 Full Automation 1.2 Semi AutomationHarshal PatilNo ratings yet

- Report - Hydraulic Pipe Bending MachineDocument2 pagesReport - Hydraulic Pipe Bending MachinedhirajNo ratings yet

- Design & Fabrication of Hydraulic Machine With Pulling & Bending OperationsDocument6 pagesDesign & Fabrication of Hydraulic Machine With Pulling & Bending OperationsLavaKumarNo ratings yet

- Industrial Project Report: AbstractDocument3 pagesIndustrial Project Report: AbstractMuhammad SanaNo ratings yet

- Pneumatic Rod Bending Machine Project ReportDocument3 pagesPneumatic Rod Bending Machine Project ReportJeyakumar NNo ratings yet

- Design and Fabrication of Bending MachineDocument14 pagesDesign and Fabrication of Bending MachineSumit Sahgal100% (2)

- Hydra Jaw 0211 H 3244 LRDocument4 pagesHydra Jaw 0211 H 3244 LRLuis Miguel Añasco CorimayhuaNo ratings yet

- Hydraulic Equipment & Machinery: Hydropower Engineering SystemsDocument4 pagesHydraulic Equipment & Machinery: Hydropower Engineering Systemsbukit_guestNo ratings yet

- Quotation For Cut To Length Line 25x2500Document13 pagesQuotation For Cut To Length Line 25x2500gourav sarafNo ratings yet

- Project PPT-2Document43 pagesProject PPT-2vennasrinivasrao4No ratings yet

- Pedal Operated XXXDocument54 pagesPedal Operated XXXfccpan22No ratings yet

- Micro Tubular TurbinesDocument8 pagesMicro Tubular TurbinesAshutosh VashishthaNo ratings yet

- BLDC Product GuideDocument36 pagesBLDC Product GuidemjtbbhrmNo ratings yet

- Hydraulic RevitingDocument29 pagesHydraulic RevitingDinesh KumarNo ratings yet

- Pipe Rolling MachineDocument1 pagePipe Rolling MachineJovelyn VistanNo ratings yet

- Acuz Shearing Machine Co., LTD.: Shearing Machine Hydraulic or Manual For Practical PurposesDocument3 pagesAcuz Shearing Machine Co., LTD.: Shearing Machine Hydraulic or Manual For Practical Purposesjixie889No ratings yet

- Automatic Bar Feeding Mechanism For Hack Saw MachineDocument12 pagesAutomatic Bar Feeding Mechanism For Hack Saw MachineAnonymous j0aO95fgNo ratings yet

- Vijay SCOTCH YOKE MECHANISM DOUBLE ACTING HACKSAWDocument31 pagesVijay SCOTCH YOKE MECHANISM DOUBLE ACTING HACKSAWSergio PugazhNo ratings yet

- Intro MD2Document1 pageIntro MD2Robert Ryan SantiagoNo ratings yet

- Hydraulic Arm Using Syringe: Hydraulic Machines Are Machinery and Tools ThatDocument6 pagesHydraulic Arm Using Syringe: Hydraulic Machines Are Machinery and Tools ThatmadhurautoNo ratings yet

- Design and Fabrication of MotorisedDocument28 pagesDesign and Fabrication of Motorisedvickram jainNo ratings yet

- METAL BENDER FinalDocument25 pagesMETAL BENDER Finalakhilesh DADORENo ratings yet

- Robotic and CNC Deburring Tools: NEW CatalogDocument12 pagesRobotic and CNC Deburring Tools: NEW Catalogspace2kNo ratings yet

- Automated Hammering MachineDocument2 pagesAutomated Hammering MachineTanvi KhuranaNo ratings yet

- Hydraulic Pipe Bending Machine: SynopsisDocument5 pagesHydraulic Pipe Bending Machine: SynopsisAnonymous j0aO95fgNo ratings yet

- Hydraulic Bearing Puller-AbstractDocument1 pageHydraulic Bearing Puller-AbstractPAVIN ENGGNo ratings yet

- MEC165Document2 pagesMEC165PRAKASH ANo ratings yet

- AUTOMATIC PIPE CUTTING MACHINE EditedDocument25 pagesAUTOMATIC PIPE CUTTING MACHINE EditedrajeshNo ratings yet

- Design and Fabrication of Hydraulic Pipe Bending MachineDocument6 pagesDesign and Fabrication of Hydraulic Pipe Bending MachineJeyakumar NNo ratings yet

- Fabrication of Tube Bending MachineDocument8 pagesFabrication of Tube Bending MachineSaif Ur RehmanNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Hydraulic and Pneumatic SystemsDocument59 pagesHydraulic and Pneumatic Systemsviahul100% (1)

- Computers in SportsDocument21 pagesComputers in SportsviahulNo ratings yet

- Water Desalination Solar Desalination Solar Cooling: Group 9 - S. Prashanth Kumar - R. Gautam Reddy - S. Prithvi RajDocument34 pagesWater Desalination Solar Desalination Solar Cooling: Group 9 - S. Prashanth Kumar - R. Gautam Reddy - S. Prithvi RajviahulNo ratings yet

- Sports TechnologyDocument19 pagesSports TechnologyviahulNo ratings yet

- Kinematics of MechanismsDocument82 pagesKinematics of MechanismsviahulNo ratings yet

- Automatic Emergency Braking SystemDocument1 pageAutomatic Emergency Braking Systemviahul100% (1)

- Packaging IndustryDocument25 pagesPackaging IndustryviahulNo ratings yet

- Water Lifting Devices10Document22 pagesWater Lifting Devices10viahulNo ratings yet

- Water Lifting Devices7Document20 pagesWater Lifting Devices7viahulNo ratings yet

- Water Lifting Devices11Document20 pagesWater Lifting Devices11viahulNo ratings yet

- Water Lifting Devices12Document26 pagesWater Lifting Devices12viahulNo ratings yet

- Water Lifting Devices8Document37 pagesWater Lifting Devices8viahulNo ratings yet

- Water Lifting Devices5Document40 pagesWater Lifting Devices5viahulNo ratings yet

- Water Lifting Devices6Document27 pagesWater Lifting Devices6viahulNo ratings yet

- Water Lifting DevicesDocument14 pagesWater Lifting DevicesviahulNo ratings yet

- Water Lifting Devices1Document5 pagesWater Lifting Devices1viahulNo ratings yet

- List of Indian Spices: Indian Spices Include A Variety of Spices Grown Across The Indian Subcontinent (ADocument9 pagesList of Indian Spices: Indian Spices Include A Variety of Spices Grown Across The Indian Subcontinent (AviahulNo ratings yet

- Water Lifting Devices2Document25 pagesWater Lifting Devices2viahulNo ratings yet

- Water Lifting Devices4Document42 pagesWater Lifting Devices4viahulNo ratings yet

- Make A Mobile Antenna To ListenDocument13 pagesMake A Mobile Antenna To ListenviahulNo ratings yet

- Standards and Quality AssuranceDocument2 pagesStandards and Quality AssuranceviahulNo ratings yet

- Broadcast TransmitterDocument6 pagesBroadcast Transmitterviahul100% (1)

- Private Limited CompaniesDocument2 pagesPrivate Limited CompaniesviahulNo ratings yet

- Summary QPDocument36 pagesSummary QPviahulNo ratings yet

- Project: Search WikipediaDocument3 pagesProject: Search WikipediaviahulNo ratings yet