Professional Documents

Culture Documents

Material Technical Data Sheet: A-SPE Marking Tapes

Uploaded by

Akhmad HarisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Technical Data Sheet: A-SPE Marking Tapes

Uploaded by

Akhmad HarisCopyright:

Available Formats

Material Technical

Data Sheet -SPE SPECIALISTS IN SAFETY

A-SPE Marking tapes

Marine Pipe Identification Tape - acc to ISO 14726

Basic identification tapes (acc to ISO14726-1) :

Type Description Ordering code

Black Waste media T01

Copper Masses T02

Brown Fuel T03

All types of tapes are available at following standard sizes:

Grey Non-flammable Gases T04

Silver Steam T05 40 mm x 25 m

70 mm x 25 m

Green Sea Water T06 160 mm x 25 m

Blue Fresh water T07

Considering many size standards available on the market we can manufacture any

Violet Acids & Alkalis T08 particular size for you.

Red Fire fighting T09

Each tape can be marked with your own logo without any additional charge.

Orange Oil other than fuel T10

Yellow Flammable gases T11

Way of ordering:

White Ait in ventilation systems T12

Flow direction marking T13 Example Multi-colour system: T27-160mm / 5 pcs

Warning tape T14 Example Signle-colour system: T01-40mm / 2 pcs + T07-40mm / 1 pc

Multi-colour permuations (acc to ISO14726-2):

Colour Ordering code Colour Ordering code

Description identification Description identification

Multi-color Single-color Multi-color Single-color

Waste media T01 T01 Fresh water T07 T07

Black water T15 T01+T07+T01 Fresh water, sanitary T29 T07+T03+T07

Grey water T16 T01+T12+T01 Potable water T30 T07+T06+T07

Waste oil T17 T01+T03+T01 Distillate T31 T07+T04+T07

Bilge water T18 T01+T06+T01 Gas turbine wash water T32 T07+T10+T07

Exhaust gas T19 T01+T04+T01 Feed water T33 T07+T05+T07

Sewage, contaminated T20 T01+T11+T01 Cooling fresh water T34 T07+T08+T07

Masses T02 T02 Chilled water T35 T07+T12+T07

T03 T03 Condensate T36 T07+T11+T07

Fuel

HFO Heavy fuel T21 T03+T01+T03 Acids & Alkalis T08 T08

Aviation fuel T22 T03+T07+T03

Fire fighting / Fire protection T09 T09

Biological fuel T23 T03+T08+T03

Fire-fighting water T37 T09+T06+T09

Gas-turbine fuel T24 T03+T12+T03

Fire-fighting gas T38 T09+T04+T09

MDO Marine Diesel Fuel T25 T03+T11+T03

Sprinkler water T39 T09+T10+T09

Non-Flammable gases T04 T04 Spray water T40 T09+T08+T09

Oxygen T26 T04+T07+T04 Fire-fighting powder T41 T09+T12+T09

Breathing gas T27 T04+T011+T04 Fire-fighting foam T42 T09+T11+T09

Nitrogen T28 T04+T06+T04

Oil other than fuel T10 T10

Refrigerant T29 T04+T02+T04

Thermal fluid T43 T10+T07+T10

Breathing air T30 T04+T12+T04

Hydraulic fluid T44 T10+T04+T10

Inert gas T31 T04+T03+T04

Lubricaition oil for steam turbines T45 T10+T05+T10

Compressed ait LP T32 T04+T10+T04

Lubricaition oil for gas turbines T46 T10+T06+T10

Compressed ait HP T33 T04+T09+T04

Lubricaition oil for gears T47 T10+T08+T10

Compressed air / regulating air T34 T04+T08+T04

Lub. Oil for int. combustion engines T48 T10+T11+T10

Steam T05 T05

Flammable gases T11 T11

Steam for heating purposes T35 T05+T01+T05

Hydrogen T49 T11+T07+T11

Sypply steam T36 T05+T11+T05

Acetylene T50 T11+T04+T11

Exhaust steam T25 T05+T12+T05

Liquid gas T51 T11+T08+T11

Sea water T06 T06

Air in ventilation systems T12 T12

Ballast water T26 T06+T08+T06

Natural exhaust gas T52 T12+T03+T12

Cooling sea water T27 T06+T11+T06

Supply air, atmospheric T53 T12+T06+T12

Sanitary sea water T28 T06+T03+T06

Natural supply air T54 T12+T11+T12

Mechanical exhaust air T55 T12+T08+T12

January 2005 page 2/2

Material Technical

Data Sheet -SPE SPECIALISTS IN SAFETY

A-SPE Marking tapes

Marine Pipe Identification Tape - acc to ISO 14726

General Description - During the application tape should be overlaped 3-4

Pipeline identification on board ships is very important cm beyond the starting edge.

for safety reasons, especially for the safety of the

entire crew. The medium flowing through the the Technical Data

pipework can cause a lot of damage, and be

80 microns (without protective

dangerous to the people on board the ship during an Thickness (average) paper and adhesive

emergency or in case of pipework damage. The

appropriate marking makes it possible to identify the pageto1/2

(FINAT TM 14) adhered

type of danger we are dealing with during the steel, no measurable

emegency and to take the steps to get rid of it. Dimensional stability shrinkage in cross directions,

in length 0,44 m max

The International ISO14726-1 (year 1999) standard

defines the basic colours which should be used for adhered to aluminum -40C to

Temperature resistance 80C, no variation

pipeline identification on board ships.

Water resistance adhered to aluminum, after

Another regulation, ISO 1476-2 (year 2002) specifies 48h / 23C, no variation

additional colours which can be used together with the

main colours for a more thorough marking of the 16 N / 25 mm (FINAT TM 1,

Adhesive power*

medium flowing through the pipework. after 24h, stainless steel)

The table included in this broshure presents the basic (DIN EN ISO 527)

colours and also all the available permutations of Tensile strength along - min. 19 Mpa

identification colours in accordance with the across - min. 19 Mpa

ISO14726-2 (year 2002) norms.

(DIN EN ISO 527)

Elongation at break along - min. 130%

Availability across - min. 150%

The identification tapes are available in two systems:

2 years (in original packaging,

Shelf life at 20C and 50% relative

Multi-colour system - tapes humidity)

with the colour combination

printed on it - this system is the Application temperature min. +10C

easiest to install.

Service life by specialist 3 years (depending on

application individual use conditions)

Single-colour system - tapes

from which you can make any

number of colour combinations

Ordering and technical support

by yourself, this is a more

economical and flexible solution, Feel free to contact our consultants who will take your

however, the installation takes order and answer any questions you might have.

longer to complete.

-SPE -SPE

Installation OFFICE POLAND OFFICE GERMANY

- Each pipe should be marked at least once in each ul. Kujawska 26 Data available soon

separate room. 81-862 Sopot, POLAND

- The best places for installing the identification tapes

are: close to the objects like valves, filters or tanks, Tel: +48 58 555 73 37

exits passing through the walls or cellings, close to the Fax: +48 58 555 73 38

room entrances.

- All surfaces must be thoroughly cleaned before Email: info@a-spe.com

applying the identification tapes. Internet: www.a-spe.com

January 2005 page 2/2

You might also like

- DeltaValve 2010 Customer VersionDocument97 pagesDeltaValve 2010 Customer VersionjoseellargoNo ratings yet

- Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, TeesDocument4 pagesPressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, TeesSaidNo ratings yet

- 1401-01 Load Chart Index - 89638775 - R1 PDFDocument10 pages1401-01 Load Chart Index - 89638775 - R1 PDFShaheed HossainNo ratings yet

- BEL - 6D Through Conduit GateDocument2 pagesBEL - 6D Through Conduit Gateasoka.pwNo ratings yet

- Mechanical Specifications For Fiberbond ProductDocument8 pagesMechanical Specifications For Fiberbond ProducthasnizaNo ratings yet

- Process Datasheet For Relief ValveDocument3 pagesProcess Datasheet For Relief Valvemadhu8087No ratings yet

- Belt Tension RecommendationsDocument2 pagesBelt Tension RecommendationsW MoralesNo ratings yet

- H1000e K FJDocument8 pagesH1000e K FJSyarif HidayatullahNo ratings yet

- All Type Hose FittingsDocument94 pagesAll Type Hose FittingsmroreneNo ratings yet

- Hydraulic Tubes and PipesDocument18 pagesHydraulic Tubes and Pipeshp_vijaykNo ratings yet

- StrainersDocument208 pagesStrainersvitcon87No ratings yet

- Allowable Pipe Span (In)Document2 pagesAllowable Pipe Span (In)komang arimbawaNo ratings yet

- 2022.02-Chemical Corrosion Guide-FinalDocument52 pages2022.02-Chemical Corrosion Guide-FinalEdward Alejandro Avendaño BeltranNo ratings yet

- Ansul F-85154Document2 pagesAnsul F-85154jlvega18No ratings yet

- 39GC C12 1PD 1 - CarrierDocument27 pages39GC C12 1PD 1 - Carrierks aksNo ratings yet

- 279D Combination GearboxDocument1 page279D Combination GearboxJorge Vásquez CarreñoNo ratings yet

- Small Book EN en NLDocument1,595 pagesSmall Book EN en NLOxbown91No ratings yet

- Gefico Brochure +UFDocument40 pagesGefico Brochure +UF1zorro10% (1)

- Instruction Sheet: W-Series Hydraulic Torque WrenchesDocument40 pagesInstruction Sheet: W-Series Hydraulic Torque WrenchesShag Shaggy100% (1)

- Devlon v-API OriginalDocument1 pageDevlon v-API OriginalCarlosIkedaNo ratings yet

- LOP For Re-Install FWP B With NPP Nusantara Rev.1Document13 pagesLOP For Re-Install FWP B With NPP Nusantara Rev.1Akbar RahmansyahNo ratings yet

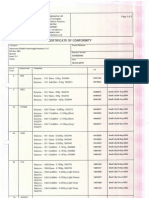

- Approved SMDL Copy of Worksheetin4500541788-40-Smdlrev00 - 20130911043508.141 - XDocument2 pagesApproved SMDL Copy of Worksheetin4500541788-40-Smdlrev00 - 20130911043508.141 - XP Sandana NaraNo ratings yet

- Unit-5 Design of Belt DrivesDocument39 pagesUnit-5 Design of Belt DrivesCHANDRASEKARANNo ratings yet

- Expanding Gate 2016 2Document56 pagesExpanding Gate 2016 2ramyzottyNo ratings yet

- Corken Compresores Amoniaco PDFDocument100 pagesCorken Compresores Amoniaco PDFNicolas BurgosNo ratings yet

- Jis g3456 Grade STPT 410 Pipes PDFDocument1 pageJis g3456 Grade STPT 410 Pipes PDFMitul MehtaNo ratings yet

- Maxi ManualDocument47 pagesMaxi ManualB Gary AcostaNo ratings yet

- Jinflex Composite Hoses BrochureDocument40 pagesJinflex Composite Hoses BrochurevkoNo ratings yet

- 12 Air Venting in Hydraulic System PDFDocument5 pages12 Air Venting in Hydraulic System PDFnarimeneNo ratings yet

- Product Data Sheet Sheave and Frame Assemblies PDFDocument1 pageProduct Data Sheet Sheave and Frame Assemblies PDFCraciun PaulNo ratings yet

- JIS - Valve StandardsDocument3 pagesJIS - Valve Standardsle wangNo ratings yet

- Crosby ShackleDocument1 pageCrosby ShacklevrandyNo ratings yet

- Certificates For Belzona 1391 & Belzona 1511 PDFDocument2 pagesCertificates For Belzona 1391 & Belzona 1511 PDFskNo ratings yet

- Flange Design: Welding UnitsDocument0 pagesFlange Design: Welding Unitsabhi1648665No ratings yet

- FEA Analysis For Hull MEG Storage Tank T-5601AB - Rev 01Document52 pagesFEA Analysis For Hull MEG Storage Tank T-5601AB - Rev 01jahiranazriNo ratings yet

- UT-CPF1-2016-V13220A-035 HP-COMP-PK13210A-SUCTION SCRUBBER (1st Stage) V-13220A 20170111Document5 pagesUT-CPF1-2016-V13220A-035 HP-COMP-PK13210A-SUCTION SCRUBBER (1st Stage) V-13220A 20170111Jinlong SuNo ratings yet

- Sedifilt Oil & Gas Brochure PDFDocument8 pagesSedifilt Oil & Gas Brochure PDFAalap DerasaryNo ratings yet

- CD 1400 Centrifugal D GasserDocument2 pagesCD 1400 Centrifugal D Gasserciucalata88No ratings yet

- Swivel GeneralDocument2 pagesSwivel GeneralVikas Kumar Pathak0% (1)

- Green Pin Standard Hydraulic ShackleDocument1 pageGreen Pin Standard Hydraulic ShackleAthox QhurienNo ratings yet

- Portable Foam Equipment DF130Document2 pagesPortable Foam Equipment DF130Taufiq Omar HasanNo ratings yet

- Reference Notation Description: 1.bottom Plate ThicknessDocument6 pagesReference Notation Description: 1.bottom Plate ThicknessSakib RafeeNo ratings yet

- Company Profile (ACE VALVE)Document20 pagesCompany Profile (ACE VALVE)DDFSFNo ratings yet

- Tyco Valves & Controls CatalogDocument6 pagesTyco Valves & Controls CatalogHasanNo ratings yet

- Comparison of FEM, HMI and CMAA Classifications - ProservCrane GroupDocument3 pagesComparison of FEM, HMI and CMAA Classifications - ProservCrane Groupengin gürayNo ratings yet

- Colour Code For Piping Systems According To Iso 14726: System Colour RAL NO. (DIN 2403)Document1 pageColour Code For Piping Systems According To Iso 14726: System Colour RAL NO. (DIN 2403)Ionut Ardeleanu100% (1)

- Cleaning Schedule DateDocument6 pagesCleaning Schedule Datedanny mackNo ratings yet

- Combined Marine Safety Catalogue PDFDocument277 pagesCombined Marine Safety Catalogue PDFJeffry KarundengNo ratings yet

- Pipe Purging BrochureDocument19 pagesPipe Purging BrochurejmsmechNo ratings yet

- Alloy Master LinksDocument1 pageAlloy Master LinksAnonymous 48jYxR1C0% (1)

- As 3791-1991 Hydraulic HoseDocument7 pagesAs 3791-1991 Hydraulic HoseSAI Global - APAC0% (1)

- Air RecieverDocument3 pagesAir Recieverjp220288No ratings yet

- Original Series METAL Pumps: Simplify Your ProcessDocument47 pagesOriginal Series METAL Pumps: Simplify Your ProcessalexanderNo ratings yet

- Bombas AllweilerDocument14 pagesBombas AllweilerCARLOS ANDRES CARVAJAL SUAREZNo ratings yet

- BB1 Vs BB2Document1 pageBB1 Vs BB2bomthanhphuNo ratings yet

- Sat System RaffaellaDocument6 pagesSat System RaffaellaMarco VacchieriNo ratings yet

- Hydratight Morgrip Swivel Ring Flyer PDFDocument2 pagesHydratight Morgrip Swivel Ring Flyer PDFSenthil KumarNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Fire Hydrant Valve Bs 5041: SpecificationDocument2 pagesFire Hydrant Valve Bs 5041: Specificationirrosel4650No ratings yet

- UN NA Code Hazardous WasteDocument458 pagesUN NA Code Hazardous WasteDevi RadityaNo ratings yet

- Mech Vent Code Sizing Table PDFDocument2 pagesMech Vent Code Sizing Table PDFdreamagiczNo ratings yet

- Duct Design STDocument7 pagesDuct Design STmiladparsmanNo ratings yet

- Get Started PDFDocument6 pagesGet Started PDFMuhammad NomanNo ratings yet

- Echo Sounder & Speedlog-Layout1Document1 pageEcho Sounder & Speedlog-Layout1Akhmad HarisNo ratings yet

- XC HRV3 q16Document7 pagesXC HRV3 q16Akhmad HarisNo ratings yet

- Metecno Panel, Metecno Span (Polyisocyanurate), Purline (Polyurethane) PanelsDocument4 pagesMetecno Panel, Metecno Span (Polyisocyanurate), Purline (Polyurethane) PanelsAkhmad HarisNo ratings yet

- BC Type Fender: FeatureDocument2 pagesBC Type Fender: FeatureAkhmad HarisNo ratings yet

- Bromic Refrigeration - Modular Coldroom Installation Manual - May 2005Document15 pagesBromic Refrigeration - Modular Coldroom Installation Manual - May 2005Akhmad HarisNo ratings yet

- Ventilation Grilles For Instal Lation Into Walls, Sills or Rec Tangular DuctsDocument18 pagesVentilation Grilles For Instal Lation Into Walls, Sills or Rec Tangular DuctsAkhmad HarisNo ratings yet

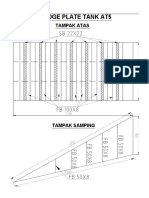

- Bridge Plate For Tank Test AT5 PDFDocument1 pageBridge Plate For Tank Test AT5 PDFAkhmad HarisNo ratings yet

- 4 Albert Embankment London Se1 7Sr Telephone: 020 7735 7611 Fax: 020 7587 3210Document5 pages4 Albert Embankment London Se1 7Sr Telephone: 020 7735 7611 Fax: 020 7587 3210Akhmad HarisNo ratings yet

- AmplopDocument1 pageAmplopAkhmad HarisNo ratings yet

- Product Code: AF-2032 (JIS F-2032)Document1 pageProduct Code: AF-2032 (JIS F-2032)Akhmad HarisNo ratings yet

- Design SpreadsheetDocument135 pagesDesign SpreadsheetRaoofNo ratings yet

- HCL Corrosion Under ControlDocument4 pagesHCL Corrosion Under ControlNXVNNo ratings yet

- Using Kusumpur Pahari As A Case Study: Alexis Foundation Research Internship: AnusandhanDocument14 pagesUsing Kusumpur Pahari As A Case Study: Alexis Foundation Research Internship: AnusandhanAarambhNo ratings yet

- Geothermal EnergyDocument2 pagesGeothermal EnergyIrene DimzyNo ratings yet

- Background Information: Discussion QuestionsDocument21 pagesBackground Information: Discussion Questionsarnoldho_20003039No ratings yet

- Illustrated Lesson Notes in Form 4 Geography For KCSE SyllabusDocument110 pagesIllustrated Lesson Notes in Form 4 Geography For KCSE SyllabusEdward MasengoNo ratings yet

- The Titration of Clay MineralsDocument10 pagesThe Titration of Clay MineralsroyamohamadyNo ratings yet

- Operation c950 PDFDocument50 pagesOperation c950 PDFsandeep5100% (2)

- Energy Efficient Air Drying of BiomassDocument24 pagesEnergy Efficient Air Drying of BiomassVisitOn.T.witte.rNo ratings yet

- Water Pollution Lecture Notes Five CIE 442 (Edited)Document67 pagesWater Pollution Lecture Notes Five CIE 442 (Edited)Anthony MulengaNo ratings yet

- 1.4 Mine Gases - Methane IDocument9 pages1.4 Mine Gases - Methane IDeepakKattimani100% (1)

- Ip 0 0 2Document4 pagesIp 0 0 2Atan B AtanNo ratings yet

- Jotun Multicolor Industry Colorant With LC 14-4-14Document8 pagesJotun Multicolor Industry Colorant With LC 14-4-14Reza HermawanNo ratings yet

- EVCO O RingeDocument24 pagesEVCO O RingeteresamcabralNo ratings yet

- Submitted by KHADIZATUL KOBRA NAHIN (2013135002) TAHMIM RAHMAN (2013135005) RAFIUL ALAM (2013135006) ABU NAEEM SHIMUL (2013135007)Document23 pagesSubmitted by KHADIZATUL KOBRA NAHIN (2013135002) TAHMIM RAHMAN (2013135005) RAFIUL ALAM (2013135006) ABU NAEEM SHIMUL (2013135007)Reshma MuktharNo ratings yet

- Captive Breeding GuidelinesDocument60 pagesCaptive Breeding GuidelineshellmaneaNo ratings yet

- General Information: Section 1Document11 pagesGeneral Information: Section 1ShaarawyNo ratings yet

- Block and Village Development Plan, Palwal, HaryanaDocument16 pagesBlock and Village Development Plan, Palwal, HaryanaNgawang TshomoNo ratings yet

- HDPE Pipe Safety SheetDocument4 pagesHDPE Pipe Safety SheetHemant ChauhanNo ratings yet

- Isricu I15889 001Document105 pagesIsricu I15889 001Josif KaevskiNo ratings yet

- Chelate SDocument19 pagesChelate SGerad ValdezNo ratings yet

- Details How The Construction Will Be Executed, Monitored and ControlledDocument86 pagesDetails How The Construction Will Be Executed, Monitored and ControlledMageshwarNo ratings yet

- Petioner CopmpendiumDocument6 pagesPetioner Copmpendiumshriya raoNo ratings yet

- Agenda For The 11th Scientific Day Institute of Technology of Cambodia Venue: ITC and Online Theme: Smart Technology For Sustainable Economic GrowthDocument4 pagesAgenda For The 11th Scientific Day Institute of Technology of Cambodia Venue: ITC and Online Theme: Smart Technology For Sustainable Economic GrowthSorn Chan Reak SmeyNo ratings yet

- Multiple Choice Questions (MCQS) : Written/Composed By: - SHAHZAD IFTIKHAR Contact # 0313-5665666 WebsiteDocument8 pagesMultiple Choice Questions (MCQS) : Written/Composed By: - SHAHZAD IFTIKHAR Contact # 0313-5665666 WebsiteFahad NazirNo ratings yet

- 0620 s17 QP 43Document16 pages0620 s17 QP 43Aryan Shah0% (1)

- Prilled Urea Prilled Urea Global Technical Data SheetDocument2 pagesPrilled Urea Prilled Urea Global Technical Data SheetdchyNo ratings yet

- Bina MAMPAN Full VersionDocument32 pagesBina MAMPAN Full VersionAhmad NorhanifNo ratings yet

- MSDS Polyamine - Bluwat ChemicalsDocument4 pagesMSDS Polyamine - Bluwat ChemicalsAiza CabolesNo ratings yet

- ChemistryDocument56 pagesChemistryxanshah100% (1)