0% found this document useful (0 votes)

150 views15 pagesRear Tipping Body Operating Manual

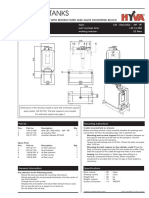

This document provides instructions for operating a rear tipping body. It describes the components of the hydraulic system used for tipping and includes warnings about ensuring safety during the tipping process. Specific instructions are given for tipping and lowering the loading area, including using the hydraulic pump and pneumatic controls located in the driver's cabin. The document also provides an abridged instruction for drivers, focusing on operating the power take-off (PTO) and controls for unsecuring, lifting, and securing the tailgate.

Uploaded by

Ahmad Khaerul AnamCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

150 views15 pagesRear Tipping Body Operating Manual

This document provides instructions for operating a rear tipping body. It describes the components of the hydraulic system used for tipping and includes warnings about ensuring safety during the tipping process. Specific instructions are given for tipping and lowering the loading area, including using the hydraulic pump and pneumatic controls located in the driver's cabin. The document also provides an abridged instruction for drivers, focusing on operating the power take-off (PTO) and controls for unsecuring, lifting, and securing the tailgate.

Uploaded by

Ahmad Khaerul AnamCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd