Professional Documents

Culture Documents

Compression Engine

Uploaded by

Alina Rajput0 ratings0% found this document useful (0 votes)

46 views15 pagesCopyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

46 views15 pagesCompression Engine

Uploaded by

Alina RajputCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 15

COMPRESSION IGNITION ENGINE:

An engine in which the combustion process

starts when the air-fuel mixture self ignites

due to high temperature in the combustion

chamber caused by high compression.

Spark ignition and Compression Ignition

engine operate on either a four stroke cycle

or a two stroke cycle

Four stroke cycle : It has four piston

strokes over two revolutions for each

cycle.

Two stroke cycle : It has two piston

strokes over one revolution for each

cycle

Compression Ignition engine operating

on a four stroke cycle

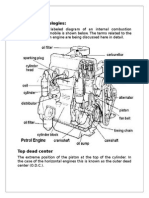

I.C. ENGINE COMPONENTS:

I.C. Engine components shown in figure1 and figure2

are defined as follows:

Cylinder Block : Body of the engine containing

cylinders, made of cast iron or aluminum as single unit.

Cylinder : The circular cylinders in the engine block in

which the pistons reciprocate back and forth.

Head : The piece which closes the end of the cylinders,

usually containing part of the clearance volume of the

combustion chamber.

Combustion chamber: The end of the cylinder between

the head and the piston face where combustion occurs.

Crankshaft : Reciprocating motion of piston

into rotary motion of the output of shaft.

A single cylinder engine are a pair of crank arms & balance

weights.

Weights are used to balance static & dynamic balancing of

rotating system

Connecting rod :Rod connecting the piston with the

rotating crankshaft.

Small end is connected to the piston by gudgeon pin & the

big end is connected to the crankshaft by crankpin .

usually made of steel or alloy forging in most engines but

may be aluminum in some small engines.

Piston rings: Metal rings that fit into circumferential

grooves around the piston and form a sliding surface

against the cylinder walls

Camshaft : Rotating shaft used to push open valves at the

proper time in the engine cycle, either directly or through

mechanical or hydraulic linkage (push rods, rocker arms,

tappets) .

Push rods : The mechanical linkage between the camshaft

and valves on overhead valve engines with the camshaft in

the crankcase.

Crankcase : Part of the engine block surrounding the

crankshaft . In many engines the oil pan makes up part of

the crankcase housing.

Exhaust manifold : Piping system which carries exhaust

gases away from the engine cylinders, usually made of cast

iron .

PISTON: It is a cylindrical portion .It is fits perfectly into

cylinder providing a gas fit. It is first link in transmitting

the gas forces to the output shaft.

I.C. Engine components apart from

components shown in the figure:

Exhaust System: Flow system for removing exhaust gases

from the cylinders, treating them, and exhausting them to

the surroundings . It consists of an exhaust manifold which

carries the exhaust gases away from the engine, a thermal or

catalytic converter to reduce emissions, a muffler to reduce

engine noise, and a tailpipe to carry the exhaust gases away

from the passenger compartment.

Flywheel : Rotating mass with a large moment of inertia

connected to the crank shaft of the engine . The purpose of

the flywheel is to store energy and furnish large angular

momentum that keeps the engine rotating between power

strokes and smooths out engine operation.

Fuel injector : A pressurized nozzle that sprays fuel

into the incoming air (SI engines )or into the cylinder

(CI engines).

Fuel pump : Electrically or mechanically driven pump

to supply fuel from the fuel tank (reservoir) to the

engine.

Glow plug : Small electrical resistance heater mounted

inside the combustion chamber of many CI engines,

used to preheat the chamber enough so that

combustion will occur when first starting a cold engine

. The glow plug is turn off after the engine is started.

Starter : Several methods are used to start IC engines.

Most are started by use of an electric motor (starter)

geared to the engine flywheel. Energy is supplied from

an electric battery

Compression stroke:

When the piston reaches BDC, the intake

valve closes and the piston travels back to

TDC with all valves closed.

This compresses air fuel mixture, raising

both stroke the spark plug is fired and the

combustion is initiated the pressure and

temperature in the cylinder.

Near the end of the compression.

FOUR STROKES OF IDEAL DIESEL CYCLE

SUCTION STROKE

COMPRESSION STROKE

FOUR STROKES OF CI ENGINE CYCLE :

Intake/Suction Stroke : The same as the intake

stroke in an SI engine with one major difference :

no fuel is added to the incoming air, refer figure.

Compression Stroke : The same as in an SI engine

except that only air is compressed and compression

is to higher pressures and temperature, refer figure.

Late in the compression stroke fuel is injected

directly into the combustion chamber, where it

mixes with very hot air.

This causes the fuel to evaporate and self ignite,

causing combustion to start.

You might also like

- Internal Combustion Engines OverviewDocument21 pagesInternal Combustion Engines OverviewRex SabersonNo ratings yet

- IC Engines PPT Lecture No 1Document33 pagesIC Engines PPT Lecture No 1VishweshRaviShrimali100% (1)

- Ic Engine NotesDocument60 pagesIc Engine Notessamarth motka100% (1)

- SME015 - 4PD0240I C Engine TerminologyDocument29 pagesSME015 - 4PD0240I C Engine Terminologykishan24812No ratings yet

- Experiment No: 3: Esme7109/Basic Mechanical Engineering Lab/Btech 1 YearDocument5 pagesExperiment No: 3: Esme7109/Basic Mechanical Engineering Lab/Btech 1 YearM ChandanNo ratings yet

- Study of Components, Systems & Working of Diesel Engine ModelDocument11 pagesStudy of Components, Systems & Working of Diesel Engine ModelFaisal NaeemNo ratings yet

- Demonstration of Compression and Expansion Process in Engine! Introduction To Internal Combustion Engines!Document49 pagesDemonstration of Compression and Expansion Process in Engine! Introduction To Internal Combustion Engines!SHANTHARAMAN P PNo ratings yet

- SME015 - 4PD0240I C Engine TerminologyDocument67 pagesSME015 - 4PD0240I C Engine TerminologyAshwin KudiNo ratings yet

- IC Engines GeneralDocument46 pagesIC Engines Generalirfan khanNo ratings yet

- FC01 UpdatedDocument13 pagesFC01 UpdatedSOLAIMANNo ratings yet

- An Engine or Motor Is A Designed To Convert One Form of IntoDocument15 pagesAn Engine or Motor Is A Designed To Convert One Form of IntomadhesuNo ratings yet

- EnergyDocument14 pagesEnergyNirmal DharavathNo ratings yet

- Introduction to Internal Combustion EnginesDocument46 pagesIntroduction to Internal Combustion Enginesranjith kumarNo ratings yet

- IC EnginesDocument8 pagesIC EnginesNo MINo ratings yet

- Automotive EnginesDocument38 pagesAutomotive EnginesWinaponNo ratings yet

- Definition of engine and types of internal and external combustion enginesDocument10 pagesDefinition of engine and types of internal and external combustion enginesAnonymous 1aCZDEbMMNo ratings yet

- Lab 1Document35 pagesLab 1Mamoon KhiljiNo ratings yet

- I C Engine TerminologyDocument47 pagesI C Engine TerminologyShubham SharmaNo ratings yet

- Unit I (IC Engines)Document13 pagesUnit I (IC Engines)prasanthiNo ratings yet

- Lecture Notes ON Internal Combustion Engine: Course Code: Me 4101Document10 pagesLecture Notes ON Internal Combustion Engine: Course Code: Me 4101MahiNo ratings yet

- EME Notes Unit 1Document11 pagesEME Notes Unit 1SumanranuNo ratings yet

- IC Engines GuideDocument41 pagesIC Engines GuideSatya NarayanaNo ratings yet

- IC EnginesDocument52 pagesIC EnginesSethu ramNo ratings yet

- Automotive Engine ReportDocument11 pagesAutomotive Engine ReportAly MohamedNo ratings yet

- Experiment # 3Document10 pagesExperiment # 3Farhan AliNo ratings yet

- ME4001: Internal Combustion Engines and Gas Turbines GuideDocument66 pagesME4001: Internal Combustion Engines and Gas Turbines GuideSubodh DanaoNo ratings yet

- Theory of Engine OperationDocument19 pagesTheory of Engine OperationGabriel Dela Cruz LagmanNo ratings yet

- Unit 1Document32 pagesUnit 1Rakeshkumarceg100% (1)

- Lecture - 2: I. C. Engines Working Principles of I.C. Engines Study of Different Components of I.C. EnginesDocument29 pagesLecture - 2: I. C. Engines Working Principles of I.C. Engines Study of Different Components of I.C. EnginesViknesh WaranNo ratings yet

- Abhay Mini InternshipDocument23 pagesAbhay Mini InternshipAbhay Raaj YadavNo ratings yet

- Engine Part IDocument39 pagesEngine Part Iaashish koiralaNo ratings yet

- IC Engines Unit 4 - TDDocument43 pagesIC Engines Unit 4 - TDchincha chuNo ratings yet

- Le2 Basic Components and Working PrinciplesDocument46 pagesLe2 Basic Components and Working Principlessaichandrasekhar_dNo ratings yet

- Automatic CarDocument3 pagesAutomatic CarBasnet VlogsNo ratings yet

- Chapter 1 Introduction: 1.1 Ic EngineDocument54 pagesChapter 1 Introduction: 1.1 Ic Engineavanish SinghNo ratings yet

- Four Cylinder Gas EngineDocument7 pagesFour Cylinder Gas EngineJelli Anne Vistal MillanesNo ratings yet

- 2Document13 pages2msaqibraza93No ratings yet

- Introduction To Internal Combustion Engine by Sarvam ChaurasiyaDocument20 pagesIntroduction To Internal Combustion Engine by Sarvam ChaurasiyasarvamNo ratings yet

- Vehicle EngineDocument31 pagesVehicle EnginenoahNo ratings yet

- Introduction About CI EngineDocument2 pagesIntroduction About CI Enginevijayakumar100% (1)

- Introduction To Ic EnginesDocument14 pagesIntroduction To Ic EnginesSai Sudheer100% (1)

- Presentation Ic Engine Unit 1 1515773629 20707Document39 pagesPresentation Ic Engine Unit 1 1515773629 20707Ram MishraNo ratings yet

- IC EnginesDocument44 pagesIC EnginesIbrahim KhaleelNo ratings yet

- Chapter 2Document41 pagesChapter 2Ibrahim KhaleelNo ratings yet

- Ice PPT 2021 30.09.2021Document123 pagesIce PPT 2021 30.09.2021yoleber398No ratings yet

- Thermal Engineering Devices & Power PlantsDocument83 pagesThermal Engineering Devices & Power Plantsommech2020No ratings yet

- Basic Mechanical Engineering Lab ManualDocument13 pagesBasic Mechanical Engineering Lab ManualAbhishek SinghNo ratings yet

- Applied ThermodynamicsDocument83 pagesApplied ThermodynamicsKaranNo ratings yet

- Automative Electronics and Hybrid VehicleDocument34 pagesAutomative Electronics and Hybrid VehicleNIKHIL ASNo ratings yet

- Introduction IC EnginesDocument8 pagesIntroduction IC EnginesSarmad Altaf Hafiz Altaf HussainNo ratings yet

- Heat engine types and componentsDocument38 pagesHeat engine types and componentshodNo ratings yet

- Parts and Working of Four Stroke Petrol EngineDocument6 pagesParts and Working of Four Stroke Petrol EngineHafeez AliNo ratings yet

- Essential For Engine OperationDocument13 pagesEssential For Engine OperationVõ Thanh LiêmNo ratings yet

- Thermodynamics Lab ReportDocument49 pagesThermodynamics Lab Reportjawad60% (5)

- Chap 3Document57 pagesChap 3jatadharaNo ratings yet

- IC Engines ClassificationDocument14 pagesIC Engines ClassificationVenkatachalam AnnamalaiNo ratings yet

- Thermo Ex.1Document10 pagesThermo Ex.1Hafeez AliNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Food Industry Guide - Production to ConsumptionDocument15 pagesFood Industry Guide - Production to ConsumptionAlina RajputNo ratings yet

- Ethanol From Lignocellulosic Biomass-1Document16 pagesEthanol From Lignocellulosic Biomass-1Alina RajputNo ratings yet

- Mohamed Mosaad Abo El-Gheit: Msc. Student, Applied Microbiology, Scu, Ismailia, EgyptDocument29 pagesMohamed Mosaad Abo El-Gheit: Msc. Student, Applied Microbiology, Scu, Ismailia, Egypttaufany99No ratings yet

- Bioethanol From SugarcaneDocument18 pagesBioethanol From SugarcaneAlina RajputNo ratings yet

- Ethanol From Lignocellulosic BiomassDocument16 pagesEthanol From Lignocellulosic BiomassAlina RajputNo ratings yet

- Distillation To Dehydration Process of Ethanol ProductionDocument13 pagesDistillation To Dehydration Process of Ethanol ProductionAlina RajputNo ratings yet

- Bioethanol Technology: by DR Sammer FatimaDocument20 pagesBioethanol Technology: by DR Sammer FatimaAlina RajputNo ratings yet

- Mohamed Mosaad Abo El-Gheit: Msc. Student, Applied Microbiology, Scu, Ismailia, EgyptDocument29 pagesMohamed Mosaad Abo El-Gheit: Msc. Student, Applied Microbiology, Scu, Ismailia, Egypttaufany99No ratings yet

- Compression EngineDocument15 pagesCompression EngineAlina RajputNo ratings yet

- Distillation To Dehydration Process of Ethanol ProductionDocument13 pagesDistillation To Dehydration Process of Ethanol ProductionAlina RajputNo ratings yet

- Bioethanol Technology: by DR Sammer FatimaDocument20 pagesBioethanol Technology: by DR Sammer FatimaAlina RajputNo ratings yet

- Bioethanol Technology: by DR Sammer FatimaDocument20 pagesBioethanol Technology: by DR Sammer FatimaAlina RajputNo ratings yet

- @@represented To - Sir Khizr-1Document58 pages@@represented To - Sir Khizr-1Alina RajputNo ratings yet

- @@represented To - Sir Khizr-1Document58 pages@@represented To - Sir Khizr-1Alina RajputNo ratings yet

- Genetics Engineering PPT Grp#09Document52 pagesGenetics Engineering PPT Grp#09Alina RajputNo ratings yet

- MEGA software for molecular evolution analysisDocument31 pagesMEGA software for molecular evolution analysisAlina RajputNo ratings yet

- @@represented To - Sir Khizr-1Document58 pages@@represented To - Sir Khizr-1Alina RajputNo ratings yet

- Co-Pyrolysis of Sugarcane Bagasse and Polystyrene With Ex-Situ Catalytic Bed of Metal Oxides or HZSM-5 With Focus On Liquid YieldDocument9 pagesCo-Pyrolysis of Sugarcane Bagasse and Polystyrene With Ex-Situ Catalytic Bed of Metal Oxides or HZSM-5 With Focus On Liquid Yieldbambang_teknikkimiaNo ratings yet

- Manual de Instrucciones - Autoclave Tuttnauer 3870EL-DDocument103 pagesManual de Instrucciones - Autoclave Tuttnauer 3870EL-DMARIA ALEJANDRA SIERRA GILNo ratings yet

- AH Electra 10a ManualDocument18 pagesAH Electra 10a ManualJosé A. Montiel QuirósNo ratings yet

- Dimension Stone Design ManualDocument531 pagesDimension Stone Design Manualhgogoriya100% (1)

- Energy Equation: Head Losses in Pipes (MajorDocument40 pagesEnergy Equation: Head Losses in Pipes (MajorLottiibelsNo ratings yet

- ESAS-Mockboard 1 (Dreamforce)Document13 pagesESAS-Mockboard 1 (Dreamforce)e5865domingoascotbaguioNo ratings yet

- PPSC 2022 Past Paper-1Document23 pagesPPSC 2022 Past Paper-1Hunain ShakirNo ratings yet

- Transformer Losses CalculationDocument4 pagesTransformer Losses CalculationAfef NejiNo ratings yet

- Whirlpool ADG 689-2 IX Product DatasheetDocument2 pagesWhirlpool ADG 689-2 IX Product DatasheetKyriakos AnagnostouNo ratings yet

- تقارير مختبر محركات احتراق داخليDocument19 pagesتقارير مختبر محركات احتراق داخليwesamNo ratings yet

- Freiburg's Quartier Vauban Model Sustainable DistrictDocument50 pagesFreiburg's Quartier Vauban Model Sustainable DistrictezzatNo ratings yet

- TOM MicroprojectDocument18 pagesTOM MicroprojectAkshay Khangre100% (1)

- Piston Pump - High Pressure Stall - Steering 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónDocument5 pagesPiston Pump - High Pressure Stall - Steering 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónPablo Cesar Poma ArrateaNo ratings yet

- Pipe Lukspam.Document477 pagesPipe Lukspam.Jm DaguimolNo ratings yet

- Hand Out Fire SurpressDocument69 pagesHand Out Fire SurpressSeptiawanWandaNo ratings yet

- Anschlussplan DEUTZ TCD 4.1 L4Document5 pagesAnschlussplan DEUTZ TCD 4.1 L4МаксимNo ratings yet

- Ansi C84.1 - 2016Document22 pagesAnsi C84.1 - 2016juan raulNo ratings yet

- User's Manual Vacuum PumpDocument28 pagesUser's Manual Vacuum Pumpdorin stoicuNo ratings yet

- Condition Monitoring Methods and TechniquesDocument2 pagesCondition Monitoring Methods and TechniquesMohamed Al-OdatNo ratings yet

- C10, C11Document52 pagesC10, C11Mae MegumiNo ratings yet

- Examination Paper Question 1: Charter Engineer Using Suitable Examples Discuss: (A) The Benefits For Employees To Be Chartered EngineersDocument9 pagesExamination Paper Question 1: Charter Engineer Using Suitable Examples Discuss: (A) The Benefits For Employees To Be Chartered EngineerscharlesNo ratings yet

- WSR_WK09_20240226-0303Document7 pagesWSR_WK09_20240226-0303CHRISMAR ZALSOSNo ratings yet

- Exercise ModellingDocument45 pagesExercise ModellingThạc LêNo ratings yet

- BP DieselDocument3 pagesBP Dieselariyamanjula2914No ratings yet

- S1 Heat and Light TopicDocument57 pagesS1 Heat and Light Topicmuwanguziakram02No ratings yet

- KR SCAC (R410A 50,60Hz) Saudi CO MFL67986317 0CSL0-05A (April.2021)Document140 pagesKR SCAC (R410A 50,60Hz) Saudi CO MFL67986317 0CSL0-05A (April.2021)ahmed ragabNo ratings yet

- Ref Three EditionDocument9 pagesRef Three EditionDragon DangerNo ratings yet

- L1 Unit-1 Advance WeldingDocument11 pagesL1 Unit-1 Advance WeldingSaurabh Kumar GuptaNo ratings yet

- OPERATING and MAINTENACE PLAN 2nd DRAFTDocument5 pagesOPERATING and MAINTENACE PLAN 2nd DRAFTLutendo MutiNo ratings yet

- FSDH321, FSDL321: Green Mode Fairchild Power Switch (FPS)Document20 pagesFSDH321, FSDL321: Green Mode Fairchild Power Switch (FPS)Ricardo WerlangNo ratings yet