Professional Documents

Culture Documents

Manifold Systems A Comparison of Standards

Uploaded by

Yudi Wahyudi WahyudiantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manifold Systems A Comparison of Standards

Uploaded by

Yudi Wahyudi WahyudiantoCopyright:

Available Formats

World Standards for Medical Gas Systems

A Comparison

© RFHHA. All rights reserved

Medical Gas Standards Comparison

What is a Medical Gas?

o A medical gas a medicinal product (pharmaceutical) used for treating or

preventing disease and for life support of human beings.

o The use of medical gases should be subject to prescription by a clinician.

o The physical and chemical composition of a medical gas, the maximum

levels of its contaminants and the way in which it is administered and

packaged are governed by the European Pharmacopoeia and the Medicines

Act.

Medical air is regulated as a drug under the European Pharmacopoeia

Medical air is the only drug manufactured in a hospital; by a

medical air plant

© RFHHA. All rights reserved

Medical Gas Standards Comparison

The Four Tenets of Medical Gas System Safety:

o Continuity – the gas supplies must always be available

o Adequacy – the correct flow and pressure must always be delivered

o Identity – the correct gas should always be administered

o Quality – gases must be safe and pure

There are two main standards in use internationally that provide best

practice guidance for medical gas systems and products – NFPA 99

(US) and HTM 02-01 (UK)

How does each standard maximise the safety of users and patients?

© RFHHA. All rights reserved

Medical Gas Standards Comparison

HTM 02-01 Parts A and B NFPA 99

© RFHHA. All rights reserved

The Standards Compared

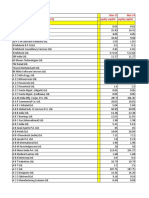

Overview and Principles NFPA 99 HTM 02-01

Date of First Publication 1984 1972

Years of Embedded Experience 21 34

Number of Pages Dedicated to Medical Gases 136 330

Published by a Government Agency

Equipment Fault Tolerance Levels 1 2

Management Structure Defined - CP, AP, AE roles

Products Regulated – CE Mark to the MDD

Quality Control Pharmacist Verification of Gas Purity

European Pharmacopoeia Quality Compliance

Risk Management to ISO 14971

© RFHHA. All rights reserved

The Standards Compared

Design Elements NFPA 99 HTM 02-01

Terminal Unit and Gas Flow Schedules

Auto Ignition Testing of High Pressure Regulators

Halogenated Polymers Banned in HP O2 Service

Bacteria Filters for Protection of Medical Vacuum

Refrigerant Dryers Disallowed

Medical Air Dew Point (ppm v/v) 1833 67

Minimum Pressure Vessel Sizes

Liquid Sealed Pumps/Compressors Disallowed

AGS and Medical Vacuum Supplies Separate

Duplex Emergency Backup Manifolds

© RFHHA. All rights reserved

The Standards Compared

Operational Management Elements NFPA 99 HTM 02-01

Operational Policy

Maintenance Contract Guidance

Equipment Maintenance Procedures Defined

Verification Procedures and Forms

Permit to Work System

Management Processes – CP, AP, AE, DNO roles

Minimum Training Requirements Defined

© RFHHA. All rights reserved

The Standards Compared

Medical Air Safety Limits

Component NFPA 99 HTM 02-01*

Oxygen 19.5-23.5 % 20.4-21.4 %

Oil Not specified 0.1 mg/m3

Water 1833 ppm 67 ppm

Carbon Monoxide (CO) 10 ppm 5 ppm

Carbon Dioxide (CO2) 500 ppm 500 ppm

Nitrogen Dioxide (NO2) Not specified 2 ppm

Nitric Oxide (NO) Not specified 2 ppm

Sulphur Dioxide (SO2) Not specified 1 ppm

*HTM 02-01 Reflects European Law. Must be verified by an independent QC pharmacist.

© RFHHA. All rights reserved

The Standards Compared

The Four Tenets NFPA 99 HTM 02-01

Continuity

Adequacy

Identity

Quality

Other Key Measures

Sustainability

Useability

Overall Value

© RFHHA. All rights reserved

Quality and Regulatory Controls

In the US, the FDA do not consider medical gas equipment to be

medical devices

o The FDA does not regulate the products or the companies making them

In Europe, most authorities consider medical gas products to be

medical devices

o Medical gas products therefore and regulated under the medical device

directive 93/42/EEC

o Medical devices companies in Europe must have a stringent ISO 13485

quality management systems that are regularly audited

US medical gas pipeline equipment making NFPA 99 equipment are

not required to have any formal quality management system

Would you take the risk?

© RFHHA. All rights reserved

Medical Air Quality

Medical Air Dew Point (water concentration)

o NFPA allows a water concentration of 1833 ppm whereas HTM 02-01 and

European Law states the maximum water concentration should be 67 ppm

o European Law limits are 27 times lower than NFPA 99!

Why?

o A very low dew point inhibits bacteria survival and growth, reducing infection

o At low ambient temperatures, liquid water could form if the air is too humid

• Anaesthesia machines and ventilators are damaged by liquid water

• At freezing temperatures ice can form, blocking the pipeline

o Higher humidity promotes oxidation of the inside of piped distribution system

(copper oxide), which will inevitably contaminate the supply

Would you take the risk?

© RFHHA. All rights reserved

Fault Tolerance Levels

Periodic maintenance of compressors and vacuum pumps is required

to protect your investment and maximise service life

Single fault tolerance should be assured during maintenance

o NFPA 99 requires only a single level of fault tolerance on supply systems

o During maintenance of a supply there is an unacceptable risk of supply

failure

o HTM 02-01 as well as European and International Standards require a single

level of fault tolerance to be maintained during maintenance

What would happen if a compressor or vacuum pumps fails during

maintenance of another?

o NFPA – the supply would fail – patients are at risk

o HTM 02-01 – the supply is maintained - patients are unaffected

© RFHHA. All rights reserved

Ignition Testing

High pressure oxygen cylinders require pressure regulators to reduce

the pressure before distribution to a pipeline

A significant risk of explosion exists unless the pressure regulator is

designed to tolerate high temperature during adiabatic compression

HTM 02-01 and other International Standards mandate auto-ignition

testing is performed to prove the pressure regulator design

NFPA 99 does not mandate such a test is performed

Would you take the risk?

© RFHHA. All rights reserved

Anaesthetic Gas Scavenging

Exhaled anaesthetic gas mixtures are captured and removed from

breathing circuits to prevent ill health of clinical staff subjected to long-

term exposure

HTM 02-01 and International Standards mandate a dedicated pipeline

system and plant for this purpose

NFPA 99 allows the use of the medical vacuum system for this purpose

o The mixture of high oxygen concentration with anaesthetic agents in contact

with high temperature oil in vacuum pumps is believed to have led to many

fires in hospital plant rooms

Would you take the risk?

© RFHHA. All rights reserved

Bacteria Filtration

Medical vacuum systems are used to collect and extract many highly

infectious materials in hospitals

The vacuum system transfers the potentially infected air out of the

hospital

HTM 02-01 and other International Standards mandate the fitting of

bacteria filters to protect the plant and exhausts contamination with

harmful bacteria

NFPA 99 does not specify the fitting of bacteria filters and so provides

no protection

Would you take the risk?

© RFHHA. All rights reserved

Summary

The two major standards for medical gas pipeline systems contain

many differences

HTM 02-01 was developed with a view to maximise patient safety and

product reliability

The differences between the standards are subtle, the consequences

may not be

Would you take the risk?

© RFHHA. All rights reserved

You might also like

- List of Guidelines 1679795815Document3 pagesList of Guidelines 1679795815Rezha AmaliaNo ratings yet

- Chemical Management StandardDocument26 pagesChemical Management Standardzam110No ratings yet

- Helicopter LiftingDocument11 pagesHelicopter LiftingWidya Ningrum100% (1)

- D86 - 19 PDFDocument29 pagesD86 - 19 PDFGuillermo ZapataNo ratings yet

- E3051 16Document10 pagesE3051 164romi89No ratings yet

- F Surface CoatingsDocument5 pagesF Surface CoatingsajayNo ratings yet

- Bp2023 - Volume VDocument1,223 pagesBp2023 - Volume VGIGI ROCIO HARO MARIÑOS100% (2)

- Hydraulic and Lube Filtration Products ParkerDocument268 pagesHydraulic and Lube Filtration Products ParkerHariharanNo ratings yet

- Astm D86 - 17Document29 pagesAstm D86 - 17Esteban Calderón NavarroNo ratings yet

- Short Tricks To Remember GK EasilyDocument3 pagesShort Tricks To Remember GK EasilyManoj KiningeNo ratings yet

- Denr Emb PDFDocument86 pagesDenr Emb PDFMylen TrinidadNo ratings yet

- Calibration and Metrology PDFDocument10 pagesCalibration and Metrology PDFMano NegraNo ratings yet

- Retaining Wall Design-REVDocument34 pagesRetaining Wall Design-REVzaheer0406100% (1)

- Auraton 2005Document24 pagesAuraton 2005Muhidin KozicaNo ratings yet

- Current Trends and Changing USP Updates in Pharmaceutical IndustriDocument36 pagesCurrent Trends and Changing USP Updates in Pharmaceutical IndustriTantri Ayu LestariNo ratings yet

- Giz2012 0398en Eu Who GuidelinesDocument51 pagesGiz2012 0398en Eu Who Guidelinesmailtorubal2573No ratings yet

- Proposal HR OutsourcingDocument7 pagesProposal HR Outsourcingraqi14850% (6)

- BMED Chapter 2 Medical Gas Design Guide NFPA Design Guide enDocument8 pagesBMED Chapter 2 Medical Gas Design Guide NFPA Design Guide enHermi DavidNo ratings yet

- Hockey Stick 1Document1,617 pagesHockey Stick 1sabyasachi sarkarNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Astm D86Document29 pagesAstm D86Difany tsabitaNo ratings yet

- PIP PCCCV002-2018 Pressure Regulators Selection CriteriaDocument7 pagesPIP PCCCV002-2018 Pressure Regulators Selection Criteria刘旭No ratings yet

- Flow Measurement GuidelinesDocument27 pagesFlow Measurement GuidelinesAkram DriraNo ratings yet

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- ASTM D86 - 20b STANDARD TEST METHOD FOR DISTILLATION PDFDocument29 pagesASTM D86 - 20b STANDARD TEST METHOD FOR DISTILLATION PDFAndy Calcaño LopezNo ratings yet

- Risk Assessment Single-Use White Paper en MRK March 2017 LowDocument4 pagesRisk Assessment Single-Use White Paper en MRK March 2017 LowRui PiresNo ratings yet

- Process Gases and Distribution Systems in Pharmaceutical ProductionDocument9 pagesProcess Gases and Distribution Systems in Pharmaceutical ProductionHenry BarriosNo ratings yet

- Penlon Medical Gas Solutions 2013Document38 pagesPenlon Medical Gas Solutions 2013Arbjan Rusi100% (1)

- IP391 - 2007 - Determination of Aromatic Hydrocarbon Types in Middle Distillates - High Performance Liquid Chromatography Method With Refractive Index Detection (RID)Document12 pagesIP391 - 2007 - Determination of Aromatic Hydrocarbon Types in Middle Distillates - High Performance Liquid Chromatography Method With Refractive Index Detection (RID)Constantinos ChristodoulouNo ratings yet

- Astm D 86-2020Document29 pagesAstm D 86-2020Mohammed AliNo ratings yet

- Ondina 15Document2 pagesOndina 15Milos Stojanovic100% (1)

- Sumer Oxygen Generator Catalogue 276c8Document10 pagesSumer Oxygen Generator Catalogue 276c8batakero137No ratings yet

- Safety Data Sheet: Hydrocarbons, C10, Aromatics, 1% NaphthaleneDocument15 pagesSafety Data Sheet: Hydrocarbons, C10, Aromatics, 1% NaphthalenebogodavidNo ratings yet

- Safety Data Sheet: Hydrocarbons, C9-C12, N-Alkanes, Isoalkanes, Cyclics, Aromatics (2-25%)Document14 pagesSafety Data Sheet: Hydrocarbons, C9-C12, N-Alkanes, Isoalkanes, Cyclics, Aromatics (2-25%)Tódor BoglárNo ratings yet

- Distillation of Petroleum Products and Liquid Fuels at Atmospheric PressureDocument29 pagesDistillation of Petroleum Products and Liquid Fuels at Atmospheric Pressurenjarac1972No ratings yet

- IPTC 11222 REACH and The HSE Case For Formate BrinesDocument11 pagesIPTC 11222 REACH and The HSE Case For Formate BrinesAminNo ratings yet

- Part E - 7 - Public Health - Medical Gas System Design (MGS)Document18 pagesPart E - 7 - Public Health - Medical Gas System Design (MGS)Raydoon SadeqNo ratings yet

- Quality Records: Neptune OrthopaedicsDocument1 pageQuality Records: Neptune Orthopaedicsdhir.ankurNo ratings yet

- ASTM D86-19 Distillation of Petroleum ProductsDocument29 pagesASTM D86-19 Distillation of Petroleum Productsrgveda18No ratings yet

- Mask Mascarillas 2mDocument6 pagesMask Mascarillas 2mOswaldo Andrés Vanegas GuillénNo ratings yet

- PE 009-11 GMP Guide (Intro) PDFDocument4 pagesPE 009-11 GMP Guide (Intro) PDFNikki Francine BaldeNo ratings yet

- FOROL FRUIT - SDB - en - USDocument14 pagesFOROL FRUIT - SDB - en - USTímea HorváthNo ratings yet

- RdsDocument5 pagesRdsikaNo ratings yet

- Safety Data Sheet According To Regulation (EC) No 1907/2006, Annex IIDocument14 pagesSafety Data Sheet According To Regulation (EC) No 1907/2006, Annex IIHicham BenNo ratings yet

- MethomylDocument25 pagesMethomylNugroho HartonoNo ratings yet

- tp160 c8 PDFDocument4 pagestp160 c8 PDFJosé JaegerNo ratings yet

- ParkerStore Catalogue 2012 - EN PDFDocument620 pagesParkerStore Catalogue 2012 - EN PDFneodymioNo ratings yet

- Dimethoate Eval Specs WHO June 2012Document33 pagesDimethoate Eval Specs WHO June 2012MartuaHaojahanSaragihSidabutarNo ratings yet

- WHO On PropoxurDocument25 pagesWHO On Propoxurgilang kusumasariNo ratings yet

- EPA GPP Criteria Energy 2022 03Document61 pagesEPA GPP Criteria Energy 2022 03OYAESPETAHNo ratings yet

- EIGA (2008) - Comparison of EP, USP & JP For Medicinal GasDocument21 pagesEIGA (2008) - Comparison of EP, USP & JP For Medicinal GashuynhhaichauchauNo ratings yet

- RA 6969 (Title II - III)Document219 pagesRA 6969 (Title II - III)ianeil18No ratings yet

- Possible Alternatives To Surgical Filtering Facepiece Respirators: HealthcareDocument5 pagesPossible Alternatives To Surgical Filtering Facepiece Respirators: HealthcareRenzo Malcolm Garcia PickmannNo ratings yet

- HiQ NitrogenDocument3 pagesHiQ NitrogenSubrata RoyNo ratings yet

- 07 Sop For Compliance of Air Pollution Guidelines of NemaDocument5 pages07 Sop For Compliance of Air Pollution Guidelines of NemaMusyoka UrbanusNo ratings yet

- Pics GMP Guide 01 (Intro)Document4 pagesPics GMP Guide 01 (Intro)clareangelNo ratings yet

- PIP PCECV002-2018 Pressure Regulators Selection GuidelinesDocument5 pagesPIP PCECV002-2018 Pressure Regulators Selection Guidelines刘旭No ratings yet

- 5 Questions About Chemical SafetyDocument2 pages5 Questions About Chemical SafetySwee Dao WenNo ratings yet

- Safety Data Sheet VermoTopDocument19 pagesSafety Data Sheet VermoTopAhmed elsayehNo ratings yet

- Safety Data Sheet: SDS: 185Xfc Xuper 1, 2017Document9 pagesSafety Data Sheet: SDS: 185Xfc Xuper 1, 2017Luzka DuranNo ratings yet

- Operating Manual 4504Document42 pagesOperating Manual 4504Nachiket PatilNo ratings yet

- Safe Handling of Compressed Gases: Kimi Zyky Lopez Reaño Lemuel Montril DivinaDocument47 pagesSafe Handling of Compressed Gases: Kimi Zyky Lopez Reaño Lemuel Montril DivinaKimi Zyky Lopez ReañoNo ratings yet

- Pharmaceutical Water Compliance Mettler ToledoDocument20 pagesPharmaceutical Water Compliance Mettler ToledoNowsathAliNo ratings yet

- Para Consulta: Distillation of Petroleum Products and Liquid Fuels at Atmospheric PressureDocument29 pagesPara Consulta: Distillation of Petroleum Products and Liquid Fuels at Atmospheric PressureJUAN CARLOSNo ratings yet

- Safety Data Sheet According To Regulation (EC) No 1907/2006, Annex IIDocument12 pagesSafety Data Sheet According To Regulation (EC) No 1907/2006, Annex IIZiurelNo ratings yet

- DP27, DP27E, DP27R and DP27Y Pilot Operated Pressure Reducing ValvesDocument36 pagesDP27, DP27E, DP27R and DP27Y Pilot Operated Pressure Reducing ValvesAntonio FedatoNo ratings yet

- Bio 11.1 LE 2 NotesDocument7 pagesBio 11.1 LE 2 NotesCode BlueNo ratings yet

- G3520 Lehe2832 02 PDFDocument6 pagesG3520 Lehe2832 02 PDFCostas Aggelidis100% (1)

- 1 Anju Bio DataDocument3 pages1 Anju Bio DataAnju BijoNo ratings yet

- Elite One PagerDocument1 pageElite One PagernikzakuNo ratings yet

- Pops Test ResultsDocument3 pagesPops Test Resultsguydennnooo2No ratings yet

- Carbohydrate NotesDocument5 pagesCarbohydrate NotesdrewNo ratings yet

- Parboiled RiceDocument38 pagesParboiled RiceArpit RohillaNo ratings yet

- Turnstile Design SheetDocument6 pagesTurnstile Design SheetArmstrongMasengaNo ratings yet

- HT 800 Medium Cellular SiliconeDocument2 pagesHT 800 Medium Cellular SiliconeDarwinPowChonLongNo ratings yet

- MBA 504 Ch3 SolutionsDocument22 pagesMBA 504 Ch3 SolutionsMohit Kumar GuptaNo ratings yet

- 2.1.3 Amount of Substance: Molar Gas Volume (Gas Volume Per Mole, Units DMDocument12 pages2.1.3 Amount of Substance: Molar Gas Volume (Gas Volume Per Mole, Units DMAliya RahmanNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (19) Installation of Conductor JumperDocument14 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (19) Installation of Conductor Jumpermohammed tofiqNo ratings yet

- DPPH (1,1-Diphenyl-2-Picrylhydrazyl) Radical Scavenging Activity of Flavonoids Obtained From Some Medicinal PlantsDocument4 pagesDPPH (1,1-Diphenyl-2-Picrylhydrazyl) Radical Scavenging Activity of Flavonoids Obtained From Some Medicinal PlantsEtika Ayu LestariNo ratings yet

- Individual TAXDocument6 pagesIndividual TAXPushpa ValliNo ratings yet

- Functions of Phosphorus in PlantsDocument2 pagesFunctions of Phosphorus in Plantspemanr1914No ratings yet

- Till Saxby Electric Pallet Truck Egv 10-12-0240 0242 0300 0302 Workshop ManualDocument22 pagesTill Saxby Electric Pallet Truck Egv 10-12-0240 0242 0300 0302 Workshop Manualmichaelfisher030690fgaNo ratings yet

- Death Claim Form Early - English - Hindi - 05112019Document9 pagesDeath Claim Form Early - English - Hindi - 05112019CHATTU HALDERNo ratings yet

- Hildegard PeplauDocument7 pagesHildegard PeplauCarmenchuParraNo ratings yet

- Reading Passage 2: HomeopathyDocument4 pagesReading Passage 2: HomeopathyNguyễn TịnhNo ratings yet

- Dr. Roberto Conrado Guevara - Response From The Laity (Oct 2)Document29 pagesDr. Roberto Conrado Guevara - Response From The Laity (Oct 2)Joviner Yabres LactamNo ratings yet

- Anesthesia: Essays and Researches General Anesthesia in Tetanus Patient Undergoing Emergency Surgery: A Challenge For AnesthesiologistDocument4 pagesAnesthesia: Essays and Researches General Anesthesia in Tetanus Patient Undergoing Emergency Surgery: A Challenge For AnesthesiologistEnrico StefanelliNo ratings yet

- Cargo Ventilation System On Liquefied Gas CarriersDocument19 pagesCargo Ventilation System On Liquefied Gas CarriersLukasz ZablockiNo ratings yet